When it comes to modern construction, Z purlins are a cornerstone for structural integrity. They are widely used in industrial, commercial, and agricultural buildings for roofing and wall support systems. But what makes Z purlins so unique, and how are they manufactured with such precision and efficiency? The answer lies in the Z Profile Z Purlin Roll Forming Machine, a cutting-edge solution that revolutionizes the production of Z purlins.

In this comprehensive 2025 guide, we’ll explore the world of Z Profile Z Purlin Roll Forming Machines, focusing on their applications, features, pricing, automation, and why Wuxi Sunway Machinery is the go-to manufacturer for roll-forming technology. Let’s dive in!

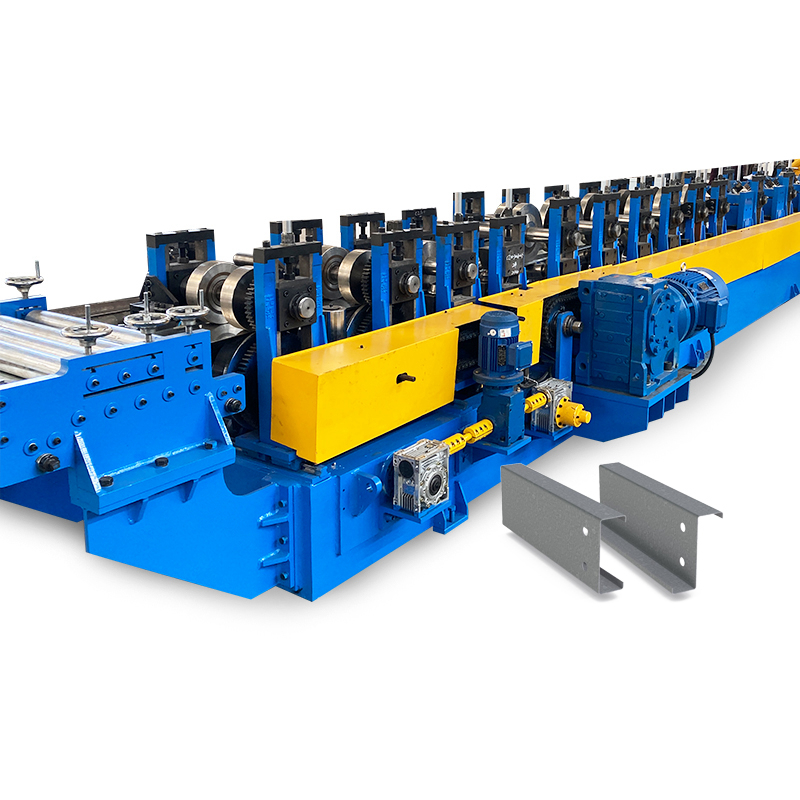

What is a Z Profile Z Purlin Roll Forming Machine?

ক Z Profile Z Purlin Roll Forming Machine is a highly specialized piece of equipment used to manufacture Z-shaped metal purlins from flat metal strips or coils. These machines use a series of rollers to bend, shape, and cut the metal into precise Z profiles that are strong, lightweight, and versatile.

Z purlins produced by these machines are used primarily as structural components in roofing and wall systems, offering excellent load-bearing capacity and ease of installation. With advanced features like quick profile switching and high-speed production, Sunway’s Z Purlin Machines are designed to meet the demands of modern construction projects.

Applications of Z Purlins

Z purlins are essential for a wide range of construction projects, thanks to their strength, versatility, and cost-effectiveness. Here are some of their key applications:

1. Roofing Support Systems

Z purlins are commonly used as secondary structural supports in roofing systems, providing stability to roof sheets and ensuring a uniform load distribution.

2. Wall Cladding Support

In wall systems, Z purlins act as horizontal supports for cladding sheets, creating a sturdy framework that enhances the building’s structural integrity.

3. Industrial Buildings

Factories, warehouses, and manufacturing facilities rely on Z purlins for their lightweight yet durable properties, making them ideal for large-span structures.

4. Agricultural Buildings

Barns, grain storage units, and livestock shelters use Z purlins due to their corrosion resistance and ability to withstand harsh environmental conditions.

5. Prefabricated Structures

Z purlins are a go-to component in modular and prefabricated buildings, where speed and efficiency are critical.

Key Features of Sunway Z Profile Z Purlin Roll Forming Machines

Not all roll-forming machines are created equal, and this is where Sunway’s expertise shines. Our Z Purlin Machines are designed with advanced features to ensure high precision, efficiency, and durability. Here’s what makes them stand out:

1. High-Precision Rollers

The hardened, chrome-plated steel rollers ensure consistent shaping of Z profiles with tight tolerances. This precision guarantees structural reliability for the end product.

2. Quick Profile Switching

Modern construction projects often require different Z purlin sizes. Sunway machines feature a quick-change system that allows operators to switch between profiles in just a few minutes, reducing downtime.

3. Advanced PLC Control System

দ্য Programmable Logic Controller (PLC) system offers user-friendly operation via a touchscreen interface. Operators can easily adjust purlin dimensions, lengths, and production speed.

4. Hydraulic Cutting Mechanism

The integrated hydraulic cutting system ensures burr-free edges and precise cutting, enhancing the quality of the finished product.

5. High-Speed Production

Sunway Z Purlin Machines can achieve production speeds of up to 20–30 meters per minute, depending on the material and profile, ensuring high output for large-scale projects.

6. Material Versatility

Our machines can process a variety of materials, including:

- Galvanized steel

- Mild steel

- High-strength steel

- Aluminum

7. Customizable Punching System

Need custom holes or slots for installation purposes? Sunway machines come with an integrated punching system that can be tailored to specific project requirements.

8. Durability and Low Maintenance

Built with high-quality components, Sunway machines are designed for long-term, heavy-duty use with minimal maintenance requirements.

Looking for more details? Visit Wuxi Sunway Machinery to explore our full range of roll-forming solutions.

Types of Sunway Z Purlin Roll Forming Machines

Sunway offers a variety of Z Purlin Machines to cater to different production needs and budgets. Here’s an overview of the most popular types:

1. Standard Z Purlin Machines

These machines are ideal for single-profile production and are cost-effective for manufacturers with focused product lines.

2. Adjustable Z Purlin Machines

Designed for flexibility, these machines can produce multiple Z purlin sizes without requiring extensive tooling changes.

3. High-Speed Z Purlin Machines

For manufacturers looking to scale operations, Sunway’s high-speed machines offer maximum efficiency and throughput.

Comparison Table: Types of Z Purlin Roll Forming Machines

| Machine Type | Primary Use | উৎপাদন গতি | Price Range (USD) |

|---|---|---|---|

| Standard Z Purlin Machine | Single-profile production | 10–20 meters/min | $50,000–$80,000 |

| Adjustable Z Purlin Machine | Multi-size production | 15–25 meters/min | $80,000–$120,000 |

| High-Speed Z Purlin Machine | Large-scale production | 20–30 meters/min | $120,000–$200,000+ |

Pricing of Sunway Z Purlin Roll Forming Machines

The cost of a Z Profile Z Purlin Roll Forming Machine varies depending on its features, capacity, and level of automation. Here’s a general pricing guide for 2025:

- Standard Machines: $50,000–$80,000

- Adjustable Machines: $80,000–$120,000

- High-Speed Machines: $120,000–$200,000+

For detailed pricing and financing options, get in touch with Sunway’s sales team.

Automation Trends in Z Purlin Roll Forming Machines

As the manufacturing world embraces Industry 4.0, automation is becoming a critical component of roll-forming technology. Here are some key automation trends shaping the future of Z Purlin Machines:

1. IoT Integration

IoT-enabled machines allow operators to monitor production metrics, machine performance, and maintenance needs remotely. Real-time data ensures seamless operations and reduces downtime.

2. Predictive Maintenance

AI-powered sensors analyze machine data to predict potential failures. By addressing issues before they occur, manufacturers can minimize downtime and repair costs.

3. Fully Automated Production Lines

From material feeding to punching, forming, and cutting, Sunway’s fully automated machines handle every step of the process, reducing labor requirements and boosting efficiency.

4. Servo-Driven Technology

Servo motors provide precise control over forming and cutting processes, improving accuracy and reducing energy consumption.

Troubleshooting Common Issues in Z Purlin Roll Forming Machines

Even the most advanced machines may encounter occasional issues. Here’s how to troubleshoot common problems:

1. Uneven Profiles

- Cause: Misaligned rollers or inconsistent material feeding.

- Solution: Recalibrate the rollers and check the material feeding system for proper alignment.

2. Material Jams

- Cause: Improper coil loading or debris in the machine.

- Solution: Clean the feeding mechanism and inspect the material for defects.

3. Burrs on Edges

- Cause: Dull cutting blades.

- Solution: Replace or sharpen the cutting blades and ensure proper alignment.

4. Inconsistent Dimensions

- Cause: Faulty PLC settings or worn components.

- Solution: Verify the PLC program and replace worn parts as needed.

For additional support, contact Sunway’s expert team.

FAQs About Sunway Z Purlin Roll Forming Machines

| Question | Answer |

|---|---|

| What is the average production speed? | Most machines can produce Z purlins at speeds of 10–30 meters per minute, depending on the model. |

| Can one machine produce multiple sizes? | Yes, adjustable machines can produce various Z purlin sizes and profiles. |

| What materials can these machines process? | Common materials include galvanized steel, mild steel, and aluminum. |

| What is the lifespan of these machines? | With proper maintenance, Sunway machines can last 10–15 years or more. |

| Are financing options available? | Yes, Sunway offers flexible financing plans. Contact Wuxi Sunway Machinery for more details. |

Environmental Benefits of Z Purlin Roll Forming Machines

Sustainability is a growing concern in the construction and manufacturing industries. Investing in a Sunway Z Profile Z Purlin Roll Forming Machine is not only good for your business but also for the planet. Here’s how these machines contribute to a greener future:

1. Minimal Material Waste

The roll-forming process is inherently efficient, utilizing nearly all of the raw material. Scrap is minimal, and any waste generated is often recyclable, reducing the overall environmental footprint.

2. Energy Efficiency

Traditional manufacturing methods consume significant amounts of energy, but Sunway’s machines are designed with servo-driven motors and optimized systems that lower energy consumption while maintaining high production rates.

3. Recyclable Materials

The Z purlins produced are typically made from 100% recyclable materials, such as galvanized steel, aluminum, or mild steel. This ensures that the final product can be reused at the end of its lifecycle, promoting a circular economy.

4. Longevity of Products

Z purlins are known for their durability, often lasting decades without the need for replacement. This reduces the demand for raw materials over time, further contributing to sustainability.

5. Cleaner Manufacturing Process

With advanced automation and precision engineering, Sunway’s machines reduce errors, scrap, and rework—leading to a cleaner, more efficient manufacturing process.

By choosing a machine from Wuxi Sunway Machinery, you’re not just investing in quality; you’re aligning your business with global sustainability goals.

Advanced Automation Features in Sunway Z Purlin Roll Forming Machines

The era of manual interventions is fading fast, and automation is taking center stage in the manufacturing world. Sunway’s Z Purlin Machines are equipped with state-of-the-art automation features that ensure seamless operations and superior output. Let’s take a closer look:

1. IoT-Enabled Smart Machines

With IoT (Internet of Things) integration, Sunway machines bring smart manufacturing to your facility:

- Remote Monitoring: Track production metrics, machine health, and material usage from anywhere in the world.

- Real-Time Alerts: Receive notifications for maintenance, material jams, or component wear before they lead to downtime.

- Data-Driven Insights: Analyze historical data to identify inefficiencies and optimize production workflows.

2. Adaptive Profile Switching

One of the standout features of Sunway machines is their ability to switch between Z purlin profiles quickly and efficiently:

- Quick Tool Changes: Change between different sizes or profiles in minutes, reducing downtime and increasing productivity.

- PLC-Controlled Adjustments: Modify dimensions, thickness, and punching patterns directly from the touchscreen interface.

3. Predictive Maintenance

AI-powered sensors continuously monitor the machine’s components, predicting issues before they occur:

- Component Health Monitoring: Track wear and tear on rollers, punches, and motors in real time.

- Proactive Repairs: Schedule maintenance during planned downtime to avoid unexpected interruptions.

- Extended Machine Lifespan: Keep your equipment in peak condition for years to come.

4. Fully Automated Production Lines

Sunway’s fully automated machines handle every step of the manufacturing process:

- Material Feeding: Automatic coil loading ensures consistent material flow.

- Forming and Punching: Integrated systems synchronize the forming and punching processes for flawless precision.

- Cutting and Stacking: Hydraulic cutting mechanisms create clean, burr-free edges, while automated stacking systems prepare the finished purlins for transport.

5. Servo-Driven Systems for Precision

Servo motors provide unmatched accuracy and energy efficiency:

- Enhanced Control: Maintain consistent quality, even at high speeds.

- Reduced Power Consumption: Save on energy costs while minimizing environmental impact.

- High-Speed Efficiency: Achieve production speeds of up to 30 meters per minute without compromising on quality.

Troubleshooting Common Issues in Z Purlin Roll Forming Machines

Even the most advanced machines may face occasional hiccups. Knowing how to troubleshoot common problems can save you time and money. Here’s a practical guide:

1. Material Jamming in the Feed

- Cause: Improper coil loading, excess tension, or debris in the feeding system.

- Solution: Check the coil alignment and tension settings. Clean the feeding mechanism and ensure the material is free of defects.

2. Uneven Z Purlin Profiles

- Cause: Misaligned rollers or inconsistent material feeding.

- Solution: Realign the rollers and verify that the material is fed evenly. Inspect the input material for thickness consistency.

3. Burrs or Rough Edges

- Cause: Dull cutting blades or incorrect hydraulic cutting pressure.

- Solution: Replace or sharpen the cutting blades. Recalibrate the cutting pressure to ensure clean, burr-free edges.

4. Inconsistent Dimensions

- Cause: Faulty PLC programming or worn servo motors.

- Solution: Check and reprogram the PLC settings. Inspect the servo motors for wear and replace components as needed.

5. Machine Downtime

- Cause: Neglected maintenance or undetected wear on critical components.

- Solution: Adhere to a regular maintenance schedule, including lubrication, cleaning, and part inspections. Use predictive maintenance tools if available.

For persistent issues, Sunway’s technical support team is just a call away. Reach out to us at Wuxi Sunway Machinery for expert assistance.

FAQs About Sunway Z Purlin Roll Forming Machines

Here are answers to some of the most frequently asked questions about Sunway’s Z Purlin Machines:

| Question | Answer |

|---|---|

| What is the average production speed? | Most machines can produce Z purlins at speeds of 10–30 meters per minute, depending on the model. |

| Can one machine produce different sizes? | Yes! Adjustable machines can produce multiple sizes and profiles with quick tooling changes. |

| What materials can these machines process? | Common materials include galvanized steel, mild steel, and aluminum. |

| Do these machines require skilled operators? | No, Sunway’s advanced PLC systems make operation simple and user-friendly, requiring minimal training. |

| What is the lifespan of the machines? | With proper maintenance, Sunway machines can last 10–15 years or more, offering excellent ROI. |

| Are financing options available? | Yes, flexible financing plans are available. Contact Wuxi Sunway Machinery for details. |

Why Choose Wuxi Sunway Machinery for Z Purlin Machines?

When it comes to roll-forming technology, Wuxi Sunway Machinery is the industry leader. Here’s why:

- Global Expertise: With decades of experience, we’ve delivered roll-forming solutions to clients across Asia, Europe, Africa, and the Americas.

- Custom Solutions: Whether you need standard machines or customized systems, we tailor our solutions to meet your specific needs.

- Uncompromising Quality: Built to international standards, our machines deliver exceptional durability, precision, and reliability.

- Comprehensive Support: From installation and training to spare parts and troubleshooting, we’re with you every step of the way.

- Innovation-Driven: Our machines feature the latest technologies, including IoT integration, predictive maintenance, and servo-driven systems.

Conclusion: Is a Sunway Z Profile Z Purlin Roll Forming Machine Right for You?

If your business involves the production of Z purlins for construction, investing in a Sunway Z Profile Z Purlin Roll Forming Machine is a no-brainer. These machines combine unmatched precision, cutting-edge automation, and exceptional efficiency, making them the ideal solution for modern manufacturers.

Ready to elevate your production capabilities? Choose Wuxi Sunway Machinery for the ultimate roll-forming experience. Let’s roll into a brighter, more productive future—together!