يتزايد الطلب على مقاطع الألومنيوم خفيفة الوزن والمتينة والمتعددة الاستخدامات بشكل كبير في صناعات مثل البناء والسيارات والإلكترونيات والطاقة المتجددة. من التصميمات المعمارية الأنيقة إلى الأطر الصناعية القوية، تُعد مقاطع الألومنيوم من المكونات الأساسية للبنية التحتية والتكنولوجيا الحديثة. ولكن كيف يتم تصنيع هذه الملامح المعقدة بهذه الدقة والحجم؟ تكمن الإجابة في ماكينات تشكيل مقاطع الألومنيوم-تقنية رائدة تتيح إنتاجاً عالي السرعة وفعالاً من حيث التكلفة وصديقاً للبيئة.

في هذا الدليل الشامل، سنتطرق في هذا الدليل الشامل إلى الميزات، والتطبيقات، والأسعار، والاتجاهات العالمية، والابتكارات، ولماذا تُعد ماكينات وشى صنواي للماكينات رائدة عالميًا في حلول تشكيل مقاطع الألومنيوم. سواء كنت محترفًا في هذا المجال أو شخصًا يستكشف أحدث ما توصلت إليه تكنولوجيا التصنيع، فإن هذه المقالة ستزودك برؤى قابلة للتنفيذ.

ما هي ماكينات تشكيل بروفيلات الألومنيوم؟

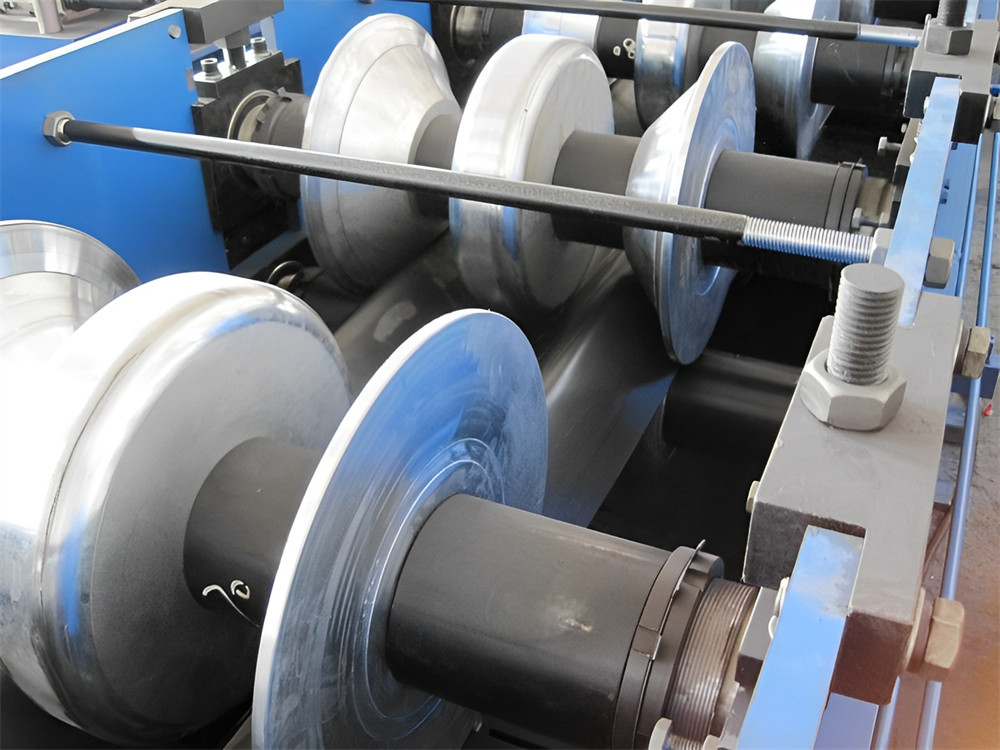

ان ماكينة تشكيل لفة الألومنيوم الملف الألومنيوم عبارة عن قطعة متخصصة من المعدات المصممة لتصنيع مقاطع الألومنيوم الدقيقة والمخصصة عن طريق تغذية صفائح أو لفائف الألومنيوم من خلال سلسلة من البكرات. تعمل هذه البكرات على تشكيل المواد تدريجيًا في شكل المقطع العرضي المطلوب، مما يضمن الاتساق والدقة والمتانة.

الميزات الأساسية

- تعدد استخدامات المواد: تم تحسين الماكينات لمعالجة درجات مختلفة من الألومنيوم، بما في ذلك الألومنيوم المطلي والأكسيد والألومنيوم الخام.

- إنتاج عالي السرعة: قادرة على إنتاج تشكيلات معقدة بسرعات تصل إلى 100 متر في الدقيقة.

- الهندسة الدقيقة: يحافظ على التفاوتات الصارمة لضمان ملاءمة كل ملف جانبي للتطبيق المقصود بشكل مثالي.

- تصميمات قابلة للتخصيص: يدعم إنشاء ملفات تعريف فريدة من نوعها لتلبية متطلبات المشروع المحددة.

- عمليات صديقة للبيئة: تقليل هدر المواد واستهلاك الطاقة، بما يتماشى مع أهداف الاستدامة.

تطبيقات ماكينات تشكيل مقاطع الألومنيوم الجانبية

لا غنى عن هذه الماكينات لتصنيع مكونات الألومنيوم المستخدمة في عدد لا يحصى من الصناعات. وفيما يلي تفصيل لتطبيقاتها الرئيسية:

1. البناء والهندسة المعمارية

- حالة الاستخدام: إنتاج مقاطع الألومنيوم للجدران الساترة، وإطارات النوافذ، وإطارات الأبواب، والأطر الهيكلية.

- لماذا هو ضروري: تضمن مكونات خفيفة الوزن ومقاومة للتآكل وسهلة التركيب والصيانة.

2. صناعة السيارات

- حالة الاستخدام: مكونات التصنيع مثل قضبان السقف، وحواجز التصادم، والزخارف الجانبية.

- لماذا هو أمر بالغ الأهمية: توفر قطعاً خفيفة الوزن ومتينة في الوقت نفسه تعمل على تحسين أداء السيارة وكفاءة استهلاك الوقود.

3. الطاقة المتجددة

- حالة الاستخدام: صياغة أنظمة التركيب والدعامات الخاصة بألواح الطاقة الشمسية وتوربينات الرياح.

- ما أهمية ذلك: تدعم قطاع الطاقة المتجددة بمكونات متينة ومقاومة للعوامل الجوية.

4. الإلكترونيات والأجهزة

- حالة الاستخدام: إنتاج المشتتات الحرارية والحاويات والمكونات الهيكلية للأجهزة الكهربائية.

- لماذا هو مفيد؟ تضمن ملفات تعريف دقيقة وعالية الجودة للتطبيقات الإلكترونية الحساسة.

5. الأثاث والتصميم الداخلي

- حالة الاستخدام: إنشاء التشكيلات الجانبية للأثاث المعياري والزخارف الزخرفية وأنظمة التقسيم.

- لماذا هي فريدة من نوعها: تقدم تصميمات عملية وممتعة من الناحية الجمالية للديكورات الداخلية الحديثة.

6. البنية التحتية للنقل

- حالة الاستخدام: تصنيع المقاطع الجانبية لمسارات السكك الحديدية وممرات المطارات وجسور المشاة.

- لماذا هي ذات قيمة: توفر حلولاً خفيفة الوزن تقلل من وقت التركيب والتكاليف.

لماذا تكتسب ماكينات تشكيل مقاطع الألومنيوم شعبية متزايدة

إن تعدد استخدامات الألومنيوم وكفاءته يجعل منه مادة مفضلة في مختلف الصناعات، و ماكينات تشكيل مقاطع الألومنيوم مناسبة تمامًا لتلبية الطلب المتزايد. وإليك السبب الذي يجعلها لا غنى عنها:

1. خفيفة الوزن ومتينة

- ما أهمية ذلك: تتميز مقاطع الألومنيوم بقوتها وخفة وزنها، مما يجعلها مثالية للتطبيقات التي يكون فيها تقليل الوزن أمرًا بالغ الأهمية، كما هو الحال في صناعات السيارات والفضاء.

2. مقاومة التآكل

- لماذا هو أمر بالغ الأهمية: يمكن لألواح الألومنيوم أن تتحمل الظروف البيئية القاسية، مما يجعلها مثالية للتطبيقات الخارجية مثل البناء وأنظمة الطاقة المتجددة.

3. التخصيص

- لماذا هو مفيد؟ يمكن أن تنتج ماكينات التشكيل بالدلفنة مقاطع جانبية بأشكال وأحجام وتشطيبات مختلفة، بما يلبي احتياجات الصناعة المتنوعة.

4. التصنيع الصديق للبيئة

- لماذا هو ضروري: الألومنيوم قابل لإعادة التدوير بدرجة كبيرة، كما أن ماكينات التشكيل بالدلفنة تقلل من النفايات، مما يدعم ممارسات الإنتاج المستدام.

5. كفاءة إنتاج عالية

- لماذا هو ضروري: صُممت ماكينات التشكيل بالدلفنة للتشغيل المستمر، مما يتيح للمصنعين تلبية متطلبات الكميات الكبيرة دون المساس بالجودة.

الملامح الرئيسية لماكينات تشكيل الألومنيوم الجانبية من الألومنيوم من ووشي سونواي

ماكينات ووشي سونواي للماكينات اسم موثوق به في صناعة التشكيل بالدلفنة، حيث تقدم حلولاً متطورة لتصنيع مقاطع الألومنيوم. وإليك سبب تميز ماكيناتها:

1. مناولة المواد المتقدمة

- المواد المدعومة:

- ألومنيوم خام

- ألومنيوم مؤكسد

- الألومنيوم المطلي

- لماذا هو مفيد؟ يضمن التوافق مع مجموعة من المواد لتطبيقات متعددة الاستخدامات.

2. الهندسة الدقيقة

- الأداء: يحقق تفاوتات تفاوتات منخفضة تصل إلى ± 0.02 مم، مما يضمن دقة الأبعاد.

- سبب أهمية ذلك: يضمن التجميع السلس والتوافق مع المكونات الأخرى.

3. أنظمة الأدوات المعيارية

- ما يقدمه: أدوات قابلة للتبديل لإنتاج تشكيلات متعددة على ماكينة واحدة.

- لماذا هي ذات قيمة: يقلل من وقت التعطل أثناء تغيير الأدوات ويزيد من مرونة الإنتاج.

4. تكامل إنترنت الأشياء والأتمتة

- ما تتيحه: المراقبة في الوقت الحقيقي، والتعديلات الآلية، والصيانة التنبؤية باستخدام أنظمة إنترنت الأشياء.

- لماذا هي ثورية؟

- يعزز كفاءة الإنتاج.

- يقلل من التكاليف التشغيلية.

5. تشغيل عالي السرعة

- الأداء: تنتج ملفات تعريف بسرعات تصل إلى 100 متر في الدقيقة.

- لماذا هو ضروري: تلبي المتطلبات الكبيرة الحجم للصناعات مثل الإنشاءات والسيارات.

6. تصميم صديق للبيئة

- ما يتضمنه: محركات موفرة للطاقة، وتقليل نفايات المواد، ودعم الألومنيوم القابل لإعادة التدوير.

- لماذا هو ضروري: يتوافق مع أهداف الاستدامة العالمية ويقلل من البصمة الكربونية للتصنيع.

7. القطع والتثقيب المتكامل

- ما يقدمه: أنظمة مدمجة لقطع وتثقيب صفائح الألومنيوم أثناء عملية التشكيل بالدلفنة.

- لماذا هي فعالة؟ يسرّع الإنتاج ويضمن مكونات جاهزة للاستخدام.

تسعير ماكينات تشكيل مقاطع الألومنيوم الجانبية

تكلفة ماكينة تشكيل لفة الألومنيوم الملف الألومنيوم يعتمد على ميزاته وسعته ومستوى التخصيص. فيما يلي دليل عام للتسعير لعام 2025:

| نوع الماكينة | الإمكانيات | نطاق السعر (بالدولار الأمريكي) |

|---|---|---|

| الماكينات القياسية | إنتاج مقاطع الألومنيوم الأساسية | 150,000–150,000–150,000–400,000 |

| الآلات المتطورة | أنظمة القطع والتثقيب المتكاملة عالية السرعة والمتكاملة | 400,000–400,000–400,000–1,000,000 |

| ماكينات قابلة للتخصيص بالكامل | إنترنت الأشياء، والأدوات المعيارية، والميزات الصديقة للبيئة | 1,000,000–1,000,000–1,000,000–2,500,000 |

للحصول على الأسعار المفصلة وخيارات التمويل، اتصل ب ماكينات ووشي سونواي للماكينات.

ابتكارات في تكنولوجيا تشكيل مقاطع الألومنيوم الجانبية

تشهد صناعة تشكيل اللفائف تطورًا سريعًا، حيث تعمل التقنيات الجديدة على تعزيز قدرات ماكينات تشكيل مقاطع الألومنيوم. إليك أحدث الابتكارات:

1. تقنية التوأم الرقمي

- ما يحاكيه: نماذج افتراضية لعملية التشكيل بالدلفنة لتحسين إعدادات الماكينة.

- لماذا هي ثورية؟

- يقلل من وقت الإعداد وتعديلات التجربة والخطأ.

- تضمن جودة متسقة من أول عملية إنتاج.

2. مراقبة الجودة المدعومة بالذكاء الاصطناعي

- ما هي وظيفتها: تراقب الأبعاد وجودة السطح وسُمك المادة في الوقت الفعلي.

- لماذا تغير قواعد اللعبة:

- يكتشف العيوب في وقت مبكر، مما يقلل من الهدر.

- يحسن جودة المنتج بشكل عام.

3. إمكانية تعدد الملامح

- ما تتيحه: إنتاج ملفات تعريف متعددة في دورة إنتاج واحدة.

- لماذا هو مفيد؟

- يزيد من سرعة الإنتاج.

- يدعم احتياجات التصنيع المتنوعة.

4. تكامل إنترنت الأشياء

- ما يقدمه: جمع البيانات في الوقت الحقيقي، والصيانة التنبؤية، والتعديلات الآلية.

- لماذا هو أمر بالغ الأهمية:

- يعزز وقت تشغيل الماكينة.

- يقلل من تكاليف الصيانة.

5. أنظمة الطلاء الصديقة للبيئة

- ما يتضمنه: أنظمة لتطبيق الطلاءات الواقية أو الزخرفية أثناء عملية التشكيل بالدلفنة.

- لماذا هي مستدامة:

- يزيل عمليات الطلاء الإضافية.

- تقلل من استهلاك الطاقة.

الأسئلة الشائعة حول ماكينات تشكيل مقاطع الألومنيوم الجانبية

| سؤال | الإجابة |

|---|---|

| ما هي المواد التي يمكن لهذه الماكينات معالجتها؟ | الألومنيوم (الخام، المؤكسد، المطلي بأكسيد الألومنيوم) والمعادن الأخرى خفيفة الوزن. |

| ما هي سرعة الإنتاج؟ | حتى 100 متر في الدقيقة، اعتمادًا على مدى تعقيد الملف الشخصي. |

| هل هذه الماكينات صديقة للبيئة؟ | نعم، فهي تشتمل على محركات موفرة للطاقة وتقلل من هدر المواد. |

| هل يمكن لهذه الماكينات التعامل مع التصميمات المخصصة؟ | بالتأكيد! تدعم الأدوات المعيارية التشكيلات المعيارية التشكيلات الجانبية المخصصة للتطبيقات المتنوعة. |

| هل تتوافق هذه الماكينات مع معايير السلامة؟ | نعم، فهي تفي بشهادات CE وISO وOSHA للسلامة والموثوقية. |

| هل يمكن أن تتكامل هذه الأجهزة مع أنظمة إنترنت الأشياء؟ | نعم، تسمح الميزات التي تدعم إنترنت الأشياء بالمراقبة في الوقت الفعلي والصيانة التنبؤية. |

قصص نجاح واقعية: ماكينات تشكيل مقاطع الألومنيوم الجانبية في العمل

تعدد استخدامات وكفاءة ماكينات تشكيل مقاطع الألومنيوم واضحة في تطبيقها في مختلف الصناعات. وفيما يلي بعض الأمثلة الواقعية التي توضح تأثيرها التحويلي:

1. دراسة حالة إفرادية: البنية التحتية للطاقة الشمسية

- العميل: شركة طاقة شمسية تدير مزارع طاقة شمسية واسعة النطاق في أمريكا الشمالية.

- التحدّي: احتاجت الشركة إلى أنظمة تركيب خفيفة الوزن ومتينة في الوقت نفسه لألواح الطاقة الشمسية التي يمكنها تحمل الظروف الجوية القاسية.

- الحل: قدمت شركة Wuxi Sunway Machinery ماكينة تشكيل بالدلفنة قادرة على معالجة الألومنيوم المؤكسد ودمج الملامح المخصصة لأقواس التثبيت.

- النتائج:

- زيادة الإنتاج بمقدار 351 تيرابايت 3 تيرابايت، مما يتيح تركيب مزارع الطاقة الشمسية بشكل أسرع.

- تسليم مكونات مقاومة للتآكل بأبعاد دقيقة.

- تقليل نفايات المواد بنسبة 20%، بما يتماشى مع أهداف الاستدامة للشركة.

2. دراسة حالة إفرادية: مورد مكونات السيارات

- العميل: شركة رائدة في توريد قطع الألومنيوم لـ السيارات الكهربائية (المركبات الكهربائية) في أوروبا.

- التحدّي: احتاج العميل إلى مقاطع ألومنيوم عالية القوة وخفيفة الوزن لحاويات بطاريات السيارات الكهربائية وحواجز التصادم.

- الحل: طوّرت شركة Wuxi Sunway ماكينة تشكيل بالدلفنة مزودة بقدرات قطع وتثقيب متكاملة للسبائك عالية القوة.

- النتائج:

- تقليل مهل الإنتاج بمقدار 40%.

- توفير مكونات تحسّن كفاءة الطاقة والسلامة في السيارة.

- تمكين العميل من توسيع محفظة منتجاته وتأمين عقود جديدة.

3. دراسة حالة إفرادية: الشركة المعمارية

- العميل: شركة إنشاءات متخصصة في التصميمات المعمارية الحديثة في الشرق الأوسط.

- التحدّي: احتاجت الشركة إلى مقاطع ألومنيوم مخصصة للحوائط الساترة والزخارف الزخرفية التي تتحمل درجات الحرارة العالية والتعرض للرمال.

- الحل: زوَّدت شركة Wuxi Sunway ماكينة تشكيل بالدلفنة مُحسَّنة للألومنيوم المطلي مسبقًا بتشطيبات سطحية متقدمة.

- النتائج:

- إنتاج مقاطع أنيقة مقاومة للعوامل الجوية تفي بالمتطلبات الجمالية والوظيفية للمشروع.

- انخفاض تكاليف الإنتاج بمقدار 25% مقارنة بطرق التصنيع التقليدية.

- تعزيز سمعة الشركة في تقديم مشاريع معمارية عالية الجودة.

4. دراسة حالة: الشركة المصنعة للأثاث المعياري

- العميل: شركة تصنيع أثاث متخصصة في التصميمات المعيارية والقابلة للتخصيص.

- التحدّي: احتاجت الشركة إلى مقاطع ألومنيوم خفيفة الوزن وسهلة التجميع لأنظمة الأثاث الخاصة بها.

- الحل: وفرت شركة Wuxi Sunway ماكينة تشكيل بالدلفنة مزودة بأدوات معيارية لإنشاء تصميمات متنوعة للمقاطع الجانبية.

- النتائج:

- زيادة مرونة الإنتاج، مما يسمح للشركة بتلبية تفضيلات العملاء المتطورة.

- تسليم المكونات بلمسة نهائية خالية من العيوب، مما يعزز من جاذبية المنتج في السوق.

- تقليل نفايات الإنتاج، ودعم مبادرات الشركة الصديقة للبيئة.

ممارسات الاستدامة في تصنيع مقاطع الألومنيوم الجانبية

الاستدامة هي محور التركيز الرئيسي في التصنيع الحديث، و ماكينات تشكيل مقاطع الألومنيوم مصممة لدعم الممارسات الصديقة للبيئة. إليك كيفية مساهمتها في مستقبل أكثر اخضراراً:

1. العمليات الموفرة للطاقة

- كيف يتم تحقيق ذلك: تقلل المحركات المتقدمة وسير العمل المحسّن من استهلاك الكهرباء.

- التأثير: تقليل البصمة الكربونية لعمليات التصنيع، بما يتماشى مع أهداف الاستدامة العالمية.

2. تقليل نفايات المواد

- كيف يتم تحقيق ذلك: تقلل أنظمة القطع والتشكيل الدقيقة من الخردة أثناء الإنتاج.

- التأثير: يحافظ على المواد الخام ويقلل من تكاليف الإنتاج.

3. دعم المواد القابلة لإعادة التدوير

- كيف يتم تحقيق ذلك: تم تصميم الماكينات لمعالجة مواد الألومنيوم القابلة لإعادة التدوير.

- التأثير: تشجع إعادة استخدام المواد وتقليل النفايات ودعم ممارسات الاقتصاد الدائري.

4. مكونات تدوم طويلاً

- ما أهمية ذلك: تتطلب مقاطع الألومنيوم المتينة استبدالاً أقل تكراراً، مما يقلل من الاستهلاك الكلي للمواد.

- التأثير: إطالة دورة حياة المنتجات، مما يقلل من الأثر البيئي.

5. تكامل الطلاء

- كيف يتم تحقيق ذلك: تدعم الماكينات الطلاءات الصديقة للبيئة التي تعزز متانة مقاطع الألومنيوم وجمالياتها.

- التأثير: يلغي الحاجة إلى عمليات طلاء إضافية، مما يقلل من استخدام الطاقة.

معايير السلامة لماكينات تشكيل مقاطع الألومنيوم الجانبية

السلامة أمر بالغ الأهمية في التصنيع، و ماكينات تشكيل مقاطع الألومنيوم مجهزة بميزات متقدمة لحماية المشغلين وضمان الامتثال للمعايير العالمية.

1. أنظمة الإيقاف في حالات الطوارئ

- ما هي وظيفتها: يسمح للمشغلين بإيقاف عمليات الماكينة على الفور في حالة الطوارئ.

- لماذا هو أمر بالغ الأهمية: يمنع الحوادث ويقلل من تلف المعدات أثناء الحوادث غير المتوقعة.

2. واقيات ودروع السلامة

- ما يتضمنه: حواجز واقية حول الأجزاء المتحركة لمنع التلامس العرضي.

- سبب أهمية ذلك: يقلل من مخاطر الإصابات الناجمة عن الخطأ البشري أو الأعطال الميكانيكية.

3. الستائر الخفيفة

- ما يكتشفه: يحدد الأجسام أو الأفراد في المناطق الخطرة ويوقف عمليات الماكينة تلقائياً.

- لماذا هي فعالة؟ تعزيز السلامة دون مقاطعة سير عمل الإنتاج.

4. الحد من الضوضاء والاهتزازات

- ما الذي يقلل: يقلل من مستويات الضوضاء والاهتزازات أثناء التشغيل.

- لماذا هو مفيد؟ يخلق بيئة عمل أكثر أماناً وراحة للمشغلين.

5. الامتثال للمعايير العالمية

- الشهادات: تلبي الماكينات معايير CE وISO 45001 وOSHA للسلامة وحماية البيئة.

- لماذا هو ضروري: ضمان الموثوقية والسلامة في الأسواق العالمية المتنوعة.

اتجاهات السوق العالمية لآلات تشكيل الألومنيوم في عام 2025

نظرًا لأن الصناعات تتكيف مع المتطلبات المتغيرة والتقدم التكنولوجي، فإن سوق ماكينات تشكيل مقاطع الألومنيوم يستمر في التوسع. فيما يلي الاتجاهات الرئيسية التي تقود النمو:

1. زيادة الاعتماد في مجال الطاقة المتجددة

- الاتجاه السائد: يؤدي نمو قطاع الطاقة المتجددة إلى زيادة الطلب على مقاطع الألومنيوم خفيفة الوزن والمقاومة للتآكل.

- التأثير: يزداد الطلب على ماكينات التشكيل بالدلفنة القادرة على إنتاج أنظمة تركيب الألواح الشمسية ومكونات توربينات الرياح.

2. التوسع في صناعة السيارات

- الاتجاه السائد: يؤدي ظهور السيارات الكهربائية (EVs) إلى زيادة الحاجة إلى مكونات الألومنيوم خفيفة الوزن.

- التأثير: يحتاج المصنعون إلى ماكينات تشكيل بالدلفنة عالية السعة لتلبية أهداف الإنتاج.

3. النمو في التحضر وتطوير البنية التحتية

- الاتجاه السائد: يؤدي التحضر السريع إلى زيادة الطلب على مواد البناء مثل إطارات الألومنيوم والأبواب والنوافذ.

- التأثير: أصبحت ماكينات التشكيل بالدلفنة المصممة للتطبيقات المعمارية ضرورية.

4. التحول نحو التصنيع المستدام

- الاتجاه السائد: تتبنى الشركات ممارسات صديقة للبيئة لتلبية توقعات المستهلكين والمتطلبات التنظيمية.

- التأثير: تكتسب الماكينات المحسّنة لكفاءة الطاقة والمواد القابلة لإعادة التدوير زخماً متزايداً.

5. التكامل مع الصناعة 4.0

- الاتجاه السائد: يؤدي اعتماد إنترنت الأشياء والذكاء الاصطناعي في التصنيع إلى زيادة الطلب على آلات التشكيل بالدرفلة الذكية.

- التأثير: أصبحت الآلات المزودة بإمكانيات المراقبة في الوقت الفعلي والصيانة التنبؤية معايير الصناعة.

لماذا تختار ماكينات Wuxi Sunway لماكينات تشكيل الألومنيوم؟

ماكينات ووشي سونواي للماكينات هي شركة رائدة عالميًا في تكنولوجيا التشكيل بالدرفلة، وتحظى بثقة المصنعين في مختلف الصناعات. وإليك سبب كونها الشريك المفضل لإنتاج مقاطع الألومنيوم:

- خبرات مثبتة: عقود من الخبرة في تصميم ماكينات التشكيل بالدلفنة عالية الأداء.

- انتشار عالمي: تُستخدم الماكينات بنجاح في آسيا وأوروبا والأمريكتين وغيرها.

- مدفوعة بالابتكار: ميزات مثل تكامل إنترنت الأشياء، والأدوات المعيارية، ومراقبة الجودة المدعومة بالذكاء الاصطناعي تميز ماكيناتهم.

- الالتزام بالاستدامة: تم تحسين الماكينات للإنتاج الصديق للبيئة، مما يدعم أهداف الاستدامة العالمية.

- الدعم الشامل: بدءاً من الاستشارة وحتى خدمة ما بعد البيع، تضمن لك Wuxi Sunway تجربة سلسة.

الخاتمة: تشكيل مستقبل التصنيع باستخدام مقاطع الألمنيوم

ماكينات تشكيل مقاطع الألومنيوم تُحدث ثورة في التصنيع الحديث من خلال الجمع بين الدقة والكفاءة والاستدامة. إن تعدد استخداماتها يجعلها لا غنى عنها للصناعات التي تتراوح من البناء والسيارات إلى الطاقة المتجددة والإلكترونيات.

هل أنت مستعد لتحويل عمليات التصنيع لديك؟ اشترك مع ماكينات ووشي سونواي للماكينات واستكشف حلولها المبتكرة للتشكيل بالدلفنة المصممة خصيصًا لتلبية احتياجاتك. دعونا معًا نشكل معًا مستقبلًا أكثر ذكاءً واستدامة - مقطع ألومنيوم واحد في كل مرة.