In the world of heating, ventilation, and air conditioning (HVAC), precision and efficiency are non-negotiable. From duct systems to structural supports, the components of HVAC systems must meet stringent quality standards while ensuring cost-effective manufacturing. Enter Оборудование для HVAC Оборудование для формовки рулонов—the game-changer in modern HVAC production.

These machines are designed to manufacture HVAC components with unmatched accuracy, speed, and consistency. Whether you’re a manufacturer looking to scale production or a contractor seeking high-quality HVAC parts, roll-forming technology offers a solution that’s efficient, sustainable, and customizable.

В этой статье мы рассмотрим what HVAC roll-forming machines are, their applications, pricing, automation capabilities, environmental benefits, and why Wuxi Sunway Machinery is a global leader in this space. Let’s dive into how these machines are shaping the future of HVAC manufacturing.

What Are HVAC Equipment Roll Forming Machines?

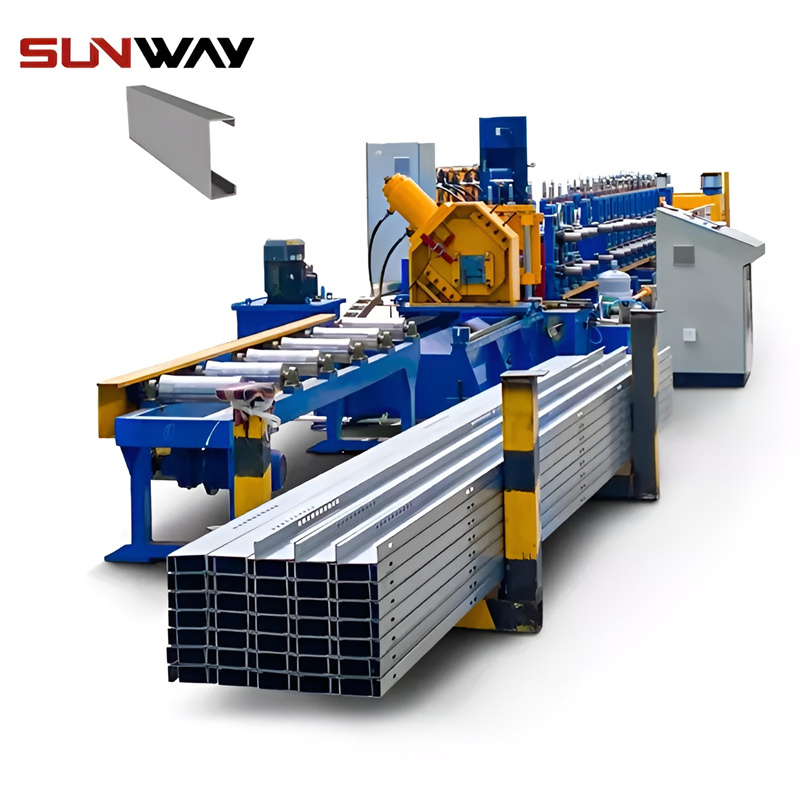

Оборудование для HVAC Оборудование для формовки рулонов are industrial systems designed to shape metal sheets or coils into specific profiles used in HVAC systems. These machines transform raw materials into components like duct panels, support channels, and frames seamlessly, ensuring precision and durability.

Основные характеристики

- Высокая точность: Produces components with exact dimensions, ensuring compatibility across HVAC systems.

- Универсальность материалов: Processes materials such as galvanized steel, aluminum, and stainless steel.

- Пользовательские профили: Supports diverse designs for different HVAC applications.

- Высокоскоростное производство: Ensures large-scale manufacturing for HVAC projects of all sizes.

- Eco-Friendly Operations: Минимизирует отходы материалов и потребление энергии.

Applications of HVAC Equipment Roll Forming Machines

HVAC systems are integral to residential, commercial, and industrial buildings, and the components manufactured by roll-forming machines are essential to their functionality. Here are the primary applications:

1. Duct Panels

- Пример использования: Producing duct panels for ventilation systems in residential and commercial buildings.

- Почему это необходимо: Ensures effective airflow while maintaining structural integrity and durability.

2. Structural Support Channels

- Пример использования: Manufacturing support channels for mounting HVAC equipment and duct systems.

- Почему это полезно: Provides a stable and secure framework for HVAC installations.

3. HVAC Unit Frames

- Пример использования: Creating frames for air handling units, condensers, and heat exchangers.

- Почему это необходимо: Ensures proper housing and protection of critical HVAC components.

4. Insulated Panels

- Пример использования: Producing insulated panels for climate-controlled HVAC systems.

- Почему это уникально: Improves energy efficiency and thermal insulation in temperature-sensitive environments.

5. Custom Profiles for Specialized HVAC Systems

- Пример использования: Crafting unique profiles for custom HVAC projects, such as industrial cooling systems or smart home HVAC units.

- Почему это актуально: Combines functionality with tailored designs to meet specific project requirements.

Why HVAC Equipment Roll Forming Machines Are Indispensable

The growing demand for efficient, durable, and high-quality HVAC systems has made Оборудование для HVAC Оборудование для формовки рулонов a necessity for manufacturers. Here’s why:

1. Customization for Diverse Needs

- Почему это важно: Supports the production of components tailored to different HVAC applications, ensuring compatibility and flexibility.

2. High Production Capacity

- Почему это полезно: Enables manufacturers to meet the increasing demand for HVAC components in residential, commercial, and industrial markets.

3. Экономичное производство

- Почему это практично: Reduces material waste, labor costs, and production time, making high-quality HVAC components more affordable.

4. Долговечность и надежность

- Почему это актуально: Produces components that can withstand environmental conditions and prolonged use, ensuring long-lasting HVAC systems.

5. Eco-Friendly Practices

- Почему это важно: Machines are designed to minimize energy consumption and support the use of recyclable materials, aligning with global sustainability goals.

Key Features of Wuxi Sunway HVAC Equipment Roll Forming Machines

Уси Sunway машины is a trusted name in the roll-forming industry, offering machines that are specifically designed for HVAC applications. Here’s what makes their machines stand out:

1. Передовые технологии обработки материалов

- Поддерживаемые материалы:

- Оцинкованная сталь

- Алюминий

- Нержавеющая сталь

- Почему это полезно: Ensures compatibility with lightweight and durable materials for HVAC systems.

2. Точное машиностроение

- Производительность: Maintains tolerances as low as ±0.02mm, ensuring seamless fitting and performance.

- Почему это важно: Guarantees high-quality outputs that meet stringent HVAC system standards.

3. Модульные системы оснастки

- Что он предлагает: Interchangeable tooling for producing multiple HVAC profiles on a single machine.

- Почему он универсален: Supports diverse requirements without the need for additional equipment.

4. Integrated Cutting, Punching, and Notching

- Что в него входит: Built-in systems for cutting, punching, and notching materials during the roll-forming process.

- Почему это эффективно: Сокращает время производства и обеспечивает готовность компонентов к установке.

5. Интеграция IoT и автоматизации

- Что это дает: Мониторинг в реальном времени, автоматическая настройка и предиктивное обслуживание с помощью систем IoT.

- Почему это революционно:

- Повышает эффективность производства.

- Минимизирует время простоя и эксплуатационные расходы.

6. Экологичный дизайн

- Что в него входит: Энергоэффективные двигатели, оптимизированные рабочие процессы и системы сокращения отходов.

- Почему он устойчив: Aligns with global sustainability goals and reduces the environmental impact of manufacturing.

Pricing of HVAC Equipment Roll Forming Machines

Стоимость HVAC Equipment Roll Forming Machine depends on its features, capacity, and customization options. Below is a general pricing guide for 2025:

| Тип машины | Возможности | Диапазон цен (USD) |

|---|---|---|

| Стандартные машины | Basic duct and channel profiles | 100,000–100,000–100,000–300,000 |

| Передовые машины | High-speed, integrated cutting and punching | 300,000–300,000–300,000–800,000 |

| Полностью настраиваемые машины | IoT-enabled, modular tooling, eco-friendly | 800,000–800,000–800,000–2,000,000 |

Для получения подробной информации о ценах и возможностях финансирования обращайтесь Уси Sunway машины.

Automation in HVAC Equipment Roll Forming Machines

Automation is a driving force in the HVAC manufacturing industry, and рулонные машины are no exception. By incorporating advanced automation technologies, these machines are redefining productivity and quality.

1. Мониторинг производства в режиме реального времени

- Что это такое: Key metrics such as production speed, defect rates, and material usage.

- Почему это ценно: Helps manufacturers optimize workflows and reduce inefficiencies.

2. Предиктивное обслуживание

- Что это дает: IoT sensors monitor machine components and predict maintenance needs.

- Почему это революционно:

- Reduces unplanned downtime.

- Продлевает срок службы машины.

3. Автоматизированные настройки

- Что он предлагает: Automatically adjusts rollers, cutters, and punches based on the material or profile being produced.

- Почему это эффективно:

- Reduces setup time.

- Обеспечивает стабильное качество всех серий продукции.

4. Контроль качества с помощью искусственного интеллекта

- Что он обнаруживает: Identifies defects in real-time and makes necessary adjustments.

- Почему это эффективно:

- Минимизация отходов.

- Enhances customer satisfaction with defect-free products.

5. Дистанционное управление и диагностика

- Что в него входит: Cloud-based systems for remote monitoring and troubleshooting.

- Почему это удобно: Allows operators to oversee production from anywhere.

Environmental Benefits of HVAC Equipment Roll Forming Machines

Sustainability is a crucial consideration in modern manufacturing, and Оборудование для HVAC Оборудование для формовки рулонов разработаны для поддержки экологически чистых практик.

1. Минимизация отходов материалов

- Как это достигается: Precision engineering ensures efficient use of raw materials.

- Воздействие: Reduces scrap and promotes sustainable resource use.

2. Энергоэффективность

- Как это работает: Machines are equipped with energy-efficient motors and optimized workflows to lower power consumption.

- Воздействие: Significantly reduces the carbon footprint of HVAC component production.

3. Использование материалов, пригодных для вторичной переработки

- Что он поддерживает: Processes materials like aluminum and galvanized steel, which are recyclable.

- Воздействие: Encourages a circular economy and reduces environmental impact.

4. Долговечные выходы

- Почему это важно: Produces durable components that minimize the need for frequent replacements.

- Воздействие: Supports sustainable HVAC systems by extending product lifespans.

FAQs About HVAC Equipment Roll Forming Machines

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Оцинкованная сталь, алюминий и нержавеющая сталь. |

| Какова скорость производства? | До 50-120 метров в минутув зависимости от материала и сложности профиля. |

| Экологичны ли эти машины? | Да, они оснащены энергосберегающими двигателями и минимизируют отходы материалов. |

| Могут ли эти машины работать с индивидуальными проектами? | Absolutely! Modular tooling supports bespoke profiles for diverse HVAC applications. |

| Каков диапазон цен на эти машины? | Цены варьируются от 100,000to100,000 to 100,000to2,000,000В зависимости от возможностей и настроек. |

| Интегрируются ли эти машины с системами IoT? | Да, функции с поддержкой IoT позволяют осуществлять мониторинг в режиме реального времени и прогнозировать техническое обслуживание. |

Real-World Success Stories: HVAC Equipment Roll Forming Machines in Action

Универсальность и эффективность Оборудование для HVAC Оборудование для формовки рулонов have allowed manufacturers across the globe to revolutionize their production processes. Here are some inspiring success stories that highlight the capabilities of these machines.

1. Large-Scale Commercial HVAC Systems in North America

Клиент: A leading HVAC contractor specializing in large commercial projects.

Вызов: The contractor needed to produce a high volume of duct panels and support channels for a high-rise office complex.

Решение: Wuxi Sunway Machinery provided a high-speed roll-forming machine capable of manufacturing duct panels and channels with integrated punching and notching features.

Результат:

- Increased production capacity by 35%, meeting project deadlines with ease.

- Reduced material waste by 18% through precision engineering.

- Enhanced the client’s reputation for delivering high-quality HVAC systems ahead of schedule.

2. Energy-Efficient HVAC Systems for Green Buildings in Europe

Клиент: A manufacturer focused on sustainable HVAC solutions for eco-friendly buildings.

Вызов: The company needed insulated panels for climate-controlled systems used in green-certified buildings.

Решение: Wuxi Sunway delivered a machine designed to produce insulated frames and panels with seamless joints for optimal thermal performance.

Результат:

- Enabled the production of energy-efficient components that met stringent EU energy standards.

- Contributed to a 20% improvement in the overall energy efficiency of the HVAC systems.

- Helped the client expand their market share in the green building sector.

3. Customized HVAC Components for Industrial Cooling in Asia

Клиент: An industrial cooling solutions provider serving factories and data centers.

Вызов: The company required custom-shaped duct panels and frames to fit non-standard HVAC layouts.

Решение: Wuxi Sunway supplied a roll-forming machine with modular tooling for creating bespoke profiles.

Результат:

- Produced custom HVAC components with 100% accuracy.

- Reduced the cost of production by 25% compared to traditional methods.

- Strengthened the company’s ability to deliver tailored solutions for unique industrial needs.

4. Lightweight HVAC Units for Residential Projects in South America

Клиент: A developer building affordable housing units with compact HVAC systems.

Вызов: The developer needed lightweight yet durable HVAC frames to fit small residential spaces.

Решение: Wuxi Sunway’s roll-forming machine processed aluminum and galvanized steel to create compact, lightweight components.

Результат:

- Reduced the weight of HVAC units by 15%, making them easier to install.

- Enhanced affordability by cutting production costs without compromising on quality.

- Enabled the developer to deliver housing projects on time and within budget.

Troubleshooting Common Issues in HVAC Equipment Roll Forming Machines

В то время как Оборудование для HVAC Оборудование для формовки рулонов are highly efficient, occasional issues may arise during production. Here’s a detailed guide to identifying and resolving potential problems.

1. Неровные профили

- Симптомы: Duct panels or frames have inconsistent dimensions or warped edges.

- Возможные причины:

- Rollers are misaligned due to wear or improper setup.

- Material thickness varies beyond acceptable limits.

- Решение:

- Регулярно проверяйте и калибруйте ролики для обеспечения правильного выравнивания.

- Используйте высококачественное и однородное сырье, чтобы избежать несоответствий.

2. Проскальзывание материала

- Симптомы: Material slips during the forming process, leading to incomplete or defective profiles.

- Возможные причины:

- Insufficient tension in the material feeder.

- Worn-out rollers or guides.

- Решение:

- Adjust feeder tension to match the material specifications.

- Replace worn rollers and guides to maintain proper grip.

3. Excessive Wear on Tools

- Симптомы: Increased frequency of tool replacements or reduced product quality.

- Возможные причины:

- Low-quality materials causing excessive wear on cutting and punching tools.

- Неправильная смазка движущихся частей.

- Решение:

- Use high-grade materials to reduce tool wear.

- Implement a regular maintenance schedule to lubricate and clean components.

4. Перегрев машины

- Симптомы: The machine shuts down unexpectedly or operates less efficiently.

- Возможные причины:

- Overloaded motors or prolonged operation at high speeds.

- Insufficient cooling mechanisms.

- Решение:

- Эксплуатируйте машину в пределах ее рекомендованной мощности.

- Ensure that the cooling system is functioning correctly and clean any blocked vents.

5. Software Glitches

- Симптомы: The control system becomes unresponsive, or automated features fail to operate.

- Возможные причины:

- Устаревшее или поврежденное программное обеспечение.

- Faulty connections in the control panel.

- Решение:

- Обновите программное обеспечение машины до последней версии.

- Inspect and secure all electrical connections.

Global Market Trends for HVAC Equipment Roll Forming Machines in 2025

The HVAC manufacturing industry is experiencing significant growth, and рулонные машины are at the center of this expansion. Here are the key global trends shaping the market:

1. Surge in Urbanization

- Тренд: Rapid urbanization is increasing the demand for HVAC systems in residential and commercial buildings.

- Воздействие: High-capacity roll-forming machines are essential to meet the growing production needs in urban areas.

2. Emphasis on Energy Efficiency

- Тренд: Governments worldwide are enforcing stricter energy efficiency standards for buildings.

- Воздействие: Machines capable of producing insulated and energy-efficient HVAC components are in high demand.

3. Growth in Smart HVAC Systems

- Тренд: The rise of smart buildings is driving demand for HVAC components compatible with IoT technology.

- Воздействие: Roll-forming machines with modular tooling for custom designs are gaining traction.

4. Expansion of Industrial Cooling

- Тренд: Data centers and industrial facilities require advanced cooling systems to support high-performance operations.

- Воздействие: Machines designed for heavy-duty and custom-shaped HVAC components are crucial for this market.

5. Ориентация на устойчивое развитие

- Тренд: Производители внедряют экологически чистые методы, чтобы соответствовать глобальным целям устойчивого развития.

- Воздействие: Energy-efficient and waste-reducing roll-forming machines are becoming the industry standard.

Additional Automation Capabilities in HVAC Equipment Roll Forming Machines

Automation continues to redefine the capabilities of Оборудование для HVAC Оборудование для формовки рулонов, making them smarter and more efficient than ever before. Here are some advanced automation features:

1. Adaptive Roller Adjustment

- Что он делает: Автоматически регулирует положение роликов в зависимости от толщины материала и требований к профилю.

- Почему это полезно: Eliminates manual adjustments, reducing downtime and enhancing precision.

2. Advanced Defect Detection

- Что в него входит: High-resolution cameras and AI algorithms to identify defects in real time.

- Почему это эффективно: Ensures only flawless components proceed to the assembly line, reducing waste.

3. Обработка нескольких материалов

- Что это дает: Seamlessly switches between different materials (e.g., steel, aluminum) within a single production run.

- Почему это революционно: Enhances flexibility and reduces setup time for diverse production needs.

4. Аналитика на основе облачных технологий

- Что это такое: Производственные показатели, производительность оборудования и графики технического обслуживания.

- Почему это удобно: Provides actionable insights to optimize operations and troubleshoot issues remotely.

Why Wuxi Sunway Machinery Remains the Industry Leader

Уси Sunway машины sets the gold standard for roll-forming machines, particularly for HVAC applications. Here’s what makes them stand out:

- Глобальная репутация: Trusted by top manufacturers worldwide for delivering reliable and innovative machines.

- Индивидуальные решения: Customizable machines designed to meet specific production needs and challenges.

- Обязательства в области устойчивого развития: Focuses on reducing energy consumption and material waste, aligning with global eco-friendly practices.

- Комплексная поддержка: Offers exceptional pre- and post-sales support, including training, maintenance, and customization services.

- Проверенный опыт: Decades of experience in designing high-performance roll-forming machinery.

Interested in enhancing your HVAC manufacturing capabilities? Contact Уси Sunway машины for a consultation.

FAQs About HVAC Equipment Roll Forming Machines

| Вопрос | Ответ |

|---|---|

| Могут ли эти машины работать с индивидуальными проектами? | Yes, Wuxi Sunway machines support modular tooling for bespoke HVAC profiles. |

| What types of materials are compatible? | Оцинкованная сталь, алюминий и нержавеющая сталь. |

| Какова средняя скорость производства? | До 50-120 метров в минутув зависимости от материала и сложности конструкции. |

| Экологичны ли эти машины? | Absolutely. They include energy-efficient motors and waste-minimizing features. |

| What’s the price range for these machines? | Цены варьируются от 100,000to100,000 to 100,000to2,000,000В зависимости от возможностей и настроек. |

| Do these machines integrate with IoT? | Да, системы с поддержкой IoT позволяют осуществлять мониторинг в режиме реального времени и проводить предиктивное обслуживание. |

Conclusion: A Smarter, More Efficient HVAC Industry

Оборудование для HVAC Оборудование для формовки рулонов are transforming the way manufacturers produce components for modern heating, ventilation, and air conditioning systems. With their precision, efficiency, and automation capabilities, these machines are paving the way for a smarter and more sustainable HVAC industry.

Ready to lead your industry with cutting-edge manufacturing technology? Partner with Уси Sunway машины today and take your production line to the next level. Together, let’s build a better, more efficient future—one HVAC component at a time.