Industrial storage systems are the backbone of warehousing, logistics, and retail industries. As businesses expand and demand for efficient storage grows, the need for durable, high-quality, and customizable shelving and racking systems has reached an all-time high. Enter the Warehouse Shelf Rack Roll Forming Machine—a transformative technology that enables the production of precision-engineered shelving and racking components. These machines help manufacturers meet the rising demand for scalable and cost-effective storage solutions while maintaining exceptional quality standards.

From uprights and beams to braces and decking panels, these machines can produce a wide variety of components needed for shelving and racking systems in warehouses, retail spaces, and industrial facilities. By automating the roll-forming process, they ensure consistent accuracy, reduce production time, and minimize material waste.

In this comprehensive guide, we’ll explore applications, features, production workflows, pricing, market trends, and why Wuxi Sunway Machinery is the preferred partner for manufacturers investing in Warehouse Shelf Rack Roll Forming Machines.

What is a Warehouse Shelf Rack Roll Forming Machine?

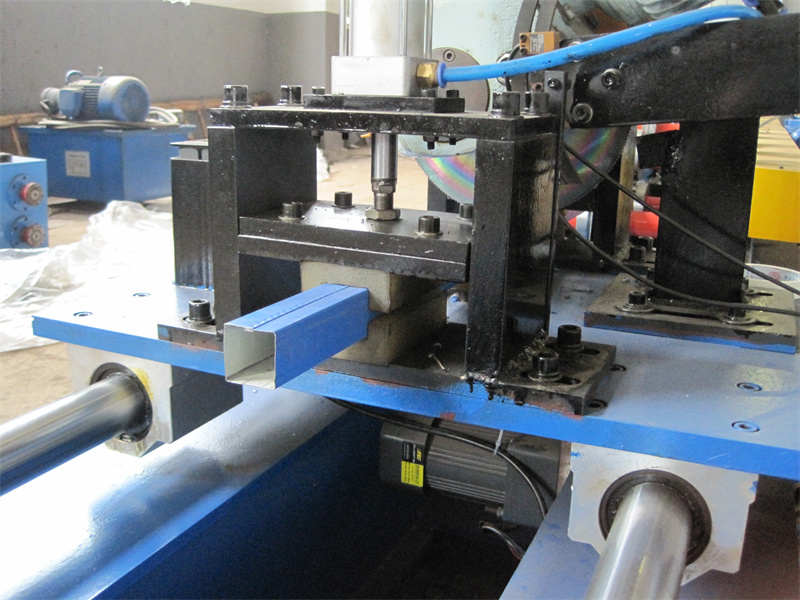

ক Warehouse Shelf Rack Roll Forming Machine is a specialized industrial system designed to manufacture the structural components of shelving and racking systems. These machines transform raw metal sheets or coils—typically made from high-strength steel or galvanized steel—into precisely shaped profiles that provide the stability and durability required for modern storage solutions.

Components Produced by Warehouse Shelf Rack Roll Forming Machines

- Uprights: Vertical supports with perforations for adjustable shelving.

- Beams: Horizontal supports that bear the weight of stored goods.

- Braces: Diagonal or horizontal braces for structural reinforcement.

- Decking Panels: Metal sheets or grids that form the surface of shelves.

- Accessories: Custom profiles for brackets, dividers, and corner plates.

By automating the production of these components, roll-forming machines help manufacturers streamline operations, improve production efficiency, and reduce costs—all while delivering high-quality storage solutions.

Applications of Warehouse Shelf Rack Roll Forming Machines

The versatility of Warehouse Shelf Rack Roll Forming Machines makes them suitable for a wide range of industries. Here’s how these machines are transforming the production of storage solutions:

1. Warehousing and Logistics

- Use Case: Producing heavy-duty shelving and racking systems for warehouses and distribution centers.

- Why It Matters: Ensures durability and scalability to handle varying storage needs and load capacities.

2. Retail and Supermarkets

- Use Case: Manufacturing lightweight yet sturdy shelving for retail stores and supermarkets.

- Why It’s Important: Offers customizable designs to match store layouts and branding aesthetics.

3. E-Commerce Fulfillment Centers

- Use Case: Crafting high-density storage racks for e-commerce warehouses.

- Why It’s Critical: Maximizes space utilization to handle large inventories and rapid order fulfillment.

4. Automotive and Industrial Facilities

- Use Case: Producing racking systems for heavy equipment, tools, and spare parts.

- Why It’s Relevant: Provides robust storage solutions capable of withstanding extreme conditions and heavy loads.

5. Cold Storage and Food Warehousing

- Use Case: Manufacturing corrosion-resistant racks for cold storage and food distribution facilities.

- Why It’s Crucial: Ensures longevity and hygiene in temperature-controlled environments.

6. Office and Residential Storage

- Use Case: Creating modular shelving systems for offices, libraries, and residential spaces.

- Why It’s Exciting: Offers stylish and functional designs for compact and organized storage.

Key Features of Wuxi Sunway Warehouse Shelf Rack Roll Forming Machines

As a global leader in roll-forming technology, Wuxi Sunway Machinery provides cutting-edge solutions designed specifically for shelving and racking production. Here’s why their machines stand out:

1. High-Speed Production

- Performance: Capable of producing up to 30–50 meters of profiles per minute, depending on material and complexity.

- Why It’s Beneficial: Meets the high-volume demands of the warehousing and logistics industry.

2. Precision Engineering

- What It Offers: Tolerances as low as ±0.1mm for critical dimensions.

- Why It’s Important: Ensures consistent quality, allowing seamless assembly and structural stability.

3. Multi-Material Compatibility

- Supported Materials:

- High-strength steel

- Galvanized steel

- Pre-coated metals

- Why It Matters: Enables manufacturers to produce components with optimal durability and corrosion resistance.

4. Customizable Tooling

- What It Allows: Quick-change tooling systems for creating custom profiles tailored to specific storage solutions.

- Why It’s Essential: Supports flexibility for manufacturers serving diverse industries and clients.

5. Integrated Punching and Cutting

- What It Offers: Built-in systems for punching holes, slots, and perforations, as well as cutting profiles to length.

- Why It’s Critical:

- Reduces secondary operations, saving time and labor costs.

- Ensures perfect alignment for adjustable shelving.

6. IoT and Automation Integration

- What It Enables: Real-time monitoring, automated adjustments, and predictive maintenance using IoT-enabled sensors.

- Why It’s Game-Changing:

- Enhances production efficiency.

- Minimizes downtime and material waste.

- Supports data-driven decision-making in smart factories.

7. Modular Design

- What It Provides: Machines with modular configurations that can be expanded or upgraded as production needs evolve.

- Why It’s Future-Proof: Accommodates growing business needs, making it a cost-effective long-term investment.

Production Workflow of a Warehouse Shelf Rack Roll Forming Machine

The production process for shelving and racking components is designed to maximize efficiency and precision. Here’s an overview of the typical workflow:

1. Material Loading

- Raw metal sheets or coils are placed on the machine’s decoiler, which feeds the material into the system.

2. Straightening and Leveling

- The material passes through a leveling system to ensure it is flat and free of defects before entering the roll-forming section.

3. Roll Forming

- The material is shaped into the desired profile as it passes through a series of rollers.

4. Punching

- Integrated punching systems create slots, holes, or perforations for adjustable shelving and assembly.

5. Cutting to Length

- Hydraulic or plasma cutting systems ensure profiles are trimmed to precise lengths.

6. Quality Inspection

- Components are inspected for dimensional accuracy, surface finish, and compliance with industry standards.

7. Stacking and Packaging

- Finished components are stacked, bundled, and prepared for transportation to warehouses or assembly lines.

Pricing of Warehouse Shelf Rack Roll Forming Machines

The cost of a Warehouse Shelf Rack Roll Forming Machine depends on its features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic profile production | $120,000–$250,000 |

| Advanced Machines | High-speed and multi-profile output | $250,000–$500,000 |

| কাস্টমাইজযোগ্য মেশিনসমূহ | Including punching, IoT, and automation | $500,000–$1,000,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Market Trends for Warehouse Shelf Rack Roll Forming Machines in 2025

The warehousing and logistics industry is experiencing a surge in demand due to e-commerce growth, urbanization, and supply chain modernization. Here are the trends driving the adoption of Warehouse Shelf Rack Roll Forming Machines:

1. Demand for High-Density Storage

- The Trend: Businesses are optimizing warehouse space to store more goods in smaller areas.

- How Machines Help:

- Produce components for space-saving racking systems like drive-in and push-back racks.

- Support innovative designs for high-density storage.

2. Growth in E-Commerce

- The Push: E-commerce companies require scalable storage solutions to handle rapid inventory turnover.

- Why It’s Relevant:

- Roll-forming machines deliver high-speed production to meet growing demand.

- Machines produce customized profiles for automated storage and retrieval systems (ASRS).

3. Sustainability Focus

- The Opportunity: Green warehousing practices are gaining traction as businesses aim to reduce their carbon footprint.

- Machine Contribution:

- Processes recyclable metals to align with sustainability goals.

- Energy-efficient operations lower electricity consumption during production.

4. Modular and Flexible Storage

- The Trend: Modular racking systems are becoming popular for their scalability and adaptability.

- How Machines Help:

- Produce interchangeable components for modular designs.

- Support quick customization to meet evolving storage needs.

FAQs About Warehouse Shelf Rack Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | High-strength steel, galvanized steel, and pre-coated metals are supported. |

| What is the average production speed? | Machines can produce up to 30–50 meters of profiles per minute, depending on complexity. |

| Can these machines produce custom profiles? | Yes, Wuxi Sunway machines support fully customizable tooling for bespoke designs. |

| Do these machines include punching systems? | Yes, integrated punching systems are standard for creating slots, holes, and perforations. |

| What is the typical lifespan of these machines? | With proper maintenance, these machines last 15–25 years or more. |

| Is training provided with the purchase? | Yes, Wuxi Sunway offers comprehensive training and after-sales support to ensure seamless operations. |

Compliance with Global Standards for Warehouse Shelving and Racking

To ensure safety, durability, and efficiency, warehouse shelving and racking systems must comply with strict international standards. Warehouse Shelf Rack Roll Forming Machines from Wuxi Sunway Machinery are engineered to produce components that meet these regulations, giving manufacturers confidence in their products.

| Standard | Region | Requirement |

|---|---|---|

| ISO 9001 | Global | Quality management principles for manufacturing processes. |

| RMI (Rack Manufacturers Institute) | North America | Guidelines for the structural integrity of industrial storage racks. |

| EN 15512 | Europe | Governs the design and testing of steel static storage systems. |

| AS 4084 | Australia | Standards for steel storage racking systems in warehouses. |

| ANSI MH16.1 | North America | Specifies design, application, and safety requirements for industrial steel racks. |

| CE Marking | Europe | Certifies compliance with EU safety and environmental regulations. |

By adhering to these standards, Wuxi Sunway Machinery ensures that the components produced by their roll-forming machines meet safety, quality, and structural integrity benchmarks required by global markets.

Sustainability Benefits of Warehouse Shelf Rack Roll Forming Machines

As businesses prioritize eco-friendly practices, Warehouse Shelf Rack Roll Forming Machines are playing a significant role in reducing the environmental impact of manufacturing. Here’s how they contribute to sustainability:

1. Efficient Material Utilization

- The Advantage: Precision engineering minimizes material waste during production.

- Environmental Impact:

- Reduces the need for excess raw materials.

- Lowers the carbon footprint of manufacturing processes.

2. Support for Recyclable Materials

- What It Enables: Machines process recyclable metals such as high-strength steel and galvanized steel.

- Why It Matters:

- Encourages the reuse of materials, promoting a circular economy.

- Reduces reliance on non-renewable resources.

3. Energy-Efficient Operations

- The Innovation: Advanced motors and workflows reduce electricity consumption.

- Why It’s Significant:

- Lowers overall energy use in production facilities.

- Supports businesses in meeting sustainability goals.

4. Durability of Components

- The Outcome: Components produced by roll-forming machines are highly durable and corrosion-resistant.

- Why It’s Sustainable:

- Extends the lifespan of shelving and racking systems.

- Reduces waste from frequent replacements or repairs.

5. Modular Design for Long-Term Use

- The Contribution: Machines produce components for modular shelving systems.

- Why It’s Important:

- Modular designs are easier to repair, reconfigure, or expand, reducing waste.

- Promotes long-term usability, aligning with green manufacturing principles.

Real-World Case Studies of Warehouse Shelf Rack Roll Forming Machines

To better understand the impact of Warehouse Shelf Rack Roll Forming Machines, let’s explore some real-world scenarios where these machines are transforming industries.

1. E-Commerce Distribution Centers

- Scenario: A global e-commerce company is expanding its distribution network with high-density storage systems.

- Machine Contribution:

- Produces custom uprights and beams for pallet racking systems.

- Ensures precision perforations for adjustable shelving configurations.

- Delivers high-speed production to meet tight project deadlines.

2. Automotive Parts Warehousing

- Scenario: An automotive manufacturer needs robust storage racks for heavy parts like engines and transmissions.

- Machine Contribution:

- Crafts heavy-duty beams and braces designed for extreme load capacities.

- Processes galvanized steel to provide corrosion resistance in humid environments.

- Supports the production of modular racks for flexible storage layouts.

3. Retail and Supermarket Shelving

- Scenario: A supermarket chain is upgrading its store shelving systems to accommodate new product lines.

- Machine Contribution:

- Produces lightweight yet durable shelving panels and decorative trims.

- Enables customization to align with the brand’s aesthetics.

- Ensures quick production to minimize store downtime during upgrades.

4. Cold Storage Facilities

- Scenario: A food distribution company is developing temperature-controlled warehouses for perishable goods.

- Machine Contribution:

- Produces corrosion-resistant uprights and beams for cold environments.

- Ensures structural stability to handle both heavy loads and temperature fluctuations.

- Processes recyclable materials to align with the company’s sustainability goals.

5. Modular Office Storage

- Scenario: A furniture manufacturer is creating modular shelving systems for office spaces.

- Machine Contribution:

- Crafts stylish and functional profiles for compact storage solutions.

- Supports innovative designs for easy assembly and reconfiguration.

- Delivers cost-effective production to meet competitive market demands.

Expanded FAQ Section for Warehouse Shelf Rack Roll Forming Machines

| Question | Answer |

|---|---|

| Can these machines handle high-strength steel? | Yes, Wuxi Sunway machines are designed to process high-strength and galvanized steel materials. |

| What is the average production speed? | Machines can produce up to 30–50 meters of profiles per minute, depending on material and design complexity. |

| Do these machines include integrated punching systems? | Yes, integrated punching systems create perforations, slots, and holes for adjustable shelving. |

| Are these machines compatible with modular racking designs? | Absolutely! They produce interchangeable components for flexible and modular storage systems. |

| What is the lifespan of these machines? | With proper maintenance, Wuxi Sunway machines last 15–25 years or more. |

| Is training included with the purchase? | Yes, Wuxi Sunway provides comprehensive training and after-sales support to ensure smooth operation. |

| How do these machines support sustainability? | By minimizing material waste, processing recyclable metals, and operating energy-efficiently. |

| What industries benefit most from these machines? | Warehousing, retail, automotive, e-commerce, cold storage, and office furniture manufacturing. |

Why Wuxi Sunway Machinery is the Industry Leader

Wuxi Sunway Machinery has solidified its reputation as a global leader in roll-forming technology for the warehousing and logistics industries. Here’s why manufacturers choose Wuxi Sunway:

- Proven Expertise: Decades of experience in delivering roll-forming solutions tailored to industrial storage needs.

- Global Reach: Trusted by clients across Asia, Europe, North America, South America, and beyond.

- Innovative Technology: Features like IoT integration, high-speed production, and customizable tooling ensure unmatched performance.

- Sustainability Commitment: Machines are designed to support eco-friendly manufacturing practices, reducing waste and energy consumption.

- Reliable Support: Comprehensive training, installation, and after-sales services ensure seamless operations.

Conclusion: Building the Future of Warehousing One Profile at a Time

দ্য Warehouse Shelf Rack Roll Forming Machine is a cornerstone of modern warehousing and logistics, enabling manufacturers to produce high-quality storage components with precision and efficiency. From e-commerce to cold storage, these machines are driving innovation and sustainability in industrial storage systems.

Ready to take your shelving and racking production to the next level? Contact Wuxi Sunway Machinery today to explore their state-of-the-art roll-forming solutions. Together, let’s build the future of warehousing—one profile at a time!