Urban landscapes are rapidly evolving, with cities striving to create functional, durable, and aesthetically pleasing public spaces. From sleek benches in parks to robust bike racks on bustling streets, urban furniture plays a pivotal role in shaping the modern cityscape. At the heart of manufacturing these essential structures are Urban Furniture Roll Forming Machines—advanced tools that enable the efficient and precise production of metal components that define urban furniture designs.

This article will delve into what urban furniture roll forming machines are, their key applications, pricing details, advanced automation features, common troubleshooting tips, and why Wuxi Sunway Machinery is a trusted partner for manufacturers in this sector. Whether you’re an urban planner, furniture manufacturer, or supplier, this guide will provide invaluable insights into this transformative technology.

What Are Urban Furniture Roll Forming Machines?

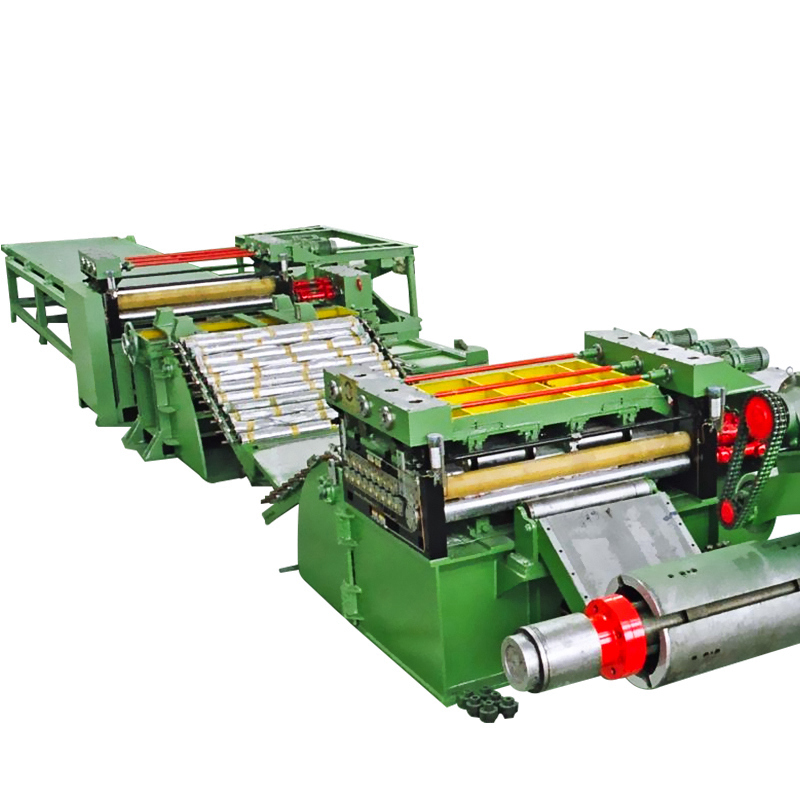

Urban Furniture Roll Forming Machines are specialized industrial machines designed to manufacture precision metal profiles used in the construction of public furniture. These machines utilize advanced cold roll-forming technology to shape metal coils into durable, weather-resistant components that are foundational to urban seating, shelters, signage, and more.

Urban furniture must strike a balance between aesthetics, functionality, and resilience. Roll-forming machines ensure that the production process meets these demands by delivering components with consistent quality, high durability, and customizable designs.

Key Features

- Material Versatility: Processes galvanized steel, stainless steel, aluminum, and other weather-resistant metals.

- Precision Engineering: Produces components with exact dimensions for seamless assembly and enhanced durability.

- High Production Speed: Enables large-scale manufacturing to meet the demands of expanding urban areas.

- Aesthetic Customization: Supports unique profiles and finishes to match city-specific architectural styles.

- Sustainability: Optimized for producing recyclable and environmentally friendly components.

Applications of Urban Furniture Roll Forming Machines

Urban furniture roll-forming machines are central to producing a wide range of structures and components that enhance public spaces. Below are some of their key applications:

1. Public Benches

- Use Case: Manufacturing frames and supports for benches in parks, bus stops, and public squares.

- Why It’s Essential: Ensures robust construction that can withstand heavy use and harsh weather conditions.

2. Bike Racks and Stands

- Use Case: Producing metal profiles for bicycle parking solutions in urban areas.

- Why It’s Relevant: Offers high durability and compatibility with modern bike storage designs.

3. Street Signage Frames

- Use Case: Crafting metal frames for street signs, directional boards, and public notices.

- Why It’s Critical: Ensures long-lasting performance and visibility in diverse weather conditions.

4. Shelters and Canopies

- Use Case: Producing structural components for bus stops, kiosks, and public shelters.

- Why It’s Unique: Combines strength with aesthetic appeal to enhance urban spaces.

5. Trash and Recycling Bins

- Use Case: Manufacturing metal frames and profiles for outdoor waste and recycling receptacles.

- Why It’s Necessary: Ensures durability, hygiene, and design consistency with urban environments.

6. Decorative Urban Elements

- Use Case: Crafting ornamental profiles used in fences, railings, and urban sculptures.

- Why It’s Beneficial: Adds aesthetic value while maintaining functionality in public spaces.

Key Features of Wuxi Sunway Urban Furniture Roll Forming Machines

Wuxi Sunway Machinery has established itself as a leader in roll-forming solutions for urban furniture manufacturing. Their machines are designed to address the unique challenges of producing public furniture components. Here’s what makes their machines stand out:

1. Material Flexibility

- What It Processes:

- Galvanized Steel

- Aluminum

- Stainless Steel

- Weather-Resistant Alloys

- Why It’s Beneficial: Accommodates a variety of materials to meet different functional and aesthetic requirements.

2. Modular Tooling

- What It Offers: Quick-change tooling for producing diverse profiles, from bench frames to signage posts.

- Why It’s Versatile: Supports multi-profile production without the need for multiple machines.

3. Integrated Cutting and Punching

- What It Includes: Built-in systems for precision cutting, punching, and notching during the roll-forming process.

- Why It’s Efficient: Reduces production time and ensures components are ready for immediate assembly.

4. Corrosion-Resistant Components

- What It Ensures: Produces profiles with enhanced corrosion resistance for outdoor applications.

- Why It’s Critical: Extends the lifespan of urban furniture in challenging weather conditions.

5. High-Speed Production

- What It Achieves: Processes up to 60 meters of profiles per minute, depending on the complexity of the design.

- Why It’s Essential: Meets the high-volume demands of urban development projects.

6. Smart Automation

- What It Incorporates: IoT-enabled systems for real-time monitoring and predictive maintenance.

- Why It’s Innovative: Minimizes downtime and maximizes operational efficiency.

Pricing of Urban Furniture Roll Forming Machines

The cost of a Urban Furniture Roll Forming Machine depends on its features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic profiles for benches, bike racks, and signage | 120,000–120,000–120,000–300,000 |

| Advanced Machines | High-speed production with integrated systems | 300,000–300,000–300,000–700,000 |

| কাস্টমাইজযোগ্য মেশিনসমূহ | Tailored for unique urban furniture designs | 700,000–700,000–700,000–1,500,000 |

For a tailored quote and financing options, contact Wuxi Sunway Machinery.

Advantages of Using Urban Furniture Roll Forming Machines

Urban furniture manufacturers face unique challenges, from meeting durability standards to staying within tight budgets. Urban Furniture Roll Forming Machines offer several advantages that make them indispensable for this industry:

1. High Durability

- Why It’s Crucial: Produces components that can endure heavy usage and extreme weather conditions.

2. Precision and Consistency

- Why It’s Beneficial: Ensures all components meet exact specifications, simplifying assembly and enhancing quality.

3. Customization

- Why It’s Essential: Supports the production of furniture tailored to specific urban aesthetics and functional needs.

4. Cost Efficiency

- Why It’s Practical: Reduces material waste and labor costs, making durable furniture more affordable for cities.

5. Scalability

- Why It’s Relevant: Meets the high-volume production demands of large-scale urban development projects.

6. Sustainability

- Why It’s Important: Minimizes waste and supports the use of recyclable materials, aligning with green city initiatives.

Automation in Urban Furniture Roll Forming Machines

Automation is revolutionizing urban furniture manufacturing, enabling greater efficiency, precision, and cost savings. Here’s how automation enhances Urban Furniture Roll Forming Machines:

1. AI-Driven Quality Assurance

- What It Does: Uses sensors and artificial intelligence to detect defects and ensure consistent quality.

- Why It’s Valuable: Minimizes waste and ensures flawless profiles for urban furniture.

2. Predictive Maintenance

- What It Tracks: IoT sensors monitor wear and tear on machine components and predict maintenance needs.

- Why It’s Revolutionary: Reduces downtime and extends the lifespan of the machine.

3. Adaptive Material Handling

- What It Adjusts: Automatically calibrates settings to accommodate different material types and thicknesses.

- Why It’s Beneficial: Improves production accuracy and eliminates manual recalibrations.

4. Remote Monitoring and Control

- What It Offers: Allows operators to monitor and control machine operations from any location.

- Why It’s Convenient: Enhances productivity and troubleshooting capabilities.

5. Multi-Profile Production

- What It Enables: Seamlessly switches between different furniture component profiles within a single production run.

- Why It’s Versatile: Supports diverse manufacturing needs without additional setup time.

FAQs About Urban Furniture Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | Galvanized steel, stainless steel, aluminum, and weather-resistant alloys. |

| What is the production speed? | Up to 60 meters per minute, depending on material and profile complexity. |

| Can these machines handle custom designs? | Yes, modular tooling supports bespoke profiles for diverse urban furniture applications. |

| Are these machines eco-friendly? | Yes, they include energy-efficient motors and minimize material waste. |

| What is the price range for these machines? | Prices range from 120,000to120,000 to 120,000to1,500,000, depending on features and customization. |

| Do these machines integrate with IoT systems? | Yes, IoT-enabled features allow real-time monitoring and predictive maintenance. |

Real-World Success Stories: Urban Furniture Roll Forming Machines in Action

Across the globe, urban furniture manufacturers are leveraging the power of Urban Furniture Roll Forming Machines to meet the evolving demands of cities. Here are some inspiring examples of how Wuxi Sunway Machinery’s solutions have driven success in real-world applications.

1. Sustainable Furniture for Smart Cities in Europe

Client: A European manufacturer specializing in eco-friendly urban furniture for smart cities.

Challenge: The client required a machine capable of producing components for benches and recycling bins using 100% recyclable materials.

Solution: Wuxi Sunway delivered a roll-forming machine optimized for aluminum and galvanized steel, with features for minimizing material waste.

Outcome:

- Produced lightweight yet sturdy components aligned with sustainability goals.

- Reduced production waste by 30%, lowering environmental impact.

- Helped the client secure contracts with multiple smart city projects across Europe.

2. Bike Parking Solutions in North America

Client: A leading urban furniture supplier in Canada focused on promoting cycling infrastructure.

Challenge: The client needed to manufacture high-strength bike racks that could withstand extreme weather conditions.

Solution: Wuxi Sunway provided a roll-forming machine equipped to process stainless steel with anti-corrosion coatings.

Outcome:

- Delivered durable bike racks that met municipal standards for public infrastructure.

- Improved production efficiency by 40%, enabling the client to scale operations.

- Enhanced the city’s cycling infrastructure, encouraging more sustainable transportation.

3. Public Benches for Urban Parks in Asia

Client: A government contractor in China tasked with furnishing parks across several cities.

Challenge: The client needed to produce large volumes of ergonomic bench frames quickly and cost-effectively.

Solution: Wuxi Sunway supplied a high-speed roll-forming machine with integrated cutting and punching systems for seamless production.

Outcome:

- Increased production capacity by 50%, meeting tight project deadlines.

- Reduced labor costs by automating the production of complex ergonomic profiles.

- Delivered benches that combined comfort, durability, and aesthetic appeal.

4. Decorative Fencing for Middle Eastern Urban Areas

Client: A construction company in Saudi Arabia specializing in urban beautification projects.

Challenge: The client required decorative metal profiles for fences, railings, and other aesthetic elements.

Solution: Wuxi Sunway provided a customizable roll-forming machine capable of producing intricate profiles with high precision.

Outcome:

- Created visually stunning decorative elements that enhanced urban landscapes.

- Reduced production time by 25%, allowing for faster project completion.

- Strengthened the client’s position as a leader in urban beautification initiatives.

Troubleshooting Common Issues with Urban Furniture Roll Forming Machines

Even the most advanced Urban Furniture Roll Forming Machines can encounter operational challenges. Identifying and resolving these issues promptly is crucial for maintaining productivity and product quality.

1. Uneven Material Feeding

- Symptoms: Material jams or feeds inconsistently, resulting in misaligned profiles.

- Possible Causes:

- Misaligned feeder rollers.

- Variations in material thickness or surface coating.

- Solution:

- Recalibrate the feeder rollers to ensure proper alignment.

- Use high-quality, consistent raw materials to minimize feeding errors.

2. Profile Deformation

- Symptoms: Finished components are warped, bent, or fail to meet design specifications.

- Possible Causes:

- Worn or misaligned rollers.

- Excessive forming pressure.

- Solution:

- Inspect and replace defective rollers regularly.

- Adjust forming pressure to prevent overstressing the material.

3. Cutting and Punching Errors

- Symptoms: Holes, notches, or cuts are misaligned or have rough edges.

- Possible Causes:

- Dull cutting tools or misaligned punching mechanisms.

- Inconsistent material feeding speed.

- Solution:

- Replace or sharpen cutting tools as needed.

- Synchronize feeding systems with cutting and punching operations.

4. Machine Overheating

- Symptoms: The machine slows down or shuts off unexpectedly during extended use.

- Possible Causes:

- Overloaded motors or blocked cooling vents.

- Solution:

- Operate the machine within its recommended capacity.

- Clean and maintain the cooling system regularly.

5. Software or Control System Glitches

- Symptoms: The machine’s control panel is unresponsive or executes commands incorrectly.

- Possible Causes:

- Outdated software or firmware.

- Electrical faults in the control system.

- Solution:

- Update the control system software to the latest version.

- Inspect and repair electrical connections as necessary.

Global Trends for Urban Furniture Manufacturing in 2025

Urban furniture is evolving to meet the needs of growing populations, sustainable city planning, and modern design aesthetics. Here are the key trends shaping the future of urban furniture manufacturing:

1. Focus on Sustainability

- Trend: Increasing demand for furniture made from recyclable and eco-friendly materials.

- Impact: Roll-forming machines optimized for processing aluminum and other sustainable materials are in high demand.

2. Smart City Integration

- Trend: Incorporation of smart features like solar-powered components and IoT-enabled benches.

- Impact: Machines must enable the production of components that integrate seamlessly with smart city infrastructure.

3. Modular and Multi-Functional Designs

- Trend: Rising preference for modular furniture that can be adapted to various city layouts.

- Impact: Roll-forming machines with modular tooling capabilities are becoming essential.

4. Customization for Urban Branding

- Trend: Cities are seeking unique furniture designs that reflect their identity and culture.

- Impact: Machines capable of producing bespoke profiles are gaining popularity.

5. Expansion in Emerging Markets

- Trend: Rapid urbanization in Asia, Africa, and South America is driving demand for affordable urban furniture.

- Impact: High-speed, cost-efficient roll-forming machines are critical for these markets.

Why Choose Wuxi Sunway Machinery for Urban Furniture Roll Forming Machines?

Wuxi Sunway Machinery has earned its reputation as a global leader in roll-forming solutions for urban furniture manufacturing. Here’s why they’re the go-to choice for manufacturers:

- Proven Expertise: Decades of experience in designing roll-forming machines for diverse industries.

- Global Reach: Trusted by clients across Asia, Europe, the Americas, and beyond.

- Customization Excellence: Tailored solutions for unique urban furniture designs.

- Innovation-Driven: Pioneers in integrating IoT, AI, and modular tooling into their machines.

- Sustainability Commitment: Designs machines that align with eco-friendly manufacturing practices.

- Comprehensive Support: Offers exceptional consultation, installation, training, and after-sales service.

Visit their official website to explore their full range of solutions.

FAQs About Urban Furniture Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | Galvanized steel, stainless steel, aluminum, and weather-resistant alloys. |

| What is the production speed? | Up to 60 meters per minute, depending on material and profile complexity. |

| Can these machines handle custom designs? | Yes, modular tooling supports bespoke profiles for diverse urban furniture applications. |

| Are these machines eco-friendly? | Yes, they include energy-efficient motors and minimize material waste. |

| What is the price range for these machines? | Prices range from 120,000to120,000 to 120,000to1,500,000, depending on features and customization. |

| Do these machines integrate with IoT systems? | Yes, IoT-enabled features allow real-time monitoring and predictive maintenance. |

Conclusion: Building Better Cities with Roll-Forming Technology

As cities worldwide strive to create more sustainable, functional, and visually appealing public spaces, Urban Furniture Roll Forming Machines are paving the way for innovation. These machines empower manufacturers to produce high-quality, durable, and customizable urban furniture components that meet the needs of modern cityscapes.

Are you ready to transform your urban furniture production? Partner with Wuxi Sunway Machinery and explore their cutting-edge roll-forming solutions. Together, let’s build better cities—one bench, bike rack, and shelter at a time.