Автомобильная промышленность - это очаг инноваций, постоянно развивающийся в соответствии с требованиями к более легким, прочным и эффективным автомобилям. В основе этой эволюции лежит роль точного производства, и Автозапчасти ролл формовочные машины являются ведущими. Эти станки позволяют производить высококачественные, прочные и индивидуально разработанные компоненты, которые имеют решающее значение для современных автомобилей.

В этой статье мы рассмотрим что такое вальцовочные станки для производства автозапчастей, их применение, преимущества, цены, возможности автоматизации, экологические преимущества и почему Wuxi Sunway Machinery является надежным именем в отрасли. Если вы производитель, стремящийся оптимизировать производственные процессы, или поставщик, ожидающий следующего большого скачка в автомобильных технологиях, это руководство даст вам необходимые сведения.

Что такое машины для формовки автозапчастей?

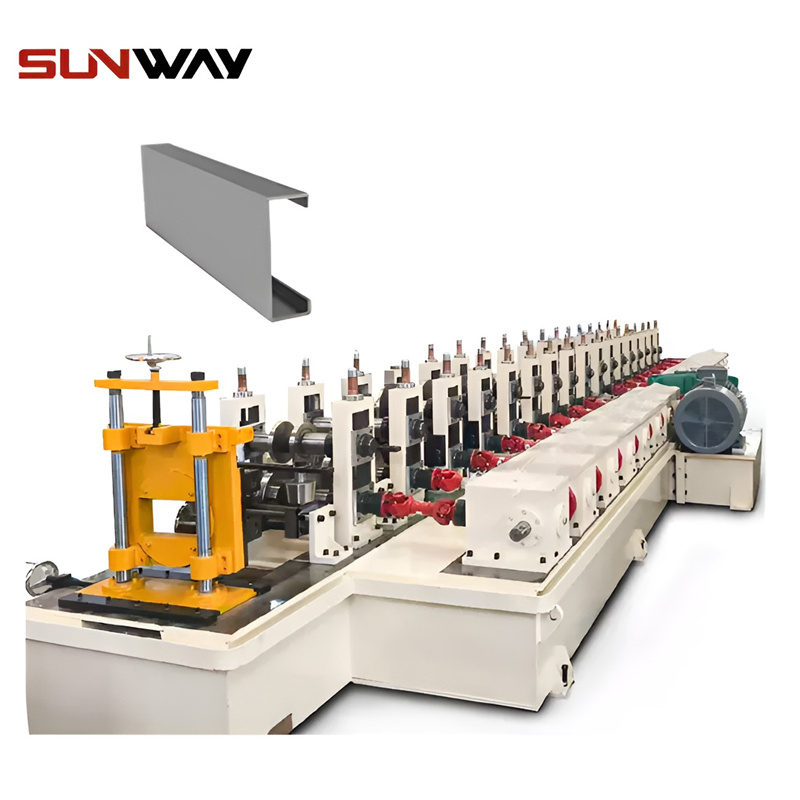

Автозапчасти ролл формовочные машины это специализированные промышленные системы, предназначенные для придания металлическим листам или рулонам определенных профилей, используемых в автомобилестроении. Эти машины используют непрерывный процесс гибки для создания компонентов с точностью и эффективностью, что позволяет наладить массовое производство без ущерба для качества.

Основные характеристики

- Высокая точность: Производит компоненты с точными техническими характеристиками, обеспечивая совместимость с конструкцией автомобиля.

- Гибкость материала: Обрабатывает легкие, но прочные материалы, такие как алюминий, высокопрочная сталь и оцинкованная сталь.

- Пользовательские профили: Поддерживает разнообразные конструкции, предназначенные для различных моделей автомобилей и областей применения.

- Высокоскоростное производство: Отвечает требованиям крупного автомобильного производства.

- Экологически чистые практики: Минимизация отходов и энергопотребления в соответствии с целями устойчивого развития.

Применение машин для формовки автозапчастей

Станки для формовки автозапчастей необходимы для производства широкого спектра компонентов, которые используются при создании современных легковых, грузовых и других транспортных средств. Вот основные области применения:

1. Конструктивные элементы автомобилей

- Пример использования: Производство структурных усилителей, таких как балки боковых ударов, рейлинги на крыше и B-стойки.

- Почему это необходимо: Повышает безопасность автомобиля, создавая компоненты, поглощающие удары и улучшающие целостность конструкции.

2. Шасси и детали рамы

- Пример использования: Производство компонентов шасси, включая поперечины, рокерные панели и усилители пола.

- Почему это полезно: Обеспечивает легкую, но прочную основу для автомобилей, повышая их производительность и топливную экономичность.

3. Дверные и оконные рамы

- Пример использования: Создание высокоточных дверных коробок, оконных каналов и уплотнительных профилей.

- Почему это необходимо: Обеспечивает идеальную посадку и долговечность, способствуя общей эстетике и функциональности автомобиля.

4. Аккумуляторные лотки для электромобилей

- Пример использования: Производство лотков и корпусов для аккумуляторных систем EV.

- Почему это уникально: Поддерживает растущий рынок электромобилей, обеспечивая легкие, устойчивые к коррозии компоненты.

5. Нестандартная отделка и декоративные детали

- Пример использования: Изготовление на заказ элементов отделки, таких как молдинги, флюгеры и акцентные профили.

- Почему это актуально: Улучшает внешний вид автомобиля, сохраняя при этом долговечность и точность.

6. Детали подвески и опоры

- Пример использования: Изготовление усилителей подвески, кронштейнов и опор.

- Почему это важно: Улучшает качество езды и устойчивость автомобиля, обеспечивая прочность и надежность компонентов подвески.

Почему станки для формовки автозапчастей незаменимы

Автомобильный сектор находится под постоянным давлением инноваций, снижения затрат и достижения целей устойчивого развития. Вот почему Автозапчасти ролл формовочные машины имеют решающее значение для достижения этих целей:

1. Точное машиностроение

- Почему это важно: Обеспечивает соответствие каждого компонента жестким конструктивным допускам, что крайне важно для безопасности и производительности автомобиля.

2. Персонализация для различных моделей

- Почему это полезно: Позволяет производителям изготавливать детали, адаптированные к конкретным моделям автомобилей, причем как для стандартных моделей, так и для автомобилей класса люкс.

3. Масштабируемость

- Почему это практично: Обеспечивает высокоскоростное производство для удовлетворения растущего спроса на автомобильные компоненты на мировых рынках.

4. Эффективность использования материалов

- Почему это экономично: Сокращение отходов материала за счет точной резки и придания формы, что снижает общие производственные затраты.

5. Легкий дизайн

- Почему это актуально: Способствует производству легких компонентов, повышающих топливную экономичность и снижающих уровень вредных выбросов, в соответствии с отраслевыми тенденциями.

6. Устойчивое развитие

- Почему это важно: Поддерживает экологически чистое производство, минимизируя потребление энергии и позволяя использовать материалы, подлежащие вторичной переработке.

Основные характеристики Wuxi Sunway Auto Parts Roll Forming Machines

Когда речь заходит о технологии валковой формовки, Уси Sunway машины является мировым лидером. Их Автозапчасти ролл формовочные машины разработаны в соответствии с высочайшими стандартами точности, эффективности и инноваций. Вот что отличает их друг от друга:

1. Передовые технологии обработки материалов

- Поддерживаемые материалы:

- Высокопрочная сталь

- Оцинкованная сталь

- Алюминий

- Нержавеющая сталь

- Почему это полезно: Обеспечивает совместимость с легкими и прочными материалами, необходимыми для производства современных автомобилей.

2. Модульные системы оснастки

- Что он предлагает: Сменная оснастка для производства нескольких деталей на одном станке.

- Почему он универсален: Поддерживает различные производственные потребности, не требуя дополнительного оборудования.

3. Встроенная резка и перфорация

- Что в него входит: Встроенные системы для точной резки, перфорации и высечки в процессе валковой формовки.

- Почему это эффективно: Сокращает время производства и обеспечивает готовность компонентов к сборке.

4. Интеграция IoT и автоматизации

- Что это дает: Мониторинг в реальном времени, автоматическая настройка и предиктивное обслуживание с помощью систем IoT.

- Почему это революционно:

- Повышает эффективность работы.

- Минимизирует время простоя и затраты на обслуживание.

5. Высокоскоростное производство

- Что это дает: Станки способны производить до 120 метров деталей в минуту.

- Почему это необходимо: Соответствует требованиям крупносерийного производства автомобилей.

6. Экологичный дизайн

- Что в него входит: Энергоэффективные двигатели, оптимизированные рабочие процессы и системы сокращения отходов.

- Почему он устойчив: Снижает воздействие производства автозапчастей на окружающую среду.

Ценообразование на Автозапчасти Рулонная формовочная машина

Стоимость Автозапчасти ролл формовочный станок зависит от таких факторов, как персонализация, дополнительные функции и производственные мощности. Ниже приведены общие цены для 2025 года:

| Тип машины | Возможности | Диапазон цен (USD) |

|---|---|---|

| Стандартные машины | Основные профили автомобилей | 150,000–150,000–150,000–400,000 |

| Передовые машины | Высокоскоростные интегрированные системы резки и штамповки | 400,000–400,000–400,000–900,000 |

| Полностью настраиваемые машины | IoT-технологии, модульная оснастка, экологичность | 900,000–900,000–900,000–2,500,000 |

Чтобы узнать конкретные цены и варианты финансирования, свяжитесь с Уси Sunway машины.

Автоматизация в станках для формовки автозапчастей

Автоматизация революционизирует автомобильную промышленность, и машины для формовки автозапчастей находятся в авангарде этой трансформации. Используя самые современные технологии, эти машины обеспечивают высочайшую эффективность и качество.

1. Мониторинг производства в режиме реального времени

- Что это такое: Ключевые показатели, такие как скорость производства, расход материалов и количество дефектов.

- Почему это ценно: Помогает производителям оптимизировать рабочие процессы и выявить неэффективность.

2. Предиктивное обслуживание

- Что это дает: IoT-датчики отслеживают износ компонентов и прогнозируют необходимость технического обслуживания.

- Почему это революционно:

- Предотвращает неожиданные поломки.

- Продлевает срок службы машины.

3. Автоматизированные настройки

- Что он предлагает: Автоматически настраивает ролики, резаки и перфораторы для различных материалов или конструкций.

- Почему это эффективно: Сокращает время настройки и обеспечивает стабильное качество.

4. Контроль качества с помощью искусственного интеллекта

- Что он обнаруживает: Выявляет дефекты в режиме реального времени и вносит необходимые коррективы для поддержания качества.

- Почему это эффективно: Сокращение отходов и повышение удовлетворенности клиентов.

5. Дистанционное управление и диагностика

- Что в него входит: Облачные системы для удаленного мониторинга, устранения неполадок и управления.

- Почему это удобно: Позволяет операторам наблюдать за производством и решать проблемы из любого места.

Экологические преимущества машин для формовки автозапчастей

Устойчивое развитие является одним из основных направлений автомобильной промышленности, и Автозапчасти ролл формовочные машины разработаны для поддержки экологически чистых практик.

1. Сокращение отходов материалов

- Как это достигается: Точное проектирование сводит к минимуму количество брака в процессе производства.

- Воздействие: Сохраняет ресурсы и уменьшает количество отходов на свалках.

2. Энергоэффективность

- Как это работает: Оснащены энергоэффективными двигателями и оптимизированными рабочими процессами для снижения энергопотребления.

- Воздействие: Уменьшает углеродный след от производства автомобилей.

3. Использование материалов, пригодных для вторичной переработки

- Что он поддерживает: Перерабатывает пригодные для вторичной переработки металлы, такие как алюминий и оцинкованная сталь.

- Воздействие: Способствует развитию многооборотной экономики и сокращению добычи ресурсов.

4. Прочные компоненты

- Почему это важно: Производит высококачественные компоненты, рассчитанные на длительный срок службы, снижая потребность в частой замене.

- Воздействие: Поддерживает устойчивое производство автомобилей благодаря увеличению срока службы деталей.

Часто задаваемые вопросы о станках для формовки автозапчастей

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Высокопрочная сталь, алюминий, оцинкованная сталь и нержавеющая сталь. |

| Какова скорость производства? | До 120 метров в минутув зависимости от материала и сложности профиля. |

| Экологичны ли эти машины? | Да, они оснащены энергосберегающими двигателями и минимизируют отходы материалов. |

| Могут ли эти машины работать с индивидуальными проектами? | Конечно! Модульная оснастка позволяет изготавливать профили на заказ для различных автомобильных применений. |

| Каков диапазон цен на эти машины? | Цены варьируются от 150,000to150,000to150,000to2,500,000В зависимости от возможностей и настроек. |

| Интегрируются ли эти машины с системами IoT? | Да, функции с поддержкой IoT позволяют осуществлять мониторинг в режиме реального времени и прогнозировать техническое обслуживание. |

Реальные истории успеха: Станки для формовки автозапчастей в действии

Трансформационные возможности Автозапчасти ролл формовочные машины позволили производителям по всему миру внедрять инновации и масштабировать свои автомобильные производственные линии. Ниже приведены некоторые реальные примеры того, как эти машины произвели революцию в производстве.

1. Лотки для аккумуляторов EV для ведущего производителя электромобилей

Клиент: Глобальный бренд электромобилей (EV).

Вызов: Производителю требовались легкие, устойчивые к коррозии лотки для аккумуляторов для линейки EV нового поколения.

Решение: Компания Wuxi Sunway поставила вальцовочную машину, предназначенную для обработки алюминия и оцинкованной стали, со встроенной перфорацией для прорезей и отверстий.

Результат:

- Снижение веса лотков для батарей на 20%, что увеличивает запас хода автомобиля.

- Скорость производства увеличилась на 30%, что позволило уложиться в сжатые сроки для запуска EV.

- Укрепление репутации компании как пионера в области экологичных автомобильных решений.

2. Структурные компоненты для производителя коммерческих грузовиков в Северной Америке

Клиент: Ведущий производитель грузовых автомобилей.

Вызов: Компании требовались сверхпрочные компоненты шасси, способные выдерживать высокие нагрузки и суровые условия эксплуатации.

Решение: Компания Wuxi Sunway поставила станок для формовки валков из высокопрочной стали с передовой оснасткой для армированных профилей.

Результат:

- Компоненты шасси обладают высочайшей прочностью и долговечностью.

- Сокращение отходов материалов на 18%, снижение производственных затрат.

- Улучшилась производительность и надежность грузовика, что повысило удовлетворенность клиентов.

3. Индивидуальные профили отделки для люксового автомобильного бренда в Европе

Клиент: Производитель автомобилей класса люкс, специализирующийся на изготовлении автомобилей на заказ.

Вызов: Автопроизводителю требовались элементы отделки, разработанные на заказ, чтобы улучшить эстетику своих автомобилей премиум-класса.

Решение: Компания Wuxi Sunway предоставила рулоноформовочную машину с модульной оснасткой для создания сложных конструкций и декоративной отделки.

Результат:

- Позволяет создавать уникальные высококачественные профили отделки.

- Повышение способности автопроизводителя предлагать клиентам индивидуальные варианты дизайна.

- Повышение позиционирования бренда на рынке в сегменте автомобилей класса люкс.

4. Легкие компоненты подвески для азиатского поставщика автомобилей

Клиент: Поставщик уровня Tier-1 для нескольких мировых автопроизводителей.

Вызов: Поставщику требовались легкие, но прочные компоненты подвески для повышения топливной эффективности автомобиля.

Решение: Компания Wuxi Sunway поставила станок для обработки высокопрочной стали с интегрированными функциями резки и штамповки.

Результат:

- Снижение массы компонентов на 15%, что способствует повышению топливной эффективности.

- Увеличение производственных мощностей на 40% позволило поставщику удовлетворить растущий спрос.

- Укрепление партнерства поставщика с ведущими автопроизводителями.

Устранение неисправностей, характерных для машин для формовки автозапчастей

Даже самые продвинутые Автозапчасти ролл формовочные машины могут столкнуться с проблемами в работе. Вот некоторые распространенные проблемы и их решения, которые помогут обеспечить бесперебойную работу вашей производственной линии.

1. Несоответствующие профили

- Симптомы: Изготовленные компоненты имеют неравномерные размеры или не соответствуют проектным спецификациям.

- Возможные причины:

- Неправильное расположение роликов или изношенная оснастка.

- Неправильная подача материала.

- Решение:

- Регулярно проверяйте и выравнивайте ролики.

- Обеспечьте правильную подачу материала путем калибровки направляющих и питателей.

2. Застревание материала

- Симптомы: Материал застревает в роликах, останавливая производство.

- Возможные причины:

- Толщина материала превышает возможности машины.

- Мусор или посторонние предметы в зоне формирования.

- Решение:

- Убедитесь, что материалы соответствуют техническим характеристикам машины.

- Очищайте ролики и направляющие перед каждым производственным циклом.

3. Чрезмерный износ инструмента

- Симптомы: Режущие и штамповочные инструменты быстро изнашиваются, что сказывается на качестве продукции.

- Возможные причины:

- Низкокачественное сырье.

- Неправильная смазка движущихся частей.

- Решение:

- Используйте высококачественные материалы, чтобы свести к минимуму износ инструмента.

- Регулярно проводите техническое обслуживание для очистки и смазки компонентов.

4. Вибрации машины

- Симптомы: Чрезмерный шум и вибрации во время работы.

- Возможные причины:

- Ослабленные компоненты или несбалансированные ролики.

- Эксплуатация машины сверх рекомендованной мощности.

- Решение:

- Затяните все компоненты и отбалансируйте ролики.

- Эксплуатируйте машину в установленных пределах.

5. Сбои в работе программного обеспечения

- Симптомы: Система управления зависает или не может выполнить команды.

- Возможные причины:

- Устаревшее программное обеспечение или микропрограмма.

- Электрические неисправности в панели управления.

- Решение:

- Обновите программное обеспечение до последней версии.

- Проверьте и отремонтируйте неисправную проводку или компоненты в панели управления.

Глобальные тенденции развития промышленности по производству машин для формовки автозапчастей в 2025 году

Автомобильная промышленность переживает смену парадигмы, вызванную развитием технологий, экологичностью и предпочтениями потребителей. Вот ключевые тенденции, формирующие рынок для Автозапчасти ролл формовочные машины:

1. Переход на электромобили (EV)

- Тренд: Глобальный переход на электромобили стимулирует спрос на легкие и коррозионностойкие компоненты.

- Воздействие: Большим спросом пользуются рулоноформовочные машины, предназначенные для обработки алюминия и других легких материалов.

2. Упор на устойчивость

- Тренд: Автопроизводители внедряют экологически чистые методы, чтобы соответствовать строгим мировым стандартам выбросов.

- Воздействие: Машины, которые минимизируют отходы и позволяют использовать перерабатываемые материалы, становятся промышленными стандартами.

3. Рост кастомизации

- Тренд: Потребители стремятся к индивидуальному дизайну автомобилей, что стимулирует спрос на индивидуальные компоненты.

- Воздействие: Модульные вальцовочные станки, способные изготавливать профили по индивидуальному заказу, находят все большее применение.

4. Интеграция "умной фабрики

- Тренд: Внедрение технологий Индустрии 4.0 меняет автомобильное производство.

- Воздействие: Лидирующее положение занимают валкообразующие машины с поддержкой IoT, мониторингом в реальном времени и предиктивным обслуживанием.

5. Рост числа легких материалов

- Тренд: Для повышения топливной эффективности все чаще используются высокопрочная сталь, алюминий и композитные материалы.

- Воздействие: Станки, оптимизированные для работы с этими материалами, имеют решающее значение для удовлетворения будущих потребностей автомобилестроения.

Расширенные возможности автоматизации в станках для формовки автозапчастей

Автоматизация - основа современного производства, и Автозапчасти ролл формовочные машины не являются исключением. Вот обзор некоторых передовых функций автоматизации:

1. Адаптивная обработка материалов

- Что он делает: Автоматически настраивает параметры в зависимости от обрабатываемого материала.

- Почему это революционно: Сокращает время настройки и обеспечивает стабильное качество различных материалов.

2. Интеллектуальное обнаружение дефектов

- Что в него входит: Системы с искусственным интеллектом, позволяющие в режиме реального времени обнаруживать дефекты поверхности, несоосности или ошибки в размерах.

- Почему это эффективно: Минимизация отходов и сокращение необходимости ручных проверок.

3. Многопрофильное производство

- Что это дает: Плавное переключение между различными профилями компонентов в рамках одного производственного цикла.

- Почему это удобно: Повышает гибкость и поддерживает различные производственные требования.

4. Аналитика на основе облачных технологий

- Что это такое: Производственные показатели, производительность оборудования и графики технического обслуживания.

- Почему это ценно: Предоставляет практические сведения для оптимизации работы и предотвращения простоев.

Воздействие на окружающую среду машин для формовки автозапчастей

Устойчивое развитие становится все более приоритетным направлением в автомобильной промышленности, и Автозапчасти ролл формовочные машины разработаны в соответствии с этими целями. Вот как они способствуют экологичности производства:

1. Эффективное использование материалов

- Как это достигается: Прецизионное проектирование снижает количество брака и обеспечивает оптимальное использование сырья.

- Воздействие: Экономия ресурсов и снижение производственных затрат.

2. Энергоэффективность

- Как это работает: Машины оснащены энергоэффективными двигателями и энергосберегающими функциями.

- Воздействие: Снижает потребление энергии и уменьшает "углеродный след" производства.

3. Поддержка вторичного сырья

- Что это дает: Для их изготовления используются такие материалы, как алюминий и оцинкованная сталь, которые легко поддаются вторичной переработке.

- Воздействие: Поощряет устойчивые практики и способствует развитию циркулярной экономики.

4. Долговечные выходы

- Почему это важно: Производит долговечные автомобильные компоненты, снижающие потребность в частой замене.

- Воздействие: Поддерживает устойчивое производство автомобилей благодаря увеличению срока службы деталей.

Почему Wuxi Sunway Machinery лидирует в отрасли производства рулонов

Благодаря десятилетиям опыта и стремлению к инновациям, Уси Sunway машины зарекомендовала себя как мировой лидер в области технологий валковой формовки. Вот почему они продолжают оставаться эталоном:

- Глобальная экспертиза: Доверие производителей из Азии, Европы, Америки и других стран.

- Настраиваемые решения: Предлагает специализированные машины для удовлетворения конкретных производственных потребностей.

- Устойчивое развитие: Разрабатывает экологически чистые машины, соответствующие глобальным экологическим целям.

- Комплексная поддержка: Предоставляет комплексные услуги, от консультаций до послепродажного обслуживания.

- Проверенные инновации: Внедряет в свои станки передовые технологии, такие как IoT, искусственный интеллект и модульная оснастка.

Узнайте больше об их продукции на сайте официальный сайт.

Часто задаваемые вопросы о станках для формовки автозапчастей

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Высокопрочная сталь, алюминий, оцинкованная сталь и нержавеющая сталь. |

| Какова скорость производства? | До 120 метров в минутув зависимости от материала и сложности профиля. |

| Экологичны ли эти машины? | Да, они оснащены энергосберегающими двигателями и минимизируют отходы материалов. |

| Могут ли эти машины работать с индивидуальными проектами? | Конечно! Модульная оснастка позволяет изготавливать профили на заказ для различных автомобильных применений. |

| Каков диапазон цен на эти машины? | Цены варьируются от 150,000to150,000to150,000to2,500,000В зависимости от возможностей и настроек. |

| Интегрируются ли эти машины с системами IoT? | Да, функции с поддержкой IoT позволяют осуществлять мониторинг в режиме реального времени и прогнозировать техническое обслуживание. |

Заключение: Ускорение развития автомобильной промышленности с помощью технологии роликовой формовки

Автозапчасти ролл формовочные машины формируют будущее автомобильного производства, обеспечивая точность, эффективность и устойчивость. От легких компонентов EV до элитной отделки на заказ - эти машины необходимы для удовлетворения требований быстро развивающейся отрасли.

Готовы ли вы внедрить инновации в свою производственную линию? Сотрудничайте с Уси Sunway машины и познакомиться с их современными решениями в области валковой формовки для автомобильного сектора. Давайте вместе ускорим будущее транспорта - по одному компоненту за раз.