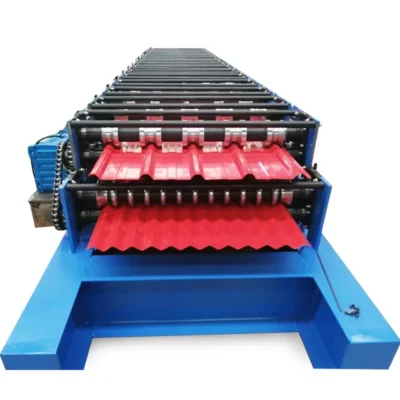

ميزات ماكينة تشكيل الأنابيب السفلية

خط تشكيل الأنابيب السفلية / ماسورة المطر، يمكن أن ينتج أنابيب سفلية / ماسورة مطر مستديرة ومربعة، ومجهزة بماكينة الكوع.

1. دقة الانحناء: يجب ألا يتجاوز الحد الأقصى لانحرافات المظهر الجانبي (الأبعاد والشكل) التفاوتات المحددة في البيانات التالية (أو ما يعادلها من تفاوتات).

2. جودة الثني: القدرة على ثني المقاطع الجانبية للتشكيل المحدد بالسمك الأقصى المحدد للفولاذ؛ ولا يسمح بتشقق الفولاذ أو الطلاء المعدني لجميع درجات الفولاذ المطلوبة.

3. سرعة الإنتاج القصوى: 0-15 متر في الدقيقة.

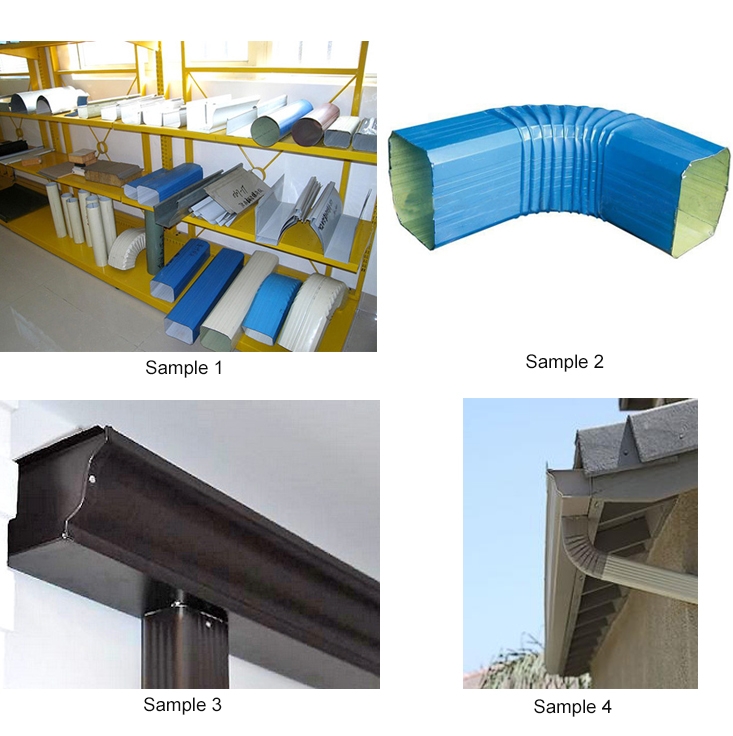

تطبيقات ماكينات تشكيل الأنابيب السفلية:

يتم استخدام المنتجات التي ينتجها خط تشكيل الأنابيب السفلية/دلفنة تشكيل ماسورة التهوية على نطاق واسع في المصنع، وورشة العمل، والمرآب، والمستودع، وسقيفة القاطرة، والشماعات، ومبنى المعارض، والسينما، والمسرح، والملعب، والحديقة، إلخ.

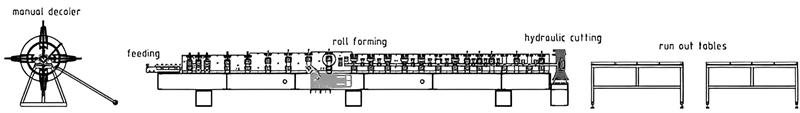

عملية تدفق

فك اللفافة - التغذية - التشكيل بالدلفنة - القطع - رف الخروج - الكوع

تكوينات الآلة

| 1. مزيل اللفافة اليدوي 3T |

2. جهاز التغذية

|

| 3. ماكينة التشكيل بالدلفنة |

4. نظام القطع اللاحق

|

| 5. رف الخروج |

6. ماكينة كوع ماسورة تصريف مياه الأمطار/أنبوب التصريف

|

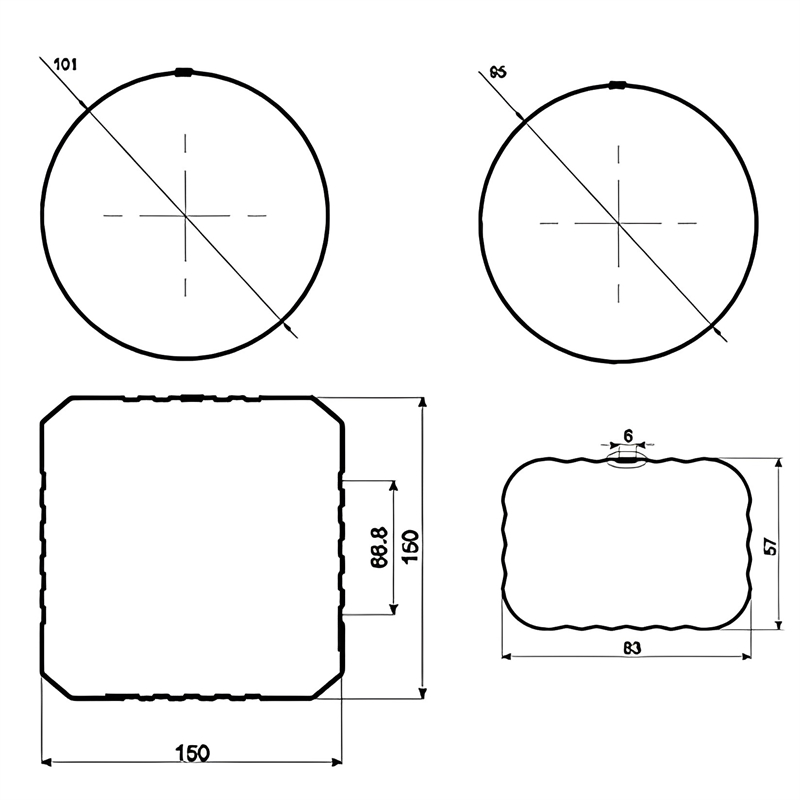

رسومات الملف الشخصي

ما هي ماكينة تشكيل الأنابيب السفلية؟

ماكينة تشكيل الأنابيب السفلية هي قطعة متخصصة من المعدات المستخدمة في عملية تصنيع الأنابيب السفلية أو أنابيب مياه الأمطار. وعادةً ما تستخدم الأنابيب السفلية لتوجيه مياه الأمطار من مزاريب السقف إلى الأرض، مما يمنع تلف أساسات المبنى.

صُممت ماكينة التشكيل بالدلفنة لتشكيل وتشكيل الصفائح المعدنية في الشكل المطلوب للأنبوب السفلي. وهي تتكون من سلسلة من البكرات والأدوات التي تقوم بثني وتشكيل الشريط المعدني أو الملف المعدني تدريجيًا إلى الشكل المطلوب. تتم برمجة الماكينة لإنتاج نتائج متسقة ودقيقة، مما يضمن أن كل أنبوب سفلي يتم إنتاجه يكون بنفس الأبعاد والمواصفات.

تبدأ العملية بتلقيم شريط أو ملف معدني مسطح في الماكينة. وأثناء مروره من خلال البكرات والأدوات، يتم تشكيل المعدن تدريجيًا على شكل الأنبوب السفلي، مع إضافة الشفاه والمنحنيات وغيرها من الميزات على طول الطريق. كما يمكن للماكينة أيضًا إجراء عمليات إضافية مثل ثقب الثقوب أو الفتحات لتركيب الأقواس أو وصلات التوصيل.

وغالبًا ما يتم التحكم في ماكينة تشكيل الأنابيب السفلية بالكمبيوتر، مما يسمح بالتحكم الدقيق في أبعاد وشكل الأنبوب السفلي الذي يتم إنتاجه. تساعد هذه الأتمتة على زيادة الكفاءة، وتقليل هدر المواد، وضمان جودة متسقة في المنتجات المصنعة.

بشكل عام، تلعب ماكينة تشكيل الأنابيب السفلية دورًا حاسمًا في إنتاج الأنابيب السفلية، حيث توفر طريقة فعالة وموثوقة لتشكيل الصفائح المعدنية في الملامح المطلوبة لأنظمة تصريف مياه الأمطار الفعالة.

ما هي ماكينة تشكيل الأنابيب السفلية المستديرة؟

إن ماكينة تشكيل الأنابيب السفلية المستديرة هي نوع محدد من ماكينات التشكيل بالدلفنة المصممة لتصنيع أنابيب مستديرة الشكل أو أنابيب مياه الأمطار. تُستخدم الأنابيب السفلية الدائرية بشكل شائع في المباني السكنية والتجارية لتوجيه مياه الأمطار من المزاريب إلى الأرض، مما يمنع تلف المياه ويضمن تصريفها بشكل مناسب.

تعمل ماكينة تشكيل الأنابيب السفلية الدائرية على مبادئ مماثلة لماكينات التشكيل بالدلفنة الأخرى ولكنها مهيأة خصيصًا لإنتاج مقاطع جانبية دائرية الشكل. وتتكون الماكينة من سلسلة من البكرات والأدوات التي تقوم بتشكيل الشريط أو الملف المعدني تدريجيًا في شكل دائري.

تبدأ العملية بتلقيم شريط أو ملف معدني مسطح في الماكينة. وأثناء مروره عبر البكرات، يتم تشكيل المعدن تدريجيًا في شكل دائري. تطبق الماكينة إجراءات الضغط والتشكيل اللازمة لتحقيق الأبعاد والمواصفات المطلوبة للأنبوب السفلي المستدير.

قد تشتمل ماكينة التشكيل بالدلفنة على أدوات وعمليات إضافية لإنشاء حواف أو درزات أو غيرها من الميزات المطلوبة لوظائف الأنبوب السفلي وتركيبه. كما يمكن أن تشتمل أيضًا على آليات تثقيب أو قطع لإنشاء ثقوب أو فتحات لربط الأقواس أو وصلات التوصيل.

وعلى غرار ماكينات التشكيل بالدلفنة الأخرى، غالبًا ما يتم التحكم في ماكينة تشكيل الأنابيب السفلية المستديرة بواسطة الكمبيوتر للتحكم الدقيق في عملية التصنيع. تسمح هذه الأتمتة بإنتاج متناسق ودقيق، مما يضمن أن كل أنبوب سفلي دائري يفي بالمواصفات المطلوبة.

وباختصار، فإن ماكينة تشكيل الأنابيب السفلية الدائرية هي عبارة عن معدات متخصصة تستخدم لتصنيع الأنابيب السفلية الدائرية الشكل. وهي تستخدم بكرات وأدوات لتشكيل الشرائط أو اللفائف المعدنية في مقاطع دائرية الشكل، مما ينتج أنابيب سفلية فعالة وموثوقة ومناسبة لأنظمة تصريف مياه الأمطار.

ما هي ماكينة تشكيل الأنابيب السفلية المربعة؟

إن ماكينة تشكيل الأنابيب السفلية المربعة هي نوع محدد من ماكينات التشكيل بالدلفنة المصممة لتصنيع أنابيب مربعة الشكل أو أنابيب مياه الأمطار. تُستخدم الأنابيب السفلية المربعة بشكل شائع في المباني السكنية والتجارية لتوجيه مياه الأمطار من المزاريب إلى الأرض، مما يوفر تصريفاً فعالاً ويمنع تلف المياه.

تعمل ماكينة تشكيل الأنابيب السفلية المربعة على مبادئ مماثلة لماكينات التشكيل بالدلفنة الأخرى ولكنها مهيأة خصيصًا لإنتاج مقاطع جانبية مربعة الشكل. وتتكون الماكينة من سلسلة من البكرات والأدوات التي تقوم بتشكيل الشريط أو الملف المعدني تدريجيًا في شكل مربع.

تبدأ العملية بتلقيم شريط أو ملف معدني مسطح في الماكينة. وأثناء مروره عبر البكرات، يتم تشكيل المعدن تدريجيًا في شكل مربع. تطبق الماكينة إجراءات الضغط والتشكيل اللازمة لتحقيق الأبعاد والمواصفات المطلوبة للأنبوب السفلي المربع.

قد تشتمل ماكينة التشكيل بالدلفنة على أدوات وعمليات إضافية لإنشاء حواف أو درزات أو غيرها من الميزات المطلوبة لوظائف الأنبوب السفلي وتركيبه. كما يمكن أن تشتمل أيضًا على آليات تثقيب أو قطع لإنشاء ثقوب أو فتحات لربط الأقواس أو وصلات التوصيل.

غالبًا ما يتم استخدام التحكم بالكمبيوتر في ماكينات تشكيل الأنابيب السفلية المربعة، مما يسمح بالتحكم الدقيق في عملية التصنيع. تضمن هذه الأتمتة إنتاجًا متسقًا ودقيقًا، مما يضمن أن كل أنبوب سفلي مربع يفي بالمواصفات المطلوبة.

وباختصار، فإن ماكينة تشكيل الأنابيب السفلية المربعة هي معدات متخصصة تستخدم لتصنيع الأنابيب السفلية المربعة الشكل. وهي تستخدم بكرات وأدوات لتشكيل الشرائح أو اللفائف المعدنية في مقاطع مربعة الشكل، مما ينتج أنابيب سفلية مناسبة لأنظمة تصريف مياه الأمطار بكفاءة وتوفر إدارة فعالة للمياه في المباني.