تعد صناعة السيارات بؤرة للابتكار، فهي تتطور باستمرار لتلبية الطلب على سيارات أخف وزناً وأقوى وأكثر كفاءة. ويكمن دور التصنيع الدقيق في صميم هذا التطور، و ماكينات تشكيل قطع غيار السيارات تقود هذه الماكينات عملية الإنتاج. فهي تتيح إنتاج مكونات عالية الجودة ومتينة ومصممة خصيصًا، وهي مكونات أساسية للسيارات الحديثة.

في هذه المقالة، سنتعمق في ما هي آلات تشكيل قطع غيار السيارات، وتطبيقاتها، ومزاياها، وأسعارها، وقدراتها في مجال الأتمتة، وفوائدها البيئية، ولماذا تعتبر Wuxi Sunway Machinery اسمًا موثوقًا به في هذه الصناعة.. إذا كنت مصنعًا تسعى إلى تبسيط عمليات الإنتاج أو موردًا يتطلع إلى تحقيق قفزة كبيرة في مجال تكنولوجيا السيارات، فسيوفر لك هذا الدليل المعلومات التي تحتاجها.

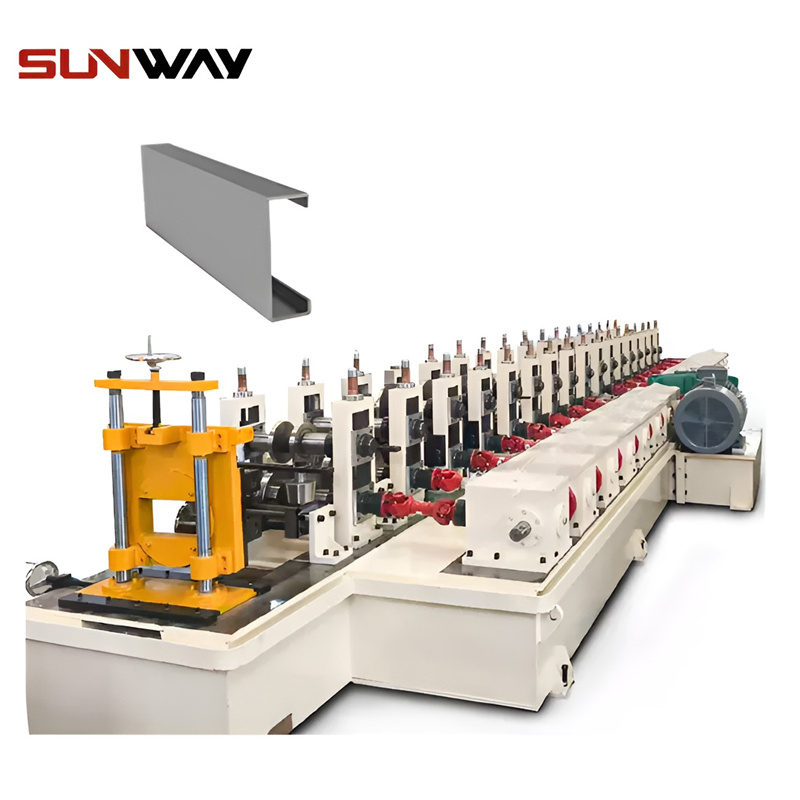

ما هي آلات تشكيل لفائف قطع غيار السيارات؟

ماكينات تشكيل قطع غيار السيارات هي أنظمة صناعية متخصصة مصممة لتشكيل الصفائح المعدنية أو اللفائف إلى أشكال محددة تستخدم في صناعة السيارات. تستخدم هذه الآلات عملية ثني مستمرة لإنتاج مكونات بدقة وكفاءة، مما يتيح الإنتاج الضخم دون المساس بالجودة.

الميزات الرئيسية

- دقة عالية: تنتج مكونات بمواصفات دقيقة، مما يضمن توافقها مع تصميمات المركبات.

- مرونة المواد: تعالج مواد خفيفة الوزن ولكنها قوية مثل الألومنيوم والفولاذ عالي القوة والفولاذ المجلفن.

- ملفات تعريف مخصصة: يدعم تصميمات متنوعة مصممة خصيصًا لمختلف طرازات المركبات والتطبيقات.

- إنتاج عالي السرعة: يلبي متطلبات تصنيع السيارات على نطاق واسع.

- الممارسات الصديقة للبيئة: يقلل من النفايات واستهلاك الطاقة، بما يتماشى مع أهداف الاستدامة.

تطبيقات آلات تشكيل لفائف قطع غيار السيارات

تعد آلات تشكيل لفائف قطع غيار السيارات ضرورية لإنتاج مجموعة واسعة من المكونات التي تدخل في صناعة السيارات والشاحنات والمركبات الحديثة الأخرى. فيما يلي التطبيقات الرئيسية:

1. مكونات هيكلية للسيارات

- حالة الاستخدام: تصنيع التعزيزات الهيكلية مثل عوارض الصدمات الجانبية وقضبان السقف والأعمدة B.

- لماذا هو ضروري: يعزز سلامة المركبة من خلال تصنيع مكونات تمتص الصدمات وتحسن السلامة الهيكلية.

2. أجزاء الهيكل والإطار

- حالة الاستخدام: إنتاج مكونات الهيكل، بما في ذلك العوارض العرضية والألواح المتأرجحة وتعزيزات الأرضية.

- لماذا هو مفيد؟ يضمن أساسًا خفيف الوزن وقويًا للمركبات، مما يحسن الأداء وكفاءة استهلاك الوقود.

3. إطارات الأبواب والنوافذ

- حالة الاستخدام: تصنيع إطارات أبواب دقيقة وقنوات نوافذ وملامح إحكام.

- لماذا هو ضروري: يضمن ملاءمة مثالية ومتانة، مما يساهم في الجمالية والوظائف العامة للسيارة.

4. صواني البطاريات للسيارات الكهربائية

- حالة الاستخدام: تصنيع الصواني والأغلفة لأنظمة بطاريات المركبات الكهربائية.

- لماذا هي فريدة من نوعها: يدعم سوق السيارات الكهربائية المتنامي من خلال توفير مكونات خفيفة الوزن ومقاومة للتآكل.

5. قطع الزخرفة والأجزاء التزيينية المخصصة

- حالة الاستخدام: إنتاج عناصر تقليم مخصصة، مثل القوالب، وشرائط العزل، وملامح التمييز.

- ما أهمية ذلك: يعزز المظهر الجمالي للسيارة مع الحفاظ على المتانة والدقة.

6. أجزاء التعليق والدعم

- حالة الاستخدام: صناعة تعزيزات التعليق والأقواس والدعامات.

- لماذا هو أمر بالغ الأهمية: يحسن جودة القيادة واستقرار السيارة من خلال ضمان مكونات تعليق قوية وموثوقة.

لماذا تعتبر آلات تشكيل قطع غيار السيارات أمرًا لا غنى عنه

يتعرض قطاع السيارات لضغوط مستمرة من أجل الابتكار وخفض التكاليف وتحقيق أهداف الاستدامة. وإليكم الأسباب ماكينات تشكيل قطع غيار السيارات تعتبر أموراً حاسمة لتحقيق هذه الأهداف:

1. الهندسة الدقيقة

- لماذا هو أمر حيوي: يضمن أن كل مكون يفي بمعايير التصميم الصارمة، وهو أمر بالغ الأهمية لسلامة المركبة وأدائها.

2. التخصيص لموديلات متنوعة

- لماذا هو مفيد؟ يتيح للمصنعين إنتاج قطع غيار مصممة خصيصًا لتصميمات محددة من المركبات، بما يتناسب مع الطرازات القياسية والسيارات الفاخرة على حد سواء.

3. قابلية التوسع

- لماذا هو عملي؟ يتيح إنتاجًا عالي السرعة لتلبية الطلب المتزايد على مكونات السيارات في الأسواق العالمية.

4. كفاءة المواد

- لماذا يعتبر اقتصاديًا: يقلل من هدر المواد من خلال القطع والتشكيل الدقيقين، مما يقلل من تكاليف الإنتاج الإجمالية.

5. تصميم خفيف الوزن

- ما أهمية ذلك: يسهل إنتاج مكونات خفيفة الوزن تعمل على تحسين كفاءة استهلاك الوقود وتقليل الانبعاثات، بما يتماشى مع اتجاهات الصناعة.

6. الاستدامة

- سبب أهمية ذلك: يدعم التصنيع الصديق للبيئة من خلال تقليل استهلاك الطاقة إلى الحد الأدنى وتمكين استخدام المواد القابلة لإعادة التدوير.

الميزات الرئيسية لآلات تشكيل لفائف قطع غيار السيارات Wuxi Sunway

عندما يتعلق الأمر بتقنية التشكيل بالدلفنة, ماكينات ووشي سونواي للماكينات هي شركة رائدة عالمياً. إنها ماكينات تشكيل قطع غيار السيارات مصممة لتلبية أعلى معايير الدقة والكفاءة والابتكار. إليك ما يميزها:

1. مناولة المواد المتقدمة

- المواد المدعومة:

- فولاذ عالي الصلابة

- الفولاذ المجلفن

- ألومنيوم

- الفولاذ المقاوم للصدأ

- لماذا هو مفيد؟ يضمن التوافق مع المواد خفيفة الوزن والمتينة الضرورية لتصنيع المركبات الحديثة.

2. أنظمة الأدوات المعيارية

- ما يقدمه: أدوات قابلة للتبديل لإنتاج تصميمات متعددة المكونات على آلة واحدة.

- لماذا هو متعدد الاستخدامات: يدعم احتياجات التصنيع المتنوعة دون الحاجة إلى معدات إضافية.

3. القطع والتثقيب المتكامل

- ما يتضمنه: أنظمة مدمجة للقطع الدقيق والتثقيب والتثقيب والحز أثناء عملية التشكيل بالدلفنة.

- لماذا هي فعالة؟ يقلل من وقت الإنتاج ويضمن توفر مكونات جاهزة للتجميع.

4. تكامل إنترنت الأشياء والأتمتة

- ما تتيحه: المراقبة في الوقت الحقيقي، والتعديلات الآلية، والصيانة التنبؤية باستخدام أنظمة إنترنت الأشياء.

- لماذا هي ثورية؟

- تعزيز الكفاءة التشغيلية.

- يقلل من وقت التعطل وتكاليف الصيانة.

5. إنتاج عالي السرعة

- ما يقدمه: آلات قادرة على إنتاج ما يصل إلى 120 مترًا من المكونات في الدقيقة.

- لماذا هو ضروري: يلبي متطلبات الإنتاج الضخم في صناعة السيارات.

6. تصميم صديق للبيئة

- ما يتضمنه: المحركات الموفرة للطاقة، وسير العمل المحسّن، وأنظمة تقليل النفايات.

- لماذا هي مستدامة: يقلل من الأثر البيئي لتصنيع قطع غيار السيارات.

أسعار آلات تشكيل لفائف قطع غيار السيارات

تكلفة آلة تشكيل لفائف قطع غيار السيارات يعتمد على عوامل مثل التخصيص والميزات المتقدمة والقدرة الإنتاجية. فيما يلي دليل عام للأسعار لعام 2025:

| نوع الماكينة | الإمكانيات | نطاق السعر (بالدولار الأمريكي) |

|---|---|---|

| الماكينات القياسية | الملفات الشخصية الأساسية للسيارات | 150,000–150,000–150,000–400,000 |

| الآلات المتطورة | أنظمة القطع والتثقيب المتكاملة عالية السرعة والمتكاملة | 400,000–400,000–400,000–900,000 |

| ماكينات قابلة للتخصيص بالكامل | ميزات صديقة للبيئة، وأدوات معيارية، ومزودة بتقنية إنترنت الأشياء | 900,000–900,000–900,000–2,500,000 |

للحصول على أسعار محددة وخيارات تمويل، اتصل بـ ماكينات ووشي سونواي للماكينات.

الأتمتة في آلات تشكيل لفائف قطع غيار السيارات

الأتمتة تحدث ثورة في صناعة السيارات، و آلات تشكيل لفائف قطع غيار السيارات تقف في طليعة هذا التحول. من خلال الاستفادة من أحدث التقنيات، توفر هذه الآلات كفاءة وجودة فائقتين.

1. مراقبة الإنتاج في الوقت الحقيقي

- ما يتتبعه: المقاييس الرئيسية مثل سرعة الإنتاج واستخدام المواد ومعدلات العيوب.

- لماذا هي ذات قيمة: يساعد المصنعين على تحسين سير العمل وتحديد أوجه القصور.

2. الصيانة التنبؤية

- ما تتيحه: تراقب مستشعرات إنترنت الأشياء تآكل المكونات وتتنبأ باحتياجات الصيانة.

- لماذا هي ثورية؟

- يمنع الأعطال غير المتوقعة.

- يطيل العمر الافتراضي للماكينة.

3. التعديلات الآلية

- ما يقدمه: يضبط الأسطوانات والقواطع والمثاقب تلقائيًا لتناسب المواد أو التصميمات المختلفة.

- لماذا هي فعالة؟ يقلل من وقت الإعداد ويضمن جودة متسقة.

4. مراقبة الجودة المدعومة بالذكاء الاصطناعي

- ما يكتشفه: يحدد العيوب في الوقت الفعلي ويقوم بالتعديلات اللازمة للحفاظ على الجودة.

- لماذا هي فعالة؟ يقلل من الهدر ويعزز رضا العملاء.

5. التحكم عن بعد والتشخيص

- ما يتضمنه: أنظمة قائمة على السحابة للمراقبة عن بُعد واستكشاف الأخطاء وإصلاحها والتحكم.

- لماذا هو ملائم؟ يتيح للمشغلين الإشراف على الإنتاج وحل المشكلات من أي مكان.

الفوائد البيئية لآلات تشكيل لفائف قطع غيار السيارات

الاستدامة هي محور اهتمام صناعة السيارات، و ماكينات تشكيل قطع غيار السيارات مصممة لدعم الممارسات الصديقة للبيئة.

1. تقليل نفايات المواد

- كيف يتم تحقيق ذلك: تقلل الهندسة الدقيقة من المواد المهملة أثناء عملية التصنيع.

- التأثير: يحافظ على الموارد ويقلل من النفايات المطمورة.

2. كفاءة الطاقة

- كيف يعمل: مزودة بمحركات موفرة للطاقة وسير عمل محسّن لتقليل استهلاك الطاقة.

- التأثير: يقلل من البصمة الكربونية لتصنيع السيارات.

3. استخدام المواد القابلة لإعادة التدوير

- ما يدعمه: يعالج المعادن القابلة لإعادة التدوير مثل الألومنيوم والفولاذ المجلفن.

- التأثير: يعزز الاقتصاد الدائري ويقلل من استخراج الموارد.

4. مكونات متينة

- ما أهمية ذلك: تنتج مكونات عالية الجودة مصممة لتدوم طويلاً، مما يقلل من الحاجة إلى الاستبدال المتكرر.

- التأثير: يدعم الإنتاج المستدام للمركبات من خلال إطالة عمر الأجزاء.

الأسئلة الشائعة حول آلات تشكيل لفائف قطع غيار السيارات

| سؤال | الإجابة |

|---|---|

| ما هي المواد التي يمكن لهذه الماكينات معالجتها؟ | الفولاذ عالي القوة، والألومنيوم، والفولاذ المجلفن، والفولاذ المقاوم للصدأ. |

| ما هي سرعة الإنتاج؟ | حتى 120 مترًا في الدقيقةحسب المادة وتعقيد المظهر الجانبي. |

| هل هذه الماكينات صديقة للبيئة؟ | نعم، فهي تشتمل على محركات موفرة للطاقة وتقلل من هدر المواد. |

| هل يمكن لهذه الماكينات التعامل مع التصميمات المخصصة؟ | بالتأكيد! تدعم الأدوات المعيارية الملامح المخصصة لمختلف تطبيقات السيارات. |

| ما هو النطاق السعري لهذه الماكينات؟ | تتراوح الأسعار من من 150,000 إلى 150,000 إلى 150,000 إلى 2,500,000، بناءً على الميزات والتخصيص. |

| هل تتكامل هذه الأجهزة مع أنظمة إنترنت الأشياء؟ | نعم، تسمح الميزات التي تدعم إنترنت الأشياء بالمراقبة في الوقت الفعلي والصيانة التنبؤية. |

قصص نجاح حقيقية: آلات تشكيل قطع غيار السيارات في العمل

القدرات التحويلية لـ ماكينات تشكيل قطع غيار السيارات مكنت الشركات المصنعة في جميع أنحاء العالم من الابتكار وتوسيع نطاق خطوط إنتاج السيارات الخاصة بها. فيما يلي بعض الأمثلة الواقعية على كيفية إحداث هذه الآلات ثورة في العمليات.

1. صواني بطاريات EV لشركة رائدة في تصنيع السيارات الكهربائية

العميل: علامة تجارية عالمية للسيارات الكهربائية (EV).

التحدّي: طلبت الشركة المصنعة صواني بطاريات خفيفة الوزن ومقاومة للتآكل لخط إنتاجها من السيارات الكهربائية من الجيل التالي.

الحل: قامت شركة Wuxi Sunway بتسليم آلة تشكيل لفائف مصممة لمعالجة الألومنيوم والفولاذ المجلفن مع ثقب مدمج للفتحات والثقوب.

النتيجة:

- تقليل وزن حوامل البطاريات بمقدار 20%، مما أدى إلى تحسين مدى السيارة.

- زيادة سرعة الإنتاج بنسبة 30%، مما أدى إلى الوفاء بالمواعيد النهائية الضيقة لإطلاق السيارة الكهربائية.

- عززت سمعة الشركة كشركة رائدة في مجال الحلول المستدامة للسيارات.

2. مكونات هيكلية لشركة تصنيع شاحنات تجارية في أمريكا الشمالية

العميل: شركة رائدة في تصنيع الشاحنات.

التحدّي: كانت الشركة بحاجة إلى مكونات هيكلية شديدة التحمل قادرة على تحمل الأحمال الثقيلة والظروف القاسية.

الحل: قامت شركة Wuxi Sunway بتوريد آلة تشكيل لفائف فولاذية عالية القوة مزودة بأدوات متطورة لتصنيع المقاطع المقواة.

النتيجة:

- تسليم مكونات الشاسيه ذات القوة والمتانة الفائقة.

- تقليل نفايات المواد بنسبة 18%، مما أدى إلى خفض تكاليف الإنتاج.

- تحسين أداء الشاحنة وموثوقيتها، مما أدى إلى زيادة رضا العملاء.

3. ملفات تعريف مخصصة لعلامة تجارية لسيارات فاخرة في أوروبا

العميل: شركة تصنيع سيارات فاخرة متخصصة في السيارات المصممة حسب الطلب.

التحدّي: طلبت شركة تصنيع السيارات عناصر زخرفية مصممة خصيصًا لتحسين المظهر الجمالي لسياراتها الفاخرة.

الحل: قدمت Wuxi Sunway آلة تشكيل لفائف مزودة بأدوات معيارية لتصميمات معقدة وتشطيبات زخرفية.

النتيجة:

- مكّن من إنشاء ملفات تعريف تقليم فريدة وعالية الجودة.

- زيادة قدرة الشركة المصنعة للسيارات على تقديم خيارات تصميم مخصصة لعملائها.

- رفع مكانة العلامة التجارية في سوق السيارات الفاخرة.

4. مكونات تعليق خفيفة الوزن لمورد سيارات آسيوي

العميل: مورد من المستوى الأول للعديد من شركات صناعة السيارات العالمية.

التحدّي: كان المورد بحاجة إلى مكونات تعليق خفيفة الوزن ومتينة في الوقت نفسه لتحسين كفاءة استهلاك الوقود في المركبة.

الحل: قامت شركة Wuxi Sunway بتسليم آلة مصممة خصيصًا لمعالجة الفولاذ عالي القوة مع ميزات قطع وتثقيب مدمجة.

النتيجة:

- تخفيض وزن المكونات بنسبة 15%، مما يساهم في تحسين كفاءة استهلاك الوقود.

- زيادة الطاقة الإنتاجية بمقدار 40%، مما مكن المورد من تلبية الطلب المتزايد.

- تعزيز شراكة المورد مع شركات تصنيع السيارات الرائدة.

استكشاف الأخطاء وإصلاحها المشاكل الشائعة في آلات تشكيل لفائف قطع غيار السيارات

حتى الأكثر تقدماً ماكينات تشكيل قطع غيار السيارات قد تواجه تحديات تشغيلية. فيما يلي بعض المشكلات الشائعة وحلولها للحفاظ على سير خط الإنتاج الخاص بك بسلاسة.

1. ملفات تعريف غير متسقة

- الأعراض: المكونات المنتجة ذات أبعاد غير متساوية أو لا تفي بمواصفات التصميم.

- الأسباب المحتملة:

- بكرات غير متحاذية أو أدوات مهترئة.

- تغذية غير صحيحة للمواد.

- الحل:

- افحص البكرات بانتظام وأعد ضبطها.

- ضمان تغذية المواد بشكل صحيح عن طريق معايرة الأدلة والمغذيات.

2. التشويش على المواد

- الأعراض: تعلق المواد في البكرات، مما يؤدي إلى توقف الإنتاج.

- الأسباب المحتملة:

- يتجاوز سمك المادة سعة الماكينة.

- وجود حطام أو أجسام غريبة في منطقة التشكيل.

- الحل:

- تحقق من أن المواد تتوافق مع مواصفات الجهاز.

- قم بتنظيف البكرات والموجهات قبل كل دورة إنتاج.

3. التآكل المفرط للأدوات

- الأعراض: تتآكل أدوات القطع واللكم بسرعة، مما يؤثر على جودة الإنتاج.

- الأسباب المحتملة:

- مواد خام منخفضة الجودة.

- تزييت غير صحيح للأجزاء المتحركة.

- الحل:

- استخدم مواد عالية الجودة لتقليل تآكل الأدوات.

- تنفيذ جدول صيانة منتظم لتنظيف المكونات وتزييتها.

4. اهتزازات الماكينة

- الأعراض: ضوضاء واهتزازات مفرطة أثناء التشغيل.

- الأسباب المحتملة:

- مكونات مفكوكة أو بكرات غير متوازنة.

- تشغيل الماكينة بما يتجاوز سعتها الموصى بها.

- الحل:

- قم بإحكام ربط جميع المكونات وموازنة البكرات.

- قم بتشغيل الماكينة ضمن الحدود المحددة.

5. أعطال البرمجيات

- الأعراض: يتجمد نظام التحكم أو يفشل في تنفيذ الأوامر.

- الأسباب المحتملة:

- البرامج أو البرامج الثابتة القديمة.

- أعطال كهربائية في لوحة التحكم.

- الحل:

- قم بتحديث البرنامج إلى أحدث إصدار.

- افحص وأصلح أي أسلاك أو مكونات معيبة في لوحة التحكم.

الاتجاهات العالمية لصناعة آلات تشكيل قطع غيار السيارات في عام 2025

تشهد صناعة السيارات تحولاً جذرياً مدفوعاً بالتقدم التكنولوجي والاستدامة وتفضيلات المستهلكين. فيما يلي أهم الاتجاهات التي تشكل السوق ماكينات تشكيل قطع غيار السيارات:

1. الانتقال إلى السيارات الكهربائية (EVs)

- الاتجاه السائد: التحول العالمي نحو السيارات الكهربائية يزيد الطلب على المكونات خفيفة الوزن والمقاومة للتآكل.

- التأثير: هناك طلب كبير على آلات التشكيل بالدرفلة المصممة للألمنيوم والمواد الخفيفة الأخرى.

2. التركيز على الاستدامة

- الاتجاه السائد: تتبنى شركات صناعة السيارات ممارسات صديقة للبيئة لتلبية المعايير العالمية الصارمة للانبعاثات.

- التأثير: أصبحت الآلات التي تقلل من النفايات وتتيح استخدام المواد القابلة لإعادة التدوير معايير صناعية.

3. صعود التخصيص

- الاتجاه السائد: يبحث المستهلكون عن تصميمات مخصصة للسيارات، مما يزيد الطلب على المكونات المخصصة.

- التأثير: تزداد شعبية آلات تشكيل اللفائف المعيارية القادرة على إنتاج مقاطع مخصصة.

4. تكامل المصنع الذكي

- الاتجاه السائد: اعتماد تقنيات الصناعة 4.0 يعيد تشكيل صناعة السيارات.

- التأثير: تقود هذه الموجة آلات تشكيل اللفائف المزودة بتقنية إنترنت الأشياء (IoT) مع مراقبة في الوقت الفعلي وصيانة تنبؤية.

5. نمو المواد خفيفة الوزن

- الاتجاه السائد: أصبح استخدام الفولاذ عالي القوة والألومنيوم والمواد المركبة أكثر انتشارًا لتحسين كفاءة استهلاك الوقود.

- التأثير: تعد الآلات المُحسّنة لهذه المواد ضرورية لتلبية احتياجات صناعة السيارات في المستقبل.

قدرات أتمتة متقدمة في آلات تشكيل لفائف قطع غيار السيارات

الأتمتة هي العمود الفقري للتصنيع الحديث، و ماكينات تشكيل قطع غيار السيارات ليست استثناءً. فيما يلي نظرة على بعض ميزات الأتمتة المتطورة:

1. مناولة المواد التكيفية

- ما هي وظيفتها: يضبط الإعدادات تلقائيًا بناءً على المادة التي يتم معالجتها.

- لماذا هي ثورية؟ يقلل من وقت الإعداد ويضمن جودة متسقة عبر المواد المختلفة.

2. الكشف الذكي عن العيوب

- ما يتضمنه: أنظمة مدعومة بالذكاء الاصطناعي تكتشف العيوب السطحية أو الاختلالات أو الأخطاء في الأبعاد في الوقت الفعلي.

- لماذا هي فعالة؟ يقلل من النفايات ويقلل من الحاجة إلى عمليات الفحص اليدوية.

3. الإنتاج متعدد الملفات الشخصية

- ما تتيحه: التبديل السلس بين ملفات تعريف المكونات المختلفة في عملية إنتاج واحدة.

- لماذا هو ملائم؟ يعزز المرونة ويدعم متطلبات التصنيع المتنوعة.

4. التحليلات المستندة إلى السحابة

- ما يتتبعه: مقاييس الإنتاج وأداء الماكينات وجداول الصيانة.

- لماذا هي ذات قيمة: يوفر رؤى قابلة للتنفيذ لتحسين العمليات ومنع التوقف عن العمل.

التأثير البيئي لآلات تشكيل لفائف قطع غيار السيارات

تعد الاستدامة محور اهتمام متزايد في صناعة السيارات، و ماكينات تشكيل قطع غيار السيارات مصممة لتتماشى مع هذه الأهداف. وإليك كيفية مساهمتها في التصنيع الصديق للبيئة:

1. الاستخدام الفعال للمواد

- كيف يتم تحقيق ذلك: تقلل الهندسة الدقيقة من النفايات وتضمن الاستخدام الأمثل للمواد الخام.

- التأثير: يحافظ على الموارد ويقلل من تكاليف الإنتاج.

2. كفاءة الطاقة

- كيف يعمل: الآلات مزودة بمحركات موفرة للطاقة وميزات توفير الطاقة.

- التأثير: يقلل من استهلاك الطاقة والانبعاثات الكربونية الناتجة عن التصنيع.

3. دعم المواد القابلة لإعادة التدوير

- ما تتيحه: تقوم بمعالجة مواد مثل الألومنيوم والفولاذ المجلفن، والتي يمكن إعادة تدويرها بسهولة.

- التأثير: يشجع الممارسات المستدامة ويعزز الاقتصاد الدائري.

4. نتائج طويلة الأمد

- ما أهمية ذلك: تنتج مكونات سيارات متينة تقلل من الحاجة إلى الاستبدال المتكرر.

- التأثير: يدعم تصنيع المركبات المستدامة من خلال إطالة عمر الأجزاء.

لماذا تتصدر شركة Wuxi Sunway Machinery صناعة تشكيل اللفائف

بفضل خبرة تمتد لعقود والتزام بالابتكار،, ماكينات ووشي سونواي للماكينات أثبتت نفسها كشركة رائدة عالمياً في تكنولوجيا تشكيل الأسطوانات. وإليكم الأسباب التي تجعلها تواصل وضع المعايير:

- الخبرة العالمية: موثوق بها من قِبل الشركات المصنعة في جميع أنحاء آسيا وأوروبا والأمريكتين وخارجها.

- حلول قابلة للتخصيص: تقدم آلات مصممة خصيصًا لتلبية احتياجات الإنتاج المحددة.

- التركيز على الاستدامة: تصميم آلات صديقة للبيئة تتوافق مع الأهداف البيئية العالمية.

- الدعم الشامل: تقدم خدمات شاملة، من الاستشارة إلى الدعم بعد البيع.

- ابتكار مثبت: تدمج تقنيات متطورة مثل إنترنت الأشياء والذكاء الاصطناعي والأدوات المعيارية في آلاتها.

اكتشف المزيد عن منتجاتهم على الموقع الرسمي.

الأسئلة الشائعة حول آلات تشكيل لفائف قطع غيار السيارات

| سؤال | الإجابة |

|---|---|

| ما هي المواد التي يمكن لهذه الماكينات معالجتها؟ | الفولاذ عالي القوة، والألومنيوم، والفولاذ المجلفن، والفولاذ المقاوم للصدأ. |

| ما هي سرعة الإنتاج؟ | حتى 120 مترًا في الدقيقةحسب المادة وتعقيد المظهر الجانبي. |

| هل هذه الماكينات صديقة للبيئة؟ | نعم، فهي تشتمل على محركات موفرة للطاقة وتقلل من هدر المواد. |

| هل يمكن لهذه الماكينات التعامل مع التصميمات المخصصة؟ | بالتأكيد! تدعم الأدوات المعيارية الملامح المخصصة لمختلف تطبيقات السيارات. |

| ما هو النطاق السعري لهذه الماكينات؟ | تتراوح الأسعار من من 150,000 إلى 150,000 إلى 150,000 إلى 2,500,000، بناءً على الميزات والتخصيص. |

| هل تتكامل هذه الأجهزة مع أنظمة إنترنت الأشياء؟ | نعم، تسمح الميزات التي تدعم إنترنت الأشياء بالمراقبة في الوقت الفعلي والصيانة التنبؤية. |

الخلاصة: تسريع صناعة السيارات باستخدام تقنية التشكيل باللف

ماكينات تشكيل قطع غيار السيارات تشكل مستقبل صناعة السيارات من خلال توفير الدقة والكفاءة والاستدامة. من مكونات السيارات الكهربائية خفيفة الوزن إلى الزخارف الفاخرة المخصصة، تعد هذه الآلات ضرورية لتلبية متطلبات صناعة سريعة التطور.

هل أنت مستعد لدفع عجلة الابتكار في خط الإنتاج الخاص بك؟ كن شريكًا مع ماكينات ووشي سونواي للماكينات واستكشف حلولهم المتطورة لتشكيل الأسطوانات لقطاع السيارات. معًا، دعونا نسرع مستقبل النقل - مكونًا تلو الآخر.