What is a C Profile Steel Roll Forming Machine?

দ্য C Profile Steel Roll Forming Machine is an innovative piece of equipment primarily designed to create C-shaped steel profiles. These machines have become essential in various industries, particularly in construction and manufacturing.

Historical Overview

Before the advent of these machines, manufacturing C-shaped steel profiles was a cumbersome and time-consuming process. However, with technological advancements, these machines have not only simplified the process but have also enhanced production efficiency.

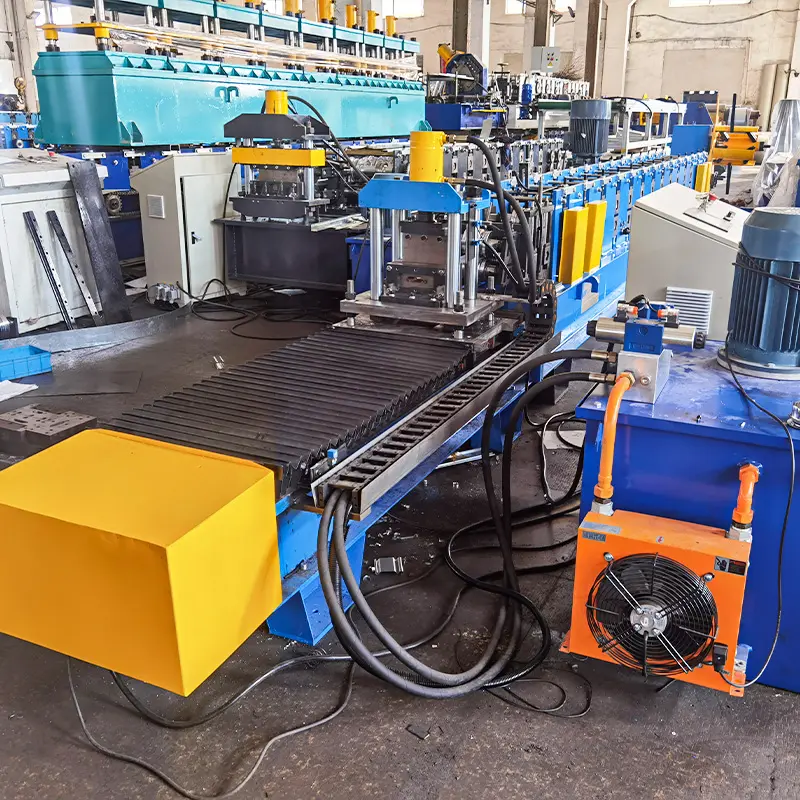

The Anatomy of the Machine

A typical C Profile Steel Roll Forming Machine consists of:

- আনকোয়লার: A section that holds and releases the steel coil for forming.

- Roll forming section: Here, the steel undergoes shape changes by passing through various stages of rollers.

- Cutting mechanism: After achieving the desired profile, the machine cuts the steel at specified lengths.

- Control system: Usually computerized to ensure precision and to control various operations.

Importance in Modern Industries

The manufacturing sector has witnessed a surge in the demand for these machines. Their significance stems from:

- দক্ষতা: They offer a rapid production rate.

- Precision: Computerized systems ensure that each steel profile is uniform.

- নমনীয়তা: Capable of handling various steel thicknesses and profiles.

Comparison with Other Machines

| বৈশিষ্ট্য | C Profile Steel Roll Forming Machine | Traditional Machines |

|---|---|---|

| গতি | High | Medium to Low |

| Accuracy | Very High | Moderate |

| খরচ | Initially High but low operating cost | Low initial but high operating cost |

Wrapping Up

To sum up, a C Profile Steel Roll Forming Machine is a groundbreaking invention in the realm of steel profile manufacturing. Its speed, precision, and efficiency have made it indispensable in the modern industrial scenario.

How Much Does a C Profile Steel Roll Forming Machine Cost?

When it comes to purchasing a C Profile Steel Roll Forming Machine, one of the primary concerns for potential buyers is the cost. Understanding the cost structure can help in making an informed decision.

Factors Influencing Cost

Several elements come into play when determining the price of these machines:

- Size and Capacity: Larger machines with higher production capacities often come with a steeper price tag.

- Technological Features: Machines equipped with advanced features, such as computerized control systems, tend to be more expensive.

- ব্র্যান্ড: Renowned brands may charge a premium due to their reputation for quality and reliability.

- Country of Origin: Machines manufactured in countries known for advanced engineering, like Germany or Japan, may be pricier than those from other regions.

Specific Price Ranges

Here’s a general breakdown of the costs associated with these machines:

| Brand Name | Price Range (USD) | Notable Features |

|---|---|---|

| SteelMaster | $20,000 – $35,000 | High-speed operation, Durable build |

| FormTech Industries | $25,000 – $50,000 | Advanced control system, Energy-efficient |

| ProRollers Inc. | $30,000 – $60,000 | Precision engineering, Excellent after-sales |

Benefits of Investment

While the initial investment may seem substantial, the benefits outweigh the costs:

- High Production Rate: With one of these machines, industries can exponentially increase their output.

- বিনিয়োগের প্রত্যাবর্তন (ROI): With increased production and efficiency, businesses can expect a swift ROI.

- দীর্ঘায়ু: These machines are built to last, ensuring a prolonged period of operation without substantial maintenance costs.

Renting vs Buying

For businesses unsure about purchasing, renting is an option. However, while renting offers short-term financial relief, buying ensures long-term benefits, especially in terms of customization and potential ROI.

Where to Buy

Several suppliers specialize in these machines:

- Direct from Manufacturer: Many businesses prefer this route due to the possibility of customization and after-sales service.

- Through a Distributor: Distributors often offer competitive pricing and may provide additional services such as installation and training.

- Used Machines: For those on a budget, purchasing a second-hand machine can be a viable option. However, thorough checks for wear and tear are essential.

What are the Types of C Profile Steel Roll Forming Machines?

When venturing into the world of C Profile Steel Roll Forming Machines, understanding the variety of types available in the market is crucial. The type of machine chosen can significantly affect production efficiency, quality of the final product, and overall cost-effectiveness.

Manual Machines

As the name suggests, manual machines require significant human intervention. These machines are:

- Simpler in design.

- Cost-effective; with price ranges typically from $10,000 to $20,000.

- Best suited for smaller operations or businesses that don’t need large quantities of C-profile steel.

Semi-Automatic Machines

A middle-ground between manual and fully automatic machines:

- Requires some human intervention, especially in loading materials and setting the initial parameters.

- Priced between $20,000 to $40,000.

- Offers better efficiency than manual machines but doesn’t match the production rate of fully automatic machines.

Fully Automatic Machines

These are the cutting-edge in C Profile Steel Roll Forming:

- Minimal human intervention required.

- Faster production rate, capable of producing large quantities in a short time.

- Typically priced between $40,000 to $80,000, depending on the features.

- Ideal for large industries where mass production is a necessity.

Hybrid Machines

These are specialized machines which can be:

- Customized as per the requirement.

- Capable of switching between manual, semi-automatic, and fully automatic modes.

- Priced anywhere between $30,000 to $70,000.

- Suited for industries with varied production requirements.

Deciding the Right Type

Making a decision will largely depend on the business’s needs. For large-scale operations, investing in a fully automatic or hybrid machine may be the right choice, despite the initial cost. Small businesses might find manual or semi-automatic machines more in line with their production and budgetary constraints.

Functions of C Profile Steel Roll Forming Machines

C Profile Steel Roll Forming Machines play a vital role in the modern construction and manufacturing landscape. They have been designed to perform a variety of functions to streamline the production process.

Forming C Profile Steel

The primary function, as the name suggests, is to transform flat sheets of steel into C-shaped profiles. This is done by feeding the sheet through a series of roll stations, each altering the shape of the material slightly until the desired profile is achieved.

কাটিং

Post the formation of the C profile, the machine employs shearing mechanisms to cut the steel into desired lengths. This ensures that each piece is uniform, meeting the specified requirements.

পাঞ্চিং

Some machines come with punching tools that create holes in the C profile steel at specified locations. This is particularly useful for construction purposes where bolting or riveting is needed.

Coating

Certain advanced machines also offer coating functionalities. This involves applying a protective layer, usually of zinc or another anti-corrosive material, to the C profile steel. This increases the lifespan of the product, especially when used in external applications.

স্ট্যাকিং

After the forming, cutting, and possible punching or coating processes, the machine stacks the finished products neatly for easy transportation or storage.

Monitoring and Quality Control

Advanced machines often come equipped with computerized control systems. These systems monitor the entire process, ensuring that each C profile steel piece is of the highest quality and matches the predefined standards.

Applications of C Profile Steel Roll Forming Machines

C Profile Steel Roll Forming Machines have revolutionized the construction and manufacturing industries. The products they create are vital in various applications due to the strength, durability, and versatility of C profile steel. This article delves deep into the myriad of applications these machines cater to.

নির্মাণ শিল্প

The C profile steel pieces are fundamental in the construction sector, being used in:

- Building Frameworks: Providing structural integrity to buildings.

- ছাদের ব্যবস্থা: Acting as support structures in roofs.

- Flooring Systems: Used as joists or bearers in flooring assemblies.

অটোমোটিভ শিল্প

Cars, trucks, and other vehicles use C profile steel in:

- Chassis Construction: These profiles offer strength without adding significant weight.

- Component Housing: Protecting critical components.

Furniture Manufacturing

In the furniture sector, the C profile steel finds its use in:

- Office Furniture: Desks, racks, and shelving units.

- Home Furniture: Bed frames and custom modular setups.

Transportation and Logistics

- Railways: C profile steel is used in the manufacturing of rail coaches and cargo containers.

- Warehousing: Storage racks and shelving units, ensuring maximum utilization of space.

Agriculture

- Machinery Framework: The strong profile provides structural integrity to heavy agricultural machines.

- Greenhouses: The skeletal framework of greenhouses often uses C profile steel for durability and strength.

Electrical and Electronics Industry

C profile steel pieces are used to house and protect sensitive electronic equipment, ensuring they are shielded from external elements.

অবকাঠামো উন্নয়ন

From bridges to bus stops, C profile steel is widely utilized in public infrastructure projects due to its durability and ease of maintenance.

Maritime Structures

Ports, docks, and even certain components of ships and boats use C profile steel for its resistance to corrosion, especially when coated adequately.

In a world increasingly reliant on strong, durable, and cost-effective materials, the importance of C profile steel, and by extension, the machines that produce them, cannot be overstated. The versatility of the material, combined with its strength and durability, ensures its continued relevance across a myriad of industries.

How Does a C Profile Steel Roll Forming Machine Benefit You?

The adoption of C Profile Steel Roll Forming Machines in the manufacturing and construction sectors has been driven by the manifold benefits they bring. This equipment is not just about enhancing productivity; it’s about revolutionizing the entire production process.

1. Enhanced Productivity

Arguably the most significant benefit, these machines dramatically increase production rates. Traditional methods of forming C profiles are labor-intensive and time-consuming. With automated machines, thousands of profiles can be produced in a fraction of the time.

2. Consistency and Precision

Every piece of C profile steel produced is uniform, meeting specified dimensions with high accuracy. This consistency ensures that the end product, whether it’s a building or a piece of furniture, is of the highest quality.

3. Cost-Effectiveness

While the initial investment might seem substantial, the return on investment is swift. Increased production rates mean more sales, and consistent quality means fewer rejections or reworks. Additionally, automation leads to reduced labor costs in the long run.

4. Versatility

Modern C Profile Steel Roll Forming Machines are versatile. They can handle various steel thicknesses and can be adjusted to produce different profile sizes. This adaptability means businesses can cater to a wider range of client requirements without needing multiple machines.

5. Reduced Waste

The precision of these machines ensures that there’s minimal waste of material. Traditional methods might lead to excess off-cuts or incorrectly formed profiles, which then have to be recycled or discarded. Automated machines dramatically reduce such wastages.

6. Safety

Automated machines reduce the need for manual handling of heavy steel sheets. This reduction in manual labor decreases the potential for workplace accidents, creating a safer environment for workers.

7. Environmentally Friendly

As previously mentioned, these machines result in less waste. Moreover, many of today’s machines are designed to be energy efficient, leading to a lower carbon footprint. This eco-friendliness is increasingly important in today’s environmentally-conscious business landscape.

How to Choose a C Profile Steel Roll Forming Machine?

Choosing the right C Profile Steel Roll Forming Machine is a pivotal decision that can shape the future of a business. It demands careful consideration of various factors to ensure maximum return on investment and operational efficiency.

1. Define Your Requirements

Before delving into the market, businesses should:

- Determine the আয়তন of production.

- Understand the sizes and thicknesses of profiles required.

- Decide on the level of automation needed.

2. Budget Consideration

While it’s tempting to go for the most advanced machine, it’s essential to balance features with budget constraints. Decide on a budget and try to find the best machine that fits within it.

3. Brand Reputation

Reputable brands generally offer higher quality machines, backed by robust after-sales support. Researching reviews and seeking industry recommendations can help in identifying trusted brands.

4. Technological Features

Modern machines come equipped with advanced features:

- Computerized Control Systems: For precision and consistency.

- Energy-Efficiency: Reducing operational costs.

- Quick Changeover Abilities: Allowing for swift transitions between different profile sizes.

5. After-Sales Support

A machine is a long-term investment, and post-purchase support is crucial. Ensure the manufacturer or distributor offers:

- প্রশিক্ষণ for machine operation.

- Maintenance and repair services.

- Availability of replacement parts.

6. Warranty and Service Terms

Understanding the warranty terms can save considerable time, money, and stress in the long run. Look for manufacturers offering extended warranty periods and transparent service terms.

A table summarizing the main consideration points can be handy:

| Consideration Points | বর্ণনা |

|---|---|

| উৎপাদন আয়তন | Estimate the number of profiles needed daily/weekly/monthly. |

| Budget | Set a maximum spend limit. |

| Brand Reputation | Research and seek recommendations. |

| Technological Features | Determine essential features vs. nice-to-haves. |

| বিক্রয়োত্তর সহায়তা | Ensure training, maintenance, and repair services. |

| Warranty Terms | Check for duration and coverage details. |

Best 10 C Profile Steel Roll Forming Machine Manufacturers

In the vast world of C Profile Steel Roll Forming Machines, choosing the right manufacturer can be daunting. A manufacturer’s reputation, product quality, and after-sales support are paramount. Here are ten of the best manufacturers in the industry, each renowned for their excellence.

1. SteelMaster Corp.

Renowned for:

- High-speed operations.

- Durable machine build.

- Extensive post-sales support.

2. FormTech Industries

Stands out for:

- Advanced computerized control systems.

- Energy-efficient machines.

- Wide range of products catering to various requirements.

3. ProRollers Inc.

Noteworthy aspects:

- Precision engineering.

- Excellent after-sales services.

- Training programs for operators.

4. ProfileMatic Systems

Known for:

- Versatile machines with quick changeover abilities.

- Competitive pricing.

- Global presence with strong distribution networks.

5. SteelForm Innovations

Attributes:

- State-of-the-art technology integration.

- Strong focus on energy efficiency.

- Customization options available.

6. PreciseRoll Industries

Highlights:

- Strong emphasis on research and development.

- Machines built for high durability.

- Comprehensive training and maintenance programs.

7. MegaSteel Manufacturing

Stand-out features:

- Wide variety of machines catering to all production volumes.

- Extensive global presence.

- Focused on constant innovation.

8. UltraForm Systems

Key aspects:

- Known for high precision and consistency.

- Strong after-sales support and maintenance services.

- Energy-efficient models available.

9. ProfiloTech Enterprises

USPs:

- Robust machine build quality.

- Competitive pricing.

- Swift and responsive customer support.

10. RapidSteel Solutions

Distinguishing factors:

- Quick delivery times.

- Customization options based on client requirements.

- Extensive warranty and service terms.

Choosing a manufacturer from this list guarantees a certain level of quality and reliability. However, it’s essential to align the choice with specific business needs, budget considerations, and long-term operational plans.

Where to Buy a C Profile Steel Roll Forming Machine?

In the expanding market of C Profile Steel Roll Forming Machines, numerous suppliers cater to the global demand. However, determining where to purchase such equipment can be overwhelming, especially with the vast range of options available. To simplify this decision, one needs to consider several factors, from the machine’s quality to the post-purchase support offered.

1. Local vs. International Suppliers

While local suppliers can offer quick delivery and easy accessibility, international suppliers, especially from manufacturing hubs, might provide more competitive prices and advanced technology.

2. Online Marketplaces

Platforms like Alibaba, Made-in-China, and IndiaMART are becoming increasingly popular for sourcing industrial machinery. These platforms allow potential buyers to:

- View multiple suppliers and products.

- Read reviews and ratings.

- Directly communicate with suppliers.

3. Industry Exhibitions

Participating in or visiting industry-specific exhibitions can be beneficial. These events:

- Showcase the latest machinery and technologies.

- Offer an opportunity to meet suppliers face-to-face.

- Provide a platform for live demonstrations.

4. Direct Manufacturer Purchase

Buying directly from manufacturers can be advantageous. It often ensures:

- Competitive pricing (by eliminating middlemen).

- Clear communication regarding customization.

- Comprehensive after-sales support.

5. Referrals and Recommendations

Industry peers can often provide valuable insights based on their experiences. Seeking recommendations:

- Helps identify reliable suppliers.

- Can provide real-life feedback on machine performance and durability.

- May offer insights into post-purchase support.

6. Recognized Global Suppliers

Well-established global suppliers often provide a balance of quality, competitive pricing, and excellent after-sales support. One such renowned manufacturer is WUXI SUNWAY MACHINERY CO., LTD. This company stands out as a professional manufacturer and exporter, deeply involved in the design, development, and production of cold roll forming machines. Upholding international quality standards, its products have earned appreciation across diverse markets worldwide, spanning Asia, Africa, Europe, South America, and Australia. The company’s commitment to excellence is further reflected in its vast global sales network.

Product Advantages of Chinese C Profile Steel Roll Forming Machine

China, as the manufacturing giant of the world, has been at the forefront in producing various industrial machines, including the C Profile Steel Roll Forming Machines. Over the years, several product advantages have positioned Chinese-made machines at a competitive edge in the global market.

1. Cost-Effectiveness

Chinese manufacturing benefits from economies of scale and a vast industrial ecosystem. This translates to:

- Competitive pricing.

- High-quality machinery at affordable rates.

2. Advanced Technology Integration

Chinese manufacturers emphasize:

- Incorporating the latest technology.

- Constant research and development.

- Ensuring machines are up-to-date with global standards.

৩. কাস্টমাইজেশন বিকল্পসমূহ

Many Chinese suppliers offer:

- Tailor-made solutions based on specific client needs.

- Flexibility in design and operational features.

4. Quality Assurance

Leading manufacturers, like WUXI SUNWAY MACHINERY CO., LTD, ensure:

- Adherence to international quality standards.

- Rigorous testing and quality checks before shipment.

5. Extensive Range

Chinese manufacturers produce a broad range of machines, catering to:

- Different production capacities.

- Various profile sizes and thicknesses.

6. Global Shipping and Installation Support

Most top-tier Chinese suppliers:

- Provide global shipping options.

- Offer on-site installation and training services.

7. After-Sales Support

Post-purchase support is vital. Chinese manufacturers often:

- Offer extended warranties.

- Provide prompt maintenance and repair services.

- Ensure the availability of spare parts.

8. Eco-Friendly Solutions

With a growing emphasis on sustainable solutions, many Chinese suppliers:

- Develop energy-efficient machines.

- Focus on minimizing waste and optimizing resource use.

Best Chinese C Profile Steel Roll Forming Machine Supplier

When considering purchasing a C Profile Steel Roll Forming Machine from China, the options might seem endless. However, among the numerous manufacturers, WUXI SUNWAY MACHINERY CO., LTD emerges as a standout choice for various reasons.

1. Comprehensive Expertise

WUXI SUNWAY not only manufactures but also plays a pivotal role in the design and development of cold roll forming machines. Their in-depth involvement at every stage of production ensures a product that is both innovative and reliable.

2. International Quality Standards

WUXI SUNWAY’s commitment to quality is evident in its adherence to global quality benchmarks. Their machines are not only top-notch but also widely appreciated across multiple markets, from Asia to Australia.

3. Global Reach

Their products have found favor in diverse markets such as Asia, Africa, Europe, South America, and Australia. This wide acceptance is a testament to the company’s excellence and its adaptability to cater to various market requirements.

4. Customer-Centric Approach

The company doesn’t just sell machines; they build relationships. From understanding specific client needs to providing post-sale support, their customer-centric approach is evident.

5. Global Sales Network

WUXI SUNWAY has developed a robust global sales network. This ensures that no matter where you are located, their products and services are within reach.

Choosing a supplier like WUXI SUNWAY MACHINERY CO., LTD guarantees not just a high-quality machine but also a partnership that will support your business’s growth and success.

FAQ

1. What is a C Profile Steel Roll Forming Machine used for?

A C Profile Steel Roll Forming Machine is primarily utilized to shape strips of metal into specific profiles, commonly C-shaped, used in various construction and manufacturing applications.

2. How does WUXI SUNWAY MACHINERY CO., LTD ensure the quality of its machines?

WUXI SUNWAY adheres to international quality standards and conducts rigorous testing and quality checks before shipping out any product. Their commitment to excellence ensures that every machine meets global benchmarks.

3. Can I get a customized C Profile Steel Roll Forming Machine from WUXI SUNWAY?

Yes, WUXI SUNWAY offers customization options to cater to specific client needs, ensuring flexibility in design and operational features.

4. How long is the warranty period for machines purchased from WUXI SUNWAY?

Warranty periods can vary based on the specific model and terms of purchase. However, WUXI SUNWAY generally provides extended warranties, showcasing their confidence in the product’s durability and performance.

5. Are spare parts readily available for machines from WUXI SUNWAY MACHINERY CO., LTD?

Absolutely. WUXI SUNWAY ensures the availability of spare parts and offers prompt maintenance and repair services, guaranteeing minimal downtime for its clients.

6. Does WUXI SUNWAY offer on-site installation and training?

Yes, most top-tier suppliers, including WUXI SUNWAY, offer on-site installation and training services to ensure smooth machine operation and to address any client concerns.

7. How does the C Profile Steel Roll Forming Machine from China differ from others in the market?

Chinese-made machines, especially those from reputable manufacturers like WUXI SUNWAY, often stand out for their cost-effectiveness, advanced technology integration, and emphasis on eco-friendly solutions, setting them apart in the global market.