نظرة عامة على ماكينات تشكيل صينية الكابلات

أ آلة تشكيل لفة علبة الكابلات هي معدات متخصصة مصممة لتصنيع metal cable trays, which are used for supporting and organizing electrical cables in buildings, industrial plants, and data centers. These machines produce perforated, ladder-type, and solid-bottom cable trays مع high efficiency and precision.

الملامح الرئيسية لماكينات تشكيل صينية الكابلات

✅ تشغيل أوتوماتيكي بالكامل – يتم التحكم فيه بواسطة PLC من أجل precision and high efficiency.

✅ ملفات تعريف قابلة للتخصيص - تنتج perforated, ladder, and solid-bottom cable trays.

✅ إنتاج عالي السرعة – قادر على الإنتاج 10-30 متراً في الدقيقة.

✅ Durable construction - الاستخدامات hardened steel rollers and hydraulic cutting systems.

✅ Integrated punching system - التمكين hole perforation for easy cable management.

سنغطي في هذا الدليل ما يلي:

✅ Types of cable tray roll forming machines

✅ كيفية عمل عملية التشكيل بالدرفلة

✅ Best materials for cable trays

✅ دليل تحليل التكاليف والتسعير

✅ أفضل الشركات المصنِّعة ولماذا تُعد Sunway Machine خيارًا موثوقًا به

هيا بنا نتعمق!

أنواع ماكينات تشكيل صينية الكابلات

مختلفة ماكينات تشكيل علبة الكابلات تلبية احتياجات مختلفة احتياجات الإنتاج ومستويات الأتمتة.

1. Perforated Cable Tray Roll Forming Machine

- تنتج perforated trays مع pre-punched holes for ventilation.

- مثالية لـ high-heat environments where airflow is necessary.

2. Ladder Cable Tray Roll Forming Machine

- ينشئ ladder-type trays مع rung supports for heavy cables.

- الأفضل لـ industrial and power plant applications.

3. Solid-Bottom Cable Tray Roll Forming Machine

- المصنوعات solid-bottom trays لـ complete cable protection.

- مناسب لـ data centers and hazardous environments.

4. Fully Automatic Cable Tray Roll Forming Machine

- سمات أتمتة CNC لـ quick profile changes.

- مثالية لـ إنتاج واسع النطاق وعالي الكفاءة.

ماكينة صنواي يوفر customized cable tray roll forming machines مع ميزات الأتمتة المتقدمة.

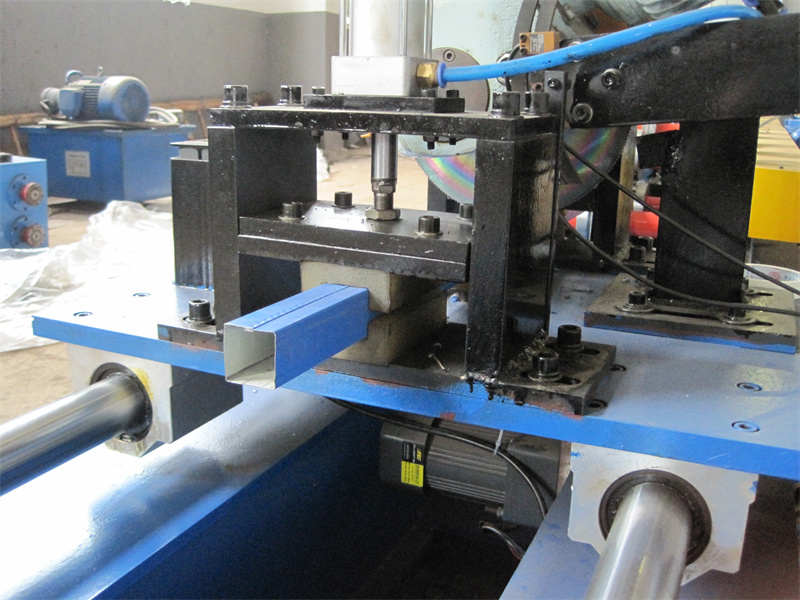

How Cable Tray Roll Forming Works

ال عملية التشكيل بالدلفنة for cable trays involves gradually shaping a flat metal sheet في high-strength cable support structure.

Step-by-Step Cable Tray Roll Forming Process

| الخطوة | الوصف |

|---|---|

| 1. التفكيك | يوضع الملف المعدني على ديكويلرتلقيم المواد في الماكينة. |

| 2. التسوية والتغذية | الورقة هي تقويم وتوجيه في محطات التشكيل. |

| 3. التثقيب والقطع | يعمل النظام الهيدروليكي ثقب الورق for cable management. |

| 4. التشكيل بالدلفنة | تمر الورقة من خلال محطات أسطوانة متعددة, forming the cable tray shape. |

| 5. Final Cutting & Stacking | The formed cable tray is قطع إلى الطول المطلوب وتكدس للشحن. |

نصيحة محترف: أ fully automated cable tray roll forming machine يضمن دقة عالية، نفايات قليلة، وسرعات إنتاج أسرع.

Best Materials for Cable Trays

اختيار المادة الصحيحة يضمن strength, corrosion resistance, and durability.

Comparison of Materials for Cable Trays

| المواد | الخصائص | الأفضل لـ |

|---|---|---|

| الفولاذ المجلفن (GI) | Corrosion-resistant, cost-effective | Standard electrical installations |

| الفولاذ المقاوم للصدأ (SS) | High strength, rust-proof | Industrial and outdoor applications |

| سبائك الألومنيوم | خفيف الوزن ومقاوم للتآكل | Data centers & IT infrastructure |

| فولاذ مطلي بالمسحوق | Aesthetic finish, durable | المباني التجارية |

ماكينة صنواي تصنع ماكينات التشكيل بالدرفلة المتوافقة مع all major cable tray materials.

Cable Tray Roll Forming Machine Price Guide

تكلفة آلة تشكيل لفة علبة الكابلات يعتمد على عوامل مثل مستوى الأتمتة وسرعة الإنتاج ونطاق الملف الشخصي.

Estimated Price Ranges for Cable Tray Roll Forming Machines

| نوع الماكينة | نطاق السعر (بالدولار الأمريكي) | سمات |

|---|---|---|

| ماكينة يدوية | 20,000–20,000 – 20,000–50,000 | تعديلات يدوية، إنتاج بسرعة منخفضة |

| ماكينة نصف أوتوماتيكية | 50,000-50,000 - 50,000-100,000 | التحكم المنطقي القابل للبرمجة القابلة للبرمجة (PLC)، يتطلب تعديلات يدوية للملف الشخصي |

| ماكينة أوتوماتيكية بالكامل | 100,000–100,000 – 100,000–250,000 | التحكم باستخدام الحاسب الآلي، التبديل السريع للملف الشخصي |

| ماكينة عالية السرعة | 250,000–250,000 – 250,000–500,000 | أتمتة متقدمة، إنتاج عالي السرعة |

هل تبحث عن عرض أسعار مخصص؟ اتصل بصن واي ماشين اليوم!

Top Cable Tray Roll Forming Machine Manufacturers

اختيار مُصنِّع موثوق يضمن آلات عالية الجودة، ودعم طويل الأمد، وخدمة عالمية.

Comparison of Leading Cable Tray Roll Forming Machine Manufacturers

| الشركة المصنعة | البلد | التخصص | الميزات الرئيسية |

|---|---|---|---|

| WUXI SUNWAY MACHINERY CO.، LTD | الصين | آلات التشكيل باللف لصواني الكابلات | تصميمات مخصصة، أتمتة عالية السرعة، آلات مزودة بتقنية إنترنت الأشياء |

| Dreistern GmbH | ألمانيا | التشكيل الدقيق للمعادن | ماكينات التحكم الرقمي باستخدام الحاسب الآلي، البحث والتطوير القوي |

| ماكينات سامكو | كندا | التشكيل بالدلفنة للبناء | الهندسة المخصصة، والأتمتة |

| مجموعة برادبري | الولايات المتحدة الأمريكية | أنظمة التشكيل بالدلفنة للخدمة الشاقة | آلات قوية، تركز على الأتمتة |

الحكم: إذا كنت تبحث عن cost-effective, high-speed cable tray roll forming machine, ماكينة صنواي هو الخيار الأفضل للمشترين العالميين.

Common Problems & Solutions in Cable Tray Roll Forming Machines

Even the most advanced cable tray roll forming machines can encounter operational challenges, such as roller misalignment, material deformation, and inaccurate perforation. معالجة هذه المشكلات بشكل استباقي يضمن smooth production and high-quality cable trays.

دليل استكشاف الأخطاء وإصلاحها

| الإصدار | السبب المحتمل | الحل |

|---|---|---|

| Distorted or Uneven Cable Trays | اختلال محاذاة الأسطوانة، إعدادات ضغط غير صحيحة | Adjust roller alignment and ensure uniform pressure distribution |

| انزلاق المواد أثناء التشكيل | بكرات التغذية المفكوكة وإعدادات الشد غير الصحيحة | أحكم ربط بكرات وحدة التغذية وضبط شد المواد |

| ثقب غير دقيق | Faulty hydraulic system, misaligned punching dies | افحص الضغط الهيدروليكي وأعد ضبط قوالب التثقيب |

| الاهتزاز المفرط للماكينة | براغي مفكوكة وأساس الماكينة غير مستقر | تأمين مكونات الماكينة وضمان ثبات التركيب |

| عدم دقة القطع | Dull cutting blades, misaligned cutters | استبدل الشفرات البالية وقم بمحاذاة القواطع بشكل صحيح |

نصيحة محترف: عادي إعادة محاذاة الأسطوانة والتعديلات التي يتم إجراؤها بواسطة المحرك المؤازر يمكن أن يتحسن cable tray accuracy by 30%.

Future Trends in Cable Tray Roll Forming Machines

ال الصناعة التحويلية is evolving, and ماكينات تشكيل علبة الكابلات are integrating الذكاء الاصطناعي وإنترنت الأشياء والأتمتة لتعزيز الكفاءة والدقة والاستدامة.

الابتكارات الرئيسية

1. مراقبة الجودة القائمة على الذكاء الاصطناعي

- مدعوم بالذكاء الاصطناعي تكتشف المستشعرات العيوب في الوقت الفعليتقليل نفايات المواد.

- يحسن product accuracy and minimizes rejection rates.

2. تكامل إنترنت الأشياء والمصانع الذكية

- تتميز الماكينات الآن بما يلي المراقبة المستندة إلى السحابةالسماح التشخيص في الوقت الحقيقي والصيانة التنبؤية.

- التحسينات تتبع الإنتاج والكفاءة التشغيلية.

3. تقنية التشكيل بالدلفنة المؤازرة

- التحسينات التحكم في السرعة، والدقة، وكفاءة الطاقة.

- يقلل البلى على المكونات الميكانيكية, increasing lifespan.

4. تعديلات الملف الشخصي المؤتمتة بالكامل

- يزيل تعديلات يدوية when switching between different cable tray profiles.

- التحكم باستخدام الحاسب الآلي الرقمي تغييرات الملف الشخصي التلقائية تقليل وقت التعطل وتحسين الكفاءة.

Upgrading to AI-powered cable tray roll forming machines can increase production efficiency by up to 50%!

Roll Forming vs. Press Braking for Cable Tray Production

يجب على الشركات المصنعة تقييم سرعة الإنتاج، وهدر المواد، وكفاءة التكلفة عند الاختيار بين التشكيل بالدلفنة والكبح بالكبس for cable tray production.

Comparison Between Roll Forming and Press Braking for Cable Trays

| الميزة | تشكيل لفة | الضغط على المكابح |

|---|---|---|

| سرعة الإنتاج | أسرع للملفات الشخصية الطويلة والمستمرة | أبطأ في الانحناءات المخصصة |

| النفايات المادية | الحد الأدنى من النفايات | ارتفاع خردة المواد |

| تكاليف الأدوات | استثمار أولي أعلى، تكلفة أقل على المدى الطويل | تكلفة أولية أقل، تكلفة تشغيلية أعلى |

| الأفضل لـ | إنتاج صناعي كبير الحجم، إنتاج صناعي كبير الحجم | مكونات معدنية مخصصة منخفضة الحجم |

الحكم: إذا كنت بحاجة إلى إنتاج مستمر عالي السرعة مع الحد الأدنى من النفايات, cable tray roll forming is the better choice.

Automation in Cable Tray Roll Forming Machines

الأتمتة هي إحداث ثورة عملية التصنيع، صناعة آلات تشكيل اللفائف أذكى وأسرع وأكثر كفاءة.

المزايا الرئيسية

| الميزة | المزايا |

|---|---|

| أنظمة التحكم PLC و CNC | يضمن دقة القياسات وتقليل الأخطاء البشرية |

| الكشف عن العيوب المستند إلى الذكاء الاصطناعي | تحديد المشكلات في الوقت الحقيقي، مما يقلل من هدر المواد |

| إنترنت الأشياء والمراقبة عن بُعد | يسمح للمشغلين بتتبع أداء الماكينة من أي مكان |

| التبديل الآلي للملف الشخصي | تقليل وقت التعطل عند التبديل بين الملفات الشخصية |

| المحركات المؤازرة الموفرة للطاقة | خفض التكاليف التشغيلية وتحسين الاستدامة |

Fully automated cable tray roll forming machines from ماكينة صنواي تحسين كفاءة الإنتاج بنسبة تصل إلى 40%!

Essential Maintenance Tips for Cable Tray Roll Forming Machines

مناسب الصيانة يضمن عمر أطول للماكينة و جودة إنتاج متسقة.

قائمة التحقق من الصيانة

| المهمة | التردد | الغرض |

|---|---|---|

| تشحيم البكرات والمحامل | أسبوعياً | يمنع البلى والتلف |

| افحص محاذاة الأسطوانة | شهرياً | يضمن إنتاج ملف تعريف دقيق |

| فحص آلية القطع | ربع سنوي | يمنع الجروح المعيبة والمحاذاة الخاطئة |

| تنظيف مكونات الماكينة | يومياً | يزيل الغبار والحطام الذي يمكن أن يؤثر على الأداء |

| تحديث البرامج والمعايرة | نصف سنويًا | يحافظ على تحسين وظائف الأتمتة |

نصيحة محترف: يمكن للصيانة المجدولة أن إطالة عمر الماكينة بمقدار 50% و تقليل حالات الفشل بنسبة 70%.

التعليمات

1. How fast can a cable tray roll forming machine produce trays?

يمكن أن تنتج النماذج عالية السرعة ما يصل إلى 30 متراً في الدقيقة، اعتماداً على الملف الشخصي.

2. What cable tray profiles can be produced?

يمكن لمعظم الآلات إنتاج perforated, ladder, and solid-bottom cable trays.

3. How much does a cable tray roll forming machine cost?

يتراوح السعر من 20,000forbasicmodels∗∗to∗∗20,000 for basic models** to **20,000forbasicmodels∗∗to∗∗500,000 for fully automated systems.

4. What materials can be used in cable tray roll forming machines?

تشمل المواد الشائعة ما يلي galvanized steel, stainless steel, aluminum, and powder-coated steel.

5. Where can I buy a high-quality cable tray roll forming machine?

ل custom-built, high-speed cable tray roll forming machinesقم بزيارة WUXI SUNWAY MACHINERY CO.، LTD.

الأفكار النهائية

الاستثمار في آلة تشكيل لفة علبة الكابلات ضروري ل efficient, high-quality cable tray production. سواء كنت بحاجة إلى نظام قياسي أو مؤتمت بالكاملاختيار الشركة المصنعة الموثوق بها يضمن الموثوقية والربحية على المدى الطويل.

WUXI SUNWAY MACHINERY CO.، LTD هو شركة عالمية رائدة في مجال التصنيع من custom-built cable tray roll forming machinesتقدم تكنولوجيا متقدمة، ودعم الخبراء، وأسعار تنافسية.

تريد custom cable tray roll forming machine? اتصل بنا اليوم!