Обзор оборудования для формовки рулонных ограждений для автомагистралей

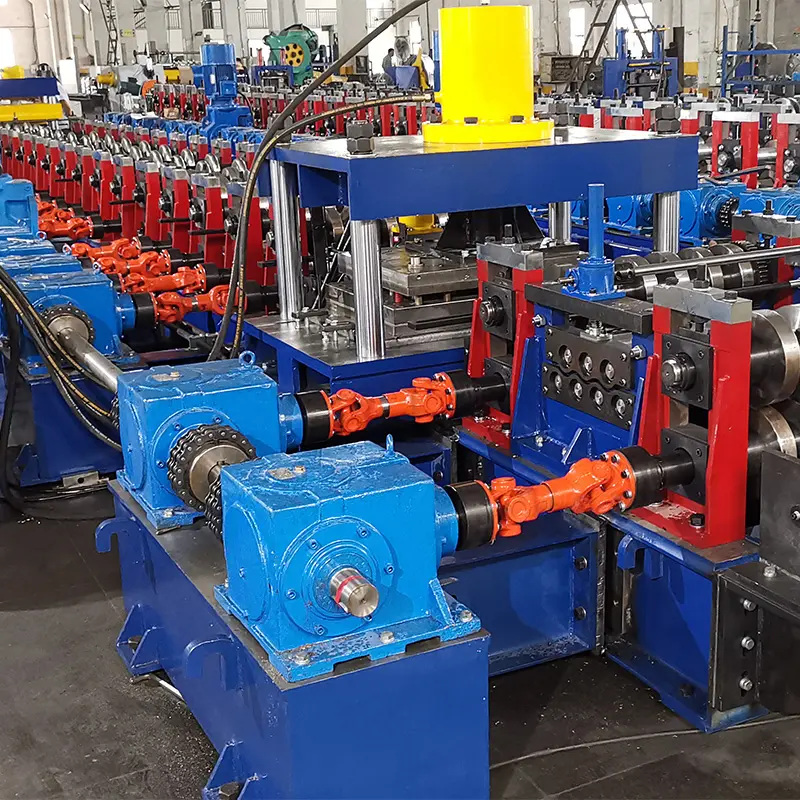

А машина для формирования рулонов ограждения шоссе это современное оборудование, предназначенное для производства стальные ограждения используемый для дорожные барьеры безопасности. Эти машины необходимы для производства Двутавровые балки, трехтавровые балки и специальные огражденияобеспечивая Высокопрочная и долговечная защита обочин дорог.

Ключевые особенности рулонных формовочных машин для производства ограждений для автомагистралей

✅ Высокоскоростное производство - Способна производить 10-30 метров в минуту.

✅ Полностью автоматическое управление - ПЛК-управление для точность и эффективность.

✅ Настраиваемые профили - Производит Ш-образные, трехгранные балки и специальные конструкции.

✅ Прочная конструкция - Построен с Ролики из высокопрочной стали и гидравлические системы резки.

✅ Совместимость с горячим цинкованием - Обеспечивает длительная коррозионная стойкость.

В этом руководстве мы рассмотрим:

✅ Типы машин для формирования рулонных ограждений

✅ Как работает процесс валковой формовки

✅ Лучшие материалы для дорожных ограждений

✅ Анализ затрат и руководство по ценообразованию

✅ Лучшие производители и почему Sunway Machine является надежным выбором

Давайте погрузимся!

Типы машин для формовки рулонных ограждений для автомагистралей

Разное машины для формирования рулонных ограждений удовлетворять различные производственные потребности и уровень автоматизации.

1. W-образная балка ограждения ролл формовки машина

- Производит стандартные ограждения из W-образных балок (наиболее часто используемый во всем мире).

- Идеально подходит для Применение для обеспечения безопасности дорожного движения.

2. Трехлучевая машина для формовки поручней

- Создает Более прочные и широкие трехлучевые ограждения для зоны повышенного риска.

- Подходит для скоростные магистрали и зоны повышенной аварийности.

3. Пользовательские ограждения ролл формовочной машины

- Предназначен для производства индивидуальные профили ограждений.

- Идеально подходит для специализированные проекты по обеспечению безопасности и нестандартные дорожные приложения.

4. Полностью автоматическая машина для формовки рулонов ограждения шоссе

- Функции Автоматизация ЧПУ для быстрая настройка профиля.

- Лучшее для крупномасштабное высокоэффективное производство.

Sunway Machine предоставляет подгонянные машины для формирования рулона ограждения шоссе с расширенные функции автоматизации.

Как работает рулонная формовка дорожных ограждений

The процесс валковой формовки для защитных ограждений включает Постепенное формирование плоского стального рулона в Высокопрочный профиль для ограждений.

Пошаговый процесс формовки рулонных ограждений для автомагистралей

| Шаг | Описание |

|---|---|

| 1. Разжижение | Стальная катушка помещается на разматыватель для подачи материала. |

| 2. Выравнивание и кормление | Лист выпрямленный и направляемый на формовочные станции. |

| 3. Перфорация и резка | Гидравлическая система выполняет пробивка отверстий для установки ограждения. |

| 4. Формование рулонов | Лист проходит через несколько роликовых станцийформируя форму ограждения. |

| 5. Окончательная резка и вывод | Сформированное ограждение разрезать на части необходимой длины и сложены. |

👉 Совет профессионала: А полностью автоматизированная машина для формирования рулонных ограждений обеспечивает высокая точность, минимум отходов и высокая скорость производства.

Лучшие материалы для дорожных ограждений

Выбор подходящий материал обеспечивает прочность, долговечность и коррозионная стойкость.

Сравнение материалов для дорожных ограждений

| Материал | Свойства | Лучшее для |

|---|---|---|

| Горячеоцинкованная сталь | Устойчивость к коррозии, долгий срок службы | Стандартные автомагистрали и дороги |

| Холоднокатаная сталь | Высокая прочность, гладкая поверхность | Городские дороги и мосты |

| Нержавеющая сталь | Стойкий к ржавчине, прочный | Высокотехнологичные инфраструктурные проекты |

| Алюминиевый сплав | Легкий, устойчивый к коррозии | Зоны с низкой проходимостью и декоративное применение |

Sunway Machine производит оборудование для формирования ограждений, совместимое с материалы для ограждений всех основных автомагистралей.

Шоссе ограждение ролл формовки машина руководство цены

Стоимость машина для формирования рулонов ограждения шоссе зависит от таких факторов, как уровень автоматизации, скорость производства и диапазон профилей.

Диапазон оценочных цен на оборудование для формовки рулонных ограждений для автомагистралей

| Тип машины | Диапазон цен (USD) | Функции |

|---|---|---|

| Ручная машина | 30,000-30,000 - 30,000-60,000 | Ручная регулировка, низкоскоростное производство |

| Полуавтомат | 60,000-60,000 - 60,000-120,000 | Управляется ПЛК, требует ручной регулировки профиля |

| Полностью автоматическая машина | 120,000-120,000 - 120,000-250,000 | Быстрое переключение профилей с ЧПУ |

| Высокоскоростная машина | 250,000-250,000 - 250,000-500,000 | Передовая автоматизация, высокоскоростное производство |

Ищете индивидуальное предложение? Свяжитесь с Sunway Machine сегодня!

Топ шоссе ограждение ролл формовочной машины производителей

Выбор надёжный производитель обеспечивает высококачественное оборудование, долгосрочная поддержка и глобальное обслуживание.

Сравнение ведущих производителей оборудования для формовки рулонных ограждений для автомагистралей

| Производитель | Страна | Специализация | Основные характеристики |

|---|---|---|---|

| WUXI SUNWAY MACHINERY CO., LTD. | Китай | Машины для формовки рулонных ограждений | Индивидуальные проекты, высокоскоростная автоматизация, машины с поддержкой IoT |

| Драйстерн ГмбХ | Германия | Прецизионная обработка металлов давлением | Станки с ЧПУ, сильные исследования и разработки |

| Самко Машинери | Канада | Рулонные профили для строительства | Индивидуальное проектирование, автоматизация |

| Группа компаний "Брэдбери | США | Сверхмощные системы формирования валков | Надежные машины, ориентированные на автоматизацию |

Вердикт: Если вы ищете экономически эффективная, высокоскоростная машина для формирования рулонов ограждения шоссе, Sunway Machine это Лучший выбор для глобальных покупателей.

Общие проблемы и решения для машин для формовки рулонных ограждений на автомагистралях

Даже с высококачественные машины для формирования рулонов ограждения шоссе, определенный оперативные задачи могут возникнуть такие проблемы, как смещение роликов, перекос материала и неточное пробивание отверстий. Выявление и решение этих проблем быстро необходим для поддержания эффективное производство и высококачественные ограждения.

Руководство по поиску и устранению неисправностей для машин для формовки рулонных ограждений на автомагистралях

| Выпуск | Возможная причина | Решение |

|---|---|---|

| Неправильно расположенные или перекрученные ограждения | Перекос роликов, неравномерное распределение давления | Проверьте и отрегулируйте выравнивание роликов и настройки давления |

| Неточное пробивание отверстий | Неисправность гидравлической системы или смещение вырубных штампов | Проверьте гидравлическое давление и отрегулируйте вырубные штампы |

| Проскальзывание материала при формовке | Ослабление роликов подающего механизма или неправильные настройки натяжения | Подтяните ролики подающего механизма и отрегулируйте натяжение материала |

| Чрезмерная вибрация машины | Ослабленные болты, неустойчивый фундамент машины | Закрепите компоненты машины и обеспечьте стабильную установку |

| Неточность резки | Изношенные режущие лезвия или смещенные резцы | Заменяйте затупившиеся лезвия и правильно выравнивайте фрезы |

Совет профессионала: Рутина выравнивание роликов и регулировка с помощью сервопривода может улучшить точность ограждения до 30%.

Будущие тенденции в области оборудования для формовки рулонных ограждений для автомагистралей

Как технологические достижения, машины для формирования рулонов ограждения шоссе становятся Умнее, быстрее и эффективнее. Производители интегрируют ИИ, IoT и автоматизация повышать производительность и контроль качества.

Ключевые инновации в области оборудования для формовки рулонных ограждений для автомагистралей в 2025 году

1. Проверка качества с помощью искусственного интеллекта

- с искусственным интеллектом датчики обнаруживают дефекты в режиме реального времениМинимизация отходов.

- Улучшает точность и последовательность производства ограждений.

2. Интеграция IoT и "умных фабрик

- Теперь машины оснащены облачное подключение, позволяя дистанционная диагностика и предиктивное обслуживание.

- Улучшает Мониторинг в режиме реального времени и эффективность работы.

3. Технология формовки валков с сервоприводом

- Улучшает контроль скорости, энергоэффективность и точность.

- Уменьшает износ механических компонентовЭто продлевает срок службы машины.

4. Полностью автоматизированная настройка профиля

- Устраняет ручные настройки при переключении между различными профилями ограждений.

- С ЧПУ автоматическое изменение профиля сократить время простоя и повысить эффективность.

Модернизация оборудования для формовки ограждений с помощью искусственного интеллекта может повысить эффективность производства до 50%!

Роликовая штамповка против прессовой штамповки для дорожных ограждений

При выборе между профилирование и торможение прессомПроизводители должны учитывать Скорость, отходы материалов и экономическая эффективность.

Сравнение между рулонной формовкой и листогибочным прессом для защитных ограждений

| Характеристика | Профилирование | Торможение нажатием |

|---|---|---|

| Скорость производства | Быстрее для длинных, непрерывных профилей | Медленнее для нестандартных изгибов |

| Материальные отходы | Минимум отходов | Повышенный отход материала |

| Затраты на оснастку | Более высокие первоначальные инвестиции, более низкие долгосрочные затраты | Более низкие первоначальные затраты, более высокие эксплуатационные расходы |

| Лучшее для | Крупносерийное промышленное производство | Изготовление металлических деталей на заказ в небольших объемах |

Вердикт: Если вам требуется высокоскоростное непрерывное производство с минимальным количеством отходов, роликовая штамповка ограждений для автомагистралей - лучший выбор.

Автоматизация в машинах для формовки рулонных ограждений для автомагистралей

Автоматизация - это Трансформация процесс производства, изготовление валковых машин Умнее, быстрее и экономичнее.

Ключевые преимущества автоматизированных машин для формовки рулонных ограждений для автомагистралей

| Характеристика | Выгода |

|---|---|

| Системы управления ПЛК и ЧПУ | Обеспечивает точность измерений и сводит к минимуму человеческие ошибки |

| Обнаружение дефектов на основе искусственного интеллекта | Выявляет проблемы в режиме реального времени, сокращая отходы материалов |

| IoT и удаленный мониторинг | Позволяет операторам отслеживать производительность машины из любого места |

| Автоматизированная смена профилей | Сокращение времени простоя при переключении между профилями |

| Энергоэффективные серводвигатели | Снижение эксплуатационных расходов и повышение устойчивости |

Полностью автоматизированное оборудование для формирования рулонных ограждений для автомагистралей от Sunway Machine повышают эффективность производства до 40%!

Основные советы по техническому обслуживанию машин для формовки рулонных ограждений для автомагистралей

Правильное обслуживание обеспечивает Увеличение срока службы оборудования и бесперебойное производство.

Контрольный список технического обслуживания машин для формовки рулонных ограждений на автомагистралях

| Задача | Частота | Назначение |

|---|---|---|

| Смазка роликов и подшипников | Еженедельник | Предотвращает износ |

| Проверьте выравнивание роликов | Ежемесячно | Обеспечивает точное изготовление профилей |

| Осмотрите режущий механизм | Ежеквартально | Предотвращает дефектные срезы и смещение |

| Чистые компоненты машины | Ежедневно | Удаляет пыль и мусор, которые могут повлиять на производительность. |

| Обновление программного обеспечения и калибровка | Раз в полгода | Оптимизация функций автоматизации |

Совет профессионала: Плановое техническое обслуживание может увеличить срок службы машины на 50% и сократить количество отказов на 70%.

FAQ: Машины для формовки рулонных ограждений

1. Как быстро станок для формирования рулонных ограждений для автомагистралей может производить ограждения?

Высокоскоростные модели могут производить до 30 метров в минутув зависимости от профиля.

2. Какие профили ограждений могут быть изготовлены?

Большинство машин могут производить W-образные, трехлучевые и нестандартные профили ограждений.

3. Сколько стоит станок для формовки рулонных ограждений?

Цена варьируется от от 30 000 для базовых моделей∗∗∗до∗∗∗30 000 для базовых моделей** до **30 000 для базовых моделей∗∗∗до∗∗∗500 000 для полностью автоматизированных систем.

4. Какие материалы могут использоваться в машинах для формирования рулонных ограждений?

Распространенные материалы включают горячеоцинкованная сталь, холоднокатаная сталь, нержавеющая сталь и алюминиевые сплавы.

5. Где я могу купить высококачественный станок для формирования рулонов ограждения шоссе?

Для высокоскоростные станки для формовки рулонных ограждений на заказ, посетите WUXI SUNWAY MACHINERY CO., LTD..

Заключительные размышления

Инвестиции в машина для формирования рулонов ограждения шоссе важно для эффективное и высококачественное производство ограждений. Нужен ли вам стандартная или полностью автоматизированная система, выбирая надёжный производитель обеспечивает долгосрочная надежность и рентабельность.

WUXI SUNWAY MACHINERY CO., LTD. это ведущий мировой производитель из Оборудование для формовки рулонных ограждений на заказ, предлагая Передовые технологии, экспертная поддержка и конкурентоспособные цены.

Хотите пользовательские шоссе ограждение ролл формирования машины? Свяжитесь с нами сегодня!