Введение

The валковая промышленность быстро развивается под влиянием технологический прогресс, автоматизация и спрос на легкие и высокопрочные материалы. По мере того как мы продвигаемся в 2025Производители должны быть впереди развивающиеся тенденции чтобы оставаться конкурентоспособными.

Но что изменения в валковой промышленности? Что такое наиболее значимые тенденции, определяющие будущее обработки металлов давлением?

В этом руководстве мы рассмотрим:

✅ Последние достижения в области технологии валковой формовки

✅ Автоматизация и искусственный интеллект при формовке валков

✅ Устойчивость и экологичность производства

✅ Новые тенденции в области материалов для обработки металлов давлением

✅ Рост рынка и перспективы развития валковой формовки

Давайте погрузимся в Тенденции развития валковой промышленности в 2025 году и далее!

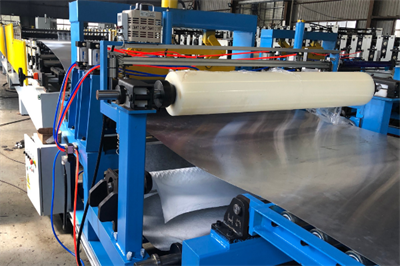

1. Автоматизация и интеллектуальные роликоформовочные машины

Автоматизация - это революция в валковой промышленностичто позволяет производителям повышение производительности труда при одновременном снижении затрат на оплату труда.

Основные достижения в области автоматизированной формовки рулонов

✅ Станки с ЧПУ и ПЛК - Повышение точности и повторяемости.

✅ Контроль качества с помощью искусственного интеллекта - Обнаружение дефектов в режиме реального времени, что позволяет сократить количество отходов.

✅ Машины с поддержкой IoT - Удаленный мониторинг и предиктивное обслуживание.

✅ Полностью автоматизированные линии для формовки рулонов - Минимизация вмешательства человека, повышение эффективности.

Преимущества автоматизации при формовке рулонов

✅ Более высокая скорость производства - Работают автоматические линии 24 часа в сутки 7 дней в неделю при минимальном контроле.

✅ Снижение затрат на оплату труда - Снижает зависимость от квалифицированных операторов.

✅ Улучшенная консистенция продукта - Исключает человеческий фактор при формовке и резке.

Совет профессионала: Ожидается, что к 2025 году более 60% производителей валков внедрят автоматизацию на основе искусственного интеллекта!

2. Устойчивое и экологичное производство

Устойчивое развитие становится Основные направления в области обработки металлов давлениемпроизводители инвестируют в энергоэффективные вальцовочные станки и перерабатываемые материалы.

Зеленые инновации в производстве рулонов

✅ Энергоэффективные серводвигатели - Снижение энергопотребления.

✅ Рулонные линии на солнечных батареях - Уменьшение углеродного следа.

✅ Перерабатываемая сталь и алюминий - Поддерживайте инициативы в области циркулярной экономики.

✅ Смазочные материалы на водной основе - Замените вредные смазочные материалы на химической основе.

Почему устойчивое развитие имеет значение

✅ Правительства внедряют ужесточение экологических норм.

✅ Потребительский спрос экологически чистые строительные материалы и металлоизделия.

✅ Компании, принимающие на вооружение Зеленое производство - конкурентное преимущество.

Совет профессионала: Устойчивое формирование валков может снизить производственные затраты на 20%, улучшая репутацию бренда!

3. Высокопрочные и легкие материалы в роликовой формовке

Спрос на Более прочные и легкие материалы растет в таких отраслях, как автомобилестроение, аэрокосмическая промышленность и строительство.

Новые материалы для роликовой формовки

✅ Передовая высокопрочная сталь (AHSS) - Используется в автомобильные шасси и структурные компоненты.

✅ Алюминиевые сплавы - Легкий, устойчивый к коррозии, идеально подходит для каркасы солнечных батарей и аэрокосмическая промышленность.

✅ Оцинкованные металлы и металлы с покрытием - Улучшение Долговечность и устойчивость к атмосферным воздействиям.

✅ Композитные металлические панели - Сочетание металлов с полимерами для улучшенное соотношение прочности и веса.

Почему легкие и прочные материалы имеют значение

✅ Производители автомобилей цель - снизить вес автомобиля для повышенная топливная эффективность.

✅ Солнечная и строительная промышленность спрос Легкие, но прочные компоненты.

✅ Сокращение транспортных расходов из-за более легкие материалы.

Совет профессионала: К 2025 году более 70% деталей, изготовленных методом прокатки, в автомобильной промышленности будут изготавливаться из высокопрочной стали Advanced High-Strength Steel (AHSS).

4. Рост производства рулонов на заказ и по требованию

Персонализация становится ключевой фактор в валковой промышленностиПроизводители предлагают Индивидуальные решения для различных отраслей промышленности.

Почему растет производство роликовой формовки на заказ

✅ Спрос на специализированные профили в солнечная энергия, стеллажи и полки, и HVAC.

✅ 3D-моделирование и интеграция CAD позволяют быстро создавать прототипы.

✅ Производство по требованию Снижает затраты на инвентаризацию и повышает гибкость.

Отрасли, стимулирующие рост производства рулонных материалов на заказ

✅ Солнечная энергия - Пользовательские профили для конструкции для монтажа солнечных батарей.

✅ Автомобильная промышленность - Точная формовка кузовные панели и усилители.

✅ Строительство - Уникальный архитектурные металлические панели и кровельные компоненты.

Совет профессионала: Изготовление рулонов на заказ позволяет предприятиям устанавливать высокие цены, сокращая при этом отходы материалов!

5. Рост и перспективы развития рынка роликовой формовки

The мировой рынок роликовой формовки Ожидается значительный рост, обусловленный спросом со стороны строительство, инфраструктура и автомобильный сектор.

Прогнозы роста рынка роликовой формовки (2025-2030)

| Регион | Темпы роста рынка | Ключевые отрасли промышленности, стимулирующие рост |

|---|---|---|

| Северная Америка | 6% CAGR | Строительство, стальные каркасы, солнечная энергия |

| Европа | 5.5% CAGR | Автомобильная промышленность, аэрокосмическая отрасль, возобновляемые источники энергии |

| Азиатско-Тихоокеанский регион | 7.2% CAGR | Инфраструктура, промышленные стеллажи, железная дорога |

| Ближний Восток и Африка | 4,8% CAGR | Кровля, трубопроводы, нефть и газ |

Факторы, стимулирующие рост рынка

✅ Быстрая урбанизация и развитие инфраструктуры.

✅ Все более широкое применение валковой формовки в проектах возобновляемой энергетики.

✅ Технологические достижения в области высокоскоростных автоматизированных машин для формовки валков.

Совет профессионала: Азиатско-Тихоокеанский регион - самый быстрорастущий рынок роликовой формовки, поскольку спрос на нее растет в строительстве и транспортных проектах!

6. Интеграция цифровых технологий и Индустрия 4.0 в производстве рулонов

The будущее валковой формовки заключается в интеллектуальное производство и цифровая интеграция.

Технологии "Индустрии 4.0" в прокатной штамповке

✅ Датчики IoT - Отслеживание производительности машины в режиме реального времени.

✅ Облачное управление производством - Удаленный мониторинг и предиктивное обслуживание.

✅ Оптимизация процессов на основе искусственного интеллекта - Сокращение отходов материалов и повышение эффективности.

✅ 3D-печать и гибридное производство - Ускоренное создание прототипов и оснастки.

Преимущества цифровой рулонной формовки

✅ Более быстрые сроки производства с автоматизация на основе данных.

✅ Снижение затрат на техническое обслуживание с предиктивная аналитика.

✅ Более высокая точность и меньше отходов благодаря искусственному интеллекту оптимизация процесса.

Совет профессионала: К 2030 году более 80% производителей валков внедрят технологии Industry 4.0!

Где купить новейшие роликовые формовочные машины для 2025 года?

Для Современные валковые машины которые соответствуют будущие требования промышленности, посетите WUXI SUNWAY MACHINERY CO., LTD..

Почему стоит выбрать WUXI SUNWAY MACHINERY?

✅ 15+ лет опыта работы в отрасли - Надежный мировой поставщик.

✅ Передовые решения для автоматизации и индивидуальной формовки рулонов.

✅ Энергоэффективные и высокоскоростные машины для максимальной производительности.

✅ Надежная послепродажная поддержка и наличие запасных частей.

Хотите обновить технологию валковой формовки? Свяжитесь с нами сегодня!

7. Роль искусственного интеллекта и робототехники в будущем рулонной формовки

Искусственный интеллект (ИИ) и робототехника преобразуют валковая промышленность улучшая Эффективность, точность и предиктивное обслуживание.

Как искусственный интеллект и робототехника меняют процесс формовки рулонов

✅ Контроль качества с помощью искусственного интеллекта - Обнаружение дефектов в режиме реального времени, что позволяет сократить количество отходов.

✅ Роботизированная обработка материалов - Автоматизирует подача, укладка и упаковка рулонов.

✅ Предиктивное обслуживание - ИИ предсказывает Отказы оборудования до их возникновенияМинимизируя время простоя.

✅ Автоматизированные системы смены инструмента - Сократите время подготовки к работе многопрофильные вальцовочные станки.

Преимущества искусственного интеллекта и робототехники при формовке рулонов

✅ Минимизирует человеческие ошибки, что приводит к высокая точность.

✅ Сокращает расходы на оплату труда автоматизируя повторяющиеся задачи.

✅ Повышает скорость производства при сохранении качества.

✅ Увеличивает срок службы оборудования предотвращая преждевременные поломки.

Совет профессионала: К 2030 году почти все высокотехнологичные валковые машины будут оснащены системой автоматизации на основе искусственного интеллекта!

8. Растущий спрос на рулонные конструкции для монтажа солнечных батарей

The солнечная энергетика процветает, и валковая формовка играет важнейшая роль в производстве конструкции для монтажа солнечных батарей.

Почему роликовая формовка идеально подходит для солнечной промышленности?

✅ Высокая точность и прочность - Обеспечивает прочный и стабильный каркасы солнечных батарей.

✅ Легкий, но прочный - Алюминиевые и оцинкованные стальные профили снижают вес.

✅ Устойчивость к коррозии - Необходим для наружные солнечные установки.

✅ Высокая скорость производства - Удовлетворяет растущий спрос на солнечная инфраструктура.

Рост мирового рынка солнечной энергии и его влияние на формовку рулонов

| Год | Стоимость мирового рынка солнечной энергии | Влияние на формовку валков |

|---|---|---|

| 2023 | $180 Миллиард | Растущий спрос на подгонянные рамки солнечных панелей |

| 2025 | $250 Миллиард | Увеличение производства стальные и алюминиевые солнечные конструкции |

| 2030 | $400 Миллиард | Полностью автоматизированные линии для формовки рулонов применение солнечной энергии |

Совет профессионала: В ближайшие годы компании, инвестирующие в рулонные профилегибочные машины для монтажа солнечных батарей, ожидает значительный рост спроса!

9. Сдвиг в сторону модульных и гибких машин для формовки рулонов

Производители переходят к модульные вальцовочные станки, что позволяет быстрая смена профилей и гибкость производства.

Почему модульная роликовая формовка - это будущее?

✅ Системы быстрой смены инструмента - Уменьшить время простоя при переключении профилей.

✅ Возможность работы с несколькими профилями - Продукты разные формы на одной машине.

✅ Масштабируемая конструкция - Легко расширить производство за счет добавление новых станций формования.

✅ Лучшая окупаемость инвестиций - Инвестируйте в Одна машина для различных применений.

Отрасли промышленности, получающие выгоду от модульной роликовой формовки

✅ Автомобильная промышленность - Продюсирование несколько компонентов тела на одной линии.

✅ Строительство - Гибкие машины для кровля, стеновые панели и каркасы.

✅ Промышленное хранение - Адаптируемые конструкции для стеллажи и полки.

Совет профессионала: Модульные валковые машины снижают затраты за счет отсутствия необходимости в нескольких специализированных линиях!

10. Расцвет 3D-печати в производстве оснастки для роликовой формовки

3D-печать совершает революцию оснастка для валковой формовкипредлагая более быстрые и более экономичные решения.

Как 3D-печать меняет формовку рулонов?

✅ Быстрое прототипирование - Разработка и тестирование новые профили для быстрой прокатки.

✅ Снижение затрат на оснастку - Традиционные штампы стоят дорого - штампы с 3D-печатью дешевле.

✅ Индивидуальная оснастка для малых партий - Идеально подходит для малосерийные, высокоточные приложения.

✅ Сложные геометрии - Создать сложные профили, изготовленные методом роликовой формовки которые раньше были невозможны.

Отрасли, использующие 3D-печатную оснастку для формовки рулонов

✅ Аэрокосмическая промышленность - Легкие и высокопрочные детали, изготовленные методом роликовой формовки.

✅ Медицинское оборудование - Прецизионные металлические детали для медицинского оборудования.

✅ Автомобильная промышленность - Нестандартные детали, изготовленные методом роликовой формовки производство электромобилей (EV).

Совет профессионала: 3D-печать снижает затраты на оснастку до 50%, что делает ее революционной для валковой формовки!

11. Глобальная конкуренция и будущее производства валков

Как глобальная конкуренция усиливаетсяПроизводители должны сосредоточиться на эффективность, автоматизация и устойчивость чтобы быть впереди.

Ключевые факторы конкуренции в отрасли производства валков

✅ Экономически эффективное производство - Снижение отходов материалов, энергопотребления и трудозатрат.

✅ Высокоскоростная автоматизация - Ускоренные производственные циклы с минимальным временем простоя.

✅ Персонализация и гибкость - Способность производить уникальные, высокодоходные продукты.

✅ Инициативы в области устойчивого развития - Соблюдение стандарты экологичного производства.

Какие страны занимают лидирующие позиции в отрасли роликовой формовки?

| Страна | Сила отрасли | Конкурентное преимущество |

|---|---|---|

| Китай | Крупнейший производитель | Экономически эффективное массовое производство |

| Германия | Точное машиностроение | Высокотехнологичная автоматизация и интеграция искусственного интеллекта |

| США | Лидер инноваций | Передовое формование материалов и устойчивое развитие |

| Индия | Быстрорастущий рынок | Доступная рабочая сила и растущий спрос на инфраструктуру |

Совет профессионала: Производители, инвестирующие в автоматизацию и устойчивое развитие, будут лидировать на мировом рынке роликовой формовки!

12. Где купить самые современные машины для формовки рулонов в 2025 году?

Для Вальцовочные станки нового поколения предназначенный для автоматизация, эффективность и устойчивость, посетите WUXI SUNWAY MACHINERY CO., LTD..

Почему стоит выбрать WUXI SUNWAY MACHINERY?

✅ 15+ лет опыта - Мировой лидер в производстве валковых машин.

✅ Высокоскоростные машины с искусственным интеллектом - Передовая автоматизация для максимальная рентабельность инвестиций.

✅ Нестандартные решения для роликовой формовки - Машины, предназначенные для Кровельные материалы, стеллажи, автомобильная промышленность и солнечная энергетика.

✅ Конкурентоспособные цены и глобальная доставка - Доступный и доставка по всему миру.

✅ Надежная послепродажная поддержка - Запасные части, техническая помощь и услуги по установке.

Хотите обновить технологию валковой формовки? Свяжитесь с нами сегодня!

ВОПРОСЫ И ОТВЕТЫ: Тенденции развития роликовой формовки в 2025 году

1. Каковы наиболее значительные технологические достижения в области валковой формовки?

- ИИ, робототехника, IoT и предиктивное обслуживание преобразуют индустрию.

2. Как устойчивое развитие влияет на формовку валков?

- Производители принимают энергоэффективное оборудование, перерабатываемые материалы и производственные линии, работающие на солнечных батареях.

3. Какие отрасли будут способствовать росту производства валков?

- Строительство, солнечная энергетика, автомобилестроение, аэрокосмическая промышленность и промышленные хранилища будут пользоваться наибольшим спросом.

4. Являются ли модульные вальцовочные станки лучше традиционных?

- Да! Они позволяют быстрое изменение профиля, возможность использования нескольких продуктов и лучшая масштабируемость.

5. Где можно найти самые современные машины для формовки валков?

- WUXI SUNWAY MACHINERY предоставляет Самые современные решения в области валковой формовки с автоматизация, искусственный интеллект и энергоэффективные конструкции.

Заключительные размышления

Промышленность по производству валков находится в процессе масштабные преобразования с автоматизация, устойчивое развитие и производство на основе искусственного интеллекта лидирует. Чтобы оставаться конкурентоспособными, производители должны инвестировать в новейшие технологии формования валков и адаптироваться к тенденции рынка.

✅ Потребность интеллектуальные высокоскоростные вальцовочные станки?

✅ Ищу индивидуальные решения по формовке валков?