Step beam roll forming machine also named P type beam Roll Forming Machine (s) is developed to produce the beam which is fixed between the upright racks.

Our intelligent roll forming machine could make various sizes of beam with thickness 1.5-3.0mm. Uncoiling, feeding, roll forming, welding, cutting etc process can be automatically realized on one line. Meantime, we have the roll forming machine to make box beam, upright rack and shelf panels. All these are components of Pallet racking system.

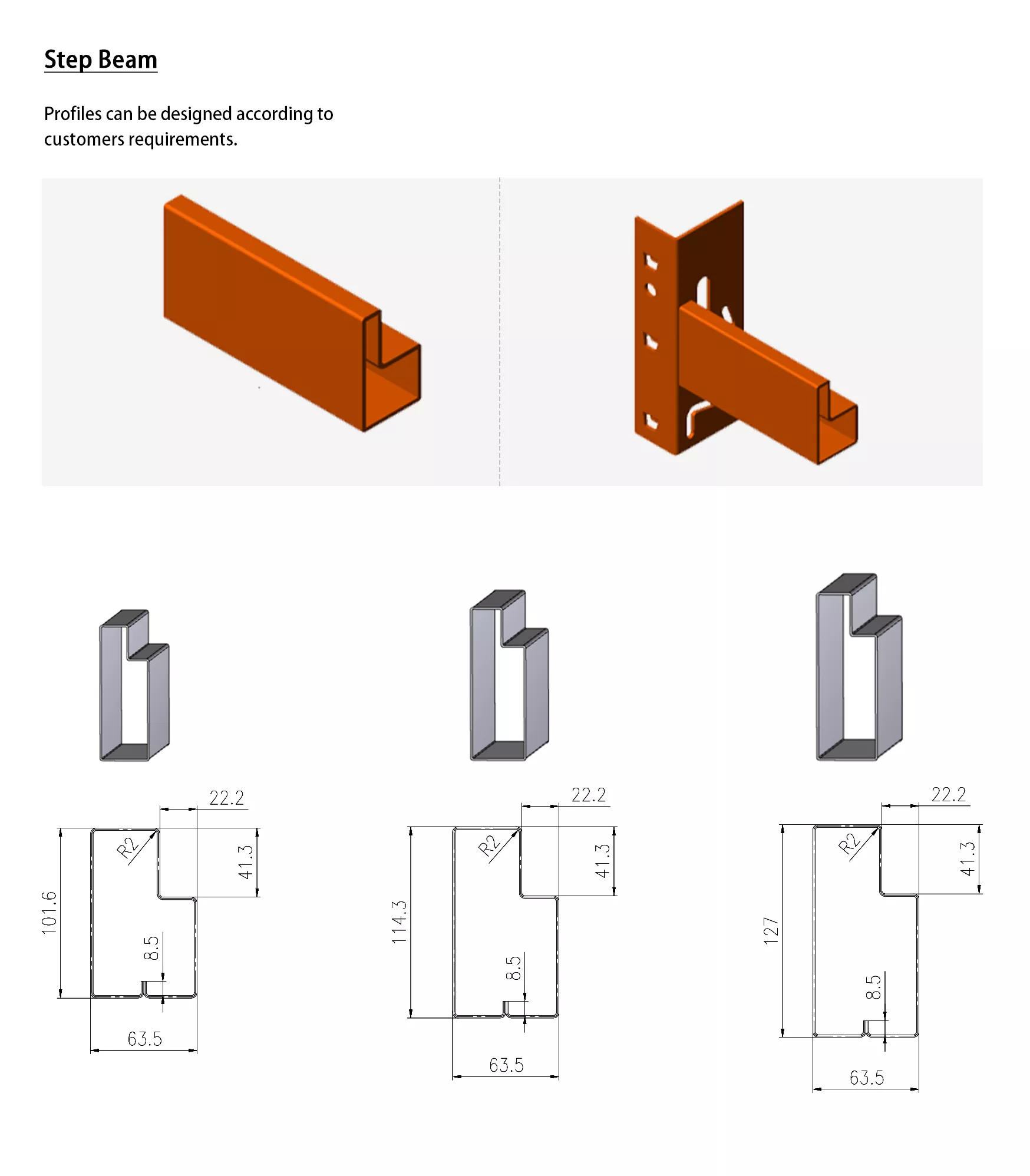

प्रोफ़ाइल चित्र

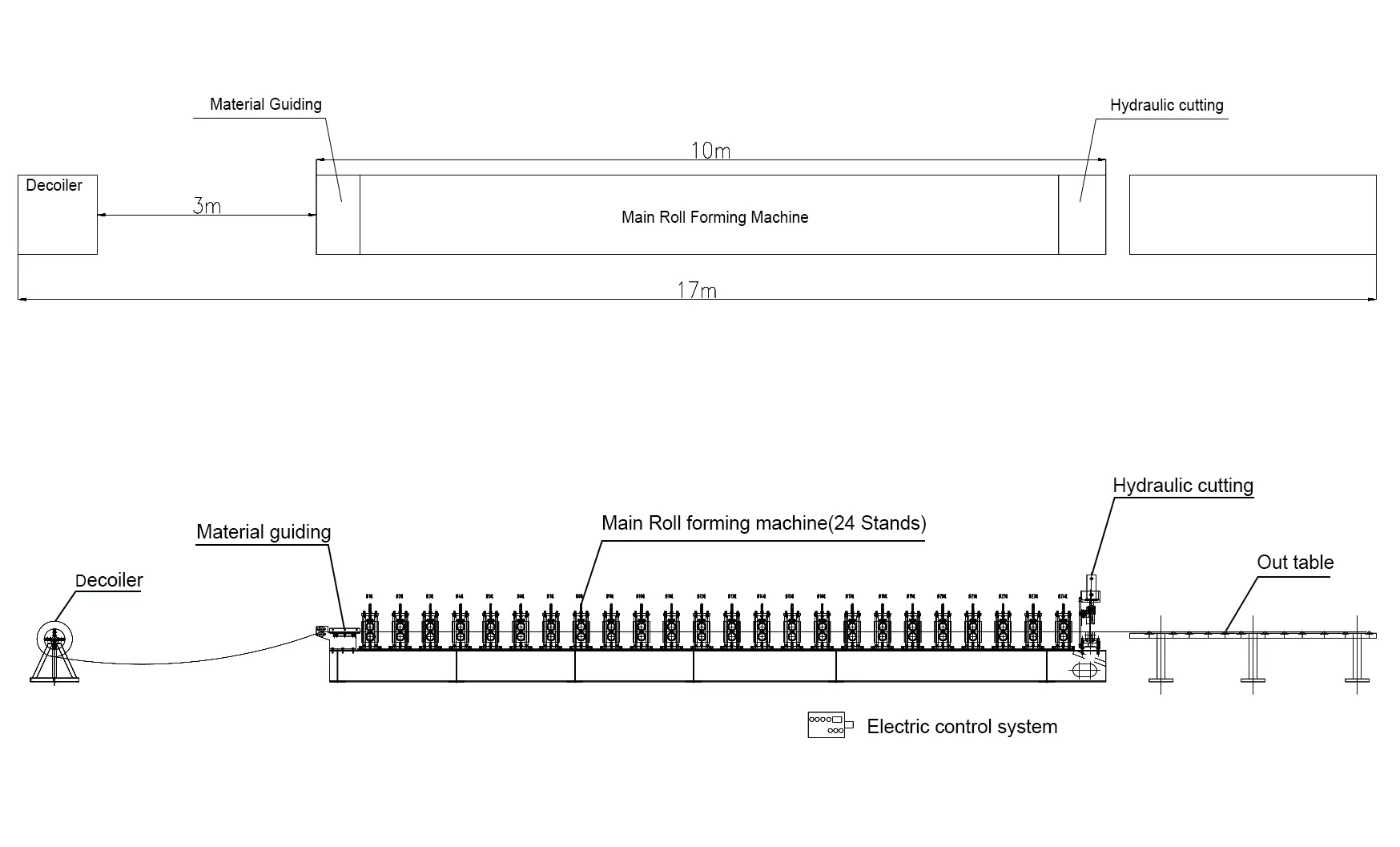

उत्पादन लाइन

उत्पाद विवरण

उत्पाद पैरामीटर

| स्टेप बीम रोल बनाने की मशीन | ||

|

मशीन योग्य सामग्री

|

ए) जस्ती कॉइल |

Thickness(MM): 1.5-3.0 as per customer

|

| B) PPGI | ||

| C) Cold-rolled Steel | ||

| D) Carbon Steel | ||

| नम्य होने की क्षमता | 250 – 350 Mpa | |

| तन्य तनाव | 350 Mpa-500 Mpa | |

| Nominal Forming Speed(M/Min) | 10-20 | * या आपकी आवश्यकता के अनुसार |

| फॉर्मिंग स्टेशन | 26 | * आपके प्रोफाइल ड्रॉइंग के अनुसार |

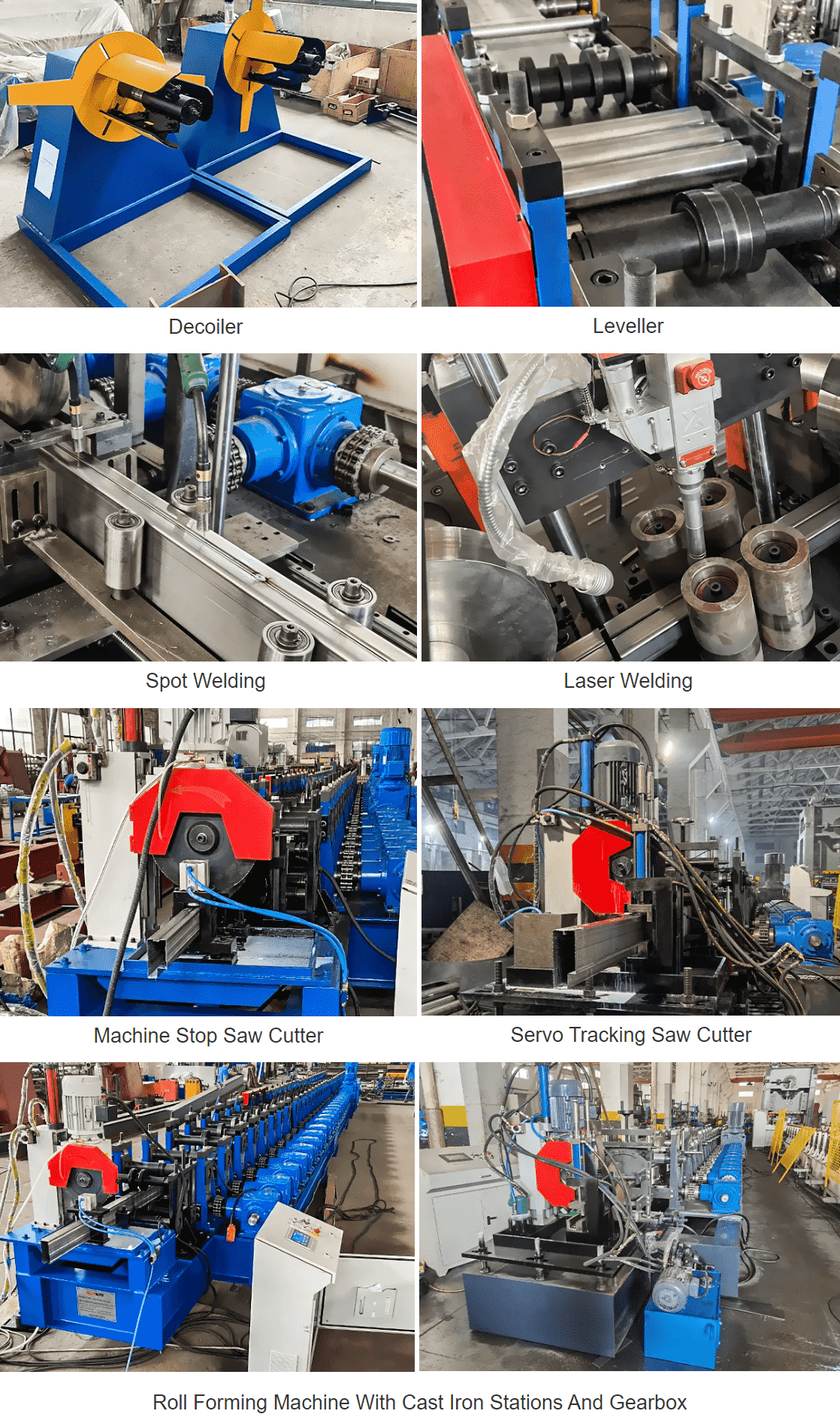

| डेकोइलर | मैनुअल डेकोइलर | * हाइड्रोलिक डेकोइलर (वैकल्पिक) |

| ड्राइविंग सिस्टम | चेन ड्राइव | * गियरबॉक्स ड्राइव (वैकल्पिक) |

| मशीन संरचना | स्टील प्लेट्स वेल्डेड | * कच्चा लोहा स्टैंड (वैकल्पिक) |

| रोलर्स की सामग्री | जीसीआर 15 | * Cr12Mov (वैकल्पिक) |

| Welding System | Spot Welding | * Laser Welding (Optional) |

| कटिंग सिस्टम | Saw Cut | * Flying Cut (Optional) |

| आवृत्ति परिवर्तक ब्रांड | यास्कावा | * सीमेंस (वैकल्पिक) |

| बिजली की आपूर्ति | 380V 50Hz 3ph | * या आपकी आवश्यकता के अनुसार |

| मशीन का रंग | औद्योगिक नीला | * या आपकी आवश्यकता के अनुसार |

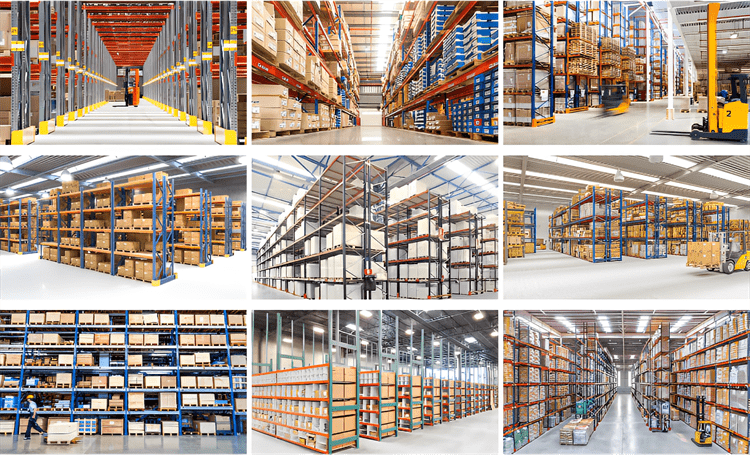

आवेदन

What is beam roll forming machine?

A beam roll forming machine is a type of industrial machinery used to manufacture beams with consistent shapes and sizes. Beams are structural elements used in construction and engineering projects to provide support and distribute loads.

The roll forming process involves passing a flat strip of metal through a series of rollers that progressively bend and shape the metal into the desired beam profile. The rollers have specific contours and designs that form the metal strip into the desired shape. The process is continuous, and the machine can produce beams of various lengths.

Beam roll forming machines typically include a decoiler to hold the metal coil, leveling equipment to straighten the strip, a series of forming rollers, and a cutting system to cut the beams to the desired lengths. The machine may also have additional features like punching or marking capabilities to add holes or identification marks to the beams.

The specifications of a beam roll forming machine can vary depending on the desired beam profile, such as I-beams, H-beams, or C-beams, and the required dimensions and thickness of the beams. The machine’s capacity and capabilities will determine the maximum size and thickness of the beams it can produce.

Beam roll forming machines are commonly used in the construction industry, steel fabrication plants, and engineering projects where beams are required. They offer high efficiency and accuracy in producing beams with consistent shapes, reducing manual labor and improving production speed.

function of pallet rack roll forming machine

A pallet rack roll forming machine is an industrial machinery used to manufacture pallet rack components. Pallet racks are storage systems commonly used in warehouses and distribution centers to store and organize palletized goods.

The main function of a pallet rack roll forming machine is to produce the structural components of a pallet rack system. These components typically include upright frames and horizontal beams. Here are the key functions of a pallet rack roll forming machine:

- Roll Forming: The machine uses a series of rollers and tooling to shape and bend metal coils into the desired profiles for upright frames and beams. The metal strip is fed into the machine, and the rollers progressively form the metal into the required shape.

- Cutting: The roll forming machine is equipped with a cutting system to cut the formed metal profiles to the desired lengths. This ensures that the upright frames and beams are manufactured to the required sizes for the pallet rack system.

- Hole Punching: Depending on the design and specifications of the pallet rack system, the roll forming machine may also include punching capabilities. This allows for the creation of holes in the profiles to accommodate additional accessories, such as beam connectors or safety pins.

- Shearing and Notching: Some pallet rack roll forming machines may have shearing and notching capabilities. These functions enable the machine to create specific features or cutouts in the metal profiles, which can be useful for customization or integration with other components.

The pallet rack roll forming machine plays a crucial role in the efficient and precise manufacturing of pallet rack components. By automating the process, it enables the production of consistent, high-quality components that meet the specific requirements of pallet rack systems.

What are the main products produced by the rack roll forming machine?

A rack roll forming machine is primarily used to manufacture various components of storage racks or shelving systems. These components are designed to provide organized storage and efficient utilization of space in warehouses, distribution centers, and retail environments. Here are the main products typically produced by a rack roll forming machine:

- Upright Frames: Upright frames are vertical structural components that form the main supports of the storage rack system. They are manufactured in various heights and thicknesses, depending on the specific requirements of the rack design. Upright frames typically feature a series of evenly spaced holes or slots to accommodate the horizontal beams and allow for adjustable shelf positions.

- Horizontal Beams: Horizontal beams are load-bearing components that connect the upright frames and provide support for the stored items. These beams are available in different lengths and load capacities to accommodate varying storage needs. They often have hooks or connectors on each end to attach to the upright frames securely.

- Diagonal Braces: Diagonal braces are additional structural components used to enhance the stability and strength of the rack system. They are typically installed diagonally between the upright frames, forming an X or V shape. Diagonal braces help prevent lateral movement and increase the overall rigidity of the rack.

- Wire Decks: Wire decks are wire mesh panels that serve as the shelf surface within the rack system. They provide support for palletized goods and allow for ventilation, light penetration, and sprinkler system effectiveness. Wire decks are available in various sizes and wire gauges to match different rack configurations and load capacities.

- Accessories: In addition to the main components mentioned above, a rack roll forming machine can also produce various accessories. These may include safety pins, beam connectors, end caps, labels, and other hardware or fasteners used for assembly and customization of the storage rack system.

It’s important to note that the specific product range and customization options may vary depending on the manufacturer, design specifications, and customer requirements. Rack roll forming machines are versatile and can be tailored to produce a wide range of storage rack components, offering flexibility to meet various storage needs.