These machines are cost-effective, efficient, and produce diverse high-quality products rapidly.

What is a corrugated roll forming machine?

The Corrugated roll forming machine for sale is manufacturing equipment that creates sheets from material rolls, used in packaging, automotive, and industrial production.

It presses rolls into corrugated shapes, often automated for high-volume custom products across materials.

Types of corrugated roll forming machines

There are many types of corrugated रोल बनाना machines for sale, each with unique benefits. Popular ones include:

- Horizontal: Roll paper sheets between plates for fast printing/packaging production.

- Vertical: Form tubes/rods for folded products like boxes.

- Container-making: Shape plastic into durable rolls for containers.

-

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line -

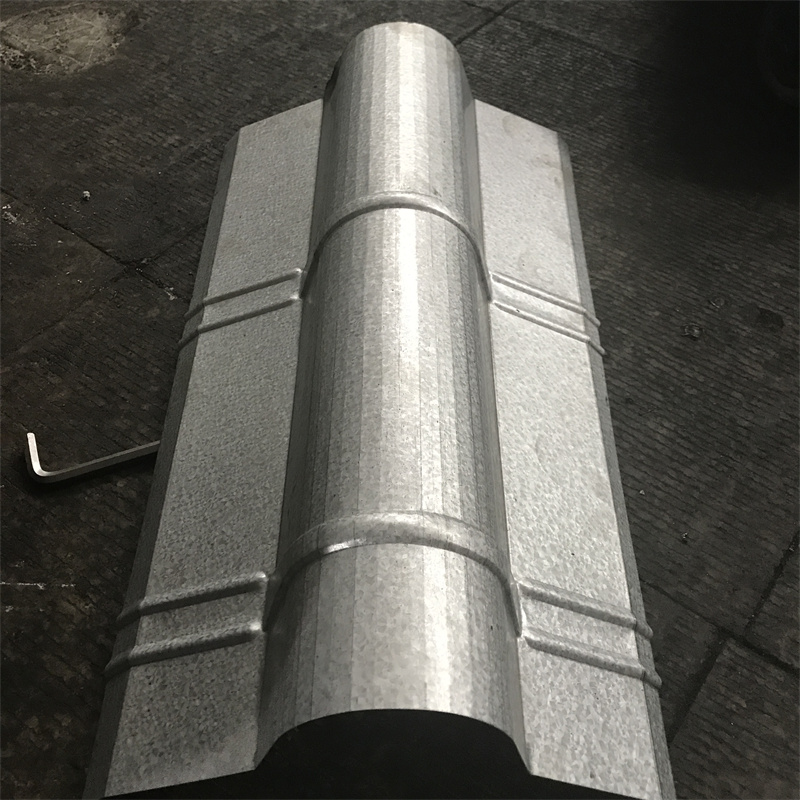

बैरल नालीदार रोल बनाने की मशीन

बैरल नालीदार रोल बनाने की मशीन -

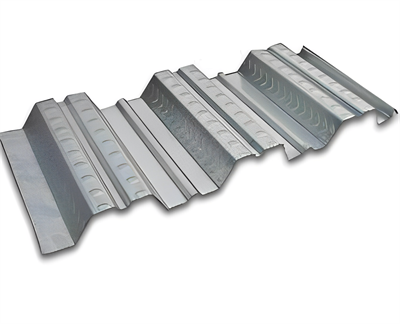

नालीदार पैनल रोल बनाने की मशीन

नालीदार पैनल रोल बनाने की मशीन -

सी सेक्शन ब्रेसिंग ओमेगा स्टोरेज रैक अपराइट पोस्ट रोल बनाने की मशीन

सी सेक्शन ब्रेसिंग ओमेगा स्टोरेज रैक अपराइट पोस्ट रोल बनाने की मशीन -

स्टील बॉक्स प्लेट रोल बनाने की मशीन बनाना

स्टील बॉक्स प्लेट रोल बनाने की मशीन बनाना -

शेल्फ कॉलम के लिए बॉक्स बीम स्टील रोल बनाने की मशीन

शेल्फ कॉलम के लिए बॉक्स बीम स्टील रोल बनाने की मशीन -

पैलेट रैकिंग स्टेप बीम पी बीम रोल बनाने की मशीन

पैलेट रैकिंग स्टेप बीम पी बीम रोल बनाने की मशीन -

गोदाम शेल्फ ईमानदार रोल बनाने की मशीन

गोदाम शेल्फ ईमानदार रोल बनाने की मशीन -

नालीदार रोल बनाने की मशीन

नालीदार रोल बनाने की मशीन

Benefits of using a corrugated roll forming machine

This innovative machine saves time and costs, producing durable custom rolls efficiently.

Enables precise customization of dimensions and shapes.

User-friendly, compact, and safe for novices.

How the corrugated roll forming machine can help your business?

For efficient manufacturing, consider the corrugated roll forming machine for boxes and similar products.

Select material (paper, plastic, metal), determine roll quantity, and plan cuts for optimal fit.

It simplifies production, accelerating business growth without complex tasks.

Applications for the Corrugated Roll Forming Machine

Versatile for various businesses, such as:

Packaging: Custom boxes and sacks.

Printing: Brochures and flyers rapidly.

T-shirts: High-volume production economically.

निष्कर्ष

Ideal for professional, durable custom corrugated packaging resistant to shipping wear.

Additional Frequently Asked Questions (FAQ)

1) What materials and thicknesses can a Corrugated Roll Forming Machine handle?

Most machines process galvanized steel, Galvalume, aluminum, and pre-painted coils from 0.25–1.0 mm (0.010–0.040 in). Roofing/panel lines commonly run 0.35–0.8 mm.

2) What production speed and tolerances are typical in 2025?

Commercial lines achieve 25–60 m/min with cut-length tolerance of ±0.5–1.0 mm using encoder/laser measurement and servo flying cutoffs.

3) How does coil quality impact corrugated panel quality?

Coil flatness, coating uniformity, and yield strength consistency directly affect panel straightness, oil-canning, and coating integrity. Specify coils to ASTM A653/EN 10346 with certificate of analysis.

4) What’s the difference between roof/wall corrugation profiles and deep-corrugated structural panels?

Roof/wall profiles have shallower sinus or trapezoidal waves for lightweight cladding; deep-corrugated profiles have higher rib depth for stiffness in industrial or structural applications.

5) What should be included in a Factory Acceptance Test (FAT) for a corrugated roll former for sale?

- Demonstrated speed at target gauge and profile

- Cut-length capability on 50+ parts (report Cp/Cpk)

- Edge waviness and camber checks

- Coating damage test on pre-painted coils

- Safety interlocks/E-stop validation and documentation

2025 Industry Trends for Corrugated Roll Forming Machines

- Faster changeovers: Recipe-driven roll-gap and guide adjustments reduce profile/gauge changeover to 5–12 minutes for multi-profile lines.

- Inline quality assurance: Vision systems verify pitch, rib height, and coating defects; laser camber/flatness monitoring reduces downstream rework.

- Energy-smart drives: Regenerative VFDs and hydraulic-on-demand packages cut energy intensity 10–20% vs. 2023 baselines.

- Traceability by default: OPC UA connectivity enables OEE dashboards, coil-to-batch traceability, and predictive maintenance via vibration/thermal sensors.

- Material optimization: Wider use of higher-yield coated steels (350–550 MPa) allows thinner gauges without sacrificing performance, saving 6–12% material.

2024–2025 Benchmarks and Buying Indicators

| KPI | 2024 Typical | 2025 Best-in-Class | Why it matters | Sources |

|---|---|---|---|---|

| Line speed (0.4–0.7 mm) | 25–45 m/min | 50–80 m/min | Throughput for roofing/cladding lines | OEM catalogs; The Fabricator |

| Changeover (profile/gauge) | 20–40 min | 5–12 min | Uptime on high-mix SKUs | OEM datasheets; integrator reports |

| Cut-length tolerance (±) | 1.0–1.5 mm | 0.5–1.0 mm | Fit, reduced scrap | Inline metrology vendors |

| Coating damage rate | 1.5–3.0% | <0.8% | Rework reduction | Coater/OEM QA notes |

| Energy use (kWh/ton) | 100–140 | 85–110 | OpEx, CO2e | U.S. DOE AMO guidance |

| Installed price (USD) | $60k–$150k | $85k–$200k | Budgeting | 2025 industry quotes |

Authoritative references:

- ASTM A653/A792 (galvanized/Galvalume): https://www.astm.org

- EN 10346 (continuously coated steel): https://standards.cen.eu

- AISI Cold-Formed Steel resources: https://www.buildusingsteel.org

- U.S. DOE Advanced Manufacturing Office: https://www.energy.gov/eere/amo

- OPC Foundation (OPC UA): https://opcfoundation.org

- The Fabricator (roll forming best practices): https://www.thefabricator.com

Latest Research Cases

Case Study 1: Inline Vision Reduces Rework on Pre-Painted Corrugated Panels (2025)

Background: Regional roofing supplier experienced coating scuffs and pitch variation on color-coated coils at 40 m/min.

Solution: Added inline vision for rib pitch and coating defect detection, micro-spray lubrication, and servo flying cutoff with laser length encoder.

Results: Coating damage rate dropped from 2.1% to 0.6%; length Cpk improved from 1.0 to 1.6; annual scrap savings ~$92k; changeover time reduced from 24 to 10 minutes.

Case Study 2: Energy-Optimized Drive Train on Legacy Corrugation Line (2024)

Background: Plant’s 15-year-old line had high kWh/ton and frequent hydraulic overheating during summer peaks.

Solution: Retrofitted regenerative VFDs, hydraulic on-demand power unit, and predictive maintenance sensors (vibration/temperature) tied to an OPC UA gateway.

Results: Energy intensity decreased 15%; unplanned downtime −22%; maintenance costs −12% year-over-year; 14-month payback.

Expert Opinions

- Phil Paxton, President, The Bradbury Group

Key viewpoint: “For corrugated panel producers, a servo flying cutoff combined with recipe-driven roll-gap yields the fastest ROI by raising speed without sacrificing cut accuracy.”

Company: https://www.bradburygroup.com - Jennifer Kinder, Director of Product Management, Samco Machinery

Key viewpoint: “Standardize supplier quotes by gauge, speed, tolerance, and coating handling—otherwise Corrugated Roll Forming Machine comparisons are apples to oranges.”

Company: https://www.samco-machinery.com - Dr. Benjamin Schafer, Professor of Civil Engineering, Johns Hopkins University

Key viewpoint: “Consistent corrugation geometry improves sheet stiffness and reduces oil-canning, which is critical for façade performance.”

Profile: https://engineering.jhu.edu

Practical Tools/Resources

- Standards and materials

- ASTM A653/A792, EN 10346 material specs: https://www.astm.org | https://standards.cen.eu

- AISI cold-formed design resources: https://www.buildusingsteel.org

- Operations and quality

- NIST SPC/process capability guides: https://www.nist.gov/manufacturing

- DOE AMO motor/drive efficiency tools: https://www.energy.gov/eere/amo

- Connectivity and data

- OPC UA implementation for machinery: https://opcfoundation.org

- Industry media/OEM discovery

- The Fabricator (process articles): https://www.thefabricator.com

- Precision Metalforming Association directory: https://www.pma.org

- Representative OEMs for corrugated lines: The Bradbury Group, Samco Machinery, Dallan, Formtek

Last updated: 2025-10-22

Changelog: Added 5 FAQs; inserted 2025 trends with benchmark table and sources; provided two recent case studies; compiled expert opinions; listed practical tools/resources tailored to Corrugated Roll Forming Machine buyers/operators

Next review date & triggers: 2026-04-22 or earlier if ASTM/EN standards update, OEM catalogs change speed/price ranges ±10%, or new case data shifts best-in-class KPIs by >10%