The demand for lightweight, durable, and versatile aluminum profiles is skyrocketing across industries like construction, automotive, electronics, and renewable energy. From sleek architectural designs to robust industrial frameworks, aluminum profiles are essential components of modern infrastructure and technology. But how are these intricate profiles manufactured with such precision and scale? The answer lies in Машины для формовки алюминиевых профилей—a groundbreaking technology that enables high-speed, cost-effective, and eco-friendly production.

В этом подробном руководстве мы рассмотрим features, applications, pricing, global trends, innovations, and why Wuxi Sunway Machinery is a global leader in aluminum profile roll-forming solutions. Whether you’re an industry professional or someone exploring the latest in manufacturing technology, this article will provide you with actionable insights.

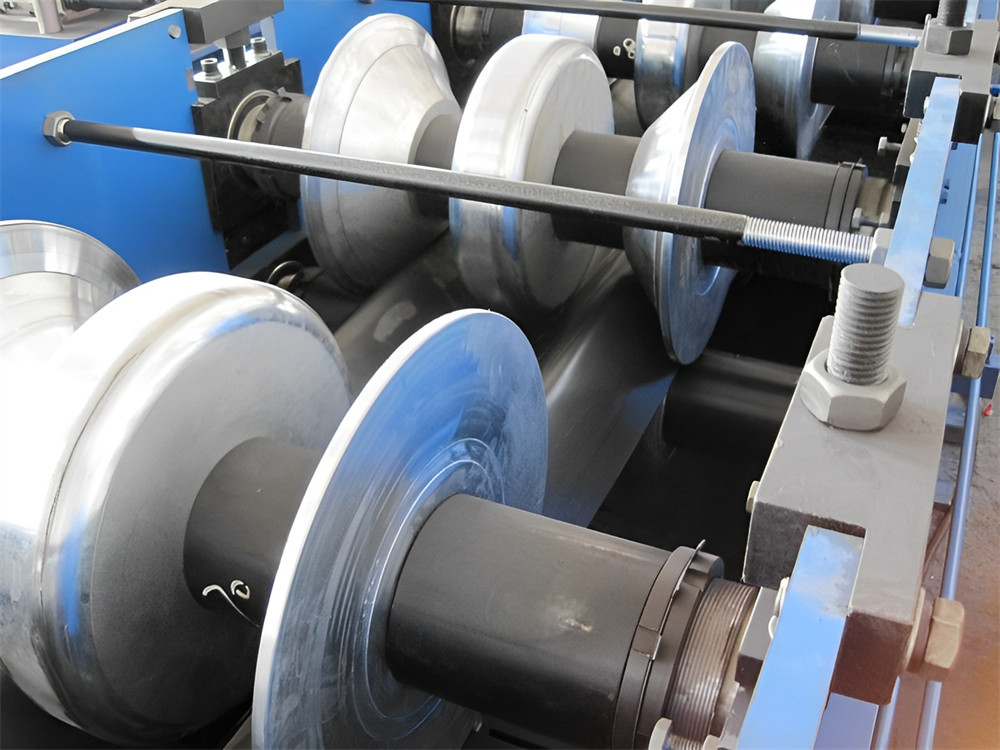

What Are Aluminum Profile Roll Forming Machines?

Ан Aluminum Profile Roll Forming Machine is a specialized piece of equipment designed to fabricate precise, custom aluminum profiles by feeding aluminum sheets or coils through a series of rollers. These rollers gradually shape the material into the desired cross-sectional profile, ensuring consistency, accuracy, and durability.

Основные характеристики

- Универсальность материалов: Machines are optimized for processing various grades of aluminum, including coated, anodized, and raw aluminum.

- Высокоскоростное производство: Capable of producing complex profiles at speeds of up to 100 meters per minute.

- Точное машиностроение: Maintains tight tolerances to ensure every profile fits its intended application perfectly.

- Customizable Designs: Supports the creation of unique profiles to meet specific project requirements.

- Eco-Friendly Operations: Reduces material wastage and energy consumption, aligning with sustainability goals.

Applications of Aluminum Profile Roll Forming Machines

These machines are indispensable for manufacturing aluminum components used across a myriad of industries. Here’s a breakdown of their key applications:

1. Construction and Architecture

- Пример использования: Producing aluminum profiles for curtain walls, window frames, door frames, and structural frameworks.

- Почему это необходимо: Ensures lightweight, corrosion-resistant components that are easy to install and maintain.

2. Автомобильная промышленность

- Пример использования: Manufacturing components like roof rails, crash barriers, and trim profiles.

- Почему это важно: Provides lightweight yet durable parts that improve vehicle performance and fuel efficiency.

3. Возобновляемая энергия

- Пример использования: Crafting mounting systems and supports for solar panels and wind turbines.

- Почему это актуально: Supports the renewable energy sector with durable, weather-resistant components.

4. Electronics and Appliances

- Пример использования: Producing heat sinks, enclosures, and structural components for electrical devices.

- Почему это полезно: Ensures precise, high-quality profiles for sensitive electronic applications.

5. Furniture and Interior Design

- Пример использования: Creating profiles for modular furniture, decorative trims, and partition systems.

- Почему это уникально: Delivers aesthetically pleasing and functional designs for modern interiors.

6. Transportation Infrastructure

- Пример использования: Manufacturing profiles for railway tracks, airport walkways, and pedestrian bridges.

- Почему это ценно: Offers lightweight solutions that reduce installation time and costs.

Why Aluminum Profile Roll Forming Machines Are Gaining Popularity

The versatility and efficiency of aluminum make it a preferred material across industries, and Машины для формовки алюминиевых профилей are perfectly suited to meet the rising demand. Here’s why they are indispensable:

1. Lightweight and Durable

- Почему это важно: Aluminum profiles are strong yet lightweight, making them ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

2. Corrosion Resistance

- Почему это важно: Aluminum profiles can withstand harsh environmental conditions, making them perfect for outdoor applications like construction and renewable energy systems.

3. Персонализация

- Почему это полезно: Roll-forming machines can produce profiles of various shapes, sizes, and finishes, catering to diverse industry needs.

4. Eco-Friendly Manufacturing

- Почему это необходимо: Aluminum is highly recyclable, and roll-forming machines minimize waste, supporting sustainable production practices.

5. High Production Efficiency

- Почему это необходимо: Roll-forming machines are designed for continuous operation, enabling manufacturers to meet high-volume demands without compromising quality.

Key Features of Wuxi Sunway Aluminum Profile Roll Forming Machines

Уси Sunway машины is a trusted name in the roll-forming industry, offering cutting-edge solutions for aluminum profile manufacturing. Here’s why their machines stand out:

1. Передовые технологии обработки материалов

- Поддерживаемые материалы:

- Raw Aluminum

- Anodized Aluminum

- Coated Aluminum

- Почему это полезно: Ensures compatibility with a range of materials for versatile applications.

2. Точное машиностроение

- Производительность: Допуски до ±0,02 мм, обеспечивающие точные размеры.

- Почему это важно: Guarantees seamless assembly and compatibility with other components.

3. Модульные системы оснастки

- Что он предлагает: Сменная оснастка для производства нескольких профилей на одном станке.

- Почему это ценно: Reduces downtime during tooling changes and increases production flexibility.

4. Интеграция IoT и автоматизации

- Что это дает: Мониторинг в реальном времени, автоматическая настройка и предиктивное обслуживание с помощью систем IoT.

- Почему это революционно:

- Повышает эффективность производства.

- Снижение эксплуатационных расходов.

5. High-Speed Operation

- Производительность: Produces profiles at speeds of up to 100 метров в минуту.

- Почему это необходимо: Meets the high-volume demands of industries like construction and automotive.

6. Экологичный дизайн

- Что в него входит: Energy-efficient motors, reduced material waste, and support for recyclable aluminum.

- Почему это необходимо: Aligns with global sustainability goals and reduces the carbon footprint of manufacturing.

7. Integrated Cutting and Punching

- Что он предлагает: Built-in systems for cutting and punching aluminum sheets during the roll-forming process.

- Почему это эффективно: Speeds up production and ensures ready-to-use components.

Pricing of Aluminum Profile Roll Forming Machines

Стоимость Aluminum Profile Roll Forming Machine depends on its features, capacity, and level of customization. Below is a general pricing guide for 2025:

| Тип машины | Возможности | Диапазон цен (USD) |

|---|---|---|

| Стандартные машины | Basic aluminum profile production | 150,000–150,000–150,000–400,000 |

| Передовые машины | Высокоскоростные интегрированные системы резки и штамповки | 400,000–400,000–400,000–1,000,000 |

| Полностью настраиваемые машины | IoT, модульная оснастка и экологичность | 1,000,000–1,000,000–1,000,000–2,500,000 |

Для получения подробной информации о ценах и возможностях финансирования обращайтесь Уси Sunway машины.

Innovations in Aluminum Profile Roll Forming Technology

The roll-forming industry is evolving rapidly, with new technologies enhancing the capabilities of Машины для формовки алюминиевых профилей. Here are the latest innovations:

1. Технология цифрового двойника

- Что он имитирует: Virtual models of the roll-forming process to optimize machine settings.

- Почему это революционно:

- Reduces setup time and trial-and-error adjustments.

- Ensures consistent quality from the first production run.

2. Контроль качества с помощью искусственного интеллекта

- Что он делает: Monitors dimensions, surface quality, and material thickness in real-time.

- Почему это изменит игру:

- Detects defects early, reducing waste.

- Улучшает общее качество продукции.

3. Возможность работы с несколькими профилями

- Что это дает: Produces multiple profiles in a single production cycle.

- Почему это полезно:

- Increases production speed.

- Supports diverse manufacturing needs.

4. Интеграция IoT

- Что он предлагает: Real-time data collection, predictive maintenance, and automated adjustments.

- Почему это важно:

- Enhances machine uptime.

- Reduces maintenance costs.

5. Eco-Friendly Coating Systems

- Что в него входит: Systems for applying protective or decorative coatings during the roll-forming process.

- Почему он устойчив:

- Eliminates additional coating processes.

- Reduces energy consumption.

FAQs About Aluminum Profile Roll Forming Machines

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Aluminum (raw, anodized, coated) and other lightweight metals. |

| Какова скорость производства? | До 100 метров в минутув зависимости от сложности профиля. |

| Экологичны ли эти машины? | Да, они оснащены энергосберегающими двигателями и минимизируют отходы материалов. |

| Могут ли эти машины работать с индивидуальными проектами? | Absolutely! Modular tooling supports bespoke profiles for diverse applications. |

| Соответствуют ли эти машины стандартам безопасности? | Yes, they meet CE, ISO, and OSHA certifications for safety and reliability. |

| Могут ли эти машины интегрироваться с системами IoT? | Да, функции с поддержкой IoT позволяют осуществлять мониторинг в режиме реального времени и прогнозировать техническое обслуживание. |

Real-World Success Stories: Aluminum Profile Roll Forming Machines in Action

Универсальность и эффективность Машины для формовки алюминиевых профилей are evident in their application across diverse industries. Here are some real-world examples that illustrate their transformative impact:

1. Case Study: Solar Energy Infrastructure

- Клиент: A solar energy company managing large-scale solar farms in North America.

- Вызов: The company needed lightweight yet durable mounting systems for solar panels that could withstand extreme weather conditions.

- Решение: Wuxi Sunway Machinery provided a roll-forming machine capable of processing anodized aluminum and integrating custom profiles for mounting brackets.

- Результаты:

- Increased production output by 35%, enabling faster installation of solar farms.

- Delivered corrosion-resistant components with precise dimensions.

- Reduced material waste by 20%, aligning with the company’s sustainability goals.

2. Case Study: Automotive Component Supplier

- Клиент: A leading supplier of aluminum parts for электромобили (EVs) in Europe.

- Вызов: The client needed high-strength, lightweight aluminum profiles for EV battery enclosures and crash barriers.

- Решение: Wuxi Sunway developed a roll-forming machine with integrated cutting and punching capabilities for high-strength alloys.

- Результаты:

- Reduced production lead times by 40%.

- Delivered components that improved vehicle energy efficiency and safety.

- Enabled the client to expand their product portfolio and secure new contracts.

3. Case Study: Architectural Firm

- Клиент: A construction company specializing in modern architectural designs in the Middle East.

- Вызов: The firm needed customized aluminum profiles for curtain walls and decorative trims that could withstand high temperatures and sand exposure.

- Решение: Wuxi Sunway supplied a roll-forming machine optimized for pre-coated aluminum with advanced surface finishes.

- Результаты:

- Produced elegant, weather-resistant profiles that met the aesthetic and functional requirements of the project.

- Reduced production costs by 25% compared to traditional fabrication methods.

- Enhanced the firm’s reputation for delivering high-quality architectural projects.

4. Case Study: Modular Furniture Manufacturer

- Клиент: A furniture manufacturer specializing in modular and customizable designs.

- Вызов: The company needed lightweight, easy-to-assemble aluminum profiles for their furniture systems.

- Решение: Wuxi Sunway provided a roll-forming machine with modular tooling for creating diverse profile designs.

- Результаты:

- Increased production flexibility, allowing the company to cater to evolving customer preferences.

- Delivered components with a flawless finish, enhancing the product’s market appeal.

- Reduced production waste, supporting the company’s eco-friendly initiatives.

Sustainability Practices in Aluminum Profile Manufacturing

Sustainability is a key focus in modern manufacturing, and Машины для формовки алюминиевых профилей are designed to support eco-friendly practices. Here’s how they contribute to a greener future:

1. Energy-Efficient Operations

- Как это достигается: Усовершенствованные двигатели и оптимизированные рабочие процессы снижают потребление электроэнергии.

- Воздействие: Lowers the carbon footprint of manufacturing processes, aligning with global sustainability goals.

2. Reduced Material Waste

- Как это достигается: Системы прецизионной резки и формовки сводят к минимуму количество брака в процессе производства.

- Воздействие: Экономия сырья и снижение производственных затрат.

3. Поддержка вторичного сырья

- Как это достигается: Machines are designed to process recyclable aluminum materials.

- Воздействие: Promotes the reuse of materials, reducing waste and supporting circular economy practices.

4. Долговечные компоненты

- Почему это важно: Durable aluminum profiles require less frequent replacement, reducing overall material consumption.

- Воздействие: Extends the lifecycle of products, minimizing environmental impact.

5. Coating Integration

- Как это достигается: Machines support eco-friendly coatings that enhance the durability and aesthetics of aluminum profiles.

- Воздействие: Eliminates the need for additional coating processes, reducing energy usage.

Safety Standards for Aluminum Profile Roll Forming Machines

Safety is paramount in manufacturing, and Машины для формовки алюминиевых профилей are equipped with advanced features to protect operators and ensure compliance with global standards.

1. Системы аварийного останова

- Что он делает: Allows operators to halt machine operations instantly in case of an emergency.

- Почему это важно: Предотвращает несчастные случаи и минимизирует повреждения оборудования во время непредвиденных происшествий.

2. Safety Guards and Shields

- Что в него входит: Защитные ограждения вокруг движущихся частей для предотвращения случайного контакта.

- Почему это важно: Снижает риск травм, вызванных человеческим фактором или механическими неисправностями.

3. Light Curtains

- Что он обнаруживает: Определяет объекты или персонал в опасных зонах и автоматически приостанавливает работу оборудования.

- Почему это эффективно: Enhances safety without interrupting production workflows.

4. Noise and Vibration Reduction

- Что он уменьшает: Минимизирует уровень шума и вибрации во время работы.

- Почему это полезно: Создает более безопасную и комфортную рабочую среду для операторов.

5. Compliance with Global Standards

- Сертификаты: Станки соответствуют стандартам CE, ISO 45001 и OSHA по безопасности и защите окружающей среды.

- Почему это необходимо: Ensures reliability and safety in diverse global markets.

Global Market Trends for Aluminum Profile Roll Forming Machines in 2025

As industries adapt to changing demands and technological advancements, the market for Машины для формовки алюминиевых профилей continues to expand. Here are the key trends driving growth:

1. Increasing Adoption in Renewable Energy

- Тренд: The renewable energy sector’s growth is fueling demand for lightweight, corrosion-resistant aluminum profiles.

- Воздействие: Roll-forming machines capable of producing solar panel mounting systems and wind turbine components are in high demand.

2. Expansion of the Automotive Industry

- Тренд: The rise of electric vehicles (EVs) is driving the need for lightweight aluminum components.

- Воздействие: Manufacturers require high-capacity roll-forming machines to meet production targets.

3. Growth in Urbanization and Infrastructure Development

- Тренд: Rapid urbanization is increasing demand for construction materials like aluminum frames, doors, and windows.

- Воздействие: Roll-forming machines designed for architectural applications are becoming essential.

4. Shift Towards Sustainable Manufacturing

- Тренд: Companies are adopting eco-friendly practices to meet consumer expectations and regulatory requirements.

- Воздействие: Machines optimized for energy efficiency and recyclable materials are gaining traction.

5. Integration with Industry 4.0

- Тренд: The adoption of IoT and AI in manufacturing is driving demand for smart roll-forming machines.

- Воздействие: Machines with real-time monitoring and predictive maintenance capabilities are becoming industry standards.

Why Choose Wuxi Sunway Machinery for Aluminum Profile Roll Forming Machines?

Уси Sunway машины is a global leader in roll-forming technology, trusted by manufacturers across industries. Here’s why they are the go-to partner for aluminum profile production:

- Проверенный опыт: Десятилетний опыт разработки высокопроизводительных вальцовочных станков.

- Глобальный охват: Machines are used successfully in Asia, Europe, the Americas, and beyond.

- Инновационный подход: Features like IoT integration, modular tooling, and AI-powered quality control set their machines apart.

- Обязательства в области устойчивого развития: Машины оптимизированы для экологичного производства, поддерживая глобальные цели устойчивости.

- Комплексная поддержка: От консультаций до послепродажного обслуживания - Wuxi Sunway обеспечивает бесперебойную работу.

Conclusion: Shaping the Future of Manufacturing with Aluminum Profiles

Машины для формовки алюминиевых профилей are revolutionizing modern manufacturing by combining precision, efficiency, and sustainability. Their versatility makes them indispensable for industries ranging from construction and automotive to renewable energy and electronics.

Ready to transform your manufacturing processes? Partner with Уси Sunway машины and explore their innovative roll-forming solutions tailored to your needs. Together, let’s shape a smarter, more sustainable future—one aluminum profile at a time.