صفائح الكسوة الصندوقية أصبحت شائعة بشكل متزايد في البناء الحديث بسبب متانتها وتعدد استخداماتها وفعاليتها من حيث التكلفة. يتعمق هذا الدليل في كل ما تحتاج إلى معرفته حول ألواح الكسوة الصندوقية - بدءًا من أنواعها وتطبيقاتها وعملية تركيبها وحتى المقارنات مع خيارات الكسوة الأخرى. في النهاية، ستحصل على جميع التفاصيل اللازمة لاتخاذ قرار مستنير.

ما هي صفائح الكسوة الصندوقية؟

صفائح الكسوة الصندوقية هي صفائح معدنية مموجة متينة تستخدم كطبقات واقية وجمالية للمباني. وعادةً ما تكون مصنوعة من الفولاذ أو الألومنيوم، وتتميز هذه الألواح بمظهر مضلع "صندوقي"، مما يوفر سلامة هيكلية معززة ومظهر عصري. تُستخدم على نطاق واسع في الأسقف وكسوة الجدران في المباني الصناعية والتجارية والزراعية.

لماذا تختار صفائح الكسوة الصندوقية؟

تُفضّل ألواح الكسوة الصندوقية بسبب نسبة قوتها العالية إلى وزنها، وطول عمرها، ومتطلبات الصيانة المنخفضة. وهي متوفرة في مختلف أنواع المعادن والتشطيبات، ويمكنها أن تتناسب مع مختلف الأنماط المعمارية وتتحمل الظروف البيئية الصعبة.

أنواع صفائح تكسية الصناديق الجانبية الصندوقية

ينطوي اختيار لوح الكسوة الصندوقي المناسب على فهم الأنواع المتاحة وكيفية اختلافها. دعنا نستكشف بعض النماذج والمواد الشائعة واستخداماتها المحددة.

| نوع صفيحة الكسوة الصندوقية | المواد | ارتفاع الضلع (مم) | السُمك (مم) | أفضل حالة استخدام |

|---|---|---|---|---|

| BPC 32/1000 | الفولاذ المجلفن | 32 | 0.5-1.2 | المباني الزراعية |

| BPC 40/1000 | فولاذ مطلي مسبقاً | 40 | 0.5-1.2 | كسوة الجدران الصناعية |

| BPC 45/1000 | ألومنيوم | 45 | 0.5-1.0 | التطبيقات الساحلية |

| بي بي سي 50/1000 | الفولاذ المقاوم للصدأ | 50 | 0.6-1.5 | البيئات عالية الرطوبة |

| بي بي سي 55/1000 | زنك مطلي بالألوان | 55 | 0.7-1.2 | التسقيف التجاري على نطاق واسع |

| BPC 60/1000 | زنكالوم | 60 | 0.8-1.3 | المستودعات ومرافق التخزين |

| BPC 65/1000 | جالفالوم | 65 | 0.7-1.4 | المشاريع السكنية |

| BPC 70/1000 | النحاس | 70 | 0.8-1.0 | المشاريع المعمارية الراقية |

| بي بي سي 75/1000 | فولاذ مطلي بالمسحوق | 75 | 0.9-1.2 | التطبيقات الصناعية الثقيلة |

| BPC 80/1000 | فولاذ مطلي | 80 | 0.6-1.2 | الكسوة التجارية متعددة الاستخدامات |

صفائح الحديد المموج مقابل صفائح الحديد المموج صفائح الكسوة الصندوقية

في حين أن كلاً من صفائح الحديد المموج وألواح التكسية الصندوقية تخدم أغراضًا متشابهة، إلا أنها تختلف في التصميم والتطبيق. تتميز الصفائح المموجة بمظهر جانبي متموج، مما قد يوفر المرونة ولكنه يفتقر إلى الصلابة الهيكلية للصفائح الصندوقية. وعلى النقيض من ذلك صفائح التشكيل الجانبي الصندوقية أكثر ثباتاً وتوفر قدرات تحمل أفضلمما يجعلها مناسبة للاستخدامات الصناعية والزراعية القوية.

مقارنة الميزات الرئيسية

| الميزة | صفائح مموجة | صفائح الكسوة الصندوقية |

|---|---|---|

| الصلابة الهيكلية | معتدل | عالية |

| سعة التحميل | أقل | أعلى |

| المظهر | تقليدي | عصري |

| تعقيد التركيب | أسهل | معتدل |

| الأفضل لـ | تطبيقات خفيفة الوزن | احتياجات شديدة التحمل وطويلة الأمد |

عملية عمل صفائح تكسية الصناديق الجانبية الصندوقية

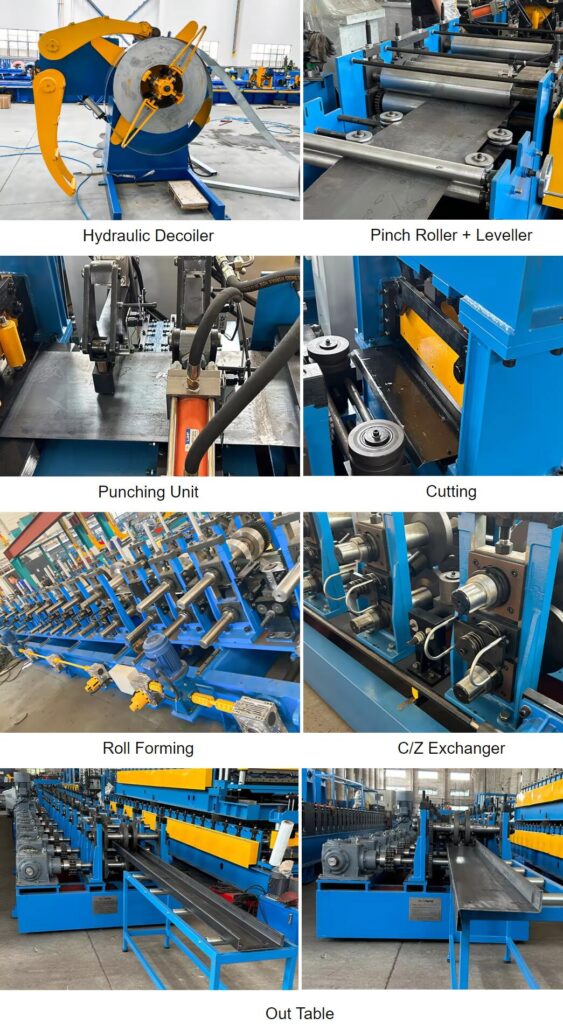

تنطوي عملية تصنيع ألواح التكسية الصندوقية على تقطيع وتمويج وطلاء المعدن لضمان طول العمر ومقاومة الطقس. تضمن هذه العملية التدريجية الحصول على منتج عالي الجودة:

- اختيار المعادن: تبدأ العملية باختيار المعدن المناسب (مثل الفولاذ المجلفن والألومنيوم) بناءً على الاستخدام النهائي.

- عملية التمويج: يتم تغذية الصفائح المعدنية من خلال بكرات لتحقيق الحواف المميزة التي تشبه الصندوق.

- الطلاء والتشطيب: وأخيرًا، يتم طلاء الصفائح بطبقات نهائية واقية، والتي قد تشمل الطلاء بالمسحوق أو الربط بالألوان أو الجلفنة، حسب المتطلبات.

المكونات الرئيسية ووظائفها

| المكوّن | الوظيفة |

|---|---|

| المعدن الأساسي | يوفر القوة الأساسية للورقة |

| الطلاء الواقي | يعزز مقاومة التآكل |

| تصميم ملف تعريف الصندوق | يضيف السلامة الهيكلية والجاذبية البصرية |

| ارتفاع الضلع | يؤثر على قدرة التحميل وتصريف المياه |

| نقاط التثبيت | تثبت الشراشف في مكانها وتمنع حركتها |

-

آلة تشكيل لوحة النقل

آلة تشكيل لوحة النقل -

ماكينة تشكيل الطرفية الطرفية لحاجز الحماية على الطريق السريع

ماكينة تشكيل الطرفية الطرفية لحاجز الحماية على الطريق السريع -

ماكينة تشكيل الأعمدة على الطريق السريع U/C

ماكينة تشكيل الأعمدة على الطريق السريع U/C -

2 ماكينة تشكيل حواجز الحماية على الطرق السريعة ذات الموجات 2

2 ماكينة تشكيل حواجز الحماية على الطرق السريعة ذات الموجات 2 -

3 ماكينات تشكيل حواجز الحماية للطرق السريعة ذات 3 موجات

3 ماكينات تشكيل حواجز الحماية للطرق السريعة ذات 3 موجات -

آلة التشكيل بالدلفنة لكروم العنب

آلة التشكيل بالدلفنة لكروم العنب -

آلة تشكيل لفة Sigma Purlin قابلة للتغيير ذات الحجم الأوتوماتيكي

آلة تشكيل لفة Sigma Purlin قابلة للتغيير ذات الحجم الأوتوماتيكي -

آلة تشكيل القوائم CZ القابلة للتغيير ذات الحجم الأوتوماتيكي

آلة تشكيل القوائم CZ القابلة للتغيير ذات الحجم الأوتوماتيكي -

آلة تشكيل القوائم Z القابلة للتغيير بالحجم الأوتوماتيكي

آلة تشكيل القوائم Z القابلة للتغيير بالحجم الأوتوماتيكي

سرعة الماكينة وكفاءتها

عند إنتاج صفائح الكسوة الصندوقية، فإن الكفاءة هي المفتاح. تتيح الماكينات الحديثة إنتاجاً عالي السرعة دون التضحية بالجودة.

| نوع الماكينة | سرعة الإنتاج (م/دقيقة) | الكفاءة |

|---|---|---|

| أداة التشكيل بالدلفنة القياسية | 15-25 | معتدل |

| آلة التشكيل بالدلفنة عالية السرعة | 30-40 | عالية |

| آلة التشكيل الآلي بالليزر | 40-50 | عالية جداً |

تطبيقات واستخدامات صفائح الكسوة الصندوقية

تُستخدم ألواح الكسوة الصندوقية على نطاق واسع في العديد من الصناعات نظرًا لقوتها وتعدد استخداماتها.

| طلب | حالة الاستخدام |

|---|---|

| الأسقف الصناعية | المصانع والمستودعات |

| الكسوة الزراعية | الحظائر وملاجئ الماشية |

| المشاريع السكنية | المنازل الحديثة والمرائب |

| المباني التجارية | مراكز البيع بالتجزئة والمباني المكتبية |

| البيئات عالية الرطوبة | حمامات السباحة ومباني المنتجعات الصحية |

تركيب وتشغيل وصيانة صفائح التكسية الصندوقية وتشغيلها وصيانتها

إن التركيب والصيانة المناسبين ضروريان لطول عمر ألواح التكسية الصندوقية.

| العملية | تفاصيل |

|---|---|

| التركيب | يتطلب مثبتات متخصصة ومحاذاة دقيقة |

| العملية | تشغيل الماكينات بالسرعات الموصى بها للسلامة |

| الصيانة | التنظيف المنتظم، خاصة في المناطق الساحلية أو الملوثة |

اختيار المورد المناسب لصفائح تكسية الصناديق الجانبية

يتضمن اختيار المورد عدة اعتبارات، مثل جودة المنتج وسرعة التسليم وخدمة العملاء. إليك دليل لمساعدتك في الاختيار:

| معايير الموردين | الأهمية | ما أهمية ذلك |

|---|---|---|

| جودة المواد | عالية جداً | يضمن المتانة والموثوقية |

| الجداول الزمنية للتسليم | عالية | يقلل من التأخير في المشروع |

| دعم العملاء | معتدل | تقديم المساعدة اللازمة في حالة وجود مشاكل |

| نطاق السعر | عالية | يساعدك على البقاء في حدود الميزانية |

مقارنة إيجابيات وسلبيات صفائح الكسوة الصندوقية

| أسبكت | المزايا | العيوب |

|---|---|---|

| المتانة | متانة عالية، وتتحمل المناخات القاسية | أثقل مقارنة ببعض المواد |

| التكلفة | فعالة من حيث التكلفة مقارنة بالبدائل | قد يتطلب التركيب الأولي خبرة |

| الخيارات الجمالية | مظهر عصري، متوفر بتشطيبات مختلفة | مرونة محدودة في التصميم |

الأسئلة الشائعة

| سؤال | الإجابة |

|---|---|

| ما هو متوسط العمر الافتراضي لصفيحة الكسوة الصندوقية؟ | عادةً ما تكون 20-30 سنة، حسب الصيانة والظروف البيئية |

| هل هذه الصفائح مناسبة للمناطق الساحلية؟ | نعم، خاصةً أنواع الألومنيوم والفولاذ المطلي |

| هل يمكن تخصيص أوراق ملف تعريف الصندوق؟ | نعم، يمكن طلبها بمقاسات وألوان وتشطيبات مخصصة |

| هل تتطلب أي صيانة خاصة؟ | يوصى بالتنظيف والفحص المنتظم، خاصة في البيئات المالحة |