Введение

Вы собираетесь приобрести подержанная валковая формовочная машина чтобы сэкономить деньги и при этом расширить производственные мощности? Многие производители выбирают подержанные валковые формовочные машины для снижения первоначальных затрат, но так ли это на самом деле. разумные инвестиции?

Покупка подержанная валковая формовочная машина может быть экономичная альтернатива если вы знаете, что искать. Однако есть и возможные рискиНапример, скрытые дефекты, устаревшие технологии и высокие эксплуатационные расходы.

В этом руководстве мы рассмотрим:

✅ Преимущества и недостатки покупки подержанного вальцовочного станка

✅ Где купить высококачественные подержанные вальцовочные станки

✅ Как осмотреть и оценить подержанную вальцовочную машину перед покупкой

✅ Сравнение стоимости: Новые и подержанные машины для формовки рулонов

✅ Основные ошибки, которых следует избегать при покупке подержанных машин

Давайте изучим, можно ли подержанная валковая формовочная машина это правильный выбор для вашего бизнеса!

Преимущества покупки подержанной роликовой формовочной машины

Покупка используемая валковая формовочная машина может обеспечить несколько преимуществ, в том числе:

1. Низкие первоначальные инвестиции

✅ Подержанная вальцовочная машина обычно стоит 30-50% меньше чем новый.

✅ Идеально подходит для стартапы и небольшие производства ищут возможность расширить производство при ограниченном бюджете.

2. Быстрая доступность

✅ В отличие от новых машин, которые имеют срок изготовления 2-6 месяцев, подержанные машины немедленно доступен.

✅ Помогает бизнесу быстрое наращивание производства не дожидаясь.

3. Доказанная эффективность

✅ Некоторые подержанные машины имеют рекорд надежностиЭто делает их более безопасными инвестициями.

✅ Часто поддерживается в хорошем состоянии предыдущими владельцами, обеспечивая постоянную эффективность.

4. Экологически чистый

✅ Покупка подержанного оборудования сокращает количество отходов и способствует устойчивому развитию в производстве.

Совет профессионала: Хорошо отремонтированная подержанная вальцовочная машина может обеспечивать высокое качество продукции еще 5-10 лет!

Недостатки покупки подержанной роликовой формовочной машины

В то время как подержанная валковая формовочная машина может сэкономить деньги, но есть и возможные недостатки рассмотреть.

1. Более высокие эксплуатационные расходы

❌ На старых машинах может быть изношенные ролики, режущие ножи или двигателичто приводит к увеличению расходов на ремонт.

❌ Запасные части могут быть трудно найтиЭто увеличивает время простоя.

2. Устаревшие технологии

❌ В подержанных машинах может отсутствовать современная автоматика, серводвигатели и системы управления с ПЛК, снижая производительность.

❌ Новые модели более энергоэффективныЭто позволяет экономить на эксплуатационных расходах в долгосрочной перспективе.

3. Отсутствие гарантии и ограниченной поддержки

❌ В отличие от новых машин, которые поставляются с гарантия и техническая поддержкаПодержанные машины часто имеют никаких гарантий.

❌ Если аппарат не работает, вам может потребоваться оплачивайте все ремонтные работы самостоятельно.

4. Скрытые дефекты и износ

❌ Некоторые продавцы не раскрывать информацию о проблемах с машинамичто приводит к неожиданным поломкам.

❌ Всегда тщательно осмотрите машину перед покупкой.

Совет профессионала: Если стоимость ремонта составляет более половины стоимости новой машины, покупка подержанной может оказаться нецелесообразной!

Где купить высококачественные рулонные формовочные машины?

Поиск надёжный источник для подержанных вальцовочных станков имеет решающее значение. Вот лучшие места, чтобы купить подержанные валковые формовочные машины:

1. Напрямую от производителей

✅ Некоторые производители, например WUXI SUNWAY MACHINERY, предложение восстановленные вальцовочные станки с проверка качества и ограниченная гарантия.

✅ Машины профессионально проверены, отремонтированы и протестированы.

2. Онлайн-маркеты

✅ Alibaba, eBay и TradeIndia есть объявления о продаже подержанных вальцовочных станков.

✅ Будь с осторожностью относитесь к неизвестным продавцам и всегда просите подробные технические характеристики машины.

3. Промышленные аукционы и ликвидационные продажи

✅ Компании часто закрываются или модернизируют свое оборудование продавать подержанные машины по низким ценам.

✅ Проверьте аукционы и ликвидационные распродажи металлообрабатывающего оборудования.

4. Дилеры и торговые посредники

✅ Некоторые дилеры купить и отремонтировать подержанные вальцовочные станки для перепродажи.

✅ Убедитесь, что они обеспечивают подробная история машины и отчеты об испытаниях.

Совет профессионала: Покупайте у проверенного производителя, такого как WUXI SUNWAY MACHINERY чтобы получить надежную, проверенную б/у вальцовочную машину!

Как осмотреть подержанную роликоформовочную машину перед покупкой

Перед покупкой подержанная валковая формовочная машинаСледуйте за этим контрольный список чтобы избежать дорогостоящих ошибок.

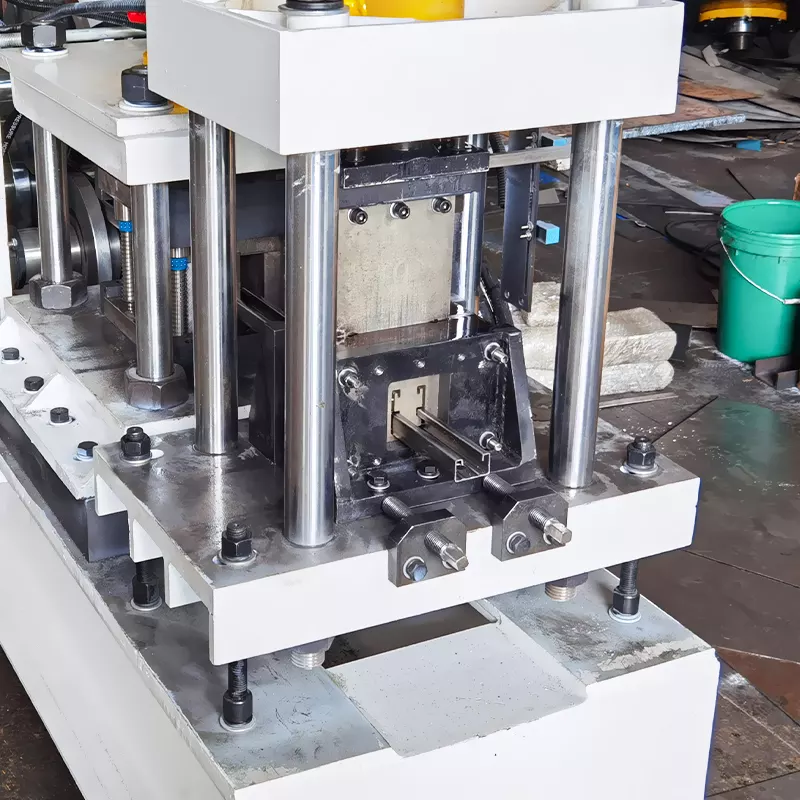

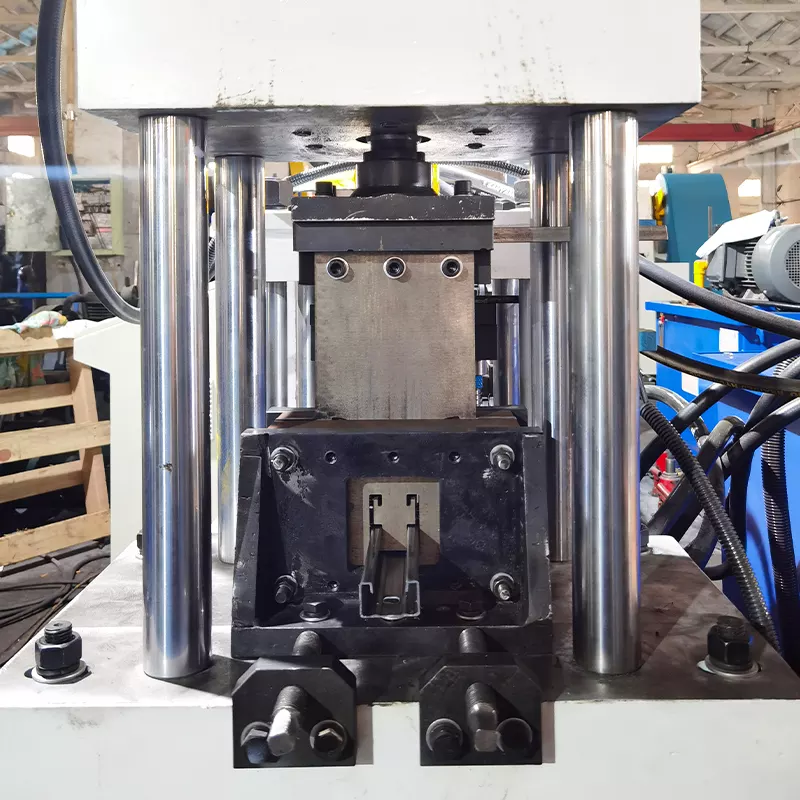

✅ 1. Проверка роликов и формовочных станций

- Ищите следы износа, ржавчины или трещин на роликах.

- Обеспечить Ролики правильно выровнены для точной формовки листов.

✅ 2. Осмотрите режущую систему

- Проверьте гидравлическую или сервоприводную систему резки для резкости и точности.

- Ищите утечки масла или изношенные режущие лезвия.

✅ 3. Оцените систему управления (ПЛК и двигатели)

- Проверка панели управления ПЛК обеспечить правильное программирование и точность.

- Убедитесь, что двигатель и система привода работают плавно и без лишнего шума.

✅ 4. Запустите тестовый производственный цикл

- Запросите живую демонстрацию чтобы увидеть машину в действии.

- Измерьте качество и скорость вывода чтобы убедиться, что он соответствует вашим производственным потребностям.

✅ 5. Попросите предоставить записи о техническом обслуживании

- Проверьте, есть ли предыдущий владелец проводил регулярное техническое обслуживание.

- Обеспечить запасные части в наличии для конкретной модели машины.

Совет профессионала: Если продавец отказывается предоставить тестовый запуск, записи технического обслуживания или историю машины, считайте это тревожным сигналом!

Новые и подержанные машины для формовки рулонов: Сравнение стоимости

| Фактор | Новая роликовая формовочная машина | Подержанные рулонные формовочные машины |

|---|---|---|

| Цена | 30,000-30,000 - 30,000-300,000 | 30-50% дешевле, чем новый |

| Технология | Новейшая автоматика и серводвигатели | Старая технология, может потребоваться модернизация |

| Продолжительность жизни | 10-15 лет | 5-10 лет (в зависимости от состояния) |

| Настройка | Полностью настраиваемый | Ограниченные возможности настройки |

| Гарантия и поддержка | Гарантия производителя включена | Отсутствие гарантии, повышенные риски ремонта |

Совет профессионала: Если подержанная машина стоит дороже, чем 60% новая, лучше вложиться в новую модель!

Основные ошибки, которых следует избегать при покупке рулонной формовочной машины второго поколения

🚫 Ошибка #1: покупка без осмотра машины

✅ Запрос видеодемонстрация или личный осмотр перед покупкой.

🚫 Ошибка #2: игнорирование доступности запасных частей

✅ Проверьте, есть ли сменные ролики, двигатели и режущие ножи все еще находятся в производстве.

🚫 Ошибка #3: покупка устаревших моделей

✅ Избегайте машин старше 10 леткак им может не хватать современная автоматизация и эффективность.

🚫 Ошибка #4: игнорирование скрытых расходов

✅ Фактор доставка, установка, ремонт и модернизация прежде чем завершить покупку.

Совет профессионала: Чтобы оправдать покупку, подержанная вальцовочная машина должна быть как минимум на 30% дешевле новой!

Как договориться о лучшей цене на вторую рулонную формовочную машину

Покупка используемая валковая формовочная машина не означает, что вы должны переплачивать. Умные переговоры помогут вам Сократите расходы и получите лучшую сделку. Вот как эффективно вести переговоры при покупке подержанной машины.

1. Изучите рыночные цены и сравните предложения

✅ Проверьте несколько объявлений из различные продавцы, производители и дилеры.

✅ Сравните характеристики, возраст, состояние машины и входящие в комплект аксессуары.

✅ Используйте эти данные, чтобы торговаться в поисках лучшей сделки.

2. Запросите полный осмотр машины перед заключением сделки

✅ Попросите подробные фотографии, видео и записи технического обслуживания.

✅ Если это возможно, посетите сайт продавца чтобы лично осмотреть машину.

✅ Если машина имеет значительный износИспользуйте это как точка переговоров по более низкой цене.

3. Договоритесь о дополнительных расходах (доставка, установка, запасные части).

✅ Некоторые продавцы дополнительная плата за упаковку, доставку и установку-попробуйте получить это включено в стоимость.

✅ Если требуются запасные части, договаривайтесь о том, чтобы их предоставляли со скидкой.

4. Попросите провести пробный запуск перед покупкой

✅ Запрос на просмотр машина в работе чтобы убедиться, что он работает правильно.

✅ Если продавец отказывается, это может указывать на скрытые дефекты.

5. Рассмотрите возможность оптовых закупок для получения больших скидок

✅ Если вам нужно несколько машин, Покупка оптом может привести к значительному снижению цен.

✅ Некоторые поставщики предлагают специальные цены для постоянных клиентов.

Совет профессионала: Если вы покупаете товары за рубежом, договоритесь о бесплатной доставке или помощи в оплате таможенных сборов!

Скрытые расходы при покупке подержанной роликовой формовочной машины

В то время как подержанная машина может показаться дешевле, чем на начальном этапеБудьте внимательны к потенциальным скрытые расходы которые могут повлиять на ваш бюджет.

1. Доставка и импортные пошлины

✅ Стоимость международных грузоперевозок варьируется от 2,000-2,000 - 2,000-10,000В зависимости от местоположения.

✅ Импортные пошлины и налоги зависят от страны - проверьте. местные нормативы перед покупкой.

2. Установка и обучение операторов

✅ Много подержанных машин не поставляются с поддержкой при установкеПоэтому вам может понадобиться нанять специалиста.

✅ Обучение оператора может потребоваться для понимать систему управления машиной.

3. Запасные части и ремонт

✅ Если модель слишком старыйЗапасные части могут быть трудно найти или на заказ, увеличивая расходы.

✅ Некоторые машины требуют регулировка роликов или заточка лезвий перед использованием.

4. Энергопотребление и эффективность

✅ Старые машины потребляют больше энергии, что приводит к более высокие затраты на электроэнергию.

✅ Новые модели более энергоэффективныйСнижение долгосрочных расходов.

5. Риски простоя производства

✅ Если машина часто ломаетсяПотерянное производственное время может дорого обойтись.

✅ Убедитесь, что машина находится в хорошее рабочее состояние перед покупкой.

Совет профессионала: При составлении бюджета на подержанную машину учитывайте как минимум 10-15% на скрытые расходы!

Восстановленные и бывшие в употреблении роликоформовочные машины: В чем разница?

Не все подержанные машины одинаковы. Некоторые продавцы предлагают восстановленные машины, который может быть лучшие инвестиции.

| Фактор | Подержанная машина | Восстановленная машина |

|---|---|---|

| Состояние | Продается "как есть" с возможным износом | Полностью проверено и отреставрировано |

| Ремонт и модернизация | Без ремонта, может потребоваться техническое обслуживание | Замена деталей, проверка электрических систем |

| Гарантия | Обычно гарантия отсутствует | Может предоставляться краткосрочная гарантия |

| Цена | Более низкая первоначальная стоимость | Немного выше, но лучше в долгосрочной перспективе |

| Уровень риска | Высокий (могут быть скрытые проблемы) | Нижний (профессионально протестирован) |

Совет профессионала: Если есть возможность, выбирайте восстановленную машину, а не бывшую в употреблении - это может стоить немного дороже, но гарантирует большую надежность!

Когда лучше купить новую роликоформовочную машину?

Хотя подержанные вальцовочные станки могут сэкономить деньги, в некоторых случаях, Покупка новой машины - лучшее долгосрочное вложение.

Купите новую машину, если:

✅ Вам нужно высокоскоростное, полностью автоматизированное производство.

✅ Ваш бизнес требует индивидуальные профили для роликовой прокатки.

✅ Вы хотите гарантия и надежная послепродажная поддержка.

✅ Вас беспокоит энергоэффективность и долгосрочные эксплуатационные расходы.

✅ Вы планируете использовать машину для 10+ лет без частой замены.

Купите подержанную машину, если:

✅ У вас есть ограниченный бюджет и хотят быстро запустить производство.

✅ Объем вашего производства составляет относительно низкий.

✅ Вам удобно периодические расходы на ремонт и техническое обслуживание.

✅ Вы находите отремонтированная машина в отличном состоянии.

Совет профессионала: Если подержанная машина стоит больше, чем 60% новая, лучше вложить деньги в новую модель!

Где купить надежные рулонные формовочные машины?

Для высококачественные подержанные и восстановленные вальцовочные станкипосмотрите WUXI SUNWAY MACHINERY CO., LTD..

Почему стоит выбрать WUXI SUNWAY MACHINERY для покупки подержанных машин?

✅ Профессионально отремонтированные машины - Проверено, протестировано и готово к использованию.

✅ Доступны запасные части и поддержка - Избегайте простоев благодаря быстрой замене запасных частей.

✅ Конкурентное ценообразование - Недорогие машины с отличная долгосрочная стоимость.

✅ Глобальная доставка и поддержка при установке - Беспроблемная доставка и помощь в настройке.

Ищете экономически эффективную вальцовочную машину? Свяжитесь с нами сегодня!

ВОПРОСЫ И ОТВЕТЫ: Покупка подержанной роликовой формовочной машины

1. Стоит ли покупать подержанную вальцовочную машину?

- Да, если машина в хорошем состоянии и вы экономите не менее 30-50% по сравнению с новой.

- Однако избегайте машин, которые требуют дорогостоящий ремонт или устаревшие модели без запасных частей.

2. Сколько стоит подержанная вальцовочная машина?

- Цена на подержанные вальцовочные станки варьируется, но обычно составляет 30-50% дешевле, чем новый.

- Ожидайте, что цены будут варьироваться от 10 000 - 10 000 - 10 000 - 150 000в зависимости от возраст, особенности и состояние.

3. Что нужно проверить перед покупкой подержанной вальцовочной машины?

- Осмотрите ролики, режущая система, двигатели, панель управления, и общее выравнивание.

- Попросите записи о техническом обслуживании и пробный запуск для проверки работоспособности.

4. Где можно найти подержанные вальцовочные станки для продажи?

- WUXI SUNWAY MACHINERY предлагает сертифицированные восстановленные вальцовочные станки.

- Онлайн-рынки, такие как Alibaba, eBay и местные промышленные аукционы также перечисляют подержанные машины.

5. Следует ли мне купить восстановленную или обычную подержанную машину для формовки валков?

- Восстановленные машины Это более безопасные инвестиции, поскольку они проверено, отремонтировано и испытано.

- Регулярно используемые машины могут быть дешевле, но поставляются с повышенные риски и возможные скрытые дефекты.

Заключительные размышления

Покупка подержанная валковая формовочная машина может быть Экономически эффективный способ расширения производстваНо очень важно оцените состояние машины, ведите разумные переговоры и учитывайте скрытые расходы.

✅ Нужен доступная и надежная вальцовочная машина?

✅ Ищу отремонтированная машина для формирования валков с гарантированным качеством?