In today’s high-tech world, monitoring equipment is essential in industries ranging from telecommunications to energy management. The demand for precision-engineered enclosures, frames, and panels that house this equipment is rising, and Мониторинг оборудования Рулонные формовочные машины are stepping up to the challenge. These machines streamline the production of high-quality metal components, ensuring the durability, accuracy, and scalability that modern monitoring systems require.

In this article, we’ll explore the applications, features, pricing, safety standards, and technological innovations of these machines, and why Уси Sunway машины is a trusted name in delivering top-tier roll-forming solutions. If you’re a manufacturer of monitoring equipment or related infrastructure, this guide will provide actionable insights into the benefits of investing in a roll-forming solution tailored for monitoring equipment.

What Are Monitoring Equipment Roll Forming Machines?

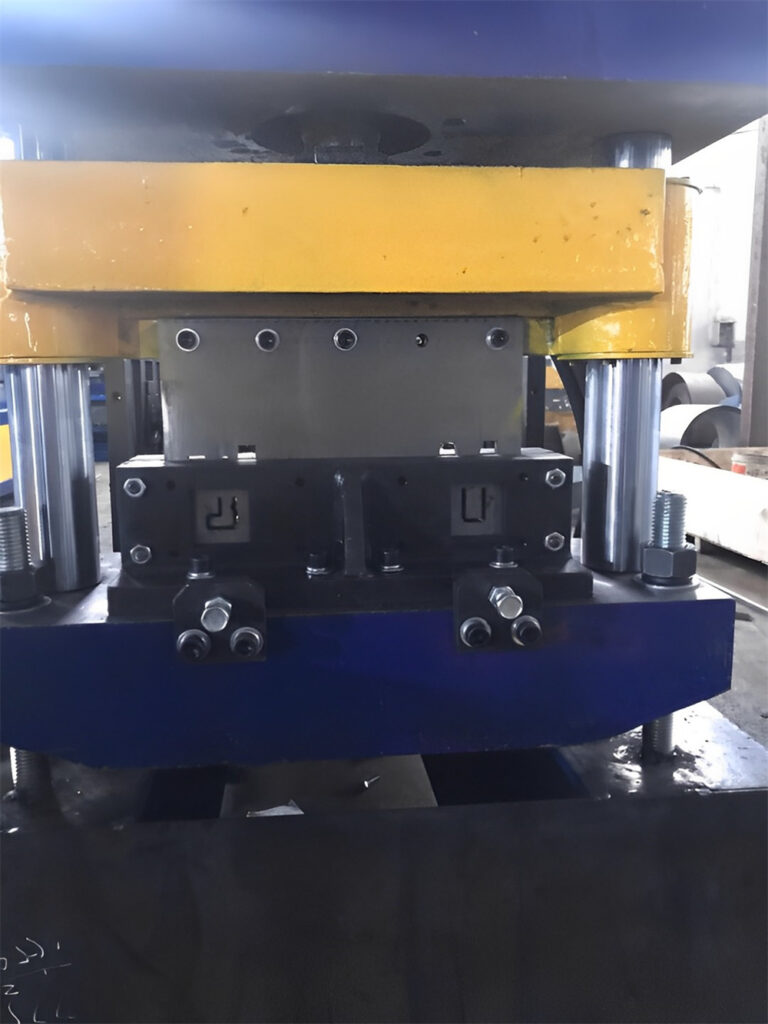

А Monitoring Equipment Roll Forming Machine is specialized machinery designed to produce metal frames, enclosures, brackets, and panels for housing monitoring systems. These systems include servers, telecommunications equipment, energy meters, control panels, and more. The machines operate by feeding metal sheets or coils into a series of rollers, gradually shaping the material into the desired profile with precision and consistency.

Основные характеристики

- Точное машиностроение: Ensures profiles meet exact specifications for compatibility with monitoring equipment.

- Customizable Tooling: Supports the production of unique designs tailored to specific monitoring systems.

- Высокоскоростное производство: Capable of delivering large quantities without compromising quality.

- Compatibility with Smart Materials: Processes materials like aluminum, stainless steel, and pre-coated metals.

- Экологически чистые практики: Reduces waste and supports the use of recyclable materials.

Applications of Monitoring Equipment Roll Forming Machines

These machines are critical to manufacturing components for monitoring systems used in diverse industries. Here are the key applications where they shine:

1. Telecommunications Infrastructure

- Пример использования: Producing enclosures and frames for telecom towers, base stations, and server racks.

- Почему это необходимо: Ensures durable, weather-resistant components capable of withstanding environmental challenges.

2. Energy Management Systems

- Пример использования: Manufacturing panels and frames for energy meters, solar panel mounts, and smart grid infrastructure.

- Почему это важно: Provides precision components that ensure the accuracy and reliability of energy monitoring systems.

3. Промышленная автоматизация

- Пример использования: Creating cabinets and enclosures for PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems.

- Почему это ценно: Protects sensitive equipment in harsh industrial environments.

4. Building Management Systems (BMS)

- Пример использования: Producing control panels and metal components for HVAC (Heating, Ventilation, and Air Conditioning) and security systems.

- Почему это актуально: Ensures compatibility with smart building technologies and IoT-enabled systems.

5. Renewable Energy Monitoring

- Пример использования: Crafting supports, brackets, and frames for wind turbines, solar inverters, and battery storage systems.

- Почему это полезно: Enables the efficient monitoring and management of renewable energy systems.

6. Транспортные системы

- Пример использования: Manufacturing components for traffic monitoring, railway signaling, and airport control systems.

- Почему это уникально: Provides durable, weather-resistant components for outdoor monitoring solutions.

Key Features of Wuxi Sunway Monitoring Equipment Roll Forming Machines

When it comes to roll-forming solutions for monitoring equipment, Уси Sunway машины is a leader in innovation and reliability. Here’s what makes their machines stand out:

1. Modular Tooling Systems

- Что он предлагает: Interchangeable tooling for producing a variety of profiles on a single machine.

- Почему это необходимо:

- Сокращает время простоя при смене оснастки.

- Supports custom designs for unique monitoring equipment applications.

2. Высокая точность и аккуратность

- Производительность: Допуски до ±0,02 мм, обеспечивающие точные размеры.

- Почему это важно:

- Guarantees seamless integration with monitoring equipment.

- Reduces rework and material waste.

3. Advanced Material Handling

- Поддерживаемые материалы:

- Оцинкованная сталь

- Нержавеющая сталь

- Алюминий

- Металлы с предварительным покрытием

- Почему это полезно:

- Ensures compatibility with materials that offer durability and corrosion resistance.

- Supports lightweight designs for modern monitoring equipment.

4. Интеграция IoT

- Что это дает:

- Real-time monitoring of machine performance and production data.

- Predictive maintenance alerts to prevent downtime.

- Почему это революционно:

- Enhances production efficiency and reduces operational costs.

- Aligns with Industry 4.0 standards.

5. High-Speed Operation

- Производительность: Производит до 30-80 метров профилей в минутув зависимости от материала и сложности конструкции.

- Почему это необходимо:

- Meets the high-volume demands of large-scale monitoring system projects.

6. Встроенная резка и перфорация

- Характеристика: Precision cutting and hole-punching capabilities integrated into the roll-forming process.

- Почему это изменит игру:

- Eliminates the need for post-production machining.

- Speeds up the delivery of ready-to-assemble components.

7. Noise and Vibration Reduction

- Что в него входит: Advanced engineering to minimize noise and vibrations during operation.

- Почему это ценно:

- Creates a safer and more comfortable working environment.

- Reduces wear and tear on machine components.

Innovations in Monitoring Equipment Roll Forming Technology

The roll-forming industry is constantly evolving, with new technologies enhancing efficiency, precision, and sustainability. Here are some of the most exciting innovations in Мониторинг оборудования Рулонные формовочные машины:

1. Контроль качества с помощью искусственного интеллекта

- Что он делает: Uses artificial intelligence to analyze production data and detect defects in real time.

- Почему это революционно:

- Improves product quality by identifying issues early.

- Reduces waste and rework.

2. Технология цифрового двойника

- Что он имитирует: Virtual models of the machine and production process to optimize settings before actual production.

- Почему это полезно:

- Reduces setup time and trial-and-error adjustments.

- Ensures consistent quality from the first run.

3. Возможность работы с несколькими профилями

- Что это дает: Produces multiple profiles simultaneously, increasing production speed and versatility.

- Почему это полезно:

- Supports complex monitoring equipment designs.

- Reduces production timelines for large projects.

4. Eco-Friendly Coating Applications

- Что в него входит: Systems for applying protective or decorative coatings during the roll-forming process.

- Почему это важно:

- Enhances the durability and aesthetics of metal components.

- Aligns with the industry’s push for sustainable manufacturing.

5. Smart Maintenance Systems

- Что это дает: Predictive maintenance alerts based on IoT data and machine learning algorithms.

- Почему это эффективно:

- Prevents unplanned downtime.

- Продлевает срок службы машины.

Pricing of Monitoring Equipment Roll Forming Machines

Стоимость Monitoring Equipment Roll Forming Machine depends on its features, capacity, and customization level. Below is a general pricing guide for 2025:

| Тип машины | Возможности | Диапазон цен (USD) |

|---|---|---|

| Стандартные машины | Basic roll-forming for monitoring equipment | 150,000–150,000–150,000–400,000 |

| Передовые машины | Высокоскоростные интегрированные системы резки и штамповки | 400,000–400,000–400,000–1,000,000 |

| Полностью настраиваемые машины | IoT, modular tooling, and multi-profile capabilities | 1,000,000–1,000,000–1,000,000–2,500,000 |

Для получения подробной информации о ценах и возможностях финансирования обращайтесь Уси Sunway машины.

Why Choose Wuxi Sunway Machinery for Monitoring Equipment Roll Forming Machines?

Уси Sunway машины is a global leader in roll-forming technology, offering unparalleled solutions for manufacturers of monitoring equipment. Here’s why they’re trusted by clients worldwide:

- Проверенный опыт: Decades of experience in designing and delivering high-performance roll-forming machines.

- Глобальный охват: Machines operating successfully across Asia, Europe, the Americas, and beyond.

- Инновационный подход: Features like IoT integration, AI-powered quality control, and modular tooling set their machines apart.

- Обязательства в области устойчивого развития: Machines optimized for energy efficiency and eco-friendly production.

- Комплексная поддержка: От первичной консультации до установки и послепродажного обслуживания, Wuxi Sunway гарантирует бесперебойную работу.

FAQs About Monitoring Equipment Roll Forming Machines

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Оцинкованная сталь, нержавеющая сталь, алюминий и предварительно покрытые металлы. |

| Какова скорость производства этих машин? | До 30–80 meters per minuteв зависимости от материала и сложности профиля. |

| Могут ли эти машины работать с индивидуальными проектами? | Yes, modular tooling supports bespoke profiles for unique monitoring systems. |

| Do these machines include safety features? | Yes, they come with emergency stops, safety guards, and noise reduction systems. |

| Экологичны ли эти машины? | Yes, they feature energy-efficient motors and reduce material waste. |

| В каких отраслях промышленности используются эти машины? | Telecommunications, energy management, industrial automation, and transportation systems. |

| Каков типичный гарантийный срок? | Машины обычно поставляются с Гарантия 1-2 годаС расширенными опциями. |

| Can these machines work with IoT systems? | Absolutely! IoT integration enables real-time monitoring and predictive maintenance. |

| Каков диапазон цен на эти машины? | Цены варьируются от 150,000to150,000to150,000to2,500,000В зависимости от функций и возможностей настройки. |

Real-World Case Studies: Monitoring Equipment Roll Forming Machines in Action

Универсальность и эффективность Мониторинг оборудования Рулонные формовочные машины have transformed manufacturing processes across various industries. Here are some real-world success stories that demonstrate their impact:

1. Case Study: Telecommunications Equipment Manufacturer

- Клиент: A global leader in producing infrastructure for 5G networks.

- Вызов: The company needed a roll-forming machine capable of producing lightweight yet durable enclosures for telecommunications towers.

- Решение: Wuxi Sunway Machinery provided a custom roll-forming machine with integrated cutting and punching capabilities.

- Результаты:

- Reduced production time by 40%, enabling faster delivery to clients.

- Enhanced product quality with precise tolerances, ensuring compatibility with 5G equipment.

- Decreased material waste by 15%, aligning with the company’s sustainability goals.

2. Case Study: Energy Management System Provider

- Клиент: A manufacturer of smart meters and energy monitoring panels in Europe.

- Вызов: The company required modular tooling to produce various panel designs for different applications.

- Решение: Wuxi Sunway delivered a roll-forming machine with interchangeable tooling systems.

- Результаты:

- Increased production flexibility, allowing the company to cater to diverse customer needs.

- Reduced downtime during tooling changes by 50%.

- Enabled the use of recyclable materials, supporting environmentally friendly production practices.

3. Case Study: Industrial Automation Supplier

- Клиент: A supplier of enclosures for PLCs and SCADA systems in North America.

- Вызов: The company needed enclosures that could withstand extreme industrial conditions, including high temperatures and humidity.

- Решение: Wuxi Sunway provided a roll-forming machine capable of processing stainless steel and aluminum with advanced surface finishes.

- Результаты:

- Produced corrosion-resistant enclosures, extending product lifespan.

- Achieved consistent quality across large production runs, meeting strict industry standards.

- Reduced operating costs by optimizing material usage.

4. Case Study: Renewable Energy Monitoring Systems

- Клиент: A company specializing in monitoring systems for solar farms and wind turbines.

- Вызов: The client needed lightweight, weather-resistant frames for outdoor applications.

- Решение: Wuxi Sunway designed a machine that processed aluminum and pre-coated metals for enhanced durability.

- Результаты:

- Increased production efficiency by 30%.

- Delivered frames that met international standards for renewable energy equipment.

- Strengthened the company’s position as a leading supplier in the renewable energy sector.

Global Market Trends for Monitoring Equipment Roll Forming Machines in 2025

As industries worldwide embrace smart technology and automation, the demand for monitoring equipment components is evolving. Here are the key market trends driving the growth of Мониторинг оборудования Рулонные формовочные машины:

1. Surge in IoT Adoption

- Тренд: The integration of IoT devices in industries such as telecommunications, energy, and manufacturing is driving the need for precise and reliable enclosures.

- Воздействие на машины:

- Machines must produce components with tight tolerances to house sensitive electronic equipment.

- IoT-enabled roll-forming machines are becoming essential for real-time production monitoring.

2. Ориентация на устойчивое развитие

- Тренд: Governments and businesses are prioritizing sustainable manufacturing practices to reduce environmental impact.

- Воздействие на машины:

- Machines must support the use of recyclable materials like aluminum and pre-coated steel.

- Energy-efficient motors and workflows are becoming standard features.

3. Increased Demand for Modular Systems

- Тренд: Modular and customizable systems are becoming popular in industries like energy management and industrial automation.

- Воздействие на машины:

- Roll-forming machines must offer modular tooling to produce diverse profiles on a single production line.

- Flexibility is a key selling point for manufacturers catering to dynamic market needs.

4. Expansion of 5G Networks

- Тренд: The global rollout of 5G networks is driving demand for telecommunications infrastructure.

- Воздействие на машины:

- Machines must produce lightweight, corrosion-resistant components for outdoor telecom installations.

- High-speed production capabilities are essential to meet tight project deadlines.

5. Рост числа проектов в области возобновляемых источников энергии

- Тренд: The renewable energy sector is expanding rapidly, requiring monitoring systems for solar farms, wind turbines, and battery storage units.

- Воздействие на машины:

- Machines must produce durable, weather-resistant components for outdoor applications.

- Precision and quality are critical to ensuring the reliability of renewable energy systems.

Safety Standards for Monitoring Equipment Roll Forming Machines

Safety is a top priority in modern manufacturing, and Мониторинг оборудования Рулонные формовочные машины are designed to meet stringent safety standards. Here are the key safety features and compliance measures:

1. CE Marking

- Region: Европа

- Требования: Ensures machines meet EU safety, health, and environmental protection standards.

- Machine Feature: Wuxi Sunway machines comply with CE regulations, providing peace of mind for European manufacturers.

2. OSHA Compliance

- Region: США

- Требования: Protects workers from hazards in the workplace under the Occupational Safety and Health Administration.

- Machine Feature: Includes emergency stop systems, safety guards, and noise reduction technologies.

3. ISO 45001 Certification

- Region: Глобальная

- Требования: Occupational health and safety management systems.

- Machine Feature: Wuxi Sunway designs its machines to minimize operator risks through ergonomic controls and automated processes.

4. Light Curtains

- Что он делает: Detects objects or personnel in hazardous zones and pauses machine operations automatically.

- Почему это важно: Prevents accidents without interrupting production workflows.

5. Safety Guards and Interlocks

- Что в него входит: Protective barriers around moving parts and interlock systems that prevent the machine from operating unless all guards are in place.

- Почему это эффективно: Снижает риск травм, вызванных человеческим фактором или механическими неисправностями.

Sustainability Practices in Monitoring Equipment Manufacturing

As industries prioritize environmental responsibility, Мониторинг оборудования Рулонные формовочные машины are adapting to support sustainable practices. Here’s how:

1. Энергоэффективность

- Особенность: Энергосберегающие двигатели и оптимизированные рабочие процессы снижают потребление электроэнергии.

- Воздействие: Lower energy usage minimizes the carbon footprint of manufacturing operations.

2. Reduced Material Waste

- Особенность: Системы прецизионной резки и формовки сводят к минимуму количество брака в процессе производства.

- Воздействие: Reduces the need for raw materials, conserving natural resources.

3. Поддержка вторичного сырья

- Особенность: Machines are designed to process materials like aluminum, which can be recycled indefinitely.

- Воздействие: Promotes circular economy practices and reduces landfill waste.

4. Долговечные компоненты

- Особенность: Долговечные компоненты требуют более редкой замены, что снижает общий расход материалов.

- Воздействие: Extends the lifecycle of monitoring equipment, reducing environmental impact.

FAQs About Monitoring Equipment Roll Forming Machines

| Вопрос | Ответ |

|---|---|

| Могут ли эти машины изготавливать нестандартные профили? | Yes, Wuxi Sunway machines feature modular tooling for unique designs. |

| Какие материалы могут обрабатывать эти машины? | Оцинкованная сталь, нержавеющая сталь, алюминий и предварительно покрытые металлы. |

| Экологичны ли эти машины? | Да, они оснащены энергосберегающими двигателями и сокращают количество отходов материалов. |

| Отвечают ли эти машины мировым стандартам безопасности? | Absolutely! They comply with CE, OSHA, and ISO 45001 certifications. |

| Are these machines suitable for high-volume production? | Yes, they can produce up to 80 meters of profiles per minute. |

| Каков гарантийный срок на эти машины? | Typically 1–2 years, with extended warranty options available. |

| Могут ли эти машины интегрироваться с системами IoT? | Да, функции с поддержкой IoT позволяют осуществлять мониторинг в режиме реального времени и прогнозировать техническое обслуживание. |

| В каких отраслях промышленности используются эти машины? | Telecommunications, energy management, industrial automation, and renewable energy sectors. |

| What is the price range of these machines? | Цены варьируются от 150,000to150,000to150,000to2,500,000В зависимости от возможностей и настроек. |

Conclusion: Leading the Future of Monitoring Equipment Manufacturing

Мониторинг оборудования Рулонные формовочные машины are shaping the future of precision and efficiency in manufacturing. With cutting-edge features, sustainability practices, and robust safety standards, these machines are essential for meeting the demands of a rapidly evolving market.

Ready to invest in the future of monitoring equipment production? Partner with Уси Sunway машины today and explore their state-of-the-art solutions. Together, let’s revolutionize manufacturing—one profile at a time.