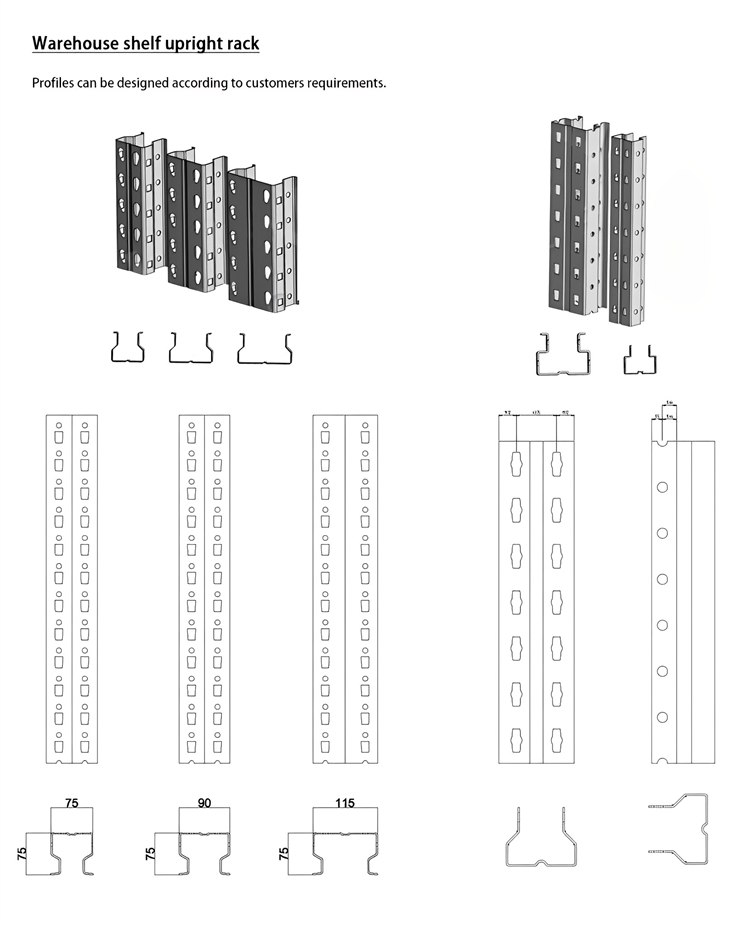

प्रोफ़ाइल चित्र

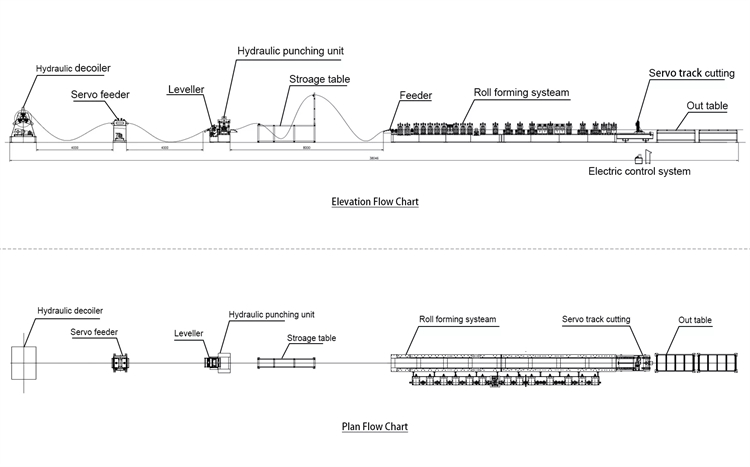

उत्पादन लाइन

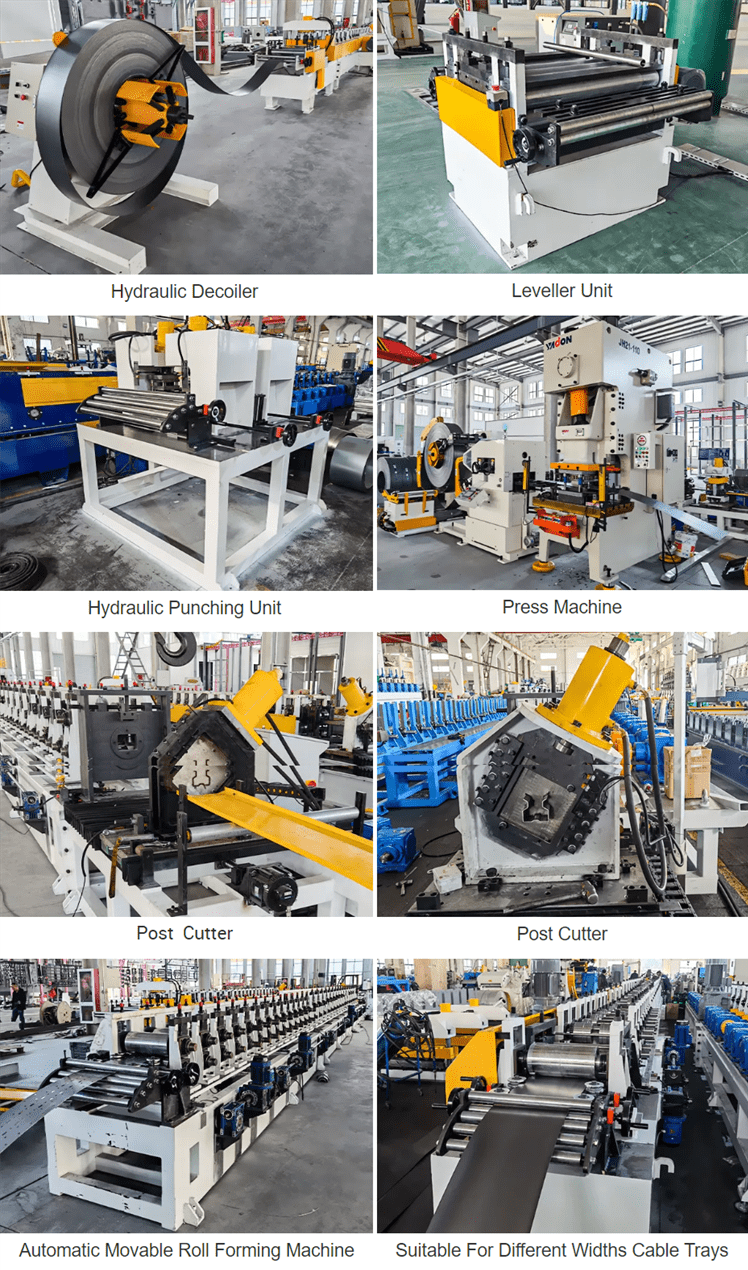

उत्पाद विवरण

仓库货架立柱辊压成型机参数

| गोदाम शेल्फ ईमानदार रोल बनाने की मशीन | ||

|

मशीन योग्य सामग्री

|

ए) जस्ती इस्पात |

厚度(mm):1.5-3.0(依客户要求)

|

| बी) स्टेनलेस स्टील | ||

| नम्य होने की क्षमता | 250 - 550 एमपीए | |

| तन्य तनाव | G250 एमपीए-G550 एमपीए | |

| डेकोइलर | मैनुअल डेकोइलर | * हाइड्रोलिक डेकोइलर (वैकल्पिक) |

| पंचिंग सिस्टम | हाइड्रोलिक पंचिंग स्टेशन | * पंचिंग प्रेस (वैकल्पिक) |

| फॉर्मिंग स्टेशन | 约 25 个机架 | * आपके प्रोफाइल ड्रॉइंग के अनुसार |

| ड्राइविंग सिस्टम | चेन ड्राइव | * गियरबॉक्स ड्राइव (वैकल्पिक) |

| मशीन संरचना | दीवार पैनल स्टेशन | * कच्चा लोहा स्टैंड (वैकल्पिक) |

| बनाने की गति | 5-15 (एम/मिन) | * या आपके प्रोफाइल ड्रॉइंग के अनुसार |

| रोलर्स की सामग्री | जीसीआर 15 | * Cr12 (वैकल्पिक) |

| कटिंग सिस्टम | हाइड्रोलिक कटिंग | * सॉ कटिंग (वैकल्पिक) |

| आवृत्ति परिवर्तक ब्रांड | यास्कावा | * सीमेंस (वैकल्पिक) |

| पीएलसी ब्रांड | पैनासोनिक | * सीमेंस (वैकल्पिक) |

| बिजली की आपूर्ति | 380V 50Hz 3ph | * या आपकी आवश्यकता के अनुसार |

| मशीन का रंग | औद्योगिक नीला | * या आपकी आवश्यकता के अनुसार |

आवेदन

What is an upright roll forming machine?

An upright roll forming machine is a type of industrial equipment used in the metalworking sector to shape and form continuous metal strips into specific profiles. It is widely employed to produce structural components with uniform cross-sections, such as beams, channels, and panels.

The machine functions by feeding the metal strip through a series of vertically arranged adjustable rollers. Each roller set is engineered to progressively shape the strip by bending it into a precise contour. The rollers are sequenced, with each performing a dedicated bending or forming task. As the strip advances, it undergoes continuous shaping until achieving the final profile.

Upright roll forming machines are celebrated for their efficiency, precision, and high output rates. They accommodate various metals, including steel, aluminum, and stainless steel, in differing thicknesses and widths. These machines serve industries like construction, automotive, aerospace, and manufacturing, where exact and consistent metal profiles are essential.

How do rack shelf roll forming machines work?

A rack shelf roll forming machine is a specialized device for producing rack shelving systems, ideal for storage in warehouses, retail outlets, and industrial facilities. Here is an overview of its typical operation:

- Material Loading: The process starts by loading a coil of sheet metal onto a decoiler, which unwinds and feeds it into the machine. The material is typically steel or aluminum.

- Straightening and Feeding: The sheet passes through a straightening unit to eliminate coil set or curvature, yielding a flat, uniform strip that is then directed into the roll forming machine.

- Roll Forming: The machine features a linear array of roll tooling stations. Each station employs rollers that incrementally shape the strip into the rack shelf profile. Precisely positioned, these rollers bend and form the metal as it progresses, with every station contributing to the final shape.

- Cutting: Upon reaching the required length, a cutting system activates—such as a flying cutoff or hydraulic shear—to sever the profile to specification.

- Stacking and Output: Cut profiles are conveyed to a stacking or output area for further handling or packaging, often with integrated stacking or palletizing systems for efficiency.

The process is fully automated, governed by a computerized control system that regulates roller speed, positioning, and cutting precision. This yields high production rates and uniform quality.

Note that specific operations and features vary by manufacturer and application needs.