Введение

Ever wondered how long, uniform metal profiles like roofing sheets, C & Z purlins, and highway guardrails are made? The answer lies in the процесс валковой формовки—an efficient, high-speed metal shaping method used across multiple industries.

А профилегибочная машина is designed to progressively shape metal sheets by passing them through a series of прецизионные ролики. Unlike traditional metal bending methods, roll forming minimizes material waste, reduces labor costs, and enhances production efficiency.

В этом руководстве мы рассмотрим:

✅ How a roll forming machine works

✅ Key components of a roll forming system

✅ Step-by-step roll forming process

✅ Типы профилегибочных машин

✅ Advantages of roll forming over other metal forming methods

Let’s dive into the mechanics behind one of the most efficient metal shaping processes in modern manufacturing!

Как работает профилегибочная машина?

А профилегибочная машина operates by gradually bending a metal strip into a specific shape through multiple sequential roller stations. Instead of bending the metal all at once (like press braking), roll forming applies incremental bends over several roller stages, ensuring smooth, precise shaping.

Basic Working Principle

1️⃣ Подача материала – A metal coil is unrolled and fed into the machine.

2️⃣ Постепенное формирование – The metal passes through a series of roller stations, each making small incremental bends.

3️⃣ Inline Processing (Optional) – Punching, notching, embossing, or welding can be integrated into the process.

4️⃣ Резка по длине – The formed profile is cut to the required size.

5️⃣ Final Product Output – The finished part is sent for inspection and packaging.

Совет профессионала: The incremental bending process ensures minimal material stress, resulting in high-strength, precision-formed profiles.

Ключевые компоненты

А высококачественная валковая формовочная машина consists of multiple essential components that work together to create complex metal profiles with precision and efficiency.

Major Components & Their Functions

| Компонент | Функция |

|---|---|

| Разматыватель | Holds and unwinds the metal coil for feeding into the machine. |

| Feeding Guide System | Aligns and directs the sheet into the rollers. |

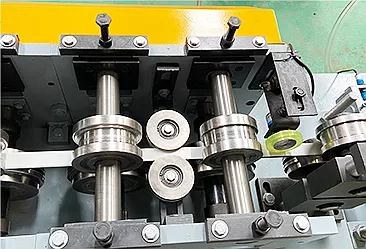

| Роликовые станции | Multiple rollers progressively shape the metal sheet. |

| Punching/Notching Unit (Optional) | Adds holes, slots, or indentations in the metal before final forming. |

| Система резки | Обрежьте сформированный профиль до нужной длины. |

| Hydraulic or Servo Motor Drive | Powers the rollers, ensuring smooth material movement. |

| Control System (PLC/CNC) | Automates and monitors the entire roll forming process. |

| Product Output Table | Collects finished parts for inspection and packaging. |

Sunway Machine предоставляет валковые формовочные машины, изготовленные по индивидуальному заказу с advanced automation and precision controls.

Пошаговый процесс формовки рулонов

The процесс валковой формовки is designed for continuous, high-speed metal shaping, making it ideal for mass production of uniform profiles.

Detailed Roll Forming Process Flow

| Шаг | Описание |

|---|---|

| 1. Загрузка материала | Металлическая катушка помещается на разматыватель, and the sheet is fed into the machine. |

| 2. Initial Feeding & Alignment | Лист проходит через alignment guides to ensure straight entry. |

| 3. Progressive Roll Forming | The metal sheet moves through несколько роликовых станций, each applying gradual bends. |

| 4. Inline Punching & Notching (If Required) | Servo-driven punching units create holes, slots, or embossing as needed. |

| 5. Резка по длине | А hydraulic or flying shear cutting system slices the formed profile at the required length. |

| 6. Final Product Output | The finished part exits onto the выходная таблица for quality inspection. |

Совет профессионала: Servo-controlled cutting systems обеспечить precise, burr-free cuts with minimal waste.

Типы

Different applications require различные типы валковых машин, each offering unique advantages на основе profile complexity, production speed, and automation level.

Comparison

| Тип машины | Лучшее для | Основные характеристики |

|---|---|---|

| Однопрофильная роликовая формовочная машина | Fixed-profile production (e.g., roofing sheets) | Cost-effective, compact design |

| Многопрофильная роликовая формовочная машина | Producing multiple profiles with quick-change tooling | Reduces downtime, increases flexibility |

| Регулируемая роликовая формовочная машина | Customizable width and shape adjustments | Ideal for C & Z purlin production |

| Высокоскоростная роликовая формовочная машина | Mass production of uniform profiles | До 50 метров в минуту |

| Fully Automated Roll Forming Machine | High-precision, CNC-controlled operations | AI-powered defect detection, IoT integration |

Looking for a custom roll forming solution? Sunway Machine предлагает high-speed, precision roll forming machines для global manufacturers.

Advantages of Roll Forming Over Other Metal Forming Methods

Roll forming is widely preferred over press braking, stamping, and extrusion due to its efficiency, precision, and cost-effectiveness.

Why Choose Roll Forming?

| Преимущество | Профилирование | Press Braking / Stamping |

|---|---|---|

| Скорость производства | Continuous process (up to 50m/min) | Slower, batch-based production |

| Материальные отходы | Minimal waste due to incremental bending | More waste due to trial-and-error adjustments |

| Labor Cost | Low – fully automated process | High – requires manual adjustments |

| Part Consistency | High uniformity for long, repeated profiles | Variations possible in batch production |

| Стоимость оснастки | Higher initial cost, but lower per-unit cost | Lower initial cost, but higher per-unit cost |

Вердикт: Roll forming is the best choice for high-volume, cost-efficient, precision manufacturing.

Common Problems & Solutions

Даже с Современные валковые машиныОператоры могут столкнуться с challenges such as material distortion, misalignment, and roller wear. Выявление и устранение этих проблем рано обеспечивает smooth production and high-quality output.

Руководство по устранению неполадок

| Выпуск | Возможная причина | Решение |

|---|---|---|

| Profile Misalignment | Incorrect roller positioning, loose material feeding | Re-calibrate rollers and adjust material guides |

| Material Slipping in the Rollers | Loose feeder rollers, improper tension settings | Подтяните ролики подающего механизма и отрегулируйте натяжение материала |

| Surface Scratches or Deformation | Dirty rollers, excessive forming pressure | Clean rollers regularly and adjust forming pressure |

| Несоответствующая длина резки | Неисправность режущей системы, смещение лезвий | Осмотрите и откалибруйте режущий механизм |

| Roller Wear Due to High Friction | Lack of lubrication, excessive pressure | Apply proper lubrication and use hardened rollers |

Совет профессионала: Обычный калибровка и смазка роликов можно увеличить срок службы машины на 40% и значительно сократить количество дефектов профиля.

Будущие тенденции в технологии формования рулонов

The валковая промышленность быстро развивается с ИИ, IoT и автоматизация, улучшая эффективность, точность и устойчивость.

Key Innovations in Roll Forming Machines for 2025

1. Обнаружение и самостоятельное исправление дефектов на основе искусственного интеллекта

- с искусственным интеллектом Камеры и датчики обнаруживают дефекты в режиме реального времениСокращение отходов материалов.

- Обеспечивает consistent profile accuracy without operator intervention.

2. IoT-Enabled Remote Monitoring

- Теперь машины оснащены cloud-based tracking, позволяя operators to monitor performance remotely.

- Включает Диагностика в реальном времени и предиктивное обслуживание.

3. Технология формовки валков с сервоприводом

- Улучшает контроль скорости, точность и энергоэффективность.

- Уменьшает износ механических компонентовЭто увеличивает срок службы машины.

4. Полностью автоматизированная настройка профиля

- Устраняет ручные настройки при переключении между различными профилями.

- С ЧПУ автоматическое изменение профиля сократить время простоя и повысить эффективность.

Переход на валковые машины с искусственным интеллектом может повысить эффективность производства до 50%!

Автоматизация в рулонных формовочных машинах

Автоматизация - это Трансформация precision metal forming, making roll forming machines Умнее, быстрее и экономичнее.

Ключевые преимущества автоматизированных машин для формовки рулонов

| Характеристика | Выгода |

|---|---|

| Системы управления ПЛК и ЧПУ | Обеспечивает точность измерений и сводит к минимуму человеческие ошибки |

| Обнаружение дефектов в режиме реального времени на основе искусственного интеллекта | Мгновенно выявляет проблемы, сокращая отходы материалов |

| IoT и удаленный мониторинг | Позволяет операторам отслеживать производительность машины из любого места |

| Автоматизированная смена профилей | Сокращение времени простоя при переключении между профилями |

| Энергоэффективные серводвигатели | Снижение эксплуатационных расходов и повышение устойчивости |

Fully automated roll forming machines from Sunway Machine повышают эффективность производства до 40%!

Essential Maintenance Tips for Roll Forming Machines

Правильно обслуживание обеспечивает увеличенный срок службы оборудования и стабильное качество продукции.

Maintenance Checklist for Roll Forming Machines

| Задача | Частота | Назначение |

|---|---|---|

| Смазка роликов и подшипников | Еженедельник | Предотвращает износ |

| Проверьте выравнивание роликов | Ежемесячно | Обеспечивает точное изготовление профилей |

| Осмотрите режущий механизм | Ежеквартально | Предотвращает дефектные срезы и смещение |

| Чистые компоненты машины | Ежедневно | Удаляет пыль и мусор, которые могут повлиять на производительность. |

| Обновление программного обеспечения и калибровка | Раз в полгода | Оптимизация функций автоматизации |

Совет профессионала: Плановое техническое обслуживание может увеличить срок службы машины на 50% и сократить количество отказов на 70%.

FAQ: Roll Forming Machine Working Principle

1. How does a roll forming machine work?

Профилегибочная машина gradually shapes metal sheets by passing them through несколько роликовых станций, each applying incremental bends until the final profile is formed.

2. What industries use roll forming machines?

Industries such as:

✅ Строительство (roofing panels, C & Z purlins)

✅ Автомобильная промышленность (structural components, crash-resistant beams)

✅ Солнечная энергия (solar mounting structures)

✅ Стеллажи и полки (warehouse racks, storage systems)

3. What materials can be used in roll forming?

К числу распространенных материалов относятся:

✅ Оцинкованная сталь (G30-G90)

✅ Нержавеющая сталь (304/316)

✅ Aluminum (6061/7075)

✅ Высокопрочная сталь

4. How much does a roll forming machine cost?

Цена варьируется от От 80 000 для базовых моделей∗∗∗ до∗∗∗80 000 для базовых моделей** до **80 000 для базовых моделей∗∗∗∗∗1 200 000 для полностью автоматизированных машин, управляемых искусственным интеллектом.

5. Where can I buy a high-quality roll forming machine?

Для высокоскоростные валковые формовочные машины, изготовленные по индивидуальному заказу, посетите WUXI SUNWAY MACHINERY CO., LTD..

Заключительные размышления

Инвестиции в профилегибочная машина важно для industries that require flexibility, efficiency, and high-speed production. Choosing a надёжный производитель обеспечивает долгосрочная надежность и рентабельность.

WUXI SUNWAY MACHINERY CO., LTD. это ведущий мировой производитель из валковые формовочные машины, изготовленные по индивидуальному заказу, предлагая Передовые технологии, экспертная поддержка и конкурентоспособные цены.

Хотите roll forming machine? Свяжитесь с нами сегодня!