نظرة عامة على آلات تشكيل حواجز الطرق السريعة

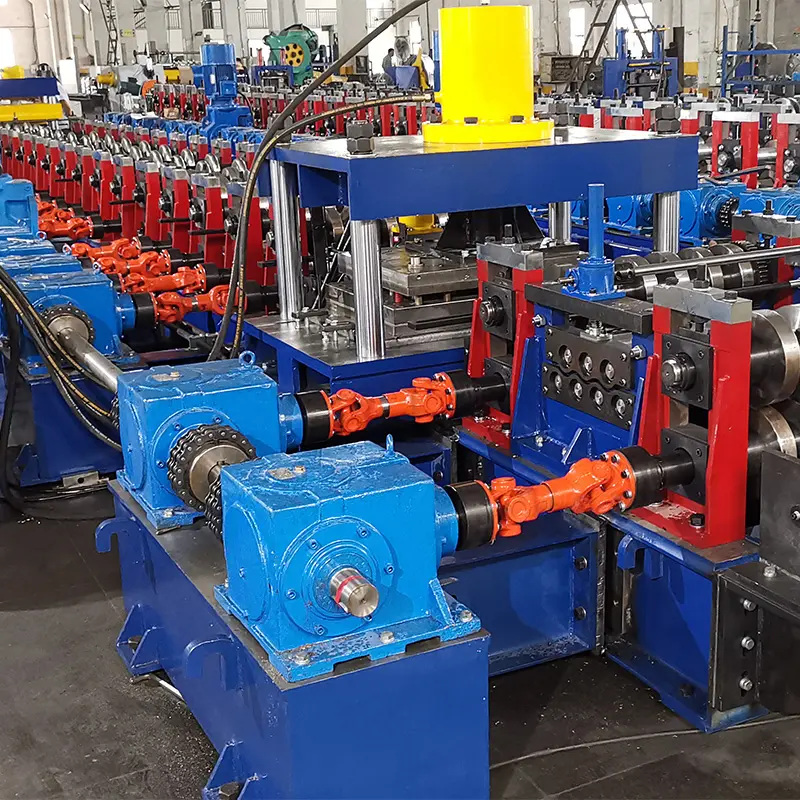

أ ماكينة تشكيل حواجز الحماية على الطرق السريعة هي جهاز متطور مصمم لتصنيع حواجز حماية فولاذية المستخدمة في حواجز السلامة على الطرق. هذه الآلات ضرورية لإنتاج حواجز أمان على شكل حرف W، وحواجز أمان ثلاثية، وحواجز أمان مخصصةضمان حماية عالية القوة ومتينة على جانب الطريق.

الميزات الرئيسية لآلات تشكيل حواجز الطرق السريعة

✅ إنتاج عالي السرعة – قادر على الإنتاج 10-30 متراً في الدقيقة.

✅ تشغيل أوتوماتيكي بالكامل – يتم التحكم فيه بواسطة PLC من أجل الدقة والكفاءة.

✅ ملفات تعريف قابلة للتخصيص - تنتج W-beam، thrie-beam، وتصميمات خاصة.

✅ هيكل متين - بنيت مع بكرات فولاذية عالية القوة وأنظمة قطع هيدروليكية.

✅ توافق الجلفنة بالغمس الساخن - يضمن مقاومة طويلة الأمد للتآكل.

سنغطي في هذا الدليل ما يلي:

✅ أنواع آلات تشكيل حواجز الطرق السريعة

✅ كيفية عمل عملية التشكيل بالدرفلة

✅ أفضل المواد المستخدمة في حواجز الطرق السريعة

✅ دليل تحليل التكاليف والتسعير

✅ أفضل الشركات المصنِّعة ولماذا تُعد Sunway Machine خيارًا موثوقًا به

هيا بنا نتعمق!

أنواع ماكينات تشكيل حواجز الحماية على الطرق السريعة

مختلفة ماكينات تشكيل الدرابزين تلبية احتياجات مختلفة احتياجات الإنتاج ومستويات الأتمتة.

1. آلة تشكيل لفائف حاجز الأمان W-Beam

- تنتج حواجز أمان قياسية على شكل حرف W (الأكثر استخدامًا في جميع أنحاء العالم).

- مثالية لـ تطبيقات السلامة على الطرق السريعة والطرق العامة.

2. آلة تشكيل حواجز الحماية ثلاثية العوارض

- ينشئ حواجز حماية أقوى وأعرض بثلاثة عوارض لـ المناطق عالية الخطورة.

- مناسب لـ الطرق السريعة والمناطق المعرضة للحوادث.

3. آلة تشكيل لفائف الحواجز الواقية المخصصة

- مصممة للتصنيع ملامح حواجز أمان مخصصة.

- مثالية لـ مشاريع السلامة المتخصصة والتطبيقات غير القياسية على الطرق.

4. آلة تشكيل حواجز الطرق السريعة الأوتوماتيكية بالكامل

- سمات أتمتة CNC لـ تعديلات سريعة على الملف الشخصي.

- الأفضل لـ إنتاج واسع النطاق وعالي الكفاءة.

ماكينة صنواي يوفر آلات تشكيل لفائف حواجز الطرق السريعة المخصصة مع ميزات الأتمتة المتقدمة.

كيف تعمل آلة تشكيل حواجز الطرق السريعة

ال عملية التشكيل بالدلفنة بالنسبة للحواجز الحامية يتضمن تشكيل لفائف فولاذية مسطحة تدريجياً في ملف تعريف حاجز أمان عالي القوة.

عملية تشكيل حواجز الطرق السريعة خطوة بخطوة

| الخطوة | الوصف |

|---|---|

| 1. التفكيك | يتم وضع لفائف الصلب على ديكويلر لتغذية المادة. |

| 2. التسوية والتغذية | الورقة هي تقويم وتوجيه في محطات التشكيل. |

| 3. التثقيب والقطع | يعمل النظام الهيدروليكي ثقب الورق لتركيب حاجز أمان. |

| 4. التشكيل بالدلفنة | تمر الورقة من خلال محطات أسطوانة متعددة, ، لتشكيل شكل الحاجز الواقي. |

| 5. القطع النهائي والإخراج | الحاجز المعدني المشكل هو قطع إلى الطول المطلوب ومكدسة. |

👉 نصيحة محترف: أ آلة تشكيل حواجز أمان مؤتمتة بالكامل يضمن دقة عالية، نفايات قليلة، وسرعات إنتاج أسرع.

أفضل المواد المستخدمة في حواجز الطرق السريعة

اختيار المادة الصحيحة يضمن القوة والمتانة ومقاومة التآكل.

مقارنة بين المواد المستخدمة في حواجز الطرق السريعة

| المواد | الخصائص | الأفضل لـ |

|---|---|---|

| الصلب المجلفن بالغمس الساخن | مقاومة للتآكل، عمر طويل | الطرق السريعة والطرق العادية |

| الفولاذ المدرفل على البارد | قوة عالية، تشطيب ناعم | الطرق والجسور الحضرية |

| الفولاذ المقاوم للصدأ | مقاومة للصدأ، متينة | مشاريع البنية التحتية المتطورة |

| سبائك الألومنيوم | خفيف الوزن ومقاوم للتآكل | المناطق ذات حركة المرور المنخفضة والتطبيقات الزخرفية |

ماكينة صنواي تصنع آلات تشكيل حواجز الحماية المتوافقة مع جميع مواد حواجز الطرق السريعة الرئيسية.

دليل أسعار آلة تشكيل حواجز الطرق السريعة

تكلفة ماكينة تشكيل حواجز الحماية على الطرق السريعة يعتمد على عوامل مثل مستوى الأتمتة وسرعة الإنتاج ونطاق الملف الشخصي.

النطاقات السعرية التقديرية لآلات تشكيل حواجز الطرق السريعة

| نوع الماكينة | نطاق السعر (بالدولار الأمريكي) | سمات |

|---|---|---|

| ماكينة يدوية | 30,000-30,000 - 30,000-60,000 | تعديلات يدوية، إنتاج بسرعة منخفضة |

| ماكينة نصف أوتوماتيكية | 60,000-60,000 - 60,000-120,000 | التحكم المنطقي القابل للبرمجة القابلة للبرمجة (PLC)، يتطلب تعديلات يدوية للملف الشخصي |

| ماكينة أوتوماتيكية بالكامل | 120,000–120,000 – 120,000–250,000 | التحكم باستخدام الحاسب الآلي، التبديل السريع للملف الشخصي |

| ماكينة عالية السرعة | 250,000–250,000 – 250,000–500,000 | أتمتة متقدمة، إنتاج عالي السرعة |

هل تبحث عن عرض أسعار مخصص؟ اتصل بصن واي ماشين اليوم!

أفضل مصنعي آلات تشكيل حواجز الطرق السريعة

اختيار مُصنِّع موثوق يضمن آلات عالية الجودة، ودعم طويل الأمد، وخدمة عالمية.

مقارنة بين الشركات الرائدة في تصنيع آلات تشكيل حواجز الطرق السريعة

| الشركة المصنعة | البلد | التخصص | الميزات الرئيسية |

|---|---|---|---|

| WUXI SUNWAY MACHINERY CO.، LTD | الصين | آلات تشكيل حواجز الطرق السريعة | تصميمات مخصصة، أتمتة عالية السرعة، آلات مزودة بتقنية إنترنت الأشياء |

| Dreistern GmbH | ألمانيا | التشكيل الدقيق للمعادن | ماكينات التحكم الرقمي باستخدام الحاسب الآلي، البحث والتطوير القوي |

| ماكينات سامكو | كندا | التشكيل بالدلفنة للبناء | الهندسة المخصصة، والأتمتة |

| مجموعة برادبري | الولايات المتحدة الأمريكية | أنظمة التشكيل بالدلفنة للخدمة الشاقة | آلات قوية، تركز على الأتمتة |

الحكم: إذا كنت تبحث عن آلة تشكيل حواجز الطرق السريعة عالية السرعة والفعالة من حيث التكلفة, ماكينة صنواي هو الخيار الأفضل للمشترين العالميين.

المشاكل الشائعة والحلول في آلات تشكيل حواجز الطرق السريعة

حتى مع آلات تشكيل لفائف حواجز الطرق السريعة عالية الجودة, ، بعض التحديات التشغيلية قد تنشأ، مثل اختلال محاذاة الأسطوانة، وتشوه المواد، وعدم دقة ثقب الثقوب. تحديد هذه المشاكل وحلها بسرعة ضروري للحفاظ على إنتاج فعال وحواجز حماية عالية الجودة.

دليل استكشاف الأعطال وإصلاحها لآلات تشكيل حواجز الطرق السريعة

| الإصدار | السبب المحتمل | الحل |

|---|---|---|

| حواجز أمان غير متوازنة أو ملتوية | اختلال محاذاة الأسطوانة، توزيع غير متساوٍ للضغط | تحقق من محاذاة الأسطوانة وإعدادات الضغط وقم بتعديلها |

| ثقب غير دقيق | نظام هيدروليكي معيب أو قوالب تثقيب غير محاذاة | افحص الضغط الهيدروليكي وأعد ضبط قوالب التثقيب |

| انزلاق المواد أثناء التشكيل | بكرات التغذية المفكوكة أو إعدادات الشد غير الصحيحة | أحكم ربط بكرات وحدة التغذية وضبط شد المواد |

| الاهتزاز المفرط للماكينة | براغي مفكوكة وأساس الماكينة غير مستقر | تأمين مكونات الماكينة وضمان ثبات التركيب |

| عدم دقة القطع | شفرات قطع بالية أو قواطع غير محاذاة | استبدل الشفرات البالية وقم بمحاذاة القواطع بشكل صحيح |

نصيحة محترف: روتين إعادة محاذاة الأسطوانة والتعديلات التي يتم إجراؤها بواسطة المحرك المؤازر يمكن أن يتحسن دقة الحاجز الواقي تصل إلى 30%.

الاتجاهات المستقبلية في آلات تشكيل حواجز الطرق السريعة

كما التقدم التكنولوجي, آلات تشكيل حواجز الطرق السريعة تصبح أذكى وأسرع وأكثر كفاءة. يقوم المصنعون بدمج الذكاء الاصطناعي وإنترنت الأشياء والأتمتة لتعزيز الإنتاجية ومراقبة الجودة.

الابتكارات الرئيسية في آلات تشكيل حواجز الطرق السريعة لعام 2025

1. فحص الجودة المدعوم بالذكاء الاصطناعي

- مدعوم بالذكاء الاصطناعي تكتشف المستشعرات العيوب في الوقت الفعلي, ، مما يقلل من النفايات.

- يحسن دقة واتساق إنتاج حواجز الأمان.

2. تكامل إنترنت الأشياء والمصانع الذكية

- تتميز الماكينات الآن بما يلي الاتصال السحابيتمكين التشخيص عن بُعد والصيانة التنبؤية.

- التحسينات المراقبة في الوقت الحقيقي والكفاءة التشغيلية.

3. تقنية التشكيل بالدلفنة المؤازرة

- يحسن التحكم في السرعة، وكفاءة الطاقة، والدقة.

- يقلل البلى على المكونات الميكانيكية, ، مما يطيل من عمر الماكينة.

4. تعديلات الملف الشخصي المؤتمتة بالكامل

- يزيل تعديلات يدوية عند التبديل بين ملفات تعريف الحواجز المختلفة.

- التحكم باستخدام الحاسب الآلي الرقمي تغييرات الملف الشخصي التلقائية تقليل وقت التعطل وتحسين الكفاءة.

يمكن أن يؤدي الترقية إلى آلات تشكيل حواجز الأمان المدعومة بالذكاء الاصطناعي إلى زيادة كفاءة الإنتاج بنسبة تصل إلى 50%!

تشكيل اللف مقابل الكبح بالضغط لحواجز الطرق السريعة

عند الاختيار بين تشكيل لفة و الضغط على الفرامليجب على المصنعين مراعاة ما يلي السرعة، هدر المواد، وكفاءة التكلفة.

مقارنة بين التشكيل باللف والضغط للكبح في حواجز الحماية

| الميزة | تشكيل لفة | الضغط على المكابح |

|---|---|---|

| سرعة الإنتاج | أسرع للملفات الشخصية الطويلة والمستمرة | أبطأ في الانحناءات المخصصة |

| النفايات المادية | الحد الأدنى من النفايات | ارتفاع خردة المواد |

| تكاليف الأدوات | استثمار أولي أعلى، تكلفة أقل على المدى الطويل | تكلفة أولية أقل، تكلفة تشغيلية أعلى |

| الأفضل لـ | إنتاج صناعي كبير الحجم، إنتاج صناعي كبير الحجم | مكونات معدنية مخصصة منخفضة الحجم |

الحكم: إذا كنت بحاجة إلى إنتاج مستمر عالي السرعة مع الحد الأدنى من النفايات, تشكيل حواجز الطرق السريعة هو الخيار الأفضل.

الأتمتة في آلات تشكيل حواجز الطرق السريعة

الأتمتة هي التحويل عملية التصنيع، صناعة آلات تشكيل اللفائف أذكى وأسرع وأكثر فعالية من حيث التكلفة.

المزايا الرئيسية لآلات تشكيل حواجز الطرق السريعة الآلية

| الميزة | المزايا |

|---|---|

| أنظمة التحكم PLC و CNC | يضمن دقة القياسات وتقليل الأخطاء البشرية |

| الكشف عن العيوب المستند إلى الذكاء الاصطناعي | تحديد المشكلات في الوقت الحقيقي، مما يقلل من هدر المواد |

| إنترنت الأشياء والمراقبة عن بُعد | يسمح للمشغلين بتتبع أداء الماكينة من أي مكان |

| التبديل الآلي للملف الشخصي | تقليل وقت التعطل عند التبديل بين الملفات الشخصية |

| المحركات المؤازرة الموفرة للطاقة | خفض التكاليف التشغيلية وتحسين الاستدامة |

آلات تشكيل حواجز الطرق السريعة المؤتمتة بالكامل من ماكينة صنواي تحسين كفاءة الإنتاج بنسبة تصل إلى 40%!

نصائح أساسية لصيانة آلات تشكيل حواجز الطرق السريعة

تضمن الصيانة السليمة عمر افتراضي أطول للماكينة وإنتاج غير منقطع.

قائمة مراجعة الصيانة لآلات تشكيل حواجز الطرق السريعة

| المهمة | التردد | الغرض |

|---|---|---|

| تشحيم البكرات والمحامل | أسبوعياً | يمنع البلى والتلف |

| افحص محاذاة الأسطوانة | شهرياً | يضمن إنتاج ملف تعريف دقيق |

| فحص آلية القطع | ربع سنوي | يمنع الجروح المعيبة والمحاذاة الخاطئة |

| تنظيف مكونات الماكينة | يومياً | يزيل الغبار والحطام الذي يمكن أن يؤثر على الأداء |

| تحديث البرامج والمعايرة | نصف سنويًا | يحافظ على تحسين وظائف الأتمتة |

نصيحة محترف: يمكن للصيانة المجدولة أن إطالة عمر الماكينة بمقدار 50% و تقليل حالات الفشل بنسبة 70%.

الأسئلة الشائعة: آلات تشكيل حواجز الطرق السريعة

1. ما هي السرعة التي يمكن أن تنتج بها آلة تشكيل حواجز الطرق السريعة حواجز الطرق؟

يمكن أن تنتج النماذج عالية السرعة ما يصل إلى 30 متراً في الدقيقة، اعتماداً على الملف الشخصي.

2. ما هي أنواع حواجز الحماية التي يمكن إنتاجها؟

يمكن لمعظم الآلات إنتاج مقاطع W-beam و thrie-beam و مقاطع حواجز أمان مخصصة.

3. كم تكلف آلة تشكيل حواجز الطرق السريعة؟

يتراوح السعر من 30,000 للنماذج الأساسية∗∗ إلى∗∗30,000 للنماذج الأساسية** إلى **30,000 للنماذج الأساسية∗∗ إلى∗∗500,000 للأنظمة المؤتمتة بالكامل.

4. ما هي المواد التي يمكن استخدامها في آلات تشكيل حواجز الطرق السريعة؟

تشمل المواد الشائعة ما يلي الفولاذ المجلفن بالغمس الساخن، الفولاذ المدلفن على البارد، الفولاذ المقاوم للصدأ، وسبائك الألومنيوم.

5. أين يمكنني شراء آلة تشكيل لفائف حواجز الطرق السريعة عالية الجودة؟

ل آلات تشكيل حواجز الطرق السريعة عالية السرعة المصممة خصيصًاقم بزيارة WUXI SUNWAY MACHINERY CO.، LTD.

الأفكار النهائية

الاستثمار في ماكينة تشكيل حواجز الحماية على الطرق السريعة ضروري ل إنتاج حواجز أمان فعالة وعالية الجودة. سواء كنت بحاجة إلى نظام قياسي أو مؤتمت بالكاملاختيار الشركة المصنعة الموثوق بها يضمن الموثوقية والربحية على المدى الطويل.

WUXI SUNWAY MACHINERY CO.، LTD هو شركة عالمية رائدة في مجال التصنيع من آلات تشكيل حواجز الطرق السريعة المصممة خصيصًاتقدم تكنولوجيا متقدمة، ودعم الخبراء، وأسعار تنافسية.

تريد آلة تشكيل لفائف حواجز الطرق السريعة المخصصة؟ اتصل بنا اليوم!