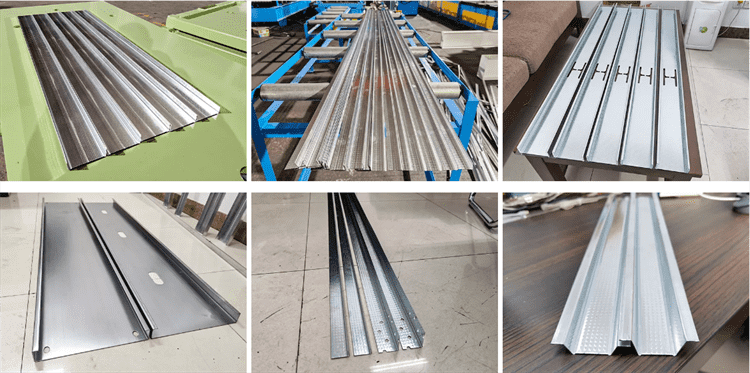

Light gauge steel roll forming machine is the most popular machine to make stud, track, furring channel, main channel (primary channel), carrying channel, wall angle, corner angle, edge bead, shadow line wall angle, top hat, clip, etc. Thickness is normally 0.4-0.6mm or up to 1.2mm. Raw material could be: cold-rolled steel, Galvanized steel, PPGI, high-tensile steel.

In Drywall system and drywall partition system, we could provide roll forming machine as following:

- Metal Stud Roll Forming Machine

- Metal track Roll Forming Machine

- Conner bead (Angle Bead / Wall Angle) Roll Forming Machine

- Metal Furring Channel Roll Forming Machine

- Main Channel (C / U) Roll Forming Machine

In Construction Industries, we are able to manufacture more machines like purlin roll forming machine, drywall roll forming machine, stud&track roll forming machine, metal deck (floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc.

We could make roll forming machine with flying cut system to make working speed faster around 40m/min. And according to your drawing, we offer you double-row roll forming machine or triple-row roll forming machine that you could make two or three profiles in one machine, it reduces your machine cost and make it more affordable.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

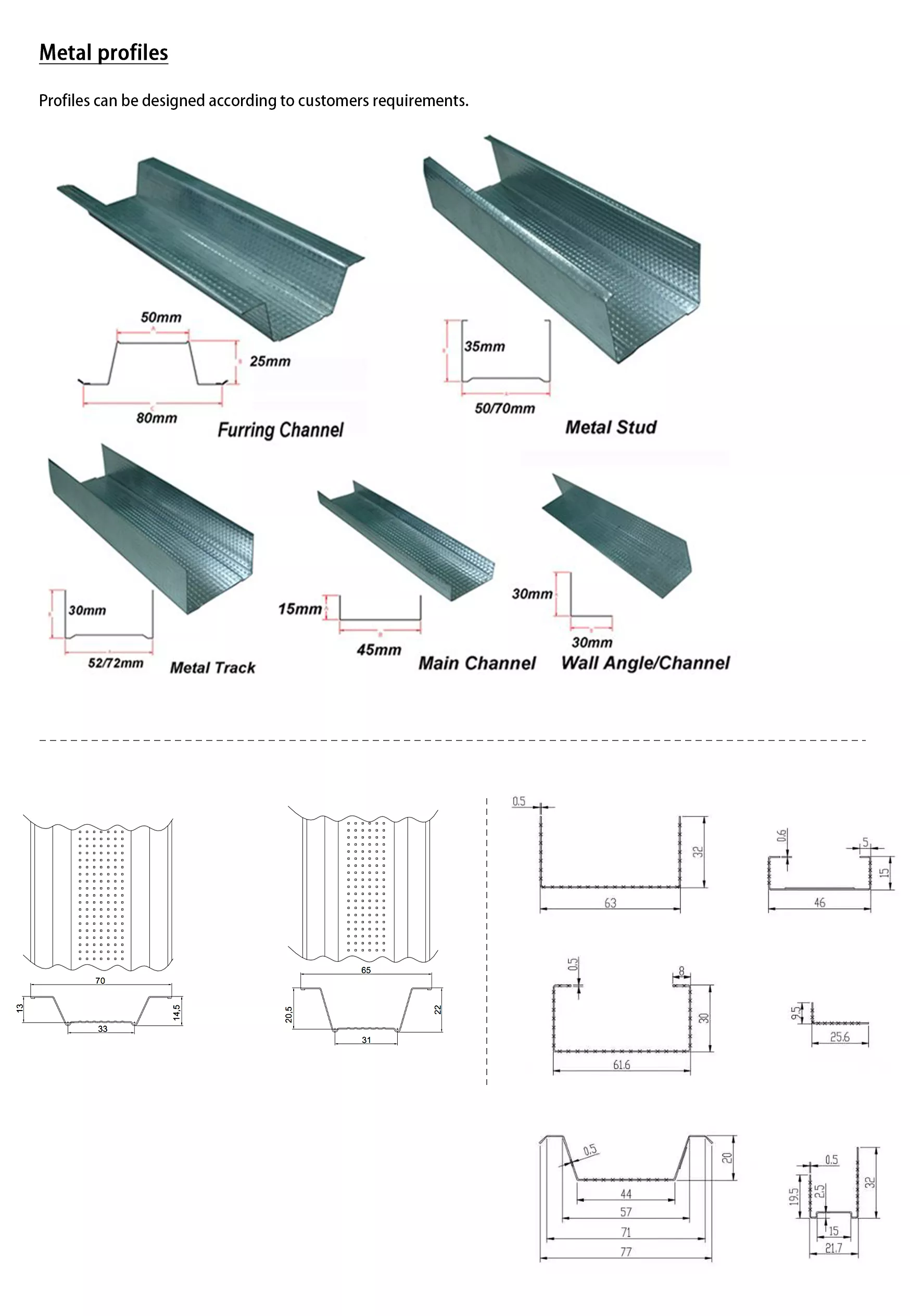

Profile Drawings of Light Gauge Steel Roll Forming Machine

The Light Gauge Steel Roll Forming Machine is designed to produce various profiles for construction purposes. The machine is capable of producing different profiles according to customer requirements. Here are some of the most common profiles that can be produced by this machine:

- Furring Channel: The furring channel is used to provide a level surface for attaching drywall or other materials. The machine can produce furring channel with dimensions of 50mm x 25mm x 80mm.

- Metal Stud: The metal stud is used to frame walls in commercial and residential buildings. The machine can produce metal stud with dimensions of 35mm x 50/70mm.

- Metal Track: The metal track is used to provide support for suspended ceilings and partition walls. The machine can produce metal track with dimensions of 30mm x 52/72mm.

- Main Channel: The main channel is used to provide support for the metal studs and tracks. The machine can produce main channel with dimensions of 15mm x 45mm.

- Wall Angle/Channel: The wall angle/channel is used to provide a neat finish to the corners of walls. The machine can produce wall angle/channel with dimensions of 30mm x 30mm.

In summary, the হালকা গেজ ইস্পাত রোল গঠন মেশিন can produce a variety of profiles according to customer requirements. The profiles include furring channel, metal stud, metal track, main channel, and wall angle/channel.

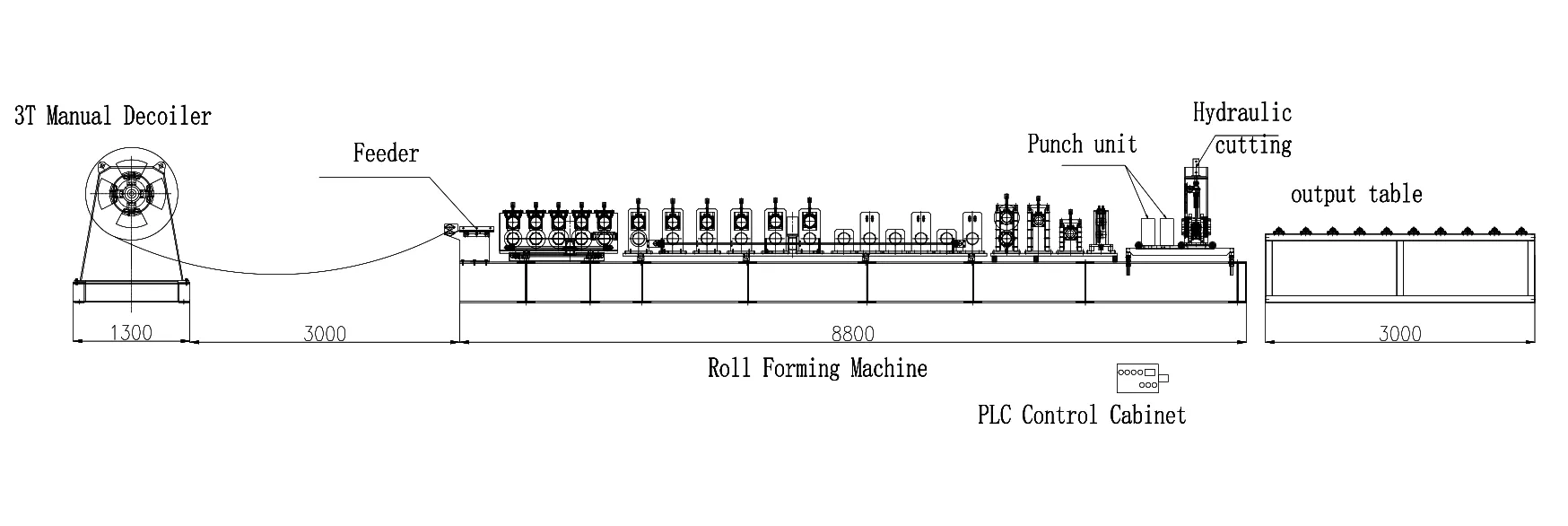

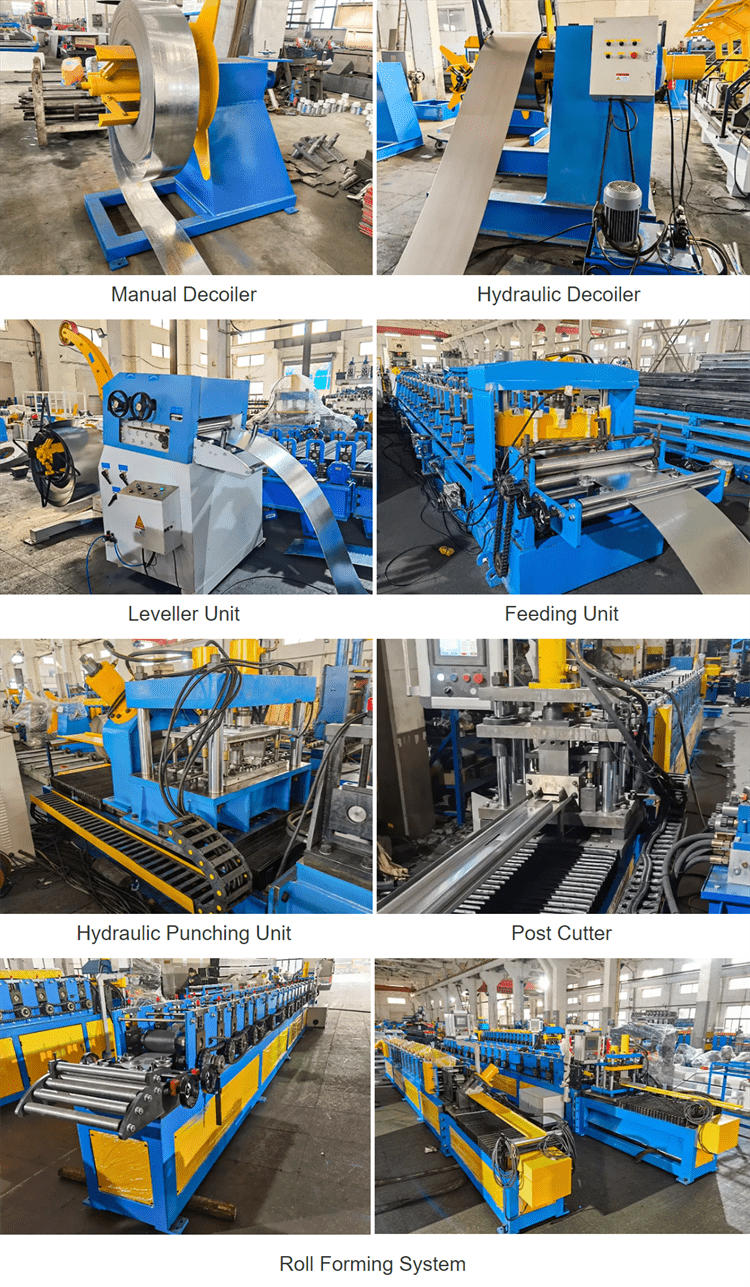

Production Line of Light Gauge Steel Roll Forming Machine

The production line of the Light Gauge Steel Roll Forming Machine includes the following equipment:

- 3T Manual Decoiler: The manual decoiler is used to hold and unwind the steel coil. The machine can handle up to 3 tons of coil weight.

- Feeder: The feeder is used to feed the steel coil into the machine. It is equipped with rollers that guide the coil and ensure it is properly aligned for the roll forming process.

- Punch Unit: The punch unit is used to create holes or slots in the steel profile. This is done before the roll forming process and is necessary for certain applications.

- Roll Forming Machine: The roll forming machine is the main equipment in the production line. It forms the steel profile by passing the steel strip through a series of rollers that shape it into the desired profile.

- Hydraulic Cutting: The hydraulic cutting unit is used to cut the steel profile to the required length. It is equipped with a hydraulic cylinder that exerts a cutting force on the profile.

- Output Table: The output table is used to collect the finished profiles as they come out of the roll forming machine. It is equipped with rollers that guide the profiles and ensure they are stacked neatly.

- PLC Control Cabinet: The PLC control cabinet is the brain of the production line. It is used to control the speed and movement of the equipment, monitor the production process, and adjust settings as needed.

In summary, the production line of the Light Gauge Steel Roll Forming Machine includes a manual decoiler, feeder, punch unit, roll forming machine, hydraulic cutting unit, output table, and PLC control cabinet. These equipment work together to produce high-quality steel profiles for construction purposes.

Product Details of Light Gauge Steel Roll Forming Machine

Our Light Gauge Steel Roll Forming Machine is a versatile solution for producing high-quality steel profiles for construction purposes. It comes equipped with various components, including a manual or hydraulic decoiler, leveller unit, feeding unit, hydraulic punching unit, post cutter, and roll forming system.

- Manual Decoiler: The manual decoiler is a basic version of the machine that requires the operator to manually load and unload the coil. It is suitable for small scale production and low volume projects.

- Hydraulic Decoiler: The hydraulic decoiler is an advanced version of the machine that is equipped with a hydraulic system to automatically load and unload the coil. It is suitable for high volume production and heavy duty applications.

- Leveller Unit: The leveller unit is used to straighten the steel strip before it is fed into the roll forming system. It is equipped with rollers that apply pressure on the strip to remove any bends or curves.

- Feeding Unit: The feeding unit is used to guide the steel strip into the roll forming system. It is equipped with rollers that move the strip through the system at a constant speed.

- Hydraulic Punching Unit: The hydraulic punching unit is used to create holes or slots in the steel profile. It is equipped with a hydraulic cylinder that exerts a punching force on the profile.

- Post Cutter: The post cutter is used to cut the steel profile to the desired length. It is equipped with a hydraulic cylinder that exerts a cutting force on the profile.

- Roll Forming System: The roll forming system is the heart of the machine. It consists of a series of rollers that gradually shape the steel strip into the desired profile.

In summary, the Light Gauge Steel Roll Forming Machine is equipped with a manual or hydraulic decoiler, leveller unit, feeding unit, hydraulic punching unit, post cutter, and roll forming system. These components work together to produce high-quality steel profiles.

Product Parameters of Light Gauge Steel Roll Forming Machine

| হালকা গেজ ইস্পাত রোল গঠন মেশিন | ||

|

Machinable উপাদান

|

ক) গ্যালভানাইজড কয়েল |

Thickness(MM):0.4-0.6mm, sometimes up to 1.2mm or as per your requirements

|

| খ) পিপিজিআই | ||

| C) Carbon steel Coil | ||

| উত্পাদন শক্তি | 250 - 550 এমপিএ | |

| টেনসিল স্ট্রেস | 350 এমপিএ-550 এমপিএ | |

| Nominal Forming Speed | 10-40(M/MIN) | |

| স্টেশন গঠন | 8-14 | * আপনার প্রোফাইল অঙ্কন অনুযায়ী |

| ডিকয়লার | ম্যানুয়াল ডিকয়লার | * হাইড্রোলিক ডিকয়লার (ঐচ্ছিক) |

| পাঞ্চিং সিস্টেম | Hydraulic Punching | * পাঞ্চিং প্রেস (ঐচ্ছিক) |

| প্রধান মেশিন মোটর ব্র্যান্ড | Sino-Germany Brand | * সিমেন্স (ঐচ্ছিক) |

| ড্রাইভিং সিস্টেম | চেইন ড্রাইভ | * গিয়ারবক্স ড্রাইভ (ঐচ্ছিক) |

| মেশিন স্ট্রাকচার | ওয়াল প্যানেল স্টেশন | * নকল আয়রন স্টেশন (ঐচ্ছিক) |

| রোলারের উপাদান | ইস্পাত #45 | * GCr 15(Optional) |

| কাটিং সিস্টেম | পোস্ট-কাটিং | * Flying Servo Cutting (Optional) |

| ফ্রিকোয়েন্সি চেঞ্জার ব্র্যান্ড | Delta | * সিমেন্স (ঐচ্ছিক) |

| পিএলসি ব্র্যান্ড | Delta | * সিমেন্স (ঐচ্ছিক) |

| পাওয়ার সাপ্লাই | 380V 50Hz | * অথবা আপনার প্রয়োজন অনুযায়ী |

| মেশিনের রঙ | শিল্প নীল | * অথবা আপনার প্রয়োজন অনুযায়ী |

Application of Light Gauge Steel Roll Forming Machine

Our Light Gauge Steel Roll Forming Machine is an incredibly versatile machine with numerous applications in the construction industry. Here are some of the applications of this machine:

- Framing: The machine can produce metal studs and tracks that are used for framing walls in commercial and residential buildings.

- Suspended Ceilings: The machine can produce metal tracks that are used to provide support for suspended ceilings in buildings.

- Drywall Partitioning: The machine can produce furring channels that provide a level surface for attaching drywall or other materials for partitioning purposes.

- Roofing: The machine can produce metal roof panels used for roofing applications in commercial and residential buildings.

- Cladding: The machine can produce metal panels used for cladding the exterior of buildings.

- Decking: The machine can produce metal decking used for flooring in buildings.

- Signage: The machine can produce metal frames and supports for signs and billboards.

Choose our Light Gauge Steel Roll Forming Machine for reliable and efficient production of steel profiles for various construction applications. Contact us today to learn more about how it can benefit your business.

What is light gauge steel roll forming machine?

A light gauge steel roll forming machine is a type of manufacturing equipment used to produce steel profiles or sections with a relatively thin gauge or thickness. It is specifically designed for processing light gauge steel, which typically ranges from 0.4 to 3 millimeters in thickness.

The roll forming process involves passing a continuous strip of steel through a series of rollers, each set of which gradually shapes the steel into the desired profile. These rollers are typically arranged in a sequence and are adjustable to create the specific dimensions and features required for the finished steel section.

The light gauge steel roll forming machine consists of several components, including a decoiler to hold the steel coil, a feeding system to move the steel strip into the machine, a series of forming rollers, cutting tools, and a control system. The machine may also have additional modules for punching holes, embossing patterns, or adding other features to the steel profiles.

The use of a roll forming machine offers several advantages in the production of light gauge steel profiles. It provides high precision and repeatability, allowing for consistent and accurate shaping of the steel sections. It is a continuous process, enabling efficient production with minimal material waste. Additionally, the machine can be easily adjusted to create different profiles, making it versatile for various applications in industries such as construction, automotive, and manufacturing.

application of light gauge steel roll forming machine

The light gauge steel roll forming machine finds application in various industries and construction projects. Some of the common applications include:

- Construction Industry: Light gauge steel roll forming machines are extensively used in the construction of residential, commercial, and industrial buildings. They can produce steel profiles for wall studs, roof trusses, floor joists, ceiling grids, and other structural components. Light gauge steel offers advantages such as high strength, durability, and ease of installation, making it a popular choice in modern construction.

- Automotive Industry: The automotive industry utilizes light gauge steel roll forming machines to produce components for vehicle frames, chassis, doors, window channels, and other structural parts. Light gauge steel provides excellent strength-to-weight ratio, corrosion resistance, and cost-effectiveness, making it suitable for automotive applications.

- Furniture Manufacturing: Roll formed steel profiles produced by these machines are also used in the furniture manufacturing industry. They are used to create frames, shelves, drawers, and other structural elements of furniture pieces. Light gauge steel offers strength, stability, and design flexibility for creating sturdy and durable furniture.

- Storage Systems: Light gauge steel roll forming machines are employed in the production of storage systems such as shelving units, racks, and cabinets. These systems require profiles with specific dimensions and configurations to accommodate different storage needs, and roll forming allows for the efficient and precise manufacturing of such profiles.

- Electrical Enclosures: Roll formed steel profiles are used in the fabrication of electrical enclosures and control panels. Light gauge steel offers electrical grounding capabilities, impact resistance, and protection against environmental factors, making it suitable for enclosures used in various industries, including power distribution, telecommunications, and automation.

- Solar Panel Mounting Systems: Light gauge steel roll forming machines are utilized to manufacture profiles for solar panel mounting systems. These profiles provide structural support and facilitate the installation of solar panels on roofs or in ground-mounted systems. The flexibility of roll forming allows for the production of customized profiles to meet specific project requirements.

These are just a few examples of the applications of light gauge steel roll forming machines. The versatility of the machines enables them to cater to a wide range of industries that require cost-effective, lightweight, and durable steel profiles.