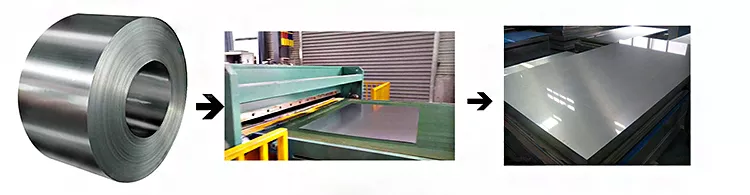

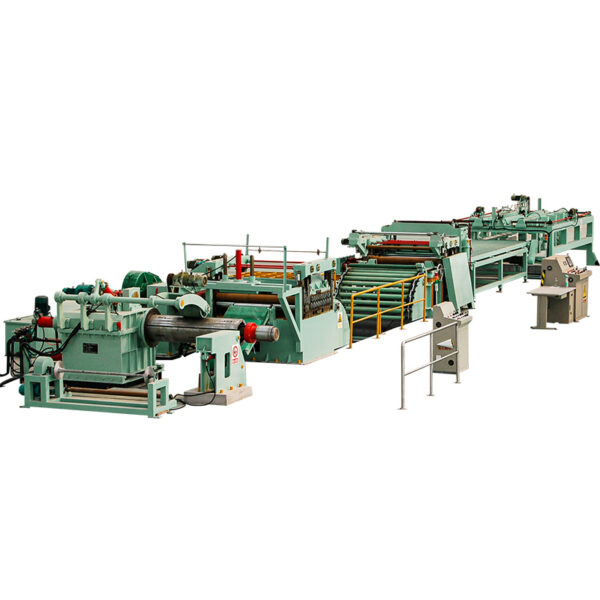

सनवे ऑटोमैटिक कट टू लेंथ लाइन का उपयोग अनकॉइलिंग, लेवलिंग और स्वचालित लंबाई मापने और काटने के लिए किया जाता है। एसी चर आवृत्ति और सर्वो नियंत्रण द्वारा विद्युत नियंत्रण, जिसमें बेहतर लंबाई सटीकता और दक्षता है।

钢卷定长切割生产线详情

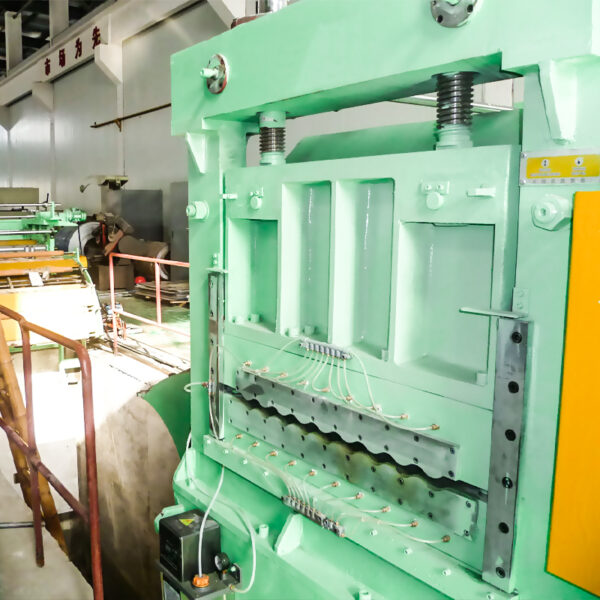

स्टैंड बेस

उच्च शक्ति और भारी कर्तव्य के साथ कच्चे माल के रूप में उच्च गुणवत्ता वाले स्टील का चयन करें, जिसमें विरूपण के लिए मजबूत प्रतिरोध है।

मोटर

ड्राइव सिस्टम के लिए शीर्ष ब्रांड मोटर को अपनाएं, अधिक स्थिर और प्रभावी।

उच्च स्वचालित

कट टू लेंथ मशीन पीएलसी सिस्टम को अपनाती है। ग्राहक उत्पादन मात्रा, नियंत्रण कैबिनेट पर उत्पादन की गति निर्धारित कर सकता है।

अनुकूलन

वरिष्ठ और अनुभवी इंजीनियर आपके अनुकूलित करने के लिए पूरी प्रक्रिया को नियंत्रित करते हैं।

钢卷定长切割生产线参数

| 加工厚度 | 0.1~3mm |

| 加工宽度 | 100-2000mm |

| 定长精度 | ±1.5 mm |

| 切割速度 | 1-200m/min |

| 卷内径 | 500/610 mm |

| 卷外径 | ≤2000 mm |

| 定长范围 | 500~4000mm |

| 板材矫平平直度 | ≤±1.5mm/m² |

| 长度公差 | ≤±1.5mm /m² |

| 对角线公差 | ≤±1.2mm/m² |

| 矫平精度 | ≤2mm/m² |

| 切割长度 | 500~3000mm |

以上参数仅供参考,机器可根据需求定制

What is a combined cut to length machine and slitting line production line?

Processes large metal coils into sheets/strips per requirements.

Key components:

- Uncoiler: Feeds coil.

- Leveler: Flattens strip.

- Slitter: Cuts into narrower strips.

- Recoiler: Winds strips.

- Cut-to-length: Shears to length.

- 堆垛机:定长切裁的板材或纵剪条带以有序方式堆垛,便于包装或后续加工。

定长切裁机与纵剪机组相结合的生产线,在生产不同长度板材和较窄条带方面提供了灵活性。它使制造商能够高效地将大型金属卷材(如钢或铝)加工成更小、更易用的形式,适用于汽车、建筑、家电等多种应用。

全自动钢卷定长切裁机的应用

全自动钢卷定长切裁机在多个行业中有广泛应用。以下是一些常见应用:

- 金属服务中心:钢卷定长切裁机在金属服务中心中被广泛使用。这些中心从制造商处接收大型钢卷,并根据客户需求将其加工成较小、定制尺寸的板材或条带。定长切裁机确保切割精准准确,使服务中心能够满足多样化的客户需求。

- 汽车行业:在汽车行业中,钢卷定长切裁机用于生产尺寸精确的钢板或条带。这些钢板/条带用于制造汽车车身面板、底盘部件、车架和其他结构件。该机确保切割一致且高质量,从而提升汽车行业的生产效率。

- 建筑行业:建筑行业经常需要特定长度和尺寸的钢板或条带,用于屋顶、覆面、结构元件和加固等应用。全自动钢卷定长切裁机可快速准确地将卷材切成所需长度,促进建筑过程顺利进行。

- 家电及白色家电:冰箱、洗衣机、空调和厨具等家电制造商使用钢卷定长切裁机将钢卷加工成板材或条带,用于制作外壳面板、柜体、门板和其他部件。该机确保尺寸一致、边缘平滑,从而生产高质量成品。

- 金属加工:钢卷定长切裁机应用于各种金属加工过程,需要精准切割钢板或条带。这些机器帮助加工商生产支架、车架、支撑件和其他定制部件,具有特定尺寸。

- 包装行业:全自动钢卷定长切裁机在包装行业中用于生产预定长度的钢板或条带。这些材料用于金属桶、容器、箱子和托盘等包装应用。该机确保高效可靠的生产,提升包装行业的生产力。

总体而言,全自动钢卷定长切裁机的应用遍及需要精准定制切割钢卷成板材或条带的行业。该机的自动化、精度和效率有助于简化制造过程、提升产品质量并满足客户规格要求。

समीक्षा

अभी तक कोई समीक्षा नहीं।