تعمل صناعة الدفاع في أصعب الظروف، مما يتطلب معدات تجمع بين القوة والمتانة والموثوقية. من مكونات المركبات المدرعة إلى الملفات الهيكلية للقواعد العسكرية، يُعد إنتاج الأجزاء عالية الأداء أمرًا حاسمًا للأمن القومي. إليكم ماكينات تشكيل المعدات العسكرية، وهي التكنولوجيا المتقدمة وراء العديد من المكونات المتينة والدقيقة المستخدمة في التطبيقات العسكرية. تلبي هذه الآلات المعايير الصارمة لتصنيع الدفاع، مما يمكن من إنتاج ملفات قادرة على تحمل البيئات القاسية والظروف الشاقة.

في هذا الدليل، سنستكشف التطبيقات، والميزات، والأسعار، واتجاهات السوقوكيف ماكينات ووشي سونواي للماكينات تتقدم حلول التشكيل باللف لصناعة الدفاع. سواء كنت مقاول دفاع أو مهندس عسكري أو مجرد مهتم بتكنولوجيا البنية التحتية العسكرية الحديثة، يغطي هذا المقال احتياجاتك.

ما هي ماكينة تشكيل اللف للمعدات العسكرية؟

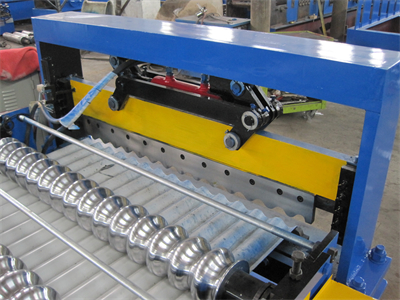

أ ماكينة تشكيل اللف للمعدات العسكرية وهي معدة متخصصة مصممة لإنتاج ملفات متينة عالية الأداء تُستخدم في بناء المركبات العسكرية والبنى التحتية والمعدات. تعالج هذه الآلات صفائح معدنية مسطحة أو لفائف —عادة ما تكون مصنوعة من فولاذ عالي القوة، سبائك درجة باليستية، أو مواد مقاومة للتآكل—إلى أشكال دقيقة تلبي متطلبات العمليات العسكرية الصارمة.

المكونات الرئيسية المنتجة

- ألواح المركبات المدرعة: ملفات تُستخدم في الدبابات، ناقلات الأفراد المدرعة (APC)، وغيرها من المركبات العسكرية.

- حوامل الأسلحة: مكونات لتركيب الأسلحة على المنصات البرية أو الجوية أو البحرية.

- إطارات المأوى المحمول: ملفات خفيفة الوزن لكنها متينة للخيام العسكرية ومآوي الحقول.

- ملفات بنية تحتية القواعد: عوارض وقنوات ودعامات لبناء القواعد العسكرية والمعسكرات.

- أنظمة تخزين الذخيرة: ملفات للرفوف والحاويات المستخدمة في تخزين الأسلحة والذخيرة بأمان.

- ملفات تعريف مخصصة: تصاميم فريدة لتطبيقات عسكرية متخصصة، مثل أنظمة الرادار ومنصات الطائرات بدون طيار وأبراج الاتصالات.

تتفوق هذه الآلات في أتمتة إنتاج المكونات العسكرية، مما يضمن الدقة والتوحيد والامتثال لمعايير الدفاع الصارمة.

تطبيقات ماكينات تشكيل اللف للمعدات العسكرية

تعدد الاستخدامات ماكينات تشكيل المعدات العسكرية مما يجعلها لا غنى عنها في مجموعة واسعة من التطبيقات المتعلقة بالدفاع. إليك بعض الحالات الرئيسية للاستخدام:

1. تصنيع المركبات المدرعة

- حالة الاستخدام: إنتاج الألواح والملفات الهيكلية للدبابات وناقلات الأفراد المدرعة والمركبات المقاومة للألغام والكمائن (MRAP).

- لماذا هو ضروري: يضمن بقاء الأفراد والمعدات في مناطق القتال.

2. مكونات أنظمة الأسلحة

- حالة الاستخدام: تصنيع الحوامل والأقواس والإطارات لأنظمة الأسلحة على المركبات والطائرات والسفن.

- ما أهمية ذلك: يوفر السلامة الهيكلية اللازمة لعمليات الأسلحة الدقيقة والموثوقة.

3. مآوي الحقول المحمولة

- حالة الاستخدام: صناعة إطارات خفيفة الوزن للخيام والمآوي ومراكز القيادة المتنقلة.

- لماذا هي ذات قيمة: يمكن الانتشار السريع والتركيب في بيئات نائية أو معادية.

4. بناء القواعد العسكرية

- حالة الاستخدام: إنتاج العوارض والأعمدة والدعامات للثكنات والمخازن الجوية وبنى القواعد الأخرى.

- ما أهمية ذلك: يعزز متانة وأمان المنشآت العسكرية.

5. تخزين الذخيرة والأسلحة

- حالة الاستخدام: إنشاء ملفات تعريف آمنة للرفوف والخزائن والحاويات المستخدمة لتخزين الأسلحة والذخيرة.

- لماذا هو أمر بالغ الأهمية: يمنع التلف ويضمن التعامل الآمن ونقل المواد الحساسة.

6. منصات المعدات المتخصصة

- حالة الاستخدام: تصنيع ملفات تعريف لأنظمة الرادار ومنصات إطلاق الطائرات بدون طيار وأبراج الاتصالات.

- لماذا هو مفيد؟ يدعم التقنيات العسكرية المتقدمة ويعزز القدرات التشغيلية.

الميزات الرئيسية لآلات تشكيل الدرفلة للمعدات العسكرية من ووشي سونوي

ماكينات ووشي سونواي للماكينات، الرائد العالمي في تقنية الدرفلة، تقدم آلات مصممة خصيصًا لتلبية المتطلبات الفريدة لقطاع الدفاع. إليكم الميزات البارزة التي تجعل آلاتها مثالية للتصنيع العسكري:

1. معالجة المواد عالية القوة

- المواد المدعومة:

- فولاذ درجة باليستية

- سبائك الألومنيوم

- معادن مقاومة للتآكل

- تيتانيوم

- ما أهمية ذلك: يضمن إنتاج مكونات متينة قادرة على تحمل الظروف القاسية.

2. الدقة والاتساق

- الأداء: دقة أبعاد تصل إلى ±0.05 مم، مما يضمن التوحيد في التطبيقات الحرجة.

- لماذا هو أمر بالغ الأهمية: يقلل من أخطاء التجميع ويضمن التوافق مع المعدات الأخرى.

3. أدوات قابلة للتخصيص للتصاميم المتخصصة

- ما يقدمه: أنظمة أدوات معيارية لإنشاء ملفات تعريف فريدة مصممة وفقًا للمواصفات العسكرية.

- لماذا هو ضروري: يدعم إنتاج مكونات مخصصة لتطبيقات الدفاع المتخصصة.

4. أنظمة القطع والتثقيب المتكاملة

- ما يتضمنه: أنظمة للقطع الدقيق وثقب الثقوب والترقيع أثناء الإنتاج.

- لماذا هي ذات قيمة: تبسيط عملية التجميع وتقليل عمليات ما بعد الإنتاج.

5. إنتاج عالي السرعة

- الأداء: قادرة على إنتاج ما يصل إلى 20-100 متر من الملفات تعريف في الدقيقة، اعتمادًا على المادة ومدى تعقيدها.

- لماذا هو مفيد؟ يلبي الطلبات الكبيرة الحجم لمشاريع الدفاع واسعة النطاق.

6. تكامل إنترنت الأشياء والأتمتة

- ما تتيحه: المراقبة في الوقت الحقيقي، والتعديلات الآلية، والصيانة التنبؤية باستخدام أنظمة إنترنت الأشياء.

- لماذا تغير قواعد اللعبة:

- يعزز كفاءة الإنتاج.

- يقلل من وقت التعطل وتكاليف الصيانة.

- يوفر رؤى قابلة للتنفيذ من أجل التحسين المستمر.

7. معالجات سطحية محسنة

- الميزة: آلات مصممة للتعامل مع الطلاءات مثل مضاد للتآكل ومضاد للصدأ والتشطيبات العاكسة.

- لماذا هو مهم: يطيل عمر المكونات المعرضة للبيئات القاسية.

سير عمل إنتاج آلة تشكيل الدرفلة للمعدات العسكرية

يتم تحسين عملية التصنيع للمكونات العسكرية للمتانة والدقة والكفاءة. إليكم نظرة عامة على السير العملي النموذجي:

1. تحميل المواد

- يتم تحميل أوراق أو لفائف من مواد درجة باليستية على ديكويلرمما يضمن إمداداً مستمراً.

2. الاستقامة والتسوية

- وحدة تسوية تضمن تسطيح المادة وخلوها من العيوب قبل بدء الدرفلة.

3. التشكيل بالدلفنة

- تمر المادة من خلال سلسلة من البكرات التي تقوم بتشكيلها تدريجياً إلى الشكل الجانبي المطلوب، مع الحفاظ على تفاوتات صارمة.

4. التثقيب والقطع

- تضيف الأنظمة المتكاملة ثقوبًا دقيقة للمثبتات أو الموصلات وتقطع الملفات تعريف إلى أطوال مخصصة.

5. تطبيق الطلاء

- تضيف الأنظمة الاختيارية طلاءات واقية، مثل مضاد للتآكل أو التشطيبات الباليستية، أثناء أو بعد الإنتاج.

6. فحص الجودة

- يتم فحص الملفات تعريف النهائية للدقة الأبعادية والقوة والامتثال للمعايير العسكرية.

7. التعبئة والتغليف والتسليم

- يتم تجميع المكونات المكتملة وتسميتها وتجهيزها للنقل الآمن إلى مقاولي الدفاع أو المنشآت العسكرية.

تسعير آلات تشكيل الدرفلة للمعدات العسكرية

تكلفة ماكينة تشكيل اللف للمعدات العسكرية يعتمد على ميزاتها وتوافقها مع المواد وخيارات التخصيص. إليكم دليل تسعير عام لعام 2025:

| نوع الماكينة | الإمكانيات | نطاق السعر (بالدولار الأمريكي) |

|---|---|---|

| الماكينات القياسية | إنتاج ملفات تعريف أساسية لتطبيقات الدفاع | 500,000–500,000–500,000–1,200,000 |

| الآلات المتطورة | أنظمة القطع والتثقيب المتكاملة عالية السرعة والمتكاملة | 1,200,000–1,200,000–1,200,000–2,800,000 |

| ماكينات قابلة للتخصيص بالكامل | إنترنت الأشياء، والأدوات المعيارية، ومناولة المواد المتقدمة | 2,800,000–2,800,000–2,800,000–5,000,000 |

للحصول على الأسعار المفصلة وخيارات التمويل، اتصل ب ماكينات ووشي سونواي للماكينات.

اتجاهات السوق لآلات تشكيل الدرفلة للمعدات العسكرية في عام 2025

يتطور صناعة الدفاع بسرعة مدفوعًا بالتقدم التكنولوجي والعوامل الجيوسياسية. إليكم الاتجاهات التي تشكل السوق:

1. المواد المتقدمة

- الاتجاه السائد: زيادة استخدام المعادن درجة باليستية والسبائك خفيفة الوزن في المعدات العسكرية.

- دور الماكينة:

- تمكن من التشكيل الدقيق للمواد المتقدمة.

- تقليل هدر المواد من خلال الهندسة الدقيقة.

2. الأنظمة العسكرية الذاتية

- النمو: ارتفاع الطلب على الطائرات بدون طيار والروبوتات والمركبات الذاتية في عمليات الدفاع.

- مساهمة الآلة:

- إنتاج ملفات تعريف خفيفة الوزن ومتينة للمنصات الذاتية.

- دعم التصاميم الابتكارية للتقنيات العسكرية المتقدمة.

3. حلول الانتشار السريع

- التركيز: تطوير بنى تحتية عسكرية محمولة ومعيارية للانتشار السريع.

- تأثير الماكينة:

- تمكن من الإنتاج الضخم لإطارات المأوى المحمولة والهياكل الداعمة.

- دعم التجميع في الموقع باستخدام ملفات تعريف مسبقة الصنع.

4. نمو الإنفاق الدفاعي

- النمو: زيادة الميزانيات الدفاعية العالمية تدفع الطلب على المعدات العسكرية المتقدمة.

- تأثير الماكينة:

- دعم الإنتاج واسع النطاق للمكونات العسكرية.

- تعزيز كفاءة الإنتاج لتلبية المواعيد النهائية الضيقة.

أسئلة شائعة حول آلات تشكيل الدرفلة للمعدات العسكرية

| سؤال | الإجابة |

|---|---|

| ما هي المواد التي يمكن لهذه الماكينات معالجتها؟ | فولاذ درجة باليستية وسبائك الألمنيوم والتيتانيوم والمعادن مقاومة للتآكل. |

| ما هي سرعة إنتاج هذه الماكينات؟ | يمكن للآلات إنتاج ما يصل إلى 20-100 متر من الملفات تعريف في الدقيقة، اعتمادًا على المادة ومدى تعقيدها. |

| هل يمكن لهذه الماكينات التعامل مع التصميمات المخصصة؟ | نعم، تسمح أدوات معيارية بإنشاء ملفات تعريف عسكرية مخصصة. |

| هل هذه الماكينات موفرة للطاقة؟ | نعم، تشمل محركات موفرة للطاقة وسير عمل محسن لتقليل التكاليف. |

| ما هي الصناعات التي تستفيد من هذه الآلات؟ | الدفاع وأمن الوطن والبنى التحتية الثقيلة. |

| هل تتوافق هذه الماكينات مع معايير السلامة؟ | نعم، تتوافق مع معايير الجودة ISO وCE والمعايير العسكرية الخاصة. |

| ما هو العمر الافتراضي لهذه الماكينات؟ | مع الصيانة المناسبة، يمكن لهذه الماكينات أن تدوم طويلاً 20-30 سنة أو أكثر. |

| هل يتم توفير التدريب مع عملية الشراء؟ | نعم، تقدم Wuxi Sunway تدريبًا شاملاً ودعم ما بعد البيع لجميع العملاء. |

| ما هو النطاق السعري لهذه الماكينات؟ | تتراوح الأسعار من 500,000 إلى 500,000 إلى 500,000 إلى 5,000,000، حسب الميزات وخيارات التخصيص. |

| هل يمكن لهذه الآلات دعم الإنتاج المستدام؟ | نعم، تم تحسينها لتقليل النفايات ودعم المواد القابلة لإعادة التدوير. |

قصص نجاح حقيقية: آلات تشكيل الدرفلة للمعدات العسكرية في العمل

استخدام ماكينات تشكيل المعدات العسكرية تلعب دورًا محوريًا في مواجهة أكثر التحديات تعقيدًا التي يواجهها مصنعو الدفاع. إليكم أمثلة حقيقية تظهر كيف غيرت هذه الآلات الإنتاج العسكري.

1. دراسة حالة: ألواح ناقلات الأفراد المدرعة (APC)

- العميل: مقاول دفاعي عالمي متخصص في المركبات الأرضية التكتيكية.

- التحدّي: يحتاج إلى ألواح فولاذية عالية القوة لناقلات الأفراد قادرة على تحمل التهديدات الباليستية والصدمات المتفجرة.

- الحل: قدمت ووشي سونوي مكاينري آلة درفلة مصممة لمعالجة الفولاذ درجة باليستية مع أنظمة قطع وثقب متكاملة لثقوب المثبتات.

- النتائج:

- قللت وقت الإنتاج بنسبة 40%، مما سمح بتسليم المركبات بشكل أسرع.

- حسنت متانة الألواح، متجاوزة معايير الباليستيك التابعة للناتو.

- خفضت هدر المواد بنسبة 15%، محسنة تكاليف المدخلات.

2. دراسة حالة: بنى تحتية للانتشار السريع

- العميل: مورد للمأوى العسكري المحمول والمستشفيات الميدانية.

- التحدّي: يتطلب إطارات خفيفة الوزن ومعيارية للمأوى يمكن نشرها بسرعة في مناطق النزاع أو جهود إغاثة الكوارث.

- الحل: سلمت ووشي سونوي آلة درفلة قادرة على إنتاج ملفات تعريف ألمنيوم عالية القوة مع أدوات معيارية لتصاميم متنوعة.

- النتائج:

- مكنت من إنتاج مأوى يمكن تجميعه في أقل من 30 دقيقة.

- خفضت الوزن بنسبة 25% مقارنة بإطارات الفولاذ التقليدية، مما يسهل لوجستيات النقل.

- زادت متانة المأوى، مضمونة الموثوقية في البيئات القاسية.

3. دراسة حالة: رفوف تخزين الذخيرة

- العميل: شركة لوجستية تدير تخزين الذخيرة والأسلحة للقواعد العسكرية.

- التحدّي: تحتاج إلى ملفات تعريف مقاومة للتآكل لرفوف الذخيرة قادرة على تحمل درجات الحرارة والرطوبة الشديدة.

- الحل: قدمت ووشي سونوي آلة مصممة لمعالجة الفولاذ المجلفن مع طلاءات مضادة للتآكل أثناء الإنتاج.

- النتائج:

- أنتجت رفوفًا تتوافق مع متطلبات السلامة والعمر الافتراضي العسكرية.

- خفضت تكاليف الصيانة بنسبة 30% بفضل تحسين مقاومة التآكل.

- سمحت بالإنتاج الضخم الفعال لتلبية احتياجات التخزين المتزايدة.

4. دراسة حالة: إطارات الطائرات بدون طيار (UAV)

- العميل: مصنع طائرات بدون طيار يزود الجيش بطائرات UAV تكتيكية للاستطلاع واللوجستيات.

- التحدّي: كانت هناك حاجة ماسة إلى إطارات فائقة الخفة ومتينة لتحسين أوقات طيران الطائرات بدون طيار وزيادة سعة الحمولة.

- الحل: طورت ووشي سونواي آلة تشكيل باللف قادرة على معالجة المواد المركبة المتقدمة إلى ملفات مخصصة للطائرات بدون طيار.

- النتائج:

- زيادة مدة طيران الطائرات بدون طيار بنسبة 20%، مما يعزز القدرات التشغيلية.

- تقليل أوقات الإنتاج بنسبة 35%، مما يتيح التسليم الأسرع للعملاء العسكريين.

- دعم التصاميم المعيارية للطائرات بدون طيار، مما يسمح بالتخصيص السريع في الميدان.

التخصيص: الميزة الرئيسية لآلات تشكيل باللف للمعدات العسكرية

في صناعة الدفاع، لا يناسب مقاس واحد الجميع. غالباً ما تتطلب التطبيقات العسكرية ملفات مخصصة لتلبية المتطلبات التشغيلية الفريدة. توفر آلات التشكيل باللف من ماكينات ووشي سونواي للماكينات مرونة لا مثيل لها في إنشاء هذه الحلول المصممة خصيصاً.

1. أدوات معيارية

- ما يقدمه: أنظمة أدوات قابلة للتبديل بسهولة تسمح للصانعين بالتبديل بسرعة بين تصاميم الملفات المختلفة.

- لماذا هي ذات قيمة:

- تدعم احتياجات الإنتاج المتنوعة، من الألواح المدرعة إلى إطارات الملاجئ.

- يقلل من وقت التعطل المرتبط بتغيير الأدوات.

- تمكن من إنتاج دفعات صغيرة للنماذج الأولية أو المكونات المتخصصة.

2. تعدد استخدامات المواد

- المواد المدعومة:

- فولاذ درجة باليستية

- سبائك الألومنيوم

- تيتانيوم

- المواد المركبة (مثل ألياف الكربون)

- لماذا هو أمر بالغ الأهمية:

- توفر المرونة لإنتاج مكونات محسنة للقوة أو الوزن أو مقاومة التآكل.

- تدعم الابتكار في تصميم معدات الدفاع.

3. تنوع الملفات

- الإمكانيات: يمكن للآلات إنتاج مجموعة واسعة من الملفات، بما في ذلك:

- قنوات U-Channels

- ملفات Z

- عوارض صندوقية

- أشكال هندسية مخصصة

- سبب أهمية ذلك:

- تمكن الصانعين من تلبية احتياجات التطبيقات العسكرية المختلفة المحددة.

- تدعم التكامل مع مكونات أخرى للتجميع السلس.

4. تكامل الطلاء المتقدم

- ما يتضمنه: أنظمة لتطبيق الطلاءات مثل مضادات التآكل أو الطلاءات العاكسة أو التمويه أثناء الإنتاج.

- لماذا هو مفيد؟

- تعزز متانة المكونات ووظيفتها.

- يقلل من خطوات ما بعد الإنتاج، مما يوفر الوقت والتكاليف.

معايير الامتثال لآلات تشكيل باللف للمعدات العسكرية

يجب أن تلتزم المكونات العسكرية بالمعايير الدولية الصارمة لضمان السلامة والمتانة والأداء. ماكينات ووشي سونواي للماكينات تصمم آلاتها لإنتاج ملفات تلبي هذه المتطلبات أو تتجاوزها:

| قياسي | المنطقة | المتطلبات |

|---|---|---|

| مواصفات MIL-STD | الولايات المتحدة الأمريكية | تحدد متطلبات الدرجة العسكرية للمواد والمكونات. |

| آيزو 9001 | عالمي | يضمن إدارة جودة متسقة في عمليات التصنيع. |

| معايير NATO STANAG | دول عضو الناتو | يحدد معايير التوافقية والأداء للمعدات العسكرية. |

| علامة CE | أوروبا | يصادق على الامتثال لمعايير السلامة والجودة الأوروبية. |

| خفيف الوزن، قوي، مقاومة عالية للتآكل | أوروبا | تقييد المواد الخطرة في مواد التصنيع. |

| الامتثال لـ ITAR | الولايات المتحدة الأمريكية | يضمن الامتثال للوائح التجارة الدولية في الأسلحة لأغراض التصدير. |

من خلال الالتزام بهذه المعايير ماكينات ووشي سونواي للماكينات تضمن آلات تشكيل اللف لديها تقديم مكونات آمنة ومتينة ومتوافقة عالميًا.

أسئلة شائعة حول آلات تشكيل الدرفلة للمعدات العسكرية

| سؤال | الإجابة |

|---|---|

| ما هي المواد التي يمكن لهذه الماكينات معالجتها؟ | فولاذ درجة باليستية، سبائك الألمنيوم، التيتانيوم، والمواد المركبة. |

| ما هي سرعة إنتاج هذه الماكينات؟ | يمكن للآلات إنتاج ما يصل إلى 20-100 متر من الملفات تعريف في الدقيقة، اعتمادًا على المادة ومدى تعقيدها. |

| هل يمكن لهذه الماكينات التعامل مع التصميمات المخصصة؟ | نعم، تسمح أدوات معيارية بإنشاء ملفات تعريف عسكرية مخصصة. |

| هل هذه الماكينات موفرة للطاقة؟ | نعم، تتميز بمحركات موفرة للطاقة وسير عمل محسن لتقليل التكاليف التشغيلية. |

| ما هي الصناعات التي تستفيد من هذه الآلات؟ | قطاعات الدفاع والأمن الداخلي والاستجابة للطوارئ. |

| هل تتوافق هذه الماكينات مع معايير السلامة؟ | نعم، تتوافق مع MIL-STD وNATO STANAG ومعايير عسكرية دولية أخرى. |

| ما هو العمر الافتراضي لهذه الماكينات؟ | مع الصيانة المناسبة، يمكن لهذه الماكينات أن تدوم طويلاً 20-30 سنة أو أكثر. |

| هل يتم توفير التدريب مع عملية الشراء؟ | نعم، تقدم Wuxi Sunway تدريبًا شاملاً ودعم ما بعد البيع لجميع العملاء. |

| ما هو النطاق السعري لهذه الماكينات؟ | تتراوح الأسعار من 500,000 إلى 500,000 إلى 500,000 إلى 5,000,000، حسب الميزات وخيارات التخصيص. |

| هل يمكن لهذه الآلات دعم الإنتاج المستدام؟ | نعم، تم تحسينها لتقليل النفايات ودعم المواد القابلة لإعادة التدوير. |

لماذا تختار ووكسي سونواي ماكيناري لآلات تشكيل اللف للمعدات العسكرية؟

ماكينات ووشي سونواي للماكينات أقامت نفسها شريكًا موثوقًا في تصنيع الدفاع، مقدمة حلول تشكيل لف مبتكرة مصممة خصيصًا للقطاع العسكري. إليك أسباب اختيار مقاولي الدفاع لسونواي:

- عقود من الخبرة: سجل مثبت في تقديم آلات عالية الجودة للتطبيقات العسكرية.

- انتشار عالمي: موثوق به من قبل مصنعي الدفاع في آسيا وأوروبا وأمريكا الشمالية وخارجها.

- أحدث التقنيات المتطورة: ميزات مثل تكامل إنترنت الأشياء والأدوات المعيارية وأنظمة الطلاء المتقدمة تميز آلاتها.

- الالتزام بالاستدامة: آلات مصممة لتقليل التأثير البيئي من خلال كفاءة الطاقة ومعالجة المواد القابلة لإعادة التدوير.

- الدعم الشامل: من الاستشارة إلى التركيب والخدمة المستمرة، تضمن ووكسي صنويتش عمليات سلسة لعملائها.

الخاتمة: بناء دفاعات أقوى بآلات تشكيل اللف

ماكينات تشكيل المعدات العسكرية تحدث ثورة في صناعة الدفاع من خلال تمكين إنتاج مكونات عالية الأداء ومتينة وموثوقة تلبي متطلبات الحروب الحديثة والأمن. تلعب هذه الآلات دورًا حاسمًا في تعزيز القدرات الدفاعية الوطنية ودعم سيناريوهات الانتشار السريع.

جاهز لرفع مستوى إنتاج معداتك العسكرية؟ اشرك مع ماكينات ووشي سونواي للماكينات اليوم واكتشف حلول تشكيل اللف المتطورة لديها. دعونا نبني مستقبل الدفاع - شكلًا واحدًا في كل مرة.