নির্মাণ প্রকল্পের জন্য ধাতু অংশ তৈরি করার ক্ষেত্রে ব্যবসায়ী ও ব্যক্তিরা বিভিন্ন বিকল্পের সামনে দাঁড়ান। দুটি জনপ্রিয় পদ্ধতি হলো পুরলিন রোল ফর্মিং এবং ঐতিহ্যবাহী ফ্যাব্রিকেশন। উভয় পদ্ধতিই উচ্চমানের অংশ উৎপাদন করতে সক্ষম হলেও, গতি, খরচ এবং কাস্টমাইজেশনের দিক থেকে তাদের মধ্যে উল্লেখযোগ্য পার্থক্য রয়েছে। এই লেখায় আমরা পুরলিন রোল ফর্মিং এবং ঐতিহ্যবাহী ফ্যাব্রিকেশনের সুবিধা-অসুবিধা নিয়ে আলোচনা করব এবং আপনার প্রকল্পের প্রয়োজন অনুসারে কোন পদ্ধতি সবচেয়ে উপযুক্ত তা নির্ধারণে সাহায্য করব।

পুরলিন রোল ফর্মিং এবং ঐতিহ্যবাহী ফ্যাব্রিকেশনের সারাংশ

পুরলিন রোল ফর্মিং এবং ঐতিহ্যবাহী ফ্যাব্রিকেশন নির্মাণ প্রকল্পের জন্য ধাতু অংশ তৈরির দুটি সাধারণ পদ্ধতি। প্রত্যেক পদ্ধতির সারাংশ এবং তাদের মধ্যে পার্থক্য নিম্নরূপ:

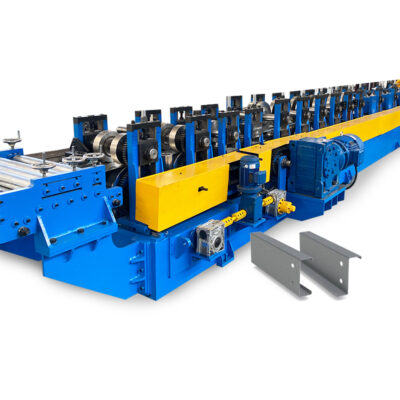

Purlin রোল গঠনপুরলিন রোল ফর্মিং: পুরলিন রোল ফর্মিং হলো একটি উৎপাদন প্রক্রিয়া যা রোল ফর্মিং মেশিন ব্যবহার করে ধাতুকে নির্দিষ্ট প্রোফাইল বা আকারে গঠন করে। ধাতুর স্ট্রিপ মেশিনে প্রবেশ করানো হয়, যেখানে এটি একাধিক রোলারের মধ্য দিয়ে অতিক্রম করে ধাপে ধাপে কাঙ্ক্ষিত আকারে গড়ে ওঠে। পুরলিন রোল ফর্মিং মানসম্পন্ন অংশের উচ্চ পরিমাণ উৎপাদনের জন্য দ্রুত, দক্ষ এবং খরচ-সাশ্রয়ী পদ্ধতি। এটি অত্যন্ত সঠিক, যা সামঞ্জস্যপূর্ণ মান এবং নির্ভুলতা নিশ্চিত করে।

ঐতিহ্যবাহী ফ্যাব্রিকেশন: ঐতিহ্যবাহী ফ্যাব্রিকেশন হলো বিশেষায়িত সরঞ্জাম এবং যন্ত্রপাতি ব্যবহার করে ধাতু অংশের ম্যানুয়াল কাটিং, বেঁকানো এবং গঠনের প্রক্রিয়া। এই পদ্ধতি অংশের আকার এবং সাইজের দিক থেকে বেশি কাস্টমাইজেশন এবং নমনীয়তা প্রদান করে। তবে ঐতিহ্যবাহী ফ্যাব্রিকেশন সময়সাপেক্ষ এবং শ্রম-নির্ভর হতে পারে, যা খরচ এবং সময়সীমা বাড়াতে পারে। এটি নির্ভুল এবং সামঞ্জস্যপূর্ণ উৎপাদন নিশ্চিত করতে দক্ষ শ্রমিকের প্রয়োজন হয়।

পুরলিন রোল ফর্মিং এবং ঐতিহ্যবাহী ফ্যাব্রিকেশনের মধ্যে প্রধান পার্থক্য হলো গতি, খরচ এবং কাস্টমাইজেশন। উচ্চ পরিমাণের মানসম্মত অংশ উৎপাদনে পুরলিন রোল ফর্মিং দ্রুততর এবং খরচ-সাশ্রয়ী, যেখানে ঐতিহ্যবাহী ফ্যাব্রিকেশন কাস্টম অংশের জন্য বেশি নমনীয়তা এবং নির্ভুলতা প্রয়োজনীয়। কোন পদ্ধতি ব্যবহার করবেন তা নির্ধারণে ব্যবসায়ী ও ব্যক্তিরা তাদের প্রকল্পের প্রয়োজন, বাজেট, সময়সীমা এবং কাঙ্ক্ষিত আউটপুট বিবেচনা করা উচিত।

purlin রোল গঠন

পুরলিন রোল ফর্মিং প্রক্রিয়ায় রোল ফর্মিং মেশিন ব্যবহার করে ধাতুকে নির্দিষ্ট প্রোফাইল বা আকারে গঠন করা হয়। এখানে জড়িত মৌলিক ধাপগুলো:

- উপকরণ প্রস্তুতি: প্রক্রিয়া শুরু হয় দীর্ঘ ধাতুর স্ট্রিপ দিয়ে, যা রোল ফর্মিং মেশিনে প্রবেশ করানো হয়। ধাতুর স্ট্রিপ গ্যালভানাইজড স্টিল, স্টেইনলেস স্টিল এবং অ্যালুমিনিয়ামসহ বিভিন্ন উপকরণ দিয়ে তৈরি হতে পারে।

- রোল ফর্মিং: ধাতুর স্ট্রিপ যখন রোল ফর্মিং মেশিনের মধ্য দিয়ে অতিবাহিত হয়, তখন এটি একাধিক রোলারের সিরিজের মধ্য দিয়ে যায় যা ধীরে ধীরে এটিকে কাঙ্ক্ষিত প্রোফাইলে রূপান্তরিত করে। প্রতিটি রোলার সেট নির্দিষ্ট পদ্ধতিতে চাপ প্রয়োগ করে ধাতুকে বাঁকিয়ে প্রোফাইল গঠন করে। প্রত্যেক রোলারের আকার ও অবস্থান কাঙ্ক্ষিত আকৃতি সঠিকভাবে উৎপাদনে অত্যন্ত গুরুত্বপূর্ণ।

- কাটিং: ধাতু কাঙ্ক্ষিত আকারে গঠিত হলে, এটি মেশিনের কাটিং বিভাগে যায়, যেখানে এটি উপযুক্ত দৈর্ঘ্যে কাটা হয়।

- ফিনিশিং: সমাপ্ত অংশগুলি সাধারণত স্তূপীকৃত করে শিপিং বা আরও প্রক্রিয়াকরণের জন্য প্যাকেজ করা হয়।

পারলিন রোল ফর্মিংয়ের সুবিধাগুলির মধ্যে গতি, নির্ভুলতা এবং খরচ-কার্যকারিতা অন্তর্ভুক্ত। রোল ফর্মিং মেশিনগুলি দ্রুত এবং স্থিরভাবে উচ্চ পরিমাণে অংশ উৎপাদন করতে পারে, যা ব্যবসায়গুলিকে গ্রাহকের চাহিদা পূরণে এবং তাদের লাভবৃদ্ধিতে সাহায্য করে। অতিরিক্তভাবে, রোল ফর্মিং মেশিনগুলি নির্ভুল সরঞ্জাম এবং প্রক্রিয়া ব্যবহার করে স্থির গুণমান এবং নির্ভুলতাসহ অংশ উৎপাদন করে, যা বর্জ্য এবং পুনর্কার্য কমায়।

পারলিন রোল ফর্মিং খরচ-কার্যকারী কারণ এটি ম্যানুয়াল শ্রমের প্রয়োজনীয়তা কমায় এবং ঐতিহ্যবাহী ফ্যাব্রিকেশন পদ্ধতির চেয়ে কম খরচে অংশ উৎপাদন করতে পারে। এটি নির্মাণ শিল্পের ব্যবসায়গুলির জন্য জনপ্রিয় যারা উচ্চ পরিমাণে মানকীকৃত অংশ উৎপাদন করতে হয়।

সামগ্রিকভাবে, পারলিন রোল ফর্মিং একটি অত্যন্ত দক্ষ এবং নির্ভুল উৎপাদন প্রক্রিয়া যা বিভিন্ন ধরনের ধাতব আকৃতি এবং প্রোফাইল উৎপাদন করতে সক্ষম। নির্ভুল যন্ত্রপাতি এবং প্রক্রিয়া ব্যবহার করে রোল ফর্মিং মেশিনগুলি শিল্প মানদণ্ড পূরণ বা অতিক্রম করা অংশসমূহ উৎপাদন করতে পারে, যা বিভিন্ন শিল্পের ব্যবসায়িক প্রতিষ্ঠানগুলির জন্য মূল্যবান বিনিয়োগ।

প্রথাগত নির্মাণ

প্রথাগত নির্মাণ একটি হস্তচালিত প্রক্রিয়া যাতে বিশেষায়িত যন্ত্রপাতি এবং সরঞ্জাম ব্যবহার করে ধাতব অংশ কাটা, বাঁকানো এবং আকার দেওয়া হয়। এখানে জড়িত মৌলিক ধাপসমূহ উল্লেখ করা হলো:

- নকশা: প্রক্রিয়াটি অংশ বা উপাদানের জন্য একটি নকশা বা নীলনকশা দিয়ে শুরু হয় যা নির্মাণ করতে হবে।

- উপকরণ নির্বাচন: ইস্পাতের মতো ধাতব উপকরণ বা অ্যালুমিনিয়ামঅংশের প্রয়োজনীয়তার ভিত্তিতে নির্বাচিত হয়।

- কাটিং: কাটার যন্ত্র যেমন আরশোলা বা কাঁচি ব্যবহার করে ধাতব উপকরণকে প্রয়োজনীয় আকার এবং আকারে কাটা হয়।

- আকার দেওয়া: তারপর বিশেষায়িত যন্ত্র যেমন প্রেস, ব্রেক বা রোলার ব্যবহার করে ধাতব উপকরণকে কাঙ্ক্ষিত আকারে বাঁকানো এবং আকার দেওয়া হয়।

- ওয়েল্ডিং: ধাতব টুকরোগুলিকে একত্রিত করে চূড়ান্ত অংশ বা উপাদান তৈরি করার জন্য ওয়েল্ড করা হয়।

- সমাপ্তি: সমাপ্ত অংশগুলি প্রয়োজন অনুসারে পরিষ্কার, মসৃণ এবং আঁকা বা আবরণ করা হয়।

প্রথাগত নির্মাণের সুবিধাসমূহের মধ্যে রয়েছে অংশগুলিকে কাস্টমাইজ করার ক্ষমতা এবং দক্ষ শ্রমিকের উপলব্ধতা। প্রথাগত নির্মাণের মাধ্যমে নির্দিষ্ট নকশা প্রয়োজনীয়তা বা অনন্য স্পেসিফিকেশন পূরণের জন্য অংশগুলিকে কাস্টমাইজ করা যায়। দক্ষ ধাতু নির্মাতারা তাদের দক্ষতা ব্যবহার করে প্রকল্পের প্রয়োজন অনুসারে অংশসমূহ তৈরি করতে পারেন। এছাড়া, প্রথাগত নির্মাণ দক্ষ শ্রমিকের উপর নির্ভর করে, যা অনেক এলাকায় সহজলভ্য। এর ফলে ব্যবসাগুলি তাদের প্রকল্প সম্পন্ন করার জন্য দ্রুত দক্ষ নির্মাতা খুঁজে পেতে পারে।

তবে, প্রথাগত নির্মাণ সময়সাপেক্ষ এবং শ্রমসাধ্য হতে পারে, যা খরচ এবং সময়সীমা বাড়াতে পারে। এটি বিশেষায়িত সরঞ্জাম এবং যন্ত্রপাতির প্রয়োজন করে, যা ক্রয় এবং রক্ষণাবেক্ষণের জন্য ব্যয়বহুল।

সামগ্রিকভাবে, প্রথাগত নির্মাণ রোল ফর্মিংয়ের চেয়ে বেশি নমনীয়তা এবং কাস্টমাইজেশন প্রদান করে এমন একটি হস্তচালিত প্রক্রিয়া। তবে এটি কম আয়তনের উৎপাদনের জন্য উপযুক্ত এবং বড় উৎপাদনের জন্য রোল ফর্মিংয়ের মতো খরচ-কার্যকর নাও হতে পারে। ব্যবসাগুলিকে তাদের নির্দিষ্ট প্রকল্পের প্রয়োজন অনুসারে উভয় পদ্ধতির সুবিধা-অসুবিধা বিবেচনা করা উচিত।

পারলিন রোল ফর্মিং এবং প্রথাগত নির্মাণের তুলনা

এখানে পারলিন রোল ফর্মিং এবং প্রথাগত নির্মাণের তুলনা দেওয়া হলো, যাতে গতি, খরচ, নির্ভুলতা এবং কাস্টমাইজেশনের দিক থেকে পার্থক্য তুলে ধরা হয়েছে:

গতি: পারলিন রোল ফর্মিং প্রথাগত নির্মাণের চেয়ে দ্রুততর কারণ এটি অটোমেটেড মেশিনের উপর নির্ভর করে অংশসমূহ দ্রুত এবং দক্ষতার সাথে উৎপাদন করে। অন্যদিকে, প্রথাগত নির্মাণ একটি হস্তচালিত প্রক্রিয়া যা সময়সাপেক্ষ এবং শ্রমসাধ্য।

খরচ: পারলিন রোল ফর্মিং সাধারণত প্রথাগত নির্মাণের চেয়ে খরচ-কার্যকর, বিশেষ করে উচ্চ আয়তনের উৎপাদনের জন্য। রোল ফর্মিং মেশিনগুলি দ্রুত এবং ন্যূনতম শ্রম দিয়ে অংশ উৎপাদন করতে পারে, যা শ্রম এবং উৎপাদন সময়ের সাথে জড়িত খরচ কমায়। অন্যদিকে, প্রথাগত নির্মাণ দক্ষ শ্রম এবং বিশেষায়িত সরঞ্জামের কারণে ব্যয়বহুল হতে পারে।

নির্ভুলতা: পার্লিন রোল ফর্মিং অত্যন্ত নির্ভুল, কারণ এটি সুনির্দিষ্ট সরঞ্জাম এবং প্রক্রিয়ার উপর নির্ভর করে সামঞ্জস্যপূর্ণ ও অভিন্ন অংশসমূহ উৎপাদন করে। ঐতিহ্যবাহী ফ্যাব্রিকেশন তুলনামূলকভাবে কম নির্ভুল হতে পারে, যেহেতু এতে হস্তচালিত কাটিং, বাঁকানো এবং আকার দেওয়া জড়িত, যা চূড়ান্ত পণ্যে বৈচিত্র্য সৃষ্টি করতে পারে।

কাস্টমাইজেশনের সুবিধা: ঐতিহ্যবাহী ফ্যাব্রিকেশন পার্লিন রোল ফর্মিংয়ের চেয়ে বেশি কাস্টমাইজেশনের সুযোগ প্রদান করে, কারণ এটি নকশা এবং কাস্টমাইজেশনে অধিক নমনীয়তা দেয়। রোল ফর্মিং মেশিনগুলি উচ্চ আয়তনে মানকীকৃত অংশ উৎপাদনের জন্য উপযুক্ত, যেখানে ঐতিহ্যবাহী ফ্যাব্রিকেশন অনন্য বা কাস্টমাইজড অংশ তৈরি করতে পারে।

সামগ্রিকভাবে, পার্লিন রোল ফর্মিং এবং ঐতিহ্যবাহী ফ্যাব্রিকেশনের মধ্যে পছন্দ প্রকল্পের নির্দিষ্ট চাহিদার উপর নির্ভর করবে। উচ্চ আয়তনের উৎপাদনের জন্য যেখানে সামঞ্জস্যপূর্ণ ও অভিন্ন অংশ প্রয়োজন, সেখানে পার্লিন রোল ফর্মিং আদর্শ। নিম্ন আয়তনের উৎপাদনের জন্য যেখানে অধিক নমনীয়তা এবং কাস্টমাইজেশন দরকার, সেখানে ঐতিহ্যবাহী ফ্যাব্রিকেশন উত্তম। ব্যবসায়গুলিকে প্রত্যেক পদ্ধতির সুবিধা-অসুবিধা যথাযথভাবে মূল্যায়ন করতে হবে এবং গতি, খরচ, নির্ভুলতা এবং কাস্টমাইজেশনের মতো উপাদান বিবেচনা করে সিদ্ধান্ত নিতে হবে।

উপসংহারে, নির্মাণ প্রকল্পের মেটাল অংশ উৎপাদনে পার্লিন রোল ফর্মিং এবং ঐতিহ্যবাহী ফ্যাব্রিকেশন দুটি জনপ্রিয় পদ্ধতি। উচ্চ আয়তনে মানকীকৃত অংশ উৎপাদনে পার্লিন রোল ফর্মিং দ্রুততর, অধিক নির্ভুল এবং খরচ-সাশ্রয়ী, যেখানে অনন্য বা কাস্টমাইজড অংশের জন্য ঐতিহ্যবাহী ফ্যাব্রিকেশন অধিক কাস্টমাইজেশন প্রদান করে। ব্যবসায় এবং ব্যক্তিগতভাবে প্রত্যেক পদ্ধতির সুবিধা-অসুবিধা যথাযথভাবে মূল্যায়ন করা উচিত। চূড়ান্তভাবে, পার্লিন রোল ফর্মিং এবং ঐতিহ্যবাহী ফ্যাব্রিকেশনের মধ্যে পছন্দ প্রকল্পের নির্দিষ্ট চাহিদা, গতি, খরচ, নির্ভুলতা এবং কাস্টমাইজেশনের মতো উপাদানের উপর নির্ভর করবে।