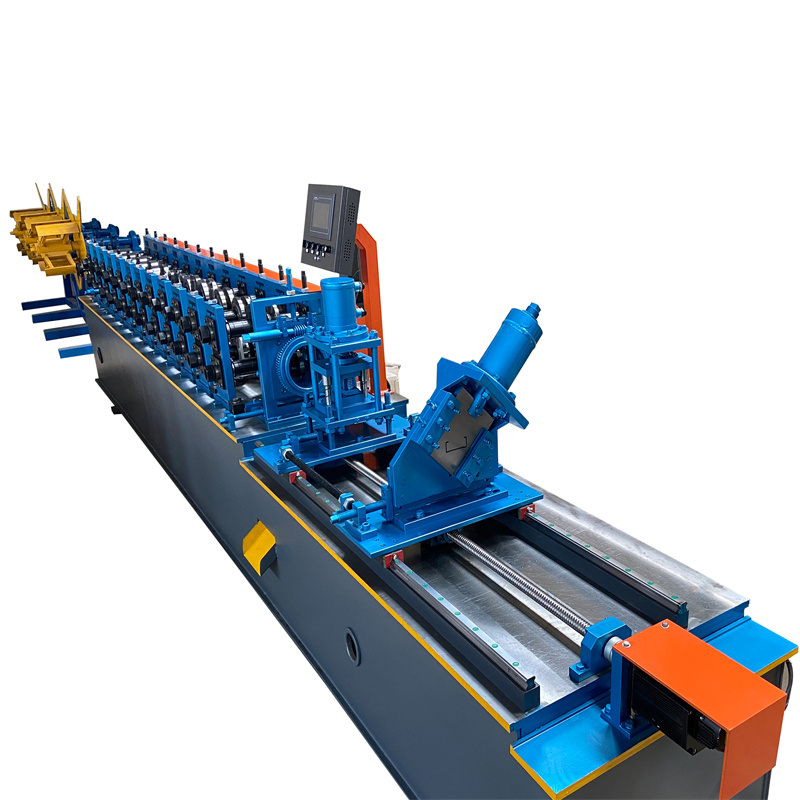

角铁辊压成型机广泛应用于汽车、航空和铁路等行业。该机器具有操作简便、生产能力高、噪音低且无操作员疲劳等特点。本文将简要概述角铁辊压成型机及其工作原理。

How a Pipe Roll Forming Machine Works and Why It’s Used? 9

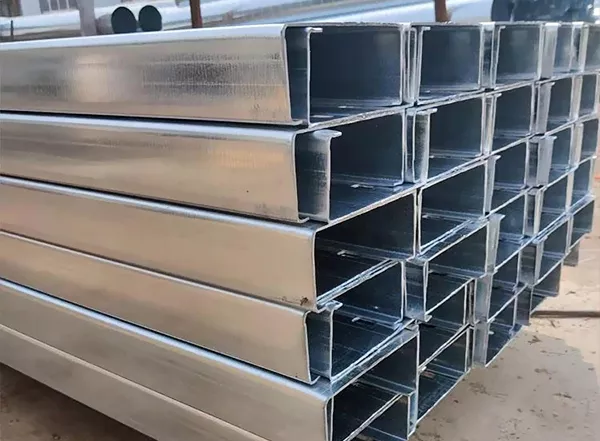

The कोण लोहा रोल बनाने की मशीन 是一种精密加工设备,可用于生产各种金属形状,包括辊子和槽道。过程从将工件定位在模具上开始,然后使用一组旋转模具创建所需形状。角铁辊压成型机还可用于从单块金属中生产不同截面或部件。

角铁辊压成型机的优势

角铁辊压成型机是一种金属冲压和弯曲机器,使用斜角模具创建定制金属零件。安装在机器上的模具通过一系列芯轴将金属切割成所需形状。此过程可实现金属的精确弯曲和角度,然后用于各种应用。

与其他金属冲压和弯曲机器相比,角铁辊压成型机具有多项优势。首先,它能创建比其他机器更复杂的形状。此外,模具可在零件周围移动,确保正确成型。这种精确成型能力使角铁辊压成型机成为许多制造应用的首选。

角铁辊压成型机如何工作?

角铁辊压成型机是一种金属加工设备,用于成型角铁或其他圆形金属形状。机器使用两个轧辊创建所需形状。第一辊固定并围绕第二辊轴旋转。此动作使待成型材料在两辊之间移动,从而形成所需形状。

-

कैरिज बोर्ड रोल बनाने की मशीन

कैरिज बोर्ड रोल बनाने की मशीन -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 वेव्स हाईवे गार्डरेल रोल फॉर्मिंग मशीन

2 वेव्स हाईवे गार्डरेल रोल फॉर्मिंग मशीन -

三波型高速公路护栏辊压成型机

三波型高速公路护栏辊压成型机 -

दो लहरें राजमार्ग रेलिंग मशीन

दो लहरें राजमार्ग रेलिंग मशीन -

तीन लहरें राजमार्ग रेलिंग मशीन

तीन लहरें राजमार्ग रेलिंग मशीन -

पीवी माउंटिंग ब्रैकेट सी शेप प्रोफाइल रोल बनाने की मशीन

पीवी माउंटिंग ब्रैकेट सी शेप प्रोफाइल रोल बनाने की मशीन -

पीवी माउंटिंग ब्रैकेट रोल बनाने की मशीन (एचएटी / ओमेगा प्रोफाइल)

पीवी माउंटिंग ब्रैकेट रोल बनाने की मशीन (एचएटी / ओमेगा प्रोफाइल)

选择角铁辊压成型机时应注意什么?

购买角铁 रोल बनाना 机器时,需要注意几点。首先,确保机器能处理您项目的尺寸和重量。其次,确保机器具备所有必要功能,如压铸铝合金模具板和自动进料系统。

在尺寸方面,大多数角铁辊压成型机可处理长达12英尺、宽2英寸的项目。但是,如果您的项目特别大或重,请在购买前咨询制造商,以免最终产品令人失望。

购买角铁辊压成型机时,另一个重要因素是其压铸铝合金模具板。此功能确保项目精确模具切割,同时提供机器的耐用性和稳定性。此外,自动进料系统使进料比手动操作模具板更轻松。

最后,选择角铁辊压成型机时,请考虑操作便利性。许多机器配备简单按钮和LCD屏幕,即使是新手也能轻松设置和使用。而且,许多机器提供保修,以防使用中出现问题。

Metal roof panel roll forming machines vary in size, speed, and cost—learn how to select the ideal one.

为您的企业购买合适的角铁辊压成型机时,请注意以下几点。这里有几条理由说明您为什么需要角铁辊压成型机:

- 容量:首先考虑机器容量。如果您刚起步,小型机器可能很合适。但是,随着业务增长,您可能需要更大容量机器来处理增加的产量。

- 速度:另一个重要因素是速度。慢速机器无法生产与快速机器相同质量的产品。请确保找到满足您具体需求的机器!

- 成型多样性:角铁辊压成型机可创建各种形状,包括圆形和椭圆形。这为您在产品设计和制造方面提供了丰富选择。

- 易用性:购买机器时,一个考虑因素是其易用性。确保控制面板易读易懂,所有功能无需在狭窄空间摸索即可访问。

निष्कर्ष

如果您正在寻找新型角铁辊压成型机,有诸多理由值得投资。不僅能节省生产零件的时间并提高效率,还能提供其他制造方法无法匹敌的优势。如果您希望拓展视野并升级制造能力,请查看我们的角铁辊压成型机系列!