Оборонная промышленность работает в самых жестких условиях и требует оборудования, сочетающего прочность, долговечность и надежность. От компонентов бронированных транспортных средств до конструкционных профилей для военных баз производство высокопроизводительных деталей критически важно для национальной безопасности. Представляем Станки для формовки рулонов военной техники, передовую технологию, стоящую за многими прочными и точными компонентами, используемыми в военных приложениях. Эти станки соответствуют строгим стандартам оборонного производства, позволяя создавать профили, способные выдерживать экстремальные условия и суровые нагрузки.

В этом руководстве мы рассмотрим приложения, характеристики, цены, тенденции рынкаи как Уси Sunway машины продвигает решения по профилированию для оборонной промышленности. Независимо от того, являетесь ли вы оборонным подрядчиком, военным инженером или просто интересуетесь технологией, обеспечивающей современную военную инфраструктуру, эта статья для вас.

Что такое профилегибочный станок для военной техники?

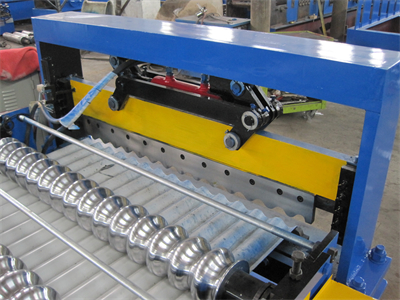

А Профилегибочный станок для военной техники представляет собой специализированное оборудование, предназначенное для производства прочных высокопроизводительных профилей, используемых в строительстве военных транспортных средств, инфраструктуры и оборудования. Эти станки обрабатывают плоские металлические листы или рулоны — обычно из высокопрочной стали, баллистических сплавов или коррозионностойких материалов— в точные формы, соответствующие строгим требованиям военных операций.

Производимые ключевые компоненты

- Панели бронированных транспортных средств: Профили для танков, бронетранспортеров (БТР) и других военных транспортных средств.

- Крепления для оружия: Компоненты для установки оружия на наземные, воздушные или морские платформы.

- Каркасы переносных укрытий: Легкие, но прочные профили для военных палаток и полевых укрытий.

- Профили для инфраструктуры баз: Балки, каналы и опоры для строительства военных баз и форпостов.

- Системы хранения боеприпасов: Профили для стеллажей и контейнеров, используемых для надежного хранения оружия и боеприпасов.

- Пользовательские профили: Уникальные конструкции для специализированных военных применений, таких как радары, платформы БПЛА и вышки связи.

Эти станки превосходят в автоматизации производства военных компонентов, обеспечивая точность, последовательность и соответствие строгим оборонным стандартам.

Применение профилегибочных станков для военной техники

Универсальность Станки для формовки рулонов военной техники делает их незаменимыми для широкого спектра оборонных применений. Ниже приведены ключевые примеры использования:

1. Производство бронированных транспортных средств

- Пример использования: Производство панелей и конструкционных профилей для танков, БТР и защищенных от мин и засад транспортных средств (MRAP).

- Почему это необходимо: Обеспечивает выживаемость личного состава и оборудования в зонах боевых действий.

2. Компоненты систем вооружения

- Пример использования: Производство креплений, кронштейнов и рам для систем вооружения на транспортных средствах, самолетах и кораблях.

- Почему это важно: Обеспечивает структурную целостность, необходимую для точной и надежной работы оружия.

3. Переносные полевые укрытия

- Пример использования: Изготовление легких каркасов для палаток, укрытий и мобильных командных центров.

- Почему это ценно: Позволяет быстрое развертывание и сборку в отдаленных или враждебных условиях.

4. Строительство военных баз

- Пример использования: Производство балок, колонн и опор для казарм, ангаров и другой инфраструктуры баз.

- Почему это актуально: Повышает долговечность и безопасность военных объектов.

5. Хранение боеприпасов и оружия

- Пример использования: Создание надежных профилей для стеллажей, шкафов и контейнеров, используемых для хранения оружия и боеприпасов.

- Почему это важно: Предотвращает повреждения и обеспечивает безопасную транспортировку чувствительных материалов.

6. Платформы для специализированного оборудования

- Пример использования: Производство профилей для радаров, пусковых платформ БПЛА и вышек связи.

- Почему это полезно: Поддерживает передовые военные технологии и повышает эксплуатационные возможности.

Ключевые особенности прокатно-профильных станков Wuxi Sunway для военного оборудования

Уси Sunway машины, глобальный лидер в технологии профилирования, предлагает машины, адаптированные к уникальным требованиям оборонного сектора. Вот выдающиеся характеристики, которые делают их машины идеальными для военного производства:

1. Обработка высокопрочных материалов

- Поддерживаемые материалы:

- Баллистическая сталь

- Алюминиевые сплавы

- Металлы, устойчивые к коррозии

- Титан

- Почему это важно: Обеспечивает производство прочных компонентов, способных выдерживать экстремальные условия.

2. Точность и последовательность

- Производительность: Размерные допуски до ±0,05 мм, гарантирующие единообразие в критических приложениях.

- Почему это важно: Снижает ошибки сборки и обеспечивает совместимость с другим оборудованием.

3. Настраиваемое оснащение для специализированных конструкций

- Что это дает: Модульные системы оснащения для создания уникальных профилей в соответствии с военными спецификациями.

- Почему это необходимо: Поддерживает производство индивидуальных компонентов для специализированных оборонных применений.

4. Интегрированные системы резки и перфорации

- Что в него входит: Системы для прецизионной резки, пробивки отверстий и перфорации в процессе производства.

- Почему это ценно: Упрощает сборку и сокращает процессы после производства.

5. Высокоскоростное производство

- Производительность: Может производить до 20-100 метров профилей в минутув зависимости от материала и сложности.

- Почему это полезно: Соответствует требованиям высоковolumного производства для крупных оборонных проектов.

6. Интеграция IoT и автоматизации

- Что это дает: Мониторинг в реальном времени, автоматическая настройка и предиктивное обслуживание с помощью систем IoT.

- Почему это изменит игру:

- Повышает эффективность производства.

- Сокращает время простоя и расходы на обслуживание.

- Предоставляет действенные идеи для постоянного совершенствования.

7. Усовершенствованные обработки поверхности

- Характеристика: Машины, предназначенные для нанесения покрытий, таких как антикоррозийные, антикоррозионные и отражающие.

- Почему это важно: Продлевает срок службы компонентов, подверженных воздействию суровых условий.

Производственный процесс прокатно-профильного станка для военного оборудования

Процесс изготовления военных компонентов оптимизирован для прочности, точности и эффективности. Ниже приведен обзор типичного процесса:

1. Загрузка материала

- Листы или рулоны баллистических материалов загружаются на разматывательОбеспечивая непрерывное снабжение.

2. Выпрямление и выравнивание

- Выравнивающее устройство обеспечивает ровную поверхность материала и отсутствие дефектов перед началом рулонной формовки.

3. Формование рулонов

- Материал проходит через ряд роликов, которые постепенно придают ему желаемый профиль, соблюдая строгие допуски.

4. Перфорация и резка

- Интегрированные системы добавляют прецизионные отверстия для крепежа или соединителей и нарезают профили по заданным длинам.

5. Нанесение покрытия

- Опциональные системы наносят защитные покрытия, такие как антикоррозийные или баллистические, во время или после производства.

6. Проверка качества

- Готовые профили проверяются на размерную точность, прочность и соответствие военным стандартам.

7. Упаковка и доставка

- Готовые компоненты упаковываются, маркируются и подготавливаются к безопасной транспортировке оборонным подрядчикам или военным объектам.

Ценообразование на прокатно-профильные станки для военного оборудования

Стоимость Профилегибочный станок для военной техники зависит от его характеристик, совместимости с материалами и опций кастомизации. Ниже приведена общая ориентировочная цена на 2025 год:

| Тип машины | Возможности | Диапазон цен (USD) |

|---|---|---|

| Стандартные машины | Базовое производство профилей для оборонных применений | 500,000–500,000–500,000–1,200,000 |

| Передовые машины | Высокоскоростные интегрированные системы резки и штамповки | 1 200 000–1 200 000–1 200 000–2 800 000 |

| Полностью настраиваемые машины | IoT, модульная оснастка и передовые технологии обработки материалов | 2 800 000–2 800 000–2 800 000–5 000 000 |

Для получения подробной информации о ценах и возможностях финансирования обращайтесь Уси Sunway машины.

Рыночные тенденции прокатно-профильных станков для военного оборудования в 2025 году

Оборонная промышленность быстро эволюционирует под влиянием технологических достижений и геополитических факторов. Вот тенденции, формирующие рынок:

1. Продвинутые материалы

- Тренд: Увеличение использования баллистических металлов и легких сплавов в военном оборудовании.

- Роль машины:

- Обеспечивает прецизионное формование продвинутых материалов.

- Снижают отходы материалов благодаря прецизионной инженерии.

2. Автономные военные системы

- Рост: Растущий спрос на БПЛА, дроны и автономные транспортные средства в оборонных операциях.

- Машинный вклад:

- Производство легких и прочных профилей для автономных платформ.

- Поддержка инновационных конструкций для передовых военных технологий.

3. Решения для быстрого развертывания

- Фокус: Разработка портативной и модульной военной инфраструктуры для быстрого развертывания.

- Удар по машине:

- Обеспечение массового производства рам для портативных укрытий и опорных конструкций.

- Поддержка сборки на месте с использованием предварительно изготовленных профилей.

4. Рост расходов на оборону

- Рост: Увеличение глобальных оборонных бюджетов стимулирует спрос на передовое военное оборудование.

- Удар по машине:

- Поддержка крупносерийного производства военных компонентов.

- Повышение эффективности производства для соблюдения сжатых сроков.

Часто задаваемые вопросы о профилегибочных машинах для военного оборудования

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Баллистическая сталь, алюминиевые сплавы, титан и коррозионностойкие металлы. |

| Какова скорость производства этих машин? | Машины могут производить до 20-100 метров профилей в минутув зависимости от материала и сложности. |

| Могут ли эти машины работать с индивидуальными проектами? | Да, модульные инструменты позволяют создавать индивидуальные военные профили. |

| Являются ли эти машины энергоэффективными? | Да, они оснащены энергоэффективными двигателями и оптимизированными рабочими процессами для снижения затрат. |

| В каких отраслях промышленности используются эти машины? | Секторы обороны, национальной безопасности и тяжелой инфраструктуры. |

| Соответствуют ли эти машины стандартам безопасности? | Да, они соответствуют стандартам ISO, CE и специальным военным требованиям к качеству. |

| Каков срок службы этих машин? | При надлежащем обслуживании эти машины могут прослужить 20-30 лет или больше. |

| Предоставляется ли обучение при покупке? | Да, Wuxi Sunway предлагает комплексное обучение и послепродажную поддержку для всех клиентов. |

| Каков диапазон цен на эти машины? | Цены варьируются от 500 000 - 500 000 - 500 000 - 500 000 - 5 000 000В зависимости от функций и возможностей настройки. |

| Могут ли эти машины поддерживать устойчивое производство? | Да, они оптимизированы для минимизации отходов и поддерживают использование материалов, пригодных для вторичной переработки. |

Реальные истории успеха: профилегибочные машины для военного оборудования в действии

Использование Станки для формовки рулонов военной техники играют ключевую роль в решении наиболее сложных задач, стоящих перед производителями оборонной продукции. Ниже приведены реальные примеры, демонстрирующие, как эти машины преобразили военное производство.

1. Кейс: Панели для бронетранспортеров (APC)

- Клиент: Глобальный подрядчик в области обороны, специализирующийся на тактических наземных транспортных средствах.

- Вызов: Нужны были высокопрочные стальные панели для APC, способные выдерживать баллистические угрозы и взрывные воздействия.

- Решение: Wuxi Sunway Machinery поставила профилегибочную машину, предназначенную для обработки баллистической стали с интегрированными системами резки и пробивки отверстий под крепеж.

- Результаты:

- Сокращение времени производства на 40%, что позволило ускорить поставку транспортных средств.

- Повышение прочности панелей в соответствии с баллистическими стандартами НАТО.

- Снижение отходов материала на 15%, оптимизация затрат на сырье.

2. Кейс: Инфраструктура для быстрого развертывания

- Клиент: Поставщик портативных военных укрытий и полевых госпиталей.

- Вызов: Требовались легкие модульные рамы для укрытий, которые можно быстро развертывать в зонах конфликтов или при ликвидации последствий стихийных бедствий.

- Решение: Wuxi Sunway поставила профилегибочную машину, способную производить высокопрочные алюминиевые профили с модульными инструментами для различных конструкций.

- Результаты:

- Обеспечение производства укрытий, собираемых менее чем за 30 минут.

- Снижение веса на 25% по сравнению с традиционными стальными рамами, упрощение логистики транспортировки.

- Повышение прочности укрытий для надежности в суровых условиях.

3. Кейс: Стеллажи для хранения боеприпасов

- Клиент: Логистическая компания, управляющая хранением боеприпасов и оружия на военных базах.

- Вызов: Нужны были коррозионностойкие профили для стеллажей под боеприпасы, выдерживающие экстремальные температуры и влажность.

- Решение: Wuxi Sunway предоставила машину для обработки оцинкованной стали с нанесением антикоррозионных покрытий в процессе производства.

- Результаты:

- Производство стеллажей, соответствующих требованиям военной безопасности и долговечности.

- Снижение затрат на обслуживание на 30% благодаря улучшенной коррозионной стойкости.

- Обеспечение эффективного массового производства для удовлетворения растущих потребностей в хранении.

4. Кейс: Рамы для БПЛА (беспилотных летательных аппаратов)

- Клиент: Производитель дронов, поставляющий военным тактические БПЛА для разведки и логистики.

- Вызов: Нужны были сверхлегкие и прочные рамы для увеличения времени полета и грузоподъемности БПЛА.

- Решение: Wuxi Sunway разработала профилегибочную машину для обработки современных композитов в индивидуальные профили для БПЛА.

- Результаты:

- Увеличение продолжительности полета БПЛА на 20%, повышение эксплуатационных возможностей.

- Сокращение сроков производства на 35%, ускорение поставок военным клиентам.

- Поддержка модульных конструкций для БПЛА, позволяющая быстрое полевое дооснащение.

Индивидуализация: ключевое преимущество профилегибочных машин для военного оборудования

В оборонной промышленности универсальный размер не подходит всем. Военные применения часто требуют индивидуальные профили для удовлетворения уникальных эксплуатационных требований. Профилегибочные машины от Уси Sunway машины предлагают непревзойденную гибкость в создании таких индивидуальных решений.

1. Модульные инструменты

- Что он предлагает: Легко заменяемые системы инструментов, позволяющие быстро переключаться между различными конструкциями профилей.

- Почему это ценно:

- Поддержка разнообразных производственных нужд — от бронированных панелей до рам укрытий.

- Сокращение времени простоя, связанного с заменой оснастки.

- Обеспечение малосерийного производства прототипов или специализированных компонентов.

2. Универсальность материала

- Поддерживаемые материалы:

- Баллистическая сталь

- Алюминиевые сплавы

- Титан

- Композитные материалы (например, углеродное волокно)

- Почему это важно:

- Обеспечение гибкости в производстве компонентов, оптимизированных по прочности, весу или коррозионной стойкости.

- Поддержка инноваций в проектировании оборонного оборудования.

3. Разнообразие профилей

- Возможности: Машины способны производить широкий спектр профилей, включая:

- U-каналы

- Z-профили

- Прямоугольные балки

- Индивидуальные геометрии

- Почему это важно:

- Обеспечение соответствия специфическим нуждам различных военных применений.

- Поддержка интеграции с другими компонентами для бесшовной сборки.

4. Интеграция передовых покрытий

- Что в него входит: Системы нанесения покрытий, таких как антикоррозионные, отражающие или камуфляжные, в процессе производства.

- Почему это полезно:

- Повышает долговечность и функциональность компонентов.

- Сокращают постпроизводственные операции, экономя время и затраты.

Стандарты соответствия для профилегибочных машин военного оборудования

Военные компоненты должны соответствовать строгим международным стандартам для обеспечения безопасности, долговечности и производительности. Уси Sunway машины разрабатывает свои машины для производства профилей, соответствующих или превосходящих эти требования:

| Стандарт | Регион | Требование |

|---|---|---|

| Спецификации MIL-STD | США | Определяют требования к материалам и компонентам военного класса. |

| ISO 9001 | Глобальная | Гарантирует постоянное управление качеством в производственных процессах. |

| Стандарты НАТО STANAG | Страны-члены НАТО | Устанавливают стандарты взаимодействия и производительности военного оборудования. |

| Маркировка CE | Европа | Сертификат соответствия европейским стандартам безопасности и качества. |

| Соответствие RoHS | Европа | Ограничение содержания опасных веществ в производственных материалах. |

| Соответствие ITAR | США | Обеспечение соблюдения Международных правил торговли оружием для экспорта. |

Придерживаясь этих стандартов, Уси Sunway машины гарантирует, что ее профилегибочные машины поставляют безопасные, долговечные и глобально соответствующие компоненты.

Часто задаваемые вопросы о профилегибочных машинах для военного оборудования

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Баллистическая сталь, алюминиевые сплавы, титан и композитные материалы. |

| Какова скорость производства этих машин? | Машины могут производить до 20-100 метров профилей в минутув зависимости от материала и сложности. |

| Могут ли эти машины работать с индивидуальными проектами? | Да, модульные инструменты позволяют создавать индивидуальные военные профили. |

| Являются ли эти машины энергоэффективными? | Да, они оснащены энергоэффективными двигателями и оптимизированными рабочими процессами для снижения эксплуатационных затрат. |

| В каких отраслях промышленности используются эти машины? | Секторы обороны, национальной безопасности и чрезвычайного реагирования. |

| Соответствуют ли эти машины стандартам безопасности? | Да, они соответствуют MIL-STD, НАТО STANAG и другим международным военным стандартам. |

| Каков срок службы этих машин? | При надлежащем обслуживании эти машины могут прослужить 20-30 лет или больше. |

| Предоставляется ли обучение при покупке? | Да, Wuxi Sunway предлагает комплексное обучение и послепродажную поддержку для всех клиентов. |

| Каков диапазон цен на эти машины? | Цены варьируются от 500 000 - 500 000 - 500 000 - 500 000 - 5 000 000В зависимости от функций и возможностей настройки. |

| Могут ли эти машины поддерживать устойчивое производство? | Да, они оптимизированы для минимизации отходов и поддерживают использование материалов, пригодных для вторичной переработки. |

Почему выбрать Wuxi Sunway Machinery для профилегибочных машин военного оборудования?

Уси Sunway машины зарекомендовала себя как надежный партнер в оборонном производстве, предлагая инновационные решения профилирования, адаптированные для военного сектора. Вот почему подрядчики обороны выбирают Sunway:

- Десятилетия опыта: Доказанный опыт поставки высококачественных машин для военных применений.

- Глобальный охват: Доверяют оборонные производители в Азии, Европе, Северной Америке и за их пределами.

- Передовые технологии: Функции вроде интеграции IoT, модульных инструментов и передовых систем покрытий выделяют их машины.

- Обязательства в области устойчивого развития: Машины спроектированы для минимизации воздействия на окружающую среду за счет энергоэффективности и работы с перерабатываемыми материалами.

- Комплексная поддержка: Начиная с консультаций и заканчивая установкой и текущим обслуживанием, компания Wuxi Sunway обеспечивает бесперебойную работу своих клиентов.

Заключение: строительство более сильной обороны с помощью профилегибочных машин

Станки для формовки рулонов военной техники революционизируют оборонную промышленность, обеспечивая производство высокопроизводительных, долговечных и надежных компонентов, отвечающих требованиям современной войны и безопасности. Эти машины играют ключевую роль в укреплении национальных оборонительных возможностей и поддержке сценариев быстрого развертывания.

Готовы повысить производство военного оборудования? Сотрудничайте с Уси Sunway машины сегодня и ознакомьтесь с их передовыми решениями профилирования. Давайте строить будущее обороны — один профиль за раз.