مقدمة

هل تفكر في شراء ماكينة التشكيل بالدلفنة المستعملة لتوفير المال أثناء توسيع طاقتك الإنتاجية؟ يختار العديد من المصنعين ماكينات التشكيل بالدلفنة المستعملة لتخفيض التكاليف الأولية، ولكن هل هو حقًا الاستثمار الذكي?

شراء ماكينة التشكيل بالدرفلة المملوكة مسبقًا يمكن أن يكون بديل فعال من حيث التكلفة إذا كنت تعرف ما الذي تبحث عنه. ومع ذلك، هناك أيضًا المخاطر التي تنطوي عليهامثل العيوب الخفية والتكنولوجيا القديمة وتكاليف الصيانة المرتفعة.

سنغطي في هذا الدليل ما يلي:

✅ مزايا وعيوب شراء ماكينة تشكيل بالدلفنة مستعملة

✅ مكان شراء ماكينات تشكيل اللفائف المستعملة عالية الجودة

✅ كيفية فحص وتقييم ماكينة التشكيل بالدلفنة المستعملة قبل الشراء

✅ مقارنة التكلفة: ماكينات التشكيل بالدرفلة الجديدة مقابل المستعملة

✅ الأخطاء الشائعة التي يجب تجنبها عند شراء آلات مستعملة

دعونا نستكشف ما إذا كان ماكينة التشكيل بالدلفنة المستعملة هو الخيار المناسب لعملك!

مزايا شراء ماكينة التشكيل بالدرفلة المستعملة

شراء ماكينة التشكيل بالدلفنة المستعملة العديد من الفوائد، بما في ذلك

1. استثمار أولي أقل

✅ تكلف ماكينة التشكيل بالدلفنة المستعملة عادةً 30-50% أقل من واحدة جديدة.

✅ مثالي لـ الشركات الناشئة وصغار المصنعين تتطلع إلى توسيع الإنتاج بميزانية محدودة

2. توافر أسرع

✅ على عكس الماكينات الجديدة التي تحتوي على مهلة التصنيع من 2-6 أشهر،الماكينات المستعملة هي متاح على الفور.

✅ يساعد الأعمال التجارية زيادة الإنتاج بسرعة دون انتظار.

3. أداء مثبت

✅ تحتوي بعض الماكينات المستعملة على سجل حافل بالموثوقيةمما يجعلها استثماراً أكثر أماناً.

✅ غالبًا ما تتم صيانتها جيدًا من قبل المالكين السابقين، مما يضمن استمرار الكفاءة.

4. صديقة للبيئة

✅ شراء المعدات المستعملة تقليل النفايات وتعزيز الاستدامة في التصنيع.

نصيحة محترف: يمكن لماكينة التشكيل بالدلفنة المستعملة التي تتم صيانتها جيدًا أن تستمر في تقديم إنتاج عالي الجودة لمدة 5-10 سنوات أخرى!

عيوب شراء ماكينة تشكيل بالدلفنة مستعملة

في حين أن ماكينة التشكيل بالدرفلة المملوكة مسبقًا يمكن أن توفر المال، وهناك أيضًا الجوانب السلبية المحتملة للنظر فيها.

1. ارتفاع تكاليف الصيانة

❌ قد تحتوي الماكينات القديمة على البكرات أو شفرات القطع أو المحركات الباليةمما يؤدي إلى ارتفاع تكاليف الإصلاح.

❌ قد تكون قطع الغيار يصعب العثور عليهازيادة وقت التوقف عن العمل.

2. تكنولوجيا عفا عليها الزمن

❌ قد تفتقر الماكينات المستعملة إلى الأتمتة الحديثة، والمحركات المؤازرة، وأنظمة التحكم PLCتقليل الإنتاجية

❌ الموديلات الأحدث أكثر كفاءة في استهلاك الطاقةتوفير التكاليف التشغيلية على المدى الطويل.

3. لا يوجد ضمان أو دعم محدود

❌ ❌ على عكس الماكينات الجديدة التي تأتي مع الضمان والدعم الفني، غالبًا ما تحتوي الماكينات المستعملة على لا توجد ضمانات.

❌ إذا تعطل الجهاز، قد تضطر إلى دفع تكاليف جميع الإصلاحات بنفسك.

4. العيوب الخفية والاهتراء

❌ بعض البائعين لا تكشف عن مشكلات الماكينةمما يؤدي إلى أعطال غير متوقعة.

❌ دائمًا افحص الماكينة جيدًا قبل الشراء.

نصيحة محترف: إذا كانت تكلفة الإصلاحات أكثر من نصف سعر الجهاز الجديد، فقد لا يكون شراء المستعمل يستحق العناء!

من أين تشتري ماكينات التشكيل بالدرفلة المستعملة عالية الجودة؟

العثور على مصدر موثوق لماكينات التشكيل بالدلفنة المستعملة أمر بالغ الأهمية. فيما يلي أفضل الأماكن لشراء ماكينات التشكيل بالدلفنة المستعملة:

1. مباشرة من المصنعين

✅ بعض الشركات المصنعة، مثل آلات WUXI SUNWAYعرض ماكينات التشكيل بالدلفنة المجددة مع فحوصات الجودة والضمانات المحدودة.

✅ الماكينات تم فحصها وإصلاحها واختبارها بشكل احترافي.

2. الأسواق عبر الإنترنت

✅ علي بابا، وإي باي، وتجارة الهند لديها قوائم بماكينات التشكيل بالدلفنة المستعملة.

✅ كن الحذر من البائعين المجهولين ودائمًا ما تطلب مواصفات الماكينة التفصيلية.

3. المزادات الصناعية ومبيعات التصفية

✅ الشركات التي تغلق أبوابها أو تقوم بتحديث معداتها في كثير من الأحيان بيع الماكينات المستعملة بأسعار أقل.

✅ تحقق مزادات معدات الأشغال المعدنية ومبيعات معدات التصفية.

4. وكلاء وبائعو الماكينات

✅ بعض التجار الشراء والتجديد ماكينات التشكيل بالدلفنة المستعملة لإعادة البيع.

✅ التأكد من أنها توفر تاريخ الماكينة المفصل وتقارير الاختبار.

نصيحة محترف: اشتر من مصنع موثوق به مثل آلات WUXI SUNWAY للحصول على ماكينة تشكيل بالدلفنة مستعملة موثوقة ومفحوصة وموثوق بها!

كيفية فحص ماكينة التشكيل بالدرفلة المستعملة قبل الشراء

قبل شراء ماكينة التشكيل بالدلفنة المستعملةاتبع هذا قائمة التحقق من الفحص لتجنب الأخطاء المكلفة.

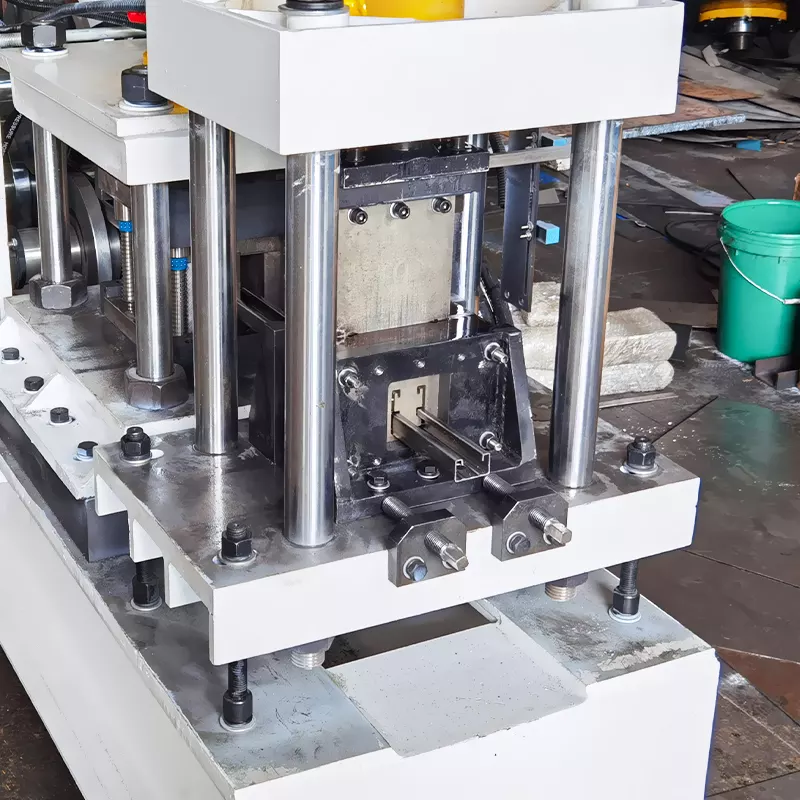

✅ 1. فحص البكرات ومحطات التشكيل

- ابحث عن علامات التآكل أو الصدأ أو التشققات على البكرات.

- تأكد من تتم محاذاة البكرات بشكل صحيح للتشكيل الدقيق للصفائح.

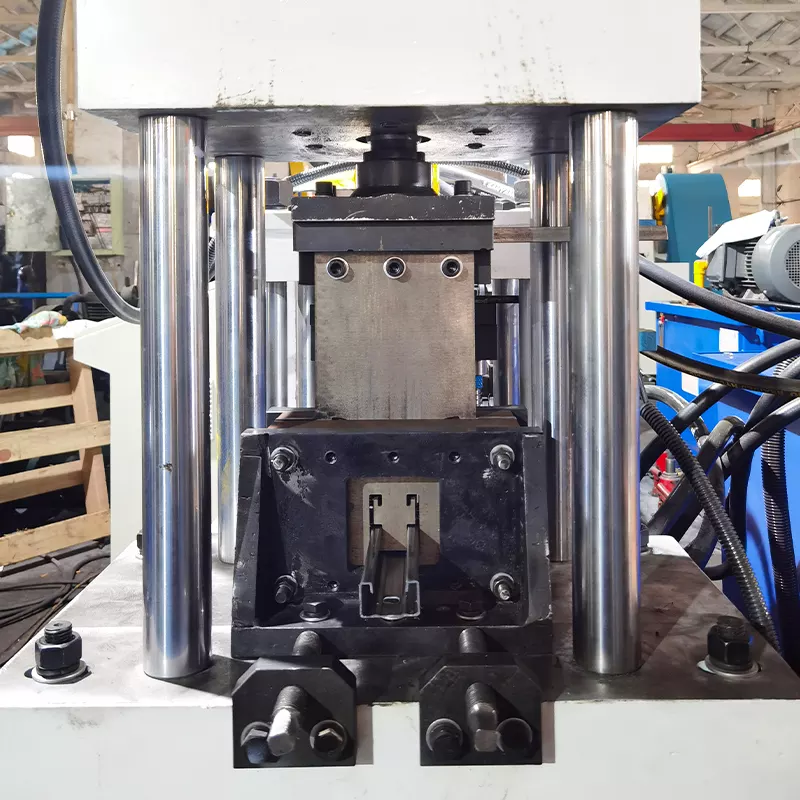

✅ 2. فحص نظام القطع

- تحقق من نظام القطع الهيدروليكي أو المؤازر للحدة والدقة.

- ابحث عن تسربات الزيت أو شفرات القطع البالية.

✅ 3. تقييم نظام التحكم (PLC والمحركات)

- اختبار لوحة التحكم PLC لضمان البرمجة السليمة والدقة.

- تأكد من أن يعمل المحرك ونظام الدفع بسلاسة دون ضوضاء مفرطة.

✅ 4. تشغيل دورة إنتاج اختبارية اختبارية

- اطلب عرضاً حياً لرؤية الآلة أثناء عملها.

- قم بقياس جودة الإخراج وسرعته للتأكد من أنها تلبي احتياجاتك الإنتاجية.

✅ 5. اطلب سجلات الصيانة

- تحقق مما إذا كان أجرى المالك السابق الصيانة الدورية.

- تأكد من قطع الغيار متوفرة لطراز الماكينة المحدد.

نصيحة محترف: إذا رفض البائع تقديم اختبار التشغيل أو سجلات الصيانة أو سجلات الصيانة أو سجل الماكينة، فاعتبر ذلك علامة حمراء!

ماكينات التشكيل بالدرفلة الجديدة مقابل المستعملة: مقارنة التكلفة

| العامل | ماكينة التشكيل بالدلفنة الجديدة | ماكينة التشكيل بالدرفلة المستعملة |

|---|---|---|

| السعر | 30,000-30,000 - 30,000-300,000 | 30-50% أرخص من الجديدة |

| التكنولوجيا | أحدث الأتمتة والمحركات المؤازرة | تقنية قديمة، قد تحتاج إلى ترقيات |

| العمر الافتراضي | 10-15 سنة | 5-10 سنوات (حسب الحالة) |

| التخصيص | قابل للتخصيص بالكامل | خيارات التخصيص المحدودة |

| الضمان والدعم | يشمل ضمان الشركة المصنعة | لا يوجد ضمان، ومخاطر إصلاح أعلى |

نصيحة محترف: إذا كانت الآلة المستعملة تكلفتها أكثر من 60% من آلة جديدة، فمن الأفضل أن تستثمر في طراز جديد!

الأخطاء الشائعة التي يجب تجنبها عند شراء ماكينة تشكيل بالدرفلة مستعملة

🚫 الخطأ #1: الشراء دون فحص الماكينة

✅ طلب عرض فيديو توضيحي أو فحص شخصي قبل الشراء.

🚫 الخطأ #2: تجاهل توفر قطع الغيار

✅ تحقق مما إذا كان استبدال البكرات، والمحركات، وشفرات القطع لا تزال قيد الإنتاج.

🚫 الخطأ #3: شراء طرازات قديمة

✅ تجنب الماكينات أكبر من 10 سنواتلأنها قد تفتقر إلى الأتمتة الحديثة والكفاءة.

🚫 الخطأ #4: تجاهل التكاليف الخفية

✅ عامل في الشحن والتركيب والتركيب والإصلاحات والتحديثات قبل إتمام عملية الشراء.

نصيحة محترف: يجب أن تكون ماكينة التشكيل بالدلفنة المستعملة أرخص بـ 30% على الأقل من ماكينة جديدة لتبرير الشراء!

كيفية التفاوض على أفضل سعر لماكينة التشكيل بالدرفلة المستعملة

شراء ماكينة التشكيل بالدلفنة المستعملة لا يعني أنه يجب أن تدفع أكثر من اللازم. يمكن أن يساعدك التفاوض الذكي على تقليل التكاليف والحصول على أفضل صفقة. إليك كيفية التفاوض بفعالية عند شراء ماكينة مستعملة.

1. البحث عن أسعار السوق ومقارنة العروض

✅ تحقق من قوائم متعددة من مختلف البائعين والمصنعين والتجار.

✅ مقارنة الميزات ✅ قارن بين الميزات, عمر الماكينة وحالتها وملحقاتها المتضمنة.

✅ استخدم هذه البيانات في مساومة للحصول على صفقة أفضل.

2. طلب فحص الماكينة بالكامل قبل إتمام الصفقة

✅ اطلب الصور ومقاطع الفيديو وسجلات الصيانة التفصيلية.

✅ إذا أمكن, قم بزيارة موقع البائع لفحص الماكينة شخصيًا.

✅ إذا كان الجهاز يحتوي على تآكل كبير، استخدم هذا كـ نقطة التفاوض بسعر أقل

3. التفاوض بشأن التكاليف الإضافية (الشحن والتركيب وقطع الغيار)

✅ بعض البائعين فرض رسوم إضافية للتغليف والشحن والتركيب-حاول الحصول على هذا مشمول في السعر.

✅ إذا كانت هناك حاجة إلى قطع غيار, تفاوض للحصول عليها بسعر مخفض.

4. اطلب إجراء تجربة قبل الشراء

✅ طلب رؤية الماكينة قيد التشغيل للتأكد من أنه يعمل بشكل صحيح.

✅ إذا رفض البائع قد يشير ذلك إلى وجود عيوب خفية.

5. فكر في الشراء بالجملة للحصول على خصومات أكبر

✅ إذا كنت بحاجة إلى أجهزة متعددة, يمكن أن يؤدي الشراء بكميات كبيرة إلى تخفيضات كبيرة في الأسعار.

✅ يقدم بعض الموردين أسعار خاصة للعملاء المتكررين.

نصيحة محترف: إذا كنت تشتري دولياً، تفاوض على الشحن المجاني أو المساعدة في الرسوم الجمركية!

التكاليف الخفية لشراء ماكينة تشكيل بالدرفلة مستعملة

في حين أن الماكينة المستعملة قد يبدو أرخص في البدايةأن تكون على دراية بإمكانية التكاليف الخفية قد يؤثر ذلك على ميزانيتك

1. رسوم الشحن والاستيراد

✅ تتراوح رسوم الشحن الدولي من 2,000-2,000 - 2,000-10,000حسب الموقع

✅ تختلف رسوم الاستيراد والضرائب حسب البلد - تحقق من ذلك اللوائح المحلية قبل الشراء.

2. التركيب وتدريب المشغل

✅ العديد من الماكينات المستعملة لا تأتي مع دعم التثبيت، لذلك قد تحتاج إلى توظيف فني.

قد يلزم تدريب المشغلين على فهم نظام التحكم في الماكينة.

3. قطع الغيار والإصلاحات

✅ إذا كان النموذج قديم جداً، قد تكون قطع الغيار يصعب العثور عليها أو مصنوعة حسب الطلبزيادة التكاليف

✅ تتطلب بعض الماكينات إعادة محاذاة الأسطوانة أو شحذ الشفرات قبل الاستخدام.

4. استهلاك الطاقة وكفاءتها

✅ الماكينات الأقدم تستهلك المزيد من الطاقةمما يؤدي إلى ارتفاع تكاليف الكهرباء.

✅ الموديلات الأحدث هي أكثر كفاءة في استهلاك الطاقةتقليل النفقات على المدى الطويل

5. مخاطر تعطل الإنتاج

✅ إذا كانت الماكينة تتعطل بشكل متكرر، يمكن أن يكون وقت الإنتاج الضائع مكلفًا.

✅ تأكد من أن الماكينة في حالة عمل جيدة قبل الشراء.

نصيحة محترف: ضع في الحسبان ما لا يقل عن 10-15% إضافية للتكاليف الخفية عند وضع ميزانية لآلة مستعملة!

آلات التشكيل بالدرفلة المجددة مقابل آلات التشكيل بالدرفلة المستعملة: ما الفرق بينهما؟

ليس كل شيء الماكينات المستعملة هي نفسها. يعرض بعض البائعين الماكينات المجددة، والتي قد تكون استثمار أفضل.

| العامل | ماكينة مستعملة | ماكينة مجددة |

|---|---|---|

| الحالة | تُباع "على حالها" مع احتمال تآكلها | تم فحصها وترميمها بالكامل |

| الإصلاحات والتحديثات | لا توجد إصلاحات، قد تحتاج إلى صيانة | استبدال قطع الغيار، وفحص الأنظمة الكهربائية |

| الضمان | عادة لا يوجد ضمان | قد يأتي مع ضمان قصير الأجل |

| السعر | تكلفة مقدمة أقل | أعلى قليلاً ولكن بقيمة أفضل على المدى الطويل |

| مستوى المخاطرة | عالية (قد يكون لها مشاكل خفية) | أقل (تم اختباره بشكل احترافي) |

نصيحة محترف: إذا أمكن، اختر آلة مُجدَّدة إن أمكن، واختر آلة مُجدَّدة بدلاً من آلة مستعملة عادية - قد تكون التكلفة أعلى قليلاً ولكنها تضمن موثوقية أفضل!

متى يجب عليك شراء ماكينة تشكيل جديدة بدلاً من ماكينة تشكيل جديدة؟

في حين أن ماكينات التشكيل بالدلفنة المستعملة يمكن أن توفر المال، في بعض الحالات, شراء ماكينة جديدة هو استثمار أفضل على المدى الطويل.

اشترِ ماكينة جديدة إذا:

✅ تحتاج إلى إنتاج عالي السرعة ومؤتمت بالكامل.

✅ يتطلب عملك تشكيلات التشكيل بالدلفنة حسب الطلب.

✅ تريد الضمان ودعم ما بعد البيع الموثوق به.

✅ أنت قلق بشأن كفاءة الطاقة وتكاليف التشغيل على المدى الطويل.

✅ تخطط لاستخدام الماكينة في أكثر من 10 سنوات بدون استبدال متكرر.

اشترِ ماكينة مستعملة إذا:

✅ لديك ميزانية محدودة وترغب في بدء الإنتاج بسرعة.

✅ حجم إنتاجك منخفضة نسبيًا.

✅ أنت مرتاح مع تكاليف الإصلاحات والصيانة العرضية.

✅ تجد ماكينة مجددة بحالة ممتازة.

نصيحة محترف: إذا كانت الماكينة المستعملة تكلف أكثر من 60% من الماكينة الجديدة، فمن الأفضل أن تستثمر في طراز جديد!

من أين تشتري ماكينات التشكيل بالدرفلة المستعملة الموثوقة؟

ل ماكينات التشكيل بالدلفنة المستعملة والمجددة عالية الجودةتحقق من WUXI SUNWAY MACHINERY CO.، LTD.

لماذا تختار WUXI SUNWAY MACHINERY للماكينات المستعملة؟

✅ ماكينات مُجدَّدة احترافيًا - تم فحصها واختبارها وجاهزة للاستخدام.

✅ قطع الغيار والدعم المتاح - تجنب وقت التعطل مع الاستبدال السريع لقطع الغيار.

✅ التسعير التنافسي - آلات ذات أسعار معقولة مع قيمة ممتازة على المدى الطويل.

✅ دعم الشحن والتركيب العالمي - توصيل بدون متاعب ومساعدة في الإعداد.

هل تبحث عن ماكينة تشكيل بالدلفنة فعالة من حيث التكلفة؟ اتصل بنا اليوم!

الأسئلة الشائعة: شراء ماكينة التشكيل بالدرفلة المستعملة

1. هل يستحق الأمر شراء ماكينة تشكيل بالدلفنة مستعملة؟

- نعم, إذا كانت الماكينة في حالة جيدة وتوفر ما لا يقل عن 30-50% مقارنةً بالجديدة.

- ومع ذلك، تجنب الماكينات التي تتطلب إصلاحات باهظة الثمن أو طرازات قديمة لا تحتوي على قطع غيار.

2. ما هي تكلفة ماكينة التشكيل بالدلفنة المستعملة؟

- يختلف سعر ماكينة التشكيل بالدلفنة المستعملة ولكنه عادةً ما يكون 30-50% أرخص من الجديدة.

- توقع أن تتراوح الأسعار بين من 10,000 إلى 10,000 إلى 10,000 إلى 10,000 إلى 150,000حسب العمر والمميزات والحالة.

3. ما الذي يجب أن أتحقق منه قبل شراء ماكينة تشكيل بالدلفنة مستعملة؟

- افحص البكرات، ونظام القطع، والمحركات, لوحة التحكموالمحاذاة الشاملة.

- اطلب سجلات الصيانة والتشغيل التجريبي للتحقق من الأداء.

4. أين يمكنني العثور على ماكينات تشكيل بالدلفنة مستعملة للبيع؟

- آلات WUXI SUNWAY العروض ماكينات التشكيل بالدلفنة المجددة المعتمدة.

- الأسواق عبر الإنترنت مثل مزادات علي بابا وإي باي والمزادات الصناعية المحلية أيضاً قائمة بالماكينات المستعملة.

5. هل يجب أن أشتري ماكينة تشكيل معاد تجديدها أم ماكينة تشكيل عادية مستعملة؟

- الماكينات المجددة هي استثمار أكثر أمانًا لأنها فحصها وإصلاحها واختبارها.

- الماكينات المستعملة العادية قد تكون أرخص لكنها تأتي مع المخاطر الأعلى والعيوب الخفية المحتملة.

الأفكار النهائية

شراء ماكينة التشكيل بالدلفنة المستعملة يمكن أن يكون طريقة فعالة من حيث التكلفة لتوسيع الإنتاجولكن من الضروري تقييم حالة الماكينة، والتفاوض بحكمة، ووضع التكاليف الخفية في الحسبان.

✅ تحتاج إلى ماكينة التشكيل بالدلفنة معقولة التكلفة والموثوقة في نفس الوقت?

✅ البحث عن ماكينة التشكيل بالدلفنة المجددة بجودة مضمونة?