Обзор оборудования для формовки кабельных лотков

А машина для производства кабельных лотков представляет собой специализированное оборудование для производства metal cable trays, which are used for supporting and organizing electrical cables in buildings, industrial plants, and data centers. These machines produce perforated, ladder-type, and solid-bottom cable trays с high efficiency and precision.

Ключевые особенности машин для формовки кабельных лотков

✅ Полностью автоматическое управление - ПЛК-управление для precision and high efficiency.

✅ Настраиваемые профили - Производит perforated, ladder, and solid-bottom cable trays.

✅ Высокоскоростное производство - Способна производить 10-30 метров в минуту.

✅ Прочная конструкция - Использование hardened steel rollers and hydraulic cutting systems.

✅ Встроенная система перфорации - Включает hole perforation for easy cable management.

В этом руководстве мы рассмотрим:

✅ Types of cable tray roll forming machines

✅ Как работает процесс валковой формовки

✅ Best materials for cable trays

✅ Анализ затрат и руководство по ценообразованию

✅ Лучшие производители и почему Sunway Machine является надежным выбором

Давайте погрузимся!

Типы машин для формовки кабельных лотков

Разное машины для формовки кабельных лотков удовлетворять различные производственные потребности и уровень автоматизации.

1. Perforated Cable Tray Roll Forming Machine

- Производит perforated trays с pre-punched holes for ventilation.

- Идеально подходит для high-heat environments where airflow is necessary.

2. Ladder Cable Tray Roll Forming Machine

- Создает ladder-type trays с rung supports for heavy cables.

- Лучшее для industrial and power plant applications.

3. Solid-Bottom Cable Tray Roll Forming Machine

- Производства solid-bottom trays для complete cable protection.

- Подходит для data centers and hazardous environments.

4. Fully Automatic Cable Tray Roll Forming Machine

- Функции Автоматизация ЧПУ для quick profile changes.

- Идеально подходит для крупномасштабное высокоэффективное производство.

Sunway Machine предоставляет customized cable tray roll forming machines с расширенные функции автоматизации.

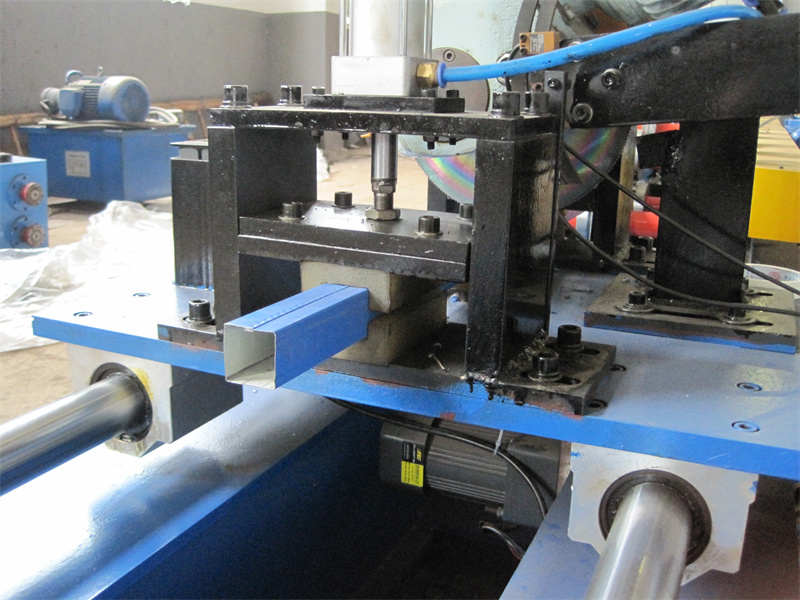

How Cable Tray Roll Forming Works

The процесс валковой формовки for cable trays involves Постепенное придание формы плоскому металлическому листу в high-strength cable support structure.

Step-by-Step Cable Tray Roll Forming Process

| Шаг | Описание |

|---|---|

| 1. Разжижение | Металлическая катушка помещается на разматывательПодача материала в машину. |

| 2. Выравнивание и кормление | Лист выпрямленный и направляемый на формовочные станции. |

| 3. Перфорация и резка | Гидравлическая система выполняет пробивка отверстий for cable management. |

| 4. Формование рулонов | Лист проходит через несколько роликовых станций, forming the cable tray shape. |

| 5. Final Cutting & Stacking | The formed cable tray is разрезать на части необходимой длины и уложены для транспортировки. |

Совет профессионала: А fully automated cable tray roll forming machine обеспечивает высокая точность, минимум отходов и высокая скорость производства.

Best Materials for Cable Trays

Выбор подходящий материал обеспечивает strength, corrosion resistance, and durability.

Comparison of Materials for Cable Trays

| Материал | Свойства | Лучшее для |

|---|---|---|

| Оцинкованная сталь (GI) | Corrosion-resistant, cost-effective | Standard electrical installations |

| Нержавеющая сталь (SS) | High strength, rust-proof | Industrial and outdoor applications |

| Алюминиевый сплав | Легкий, устойчивый к коррозии | Data centers & IT infrastructure |

| Сталь с порошковым покрытием | Aesthetic finish, durable | Коммерческие здания |

Sunway Machine производит валковые машины, совместимые с all major cable tray materials.

Cable Tray Roll Forming Machine Price Guide

Стоимость машина для производства кабельных лотков зависит от таких факторов, как уровень автоматизации, скорость производства и диапазон профилей.

Estimated Price Ranges for Cable Tray Roll Forming Machines

| Тип машины | Диапазон цен (USD) | Функции |

|---|---|---|

| Ручная машина | 20,000-20,000 - 20,000-50,000 | Ручная регулировка, низкоскоростное производство |

| Полуавтомат | 50,000-50,000 - 50,000-100,000 | Управляется ПЛК, требует ручной регулировки профиля |

| Полностью автоматическая машина | 100,000-100,000 - 100,000-250,000 | Быстрое переключение профилей с ЧПУ |

| Высокоскоростная машина | 250,000-250,000 - 250,000-500,000 | Передовая автоматизация, высокоскоростное производство |

Ищете индивидуальное предложение? Свяжитесь с Sunway Machine сегодня!

Top Cable Tray Roll Forming Machine Manufacturers

Выбор надёжный производитель обеспечивает высококачественное оборудование, долгосрочная поддержка и глобальное обслуживание.

Comparison of Leading Cable Tray Roll Forming Machine Manufacturers

| Производитель | Страна | Специализация | Основные характеристики |

|---|---|---|---|

| WUXI SUNWAY MACHINERY CO., LTD. | Китай | Машины для формовки кабельных лотков | Индивидуальные проекты, высокоскоростная автоматизация, машины с поддержкой IoT |

| Драйстерн ГмбХ | Германия | Прецизионная обработка металлов давлением | Станки с ЧПУ, сильные исследования и разработки |

| Самко Машинери | Канада | Рулонные профили для строительства | Индивидуальное проектирование, автоматизация |

| Группа компаний "Брэдбери | США | Сверхмощные системы формирования валков | Надежные машины, ориентированные на автоматизацию |

Вердикт: Если вы ищете cost-effective, high-speed cable tray roll forming machine, Sunway Machine это Лучший выбор для глобальных покупателей.

Common Problems & Solutions in Cable Tray Roll Forming Machines

Even the most advanced cable tray roll forming machines can encounter operational challenges, such as roller misalignment, material deformation, and inaccurate perforation. Решение этих вопросов проактивно обеспечивает smooth production and high-quality cable trays.

Руководство по устранению неполадок

| Выпуск | Возможная причина | Решение |

|---|---|---|

| Distorted or Uneven Cable Trays | Перекос роликов, неправильные настройки давления | Adjust roller alignment and ensure uniform pressure distribution |

| Проскальзывание материала при формовке | Ослабление роликов подающего механизма, неправильные настройки натяжения | Подтяните ролики подающего механизма и отрегулируйте натяжение материала |

| Неточное пробивание отверстий | Неисправность гидравлической системы, смещение вырубных штампов | Проверьте гидравлическое давление и отрегулируйте вырубные штампы |

| Чрезмерная вибрация машины | Ослабленные болты, неустойчивый фундамент машины | Закрепите компоненты машины и обеспечьте стабильную установку |

| Неточность резки | Dull cutting blades, misaligned cutters | Заменяйте затупившиеся лезвия и правильно выравнивайте фрезы |

Совет профессионала: Обычный выравнивание роликов и регулировка с помощью сервопривода может улучшить cable tray accuracy by 30%.

Future Trends in Cable Tray Roll Forming Machines

The обрабатывающая промышленность is evolving, and машины для формовки кабельных лотков интегрируют ИИ, IoT и автоматизация повышать эффективность, точность и устойчивость.

Ключевые инновации

1. Контроль качества на основе искусственного интеллекта

- с искусственным интеллектом датчики обнаруживают дефекты в режиме реального времениСокращение отходов материалов.

- Улучшает точность продукции и минимизация брака.

2. Интеграция IoT и "умных фабрик

- Теперь машины оснащены облачный мониторинг, позволяя Диагностика в реальном времени и предиктивное обслуживание.

- Улучшает отслеживание производства и повышение эффективности работы.

3. Технология формовки валков с сервоприводом

- Улучшает контроль скорости, точность и энергоэффективность.

- Уменьшает износ механических компонентов, increasing lifespan.

4. Полностью автоматизированная настройка профиля

- Устраняет ручные настройки when switching between different cable tray profiles.

- С ЧПУ автоматическое изменение профиля сократить время простоя и повысить эффективность.

Upgrading to AI-powered cable tray roll forming machines can increase production efficiency by up to 50%!

Roll Forming vs. Press Braking for Cable Tray Production

Производители должны оценивать скорость производства, сокращение отходов материалов и экономическая эффективность при выборе между валковая формовка и прессовое торможение for cable tray production.

Comparison Between Roll Forming and Press Braking for Cable Trays

| Характеристика | Профилирование | Торможение нажатием |

|---|---|---|

| Скорость производства | Быстрее для длинных, непрерывных профилей | Медленнее для нестандартных изгибов |

| Материальные отходы | Минимум отходов | Повышенный отход материала |

| Затраты на оснастку | Более высокие первоначальные инвестиции, более низкие долгосрочные затраты | Более низкие первоначальные затраты, более высокие эксплуатационные расходы |

| Лучшее для | Крупносерийное промышленное производство | Изготовление металлических деталей на заказ в небольших объемах |

Вердикт: Если вам требуется высокоскоростное непрерывное производство с минимальным количеством отходов, cable tray roll forming is the better choice.

Automation in Cable Tray Roll Forming Machines

Автоматизация - это революция процесс производства, изготовление валковых машин Умнее, быстрее и эффективнее.

Основные преимущества

| Характеристика | Выгода |

|---|---|

| Системы управления ПЛК и ЧПУ | Обеспечивает точность измерений и сводит к минимуму человеческие ошибки |

| Обнаружение дефектов на основе искусственного интеллекта | Выявляет проблемы в режиме реального времени, сокращая отходы материалов |

| IoT и удаленный мониторинг | Позволяет операторам отслеживать производительность машины из любого места |

| Автоматизированная смена профилей | Сокращение времени простоя при переключении между профилями |

| Энергоэффективные серводвигатели | Снижение эксплуатационных расходов и повышение устойчивости |

Fully automated cable tray roll forming machines from Sunway Machine повышают эффективность производства до 40%!

Essential Maintenance Tips for Cable Tray Roll Forming Machines

Правильно обслуживание обеспечивает увеличенный срок службы оборудования и стабильное качество продукции.

Контрольный список технического обслуживания

| Задача | Частота | Назначение |

|---|---|---|

| Смазка роликов и подшипников | Еженедельник | Предотвращает износ |

| Проверьте выравнивание роликов | Ежемесячно | Обеспечивает точное изготовление профилей |

| Осмотрите режущий механизм | Ежеквартально | Предотвращает дефектные срезы и смещение |

| Чистые компоненты машины | Ежедневно | Удаляет пыль и мусор, которые могут повлиять на производительность. |

| Обновление программного обеспечения и калибровка | Раз в полгода | Оптимизация функций автоматизации |

Совет профессионала: Плановое техническое обслуживание может увеличить срок службы машины на 50% и сократить количество отказов на 70%.

Часто задаваемые вопросы

1. How fast can a cable tray roll forming machine produce trays?

Высокоскоростные модели могут производить до 30 метров в минутув зависимости от профиля.

2. What cable tray profiles can be produced?

Большинство машин могут производить perforated, ladder, and solid-bottom cable trays.

3. How much does a cable tray roll forming machine cost?

Цена варьируется от 20 000 для базовых моделей∗∗∗to∗∗20 000 для базовых моделей** до **20 000 для базовых моделей∗∗to∗∗500 000 для полностью автоматизированных систем.

4. What materials can be used in cable tray roll forming machines?

Распространенные материалы включают galvanized steel, stainless steel, aluminum, and powder-coated steel.

5. Where can I buy a high-quality cable tray roll forming machine?

Для custom-built, high-speed cable tray roll forming machines, посетите WUXI SUNWAY MACHINERY CO., LTD..

Заключительные размышления

Инвестиции в машина для производства кабельных лотков важно для efficient, high-quality cable tray production. Нужен ли вам стандартная или полностью автоматизированная система, выбирая надёжный производитель обеспечивает долгосрочная надежность и рентабельность.

WUXI SUNWAY MACHINERY CO., LTD. это ведущий мировой производитель из custom-built cable tray roll forming machines, предлагая Передовые технологии, экспертная поддержка и конкурентоспособные цены.

Хотите custom cable tray roll forming machine? Свяжитесь с нами сегодня!