ভূমিকা

In the world of metal fabrication, innovation is the key to achieving efficiency, precision, and cost-effectiveness. One such revolutionary technology that has transformed the way metal components are manufactured is the Ameco Metal Roll Forming Machine. This article explores the features, advantages, and applications of Ameco’s roll forming machine, delving into the reasons why it has become a preferred choice for metal fabricators worldwide.

What is Ameco Metal Roll Forming Machine?

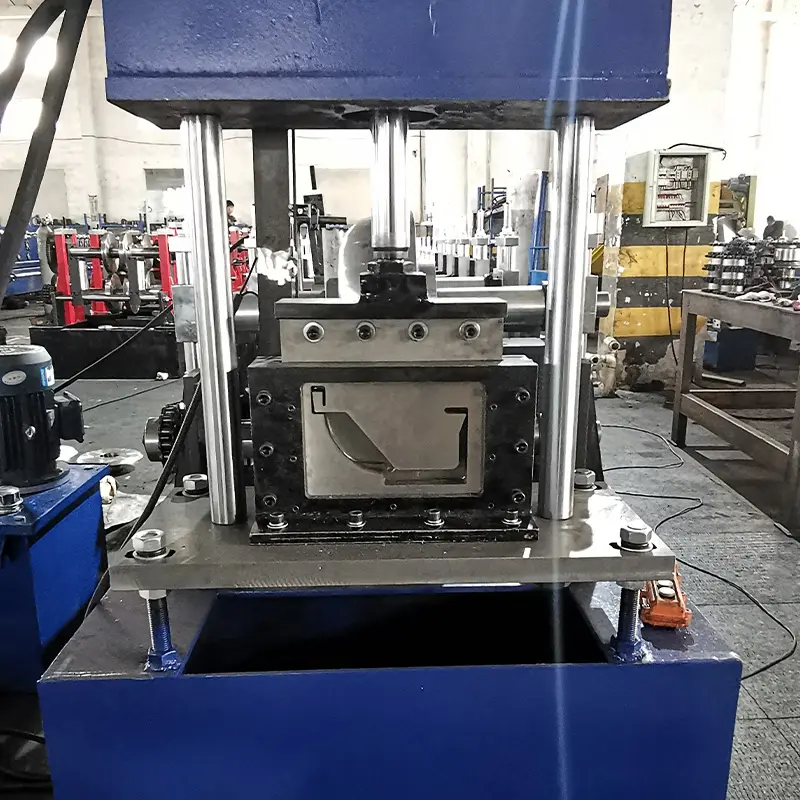

Ameco Metal Roll Forming Machine is an advanced piece of equipment used in metal fabrication to shape flat metal sheets into desired cross-section profiles. It works by passing the metal strip through successive pairs of rolls, gradually bending and forming it into the desired shape. This process ensures consistent and precise results, making it suitable for various industries that require customized metal profiles.

Advantages of Ameco Metal Roll Forming Machine

খরচ-কার্যকর উৎপাদন

Ameco’s roll forming machines are designed to optimize material usage, reducing waste significantly. This cost-effective production method translates into higher profitability for metal fabricators, making it a wise investment for long-term growth.

ডিজাইনের নমনীয়তা

The flexibility of Ameco’s roll forming machines allows for the creation of complex and intricate metal profiles. From simple bends to elaborate designs, the machine can handle a wide range of customization needs, meeting the requirements of diverse industries.

High Precision and Consistency

The precision engineered into every Ameco roll forming machine ensures that each metal component is manufactured with accuracy and consistency. This level of precision is crucial for industries that demand strict tolerances and seamless fitments.

Reduced Material Waste

Traditional metal fabrication methods often result in significant material wastage. However, with the roll forming process, the material utilization is maximized, leading to minimal scrap generation and reduced overall production costs.

How Does Ameco Metal Roll Forming Machine Work?

The operation of the Ameco Metal Roll Forming Machine is a well-coordinated process. The metal strip is fed into the machine, and a series of rollers shape it into the desired profile. The number of stands and the roller configuration can be adjusted to achieve various cross-sectional shapes. This versatility in the roll forming process makes it suitable for producing a wide array of metal components.

Types of Metal Roll Forming Machines Offered by Ameco

Ameco offers different types of roll forming machines, each catering to specific production requirements:

Single Stand Roll Forming Machine

The single stand roll forming machine is ideal for simple profiles with a straightforward bending process. It is efficient for small to medium-scale production runs.

Double Stand Roll Forming Machine

The double stand roll forming machine offers increased production capacity and versatility. It can handle more complex profiles and is suitable for medium to large-scale production.

Multi-Station Roll Forming Machine

The multi-station roll forming machine is designed for high-volume production and the manufacturing of intricate profiles. It integrates multiple stands for simultaneous shaping, significantly reducing production time.

Applications of Ameco Metal Roll Forming Machine

The versatility and efficiency of Ameco’s roll forming machines make them invaluable in various industries, including:

অটোমোটিভ শিল্প

The automotive industry relies on precise and durable metal components for vehicle assembly. Ameco’s roll forming machines can produce parts like window channels, roof rails, and bumpers with exceptional accuracy and consistency.

নির্মাণ শিল্প

In the construction sector, customized metal profiles are often required for structural and architectural applications. Ameco’s roll forming machines provide the capability to produce profiles for door frames, wall studs, and roofing components.

HVAC Industry

The HVAC industry demands intricate ductwork and ventilation components. Ameco’s roll forming machines can shape metal sheets into precisely measured ducts, elbows, and connectors, ensuring optimal airflow and system efficiency.

Furniture Manufacturing

From modern furniture to office equipment, Ameco’s roll forming machines can produce metal components for various furniture designs, enabling manufacturers to deliver aesthetically appealing and robust products.

Customization and Design Capabilities

Ameco understands that every customer may have unique requirements. Therefore, they offer comprehensive customization options to meet specific design needs. Whether it’s a new profile or modifications to an existing one, Ameco can accommodate various design requests.

রক্ষণাবেক্ষণ এবং সহায়তা

To ensure uninterrupted production and optimal performance, Ameco provides reliable maintenance services and ongoing technical support. Their team of experts assists customers in resolving any operational issues and provides training for machine operators.

Why Choose Ameco Metal Roll Forming Machine?

The Ameco Metal Roll Forming Machine stands out from its competitors for several reasons:

- Robust Construction: Ameco’s machines are built with high-quality materials, ensuring durability and longevity.

- Cutting-Edge Technology: The incorporation of the latest technology guarantees precise and consistent results.

- কাস্টমাইজেশন: Ameco offers a high degree of customization, tailoring the machine to meet specific production requirements.

- Industry Experience: With decades of experience in the field, Ameco has honed its roll forming technology to perfection.

- Excellent Customer Support: Ameco prioritizes customer satisfaction, providing prompt support and after-sales services.

Customer Reviews and Testimonials

Ameco’s roll forming machines have garnered positive reviews from satisfied customers across different industries. Many clients praise the machine’s performance, precision, and seamless integration into their production processes.

উপসংহার

The Ameco Metal Roll Forming Machine has revolutionized the metal fabrication industry by offering cost-effective, versatile, and precise solutions. Its ability to produce customized metal profiles for various applications makes it an indispensable asset for metal fabricators. With Ameco’s commitment to innovation and customer satisfaction, their roll forming machines continue to pave the way for efficiency and excellence in metal fabrication.

প্রায়শই জিজ্ঞাসিত প্রশ্ন (এফএকিউ)

What materials can be used with Ameco roll forming machines?

Ameco’s roll forming machines are capable of working with a wide range of materials, including steel, stainless steel, aluminum, copper, and other non-ferrous metals. The machine’s versatility allows it to handle different material thicknesses and grades, ensuring optimal results for various applications.

Is Ameco’s roll forming machine suitable for small-scale production?

Yes, Ameco offers roll forming machines that are well-suited for small-scale production runs. The single stand roll forming machine is an excellent choice for fabricators with lower volume requirements. It provides a cost-effective solution while maintaining high precision and consistent results.

Can Ameco provide on-site training for machine operators?

Absolutely! Ameco is committed to ensuring that their customers get the most out of their roll forming machines. They offer comprehensive on-site training for machine operators, covering machine operation, maintenance, and safety protocols. This training empowers operators to maximize productivity and efficiency.

How long does it take to set up and start using an Ameco roll forming machine?

The setup time for an Ameco roll forming machine may vary depending on the specific model and customization requirements. Generally, the installation and commissioning process can take a few days to a few weeks. However, Ameco’s expert technicians work efficiently to minimize downtime and get the machine up and running as quickly as possible.

Does Ameco offer after-sales support and spare parts?

Absolutely! Ameco understands the importance of continuous operation in the metal fabrication industry. They offer comprehensive after-sales support, including technical assistance, troubleshooting, and spare parts availability. Their dedicated support team ensures that any issues are promptly addressed, minimizing production disruptions.