When it comes to siding materials, corrugated metal siding has earned its place in the spotlight for its durability, versatility, and aesthetic appeal. But what exactly makes it so special? In this comprehensive guide, we’ll delve into the ins and outs of corrugated metal siding, covering everything from its history and manufacturing process to its various types, benefits, and even installation tips. Plus, we’ll give you a rundown on key components, suppliers, and much more. Let’s get started!

Overview of Corrugated Metal Siding

Corrugated metal siding is a popular choice for both residential and commercial buildings, characterized by its wavy or ridged pattern. This unique design not only enhances its visual appeal but also increases its strength and resilience. The material is made from sheets of metal—often steel or aluminum—treated to resist corrosion, making it a long-lasting solution for exterior cladding.

Why Choose Corrugated Metal Siding?

Imagine you’re trying to find the perfect jacket for all seasons—something sturdy for winter, breathable for summer, and stylish for casual outings. That’s what corrugated metal siding offers for your home. It combines strength, weather resistance, and aesthetic versatility, providing an excellent solution for any building project. Whether you’re building a modern home or a rustic shed, there’s a corrugated metal option that fits right in.

Guide to Corrugated Iron Sheets

Let’s break down the essentials of corrugated iron sheets. From their manufacturing to the different types available, we’ll explore everything you need to know.

What are Corrugated Iron Sheets?

Corrugated iron sheets are thin metal panels that have been molded into a series of alternating ridges and valleys. This design serves several purposes:

- Strength: The corrugated design provides structural integrity, making them resistant to bending and deformation.

- Lightweight: Despite their strength, these sheets are lightweight, making them easy to handle and install.

- Aesthetic Appeal: Available in various colors and finishes, they can enhance the visual appeal of any building.

Types of Corrugated Metal Siding

There are several types of corrugated metal siding, each with its unique properties and applications. Here’s a breakdown of the different options:

| Type of Corrugated Metal Siding | 描述 |

|---|---|

| गैल्वेनाइज्ड स्टील | Coated with zinc to resist rust and corrosion. It’s affordable and strong, perfect for industrial applications. |

| एल्यूमीनियम | Lightweight and naturally resistant to corrosion. Ideal for coastal areas where saltwater is a concern. |

| कॉपर | Offers a unique aesthetic that ages beautifully. Great for high-end applications but comes at a higher cost. |

| Zinc Coated Steel | Provides durability similar to galvanized steel but with a more refined appearance. |

| Fiber Cement | A hybrid material that mimics the appearance of metal but is made from cement and cellulose fibers. |

| Stainless Steel | Resistant to rust and staining, making it ideal for commercial kitchens and environments that require hygiene. |

| Pre-Painted Steel | Steel coated with paint before installation for enhanced color retention and corrosion resistance. |

| Cor-Ten Steel | Weathering steel that develops a rust-like patina over time, adding a unique rustic charm to buildings. |

| Sheet Metal | A broad category that includes various metals; can be customized for different applications. |

| Profiled Aluminum | Lightweight panels with unique profiles designed for specific aesthetic and structural requirements. |

The Working Process of Corrugated Metal Siding

The process of creating corrugated metal siding involves several steps, each crucial for producing high-quality sheets that meet industry standards. Here’s a look at how it all comes together:

- सामग्री चयन: High-quality metals such as steel or aluminum are selected based on the intended application and required durability.

- काटना: The raw metal sheets are cut to size, ensuring they meet the specifications for the desired project.

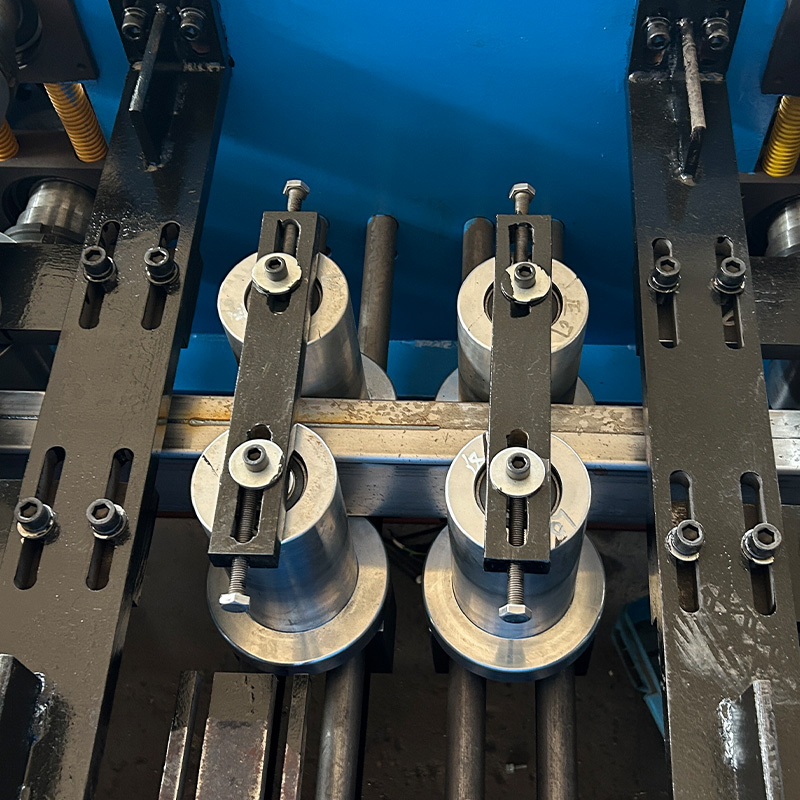

- Corrugating: Using specialized machinery, the metal sheets are passed through rollers that create the characteristic ridged pattern. This process adds strength while maintaining a lightweight structure.

- Finishing: The corrugated sheets are treated with protective coatings to prevent rust and corrosion. This might include galvanization or powder coating for added durability and aesthetic appeal.

- Quality Control: The final products undergo rigorous testing to ensure they meet quality standards before being shipped to suppliers.

Key Components of Corrugated Metal Siding

To better understand how corrugated metal siding functions, it’s essential to know its key components and their functions. Here’s a breakdown:

| Component | Function |

|---|---|

| Metal Panels | The primary component providing structure and insulation. |

| Fasteners | Connect and secure the panels to the building frame, ensuring stability. |

| Flashing | Protects joints and edges from water infiltration, preventing leaks. |

| Underlayment | A protective layer applied beneath the panels to enhance moisture resistance. |

| Sealants | Used to create airtight seals around edges and joints to prevent air and water leaks. |

| Trim Pieces | Finish edges and corners for aesthetic appeal and added protection against weather elements. |

Machine Speed and Efficiency in Corrugated Metal Production

When it comes to the production of corrugated metal siding, efficiency is key. The speed of the machinery used can significantly impact overall productivity. Here’s how it breaks down:

| Machine Type | Speed (Feet/Minute) | Efficiency (%) |

|---|---|---|

| रोल बनाने की मशीन | 50-100 | 85-95 |

| Slitting Machine | 100-150 | 90-98 |

| Shearing Machine | 60-120 | 80-90 |

| Corrugating Machine | 40-70 | 80-95 |

Customized Mechanical Parameters

Customization plays a crucial role in the production of corrugated metal siding. Here’s a look at some mechanical parameters that can be tailored for specific applications:

| Parameter | 描述 |

|---|---|

| Gauge Thickness | The thickness of the metal, affecting durability and weight. |

| Profile Height | The height of the corrugation, impacting insulation and strength. |

| Lebar Panel | The width of the metal sheets, which can be adjusted for different applications. |

| Coating Type | Options for coatings, such as galvanization or powder coating, for corrosion resistance. |

Applications of Corrugated Metal Siding

Corrugated metal siding is versatile and can be used in various applications. Here’s a look at some of the most common uses:

| Application Area | 描述 |

|---|---|

| Residential Homes | Adds a modern touch and is resistant to weathering. |

| 商业建筑 | Durable and aesthetically pleasing for storefronts and offices. |

| : Provide support and stability for roofs against loads and weather. | Ideal for barns and storage facilities due to its resilience. |

| Industrial Structures | Used in warehouses and factories for strong, protective exteriors. |

| Sheds and Garages | A popular choice for backyard structures due to ease of installation. |

| Fences and Walls | Offers privacy and security while maintaining a sleek look. |

Installation, Operation, and Maintenance of Corrugated Metal Siding

Installing corrugated metal siding is a straightforward process, but it requires careful attention to detail to ensure longevity. Here’s a quick overview:

| Phase | विवरण |

|---|---|

| Installation | Requires proper framing and alignment of panels; often involves the use of specialized fasteners. |

| Operation | Routine inspections to ensure integrity and check for any signs of rust or damage. |

| Maintenance | Periodic cleaning and resealing of joints to prevent leaks; reapplying protective coatings as needed. |

Suppliers and Pricing Details for Corrugated Metal Siding

Finding the right supplier is crucial for ensuring you get high-quality materials at a fair price. Here’s a look at some reputable suppliers and their pricing ranges:

| Supplier | Material Offered | Price Range (Per Square Foot) |

|---|---|---|

| Metal Sales | Galvanized Steel, Aluminum | $2.00 – $4.50 |

| ABC Supply Co. | Copper, Pre-Painted Steel | $3.00 – $6.00 |

| Duro-Last | Custom Fabricated Options | $3.50 – $7.00 |

| McElroy Metal | Stainless Steel, Zinc Coated Steel | $2.50 – $5.50 |

| The Home Depot | Basic Galvanized and Aluminum Sheets | $1.50 – $4.00 |

| Lowe’s | Pre-Fabricated Panels | $2.00 – $5.00 |

Choosing the Right Supplier for Corrugated Metal Siding

Selecting the right supplier can make all the difference in your project’s success. Here are some factors to consider:

| Criteria | विवरण |

| customization options | that fit your specific project requirements, whether that’s custom sizes, finishes, or colors. |

| Lead Times | Check the supplier’s lead times to ensure they can meet your project deadlines. |

| Customer Service | A responsive and knowledgeable customer service team can make the process smoother. |

| Warranty | A solid warranty can provide peace of mind, especially for long-term installations. |

| Reputation | Look at reviews and testimonials to gauge the supplier’s reputation in the market. |

| Delivery Options | Consider the logistics—some suppliers offer free or discounted shipping depending on your location and order size. |

Pros and Cons of Corrugated Metal Siding

Every material has its advantages and limitations. Here’s a breakdown of the pros and cons of using corrugated metal siding:

| Pros | Cons |

|---|---|

| Durability: Highly resistant to weather, pests, and fire, making it one of the most durable siding options available. | Noise: Can be noisy during heavy rain or hailstorms unless properly insulated. |

| Aesthetic Versatility: Available in a variety of finishes and colors, fitting both modern and rustic aesthetics. | 成本: Premium materials like copper or stainless steel can be expensive. |

| 低维护: Requires minimal upkeep, with only occasional cleaning and re-sealing needed. | Installation Difficulty: Can be challenging to install without professional help, particularly for DIYers. |

| 能效高: Reflects sunlight, which can help keep buildings cooler in the summer. | Denting and Scratching: Although strong, it can be prone to dents and scratches, particularly with softer metals like aluminum. |

| Sustainability: Often made from recycled materials and can be recycled again, reducing environmental impact. | Thermal Expansion: Metal expands and contracts with temperature changes, which can lead to warping if not installed correctly. |

How to Choose the Right Corrugated Metal Siding for Your Project

Choosing the right corrugated metal siding involves more than just picking a material. Here’s a detailed guide to help you make the best decision:

- Identify Your Project Needs: Consider what you need from your siding—durability, aesthetic appeal, budget, etc. For example, if you’re in a coastal area, aluminum’s corrosion resistance might make it the best choice.

- Consider the Climate: The climate can greatly impact your choice. Steel, while strong, may not be the best in humid or coastal areas due to potential rust issues, even if galvanized.

- Check for Local Building Codes: Ensure that the siding you choose complies with local building codes and regulations. Some areas may have restrictions on the types of materials that can be used.

- Aesthetic Preferences: Choose a finish and color that complements your building’s architecture. For instance, Cor-Ten steel offers a rustic look that can beautifully contrast with modern architectural designs.

- Budget Considerations: Calculate the overall costs, including materials, installation, and any necessary treatments or coatings. Don’t forget to factor in long-term maintenance costs as well.

- Longevity and Warranty: Consider the lifespan of the material. Copper and stainless steel offer exceptional longevity but at a higher upfront cost. Also, check the warranty offered by the supplier.

- Supplier Reputation: As mentioned earlier, choose a supplier known for high-quality products and reliable service. A good supplier can provide valuable advice and customization options.

Comparing Corrugated Metal Siding Options

Here’s a comparison of some popular corrugated metal siding materials based on key criteria:

| सामग्री | Durability | Aesthetics | 成本 | Maintenance | Best For |

|---|---|---|---|---|---|

| गैल्वेनाइज्ड स्टील | High | Industrial, modern | $$ | Low | Industrial, commercial buildings |

| एल्यूमीनियम | Medium | Clean, modern | $$$ | Low | Coastal homes, modern homes |

| कॉपर | Very High | Unique, luxurious | $$$$ | Low | High-end residential or commercial |

| Stainless Steel | Very High | Sleek, polished | $$$ | Very Low | Commercial kitchens, industrial |

| Cor-Ten Steel | High | Rustic, weathered | $$$ | Medium | Artistic or rustic designs |

| Pre-Painted Steel | High | Versatile, various colors | $$ | Low | Residential, commercial |

Installation, Operation, and Maintenance of Corrugated Metal Siding

Proper installation and maintenance are key to ensuring the longevity and effectiveness of your corrugated metal siding. Let’s dive into the details:

स्थापना प्रक्रिया

Installing corrugated metal siding involves several steps. Here’s a simplified overview:

- Preparation: Before installation, ensure the surface is clean and free of any debris. If you’re installing over existing siding, make sure it’s in good condition and properly prepared.

- Measuring and Cutting: Measure the area to determine the number of panels required. Cut the metal sheets to size using tin snips or a metal cutting saw.

- Installing the Underlayment: Apply an underlayment to the surface. This layer acts as a barrier against moisture and adds an extra layer of insulation.

- Panel Installation: Starting from one corner, align the first panel and secure it with fasteners. Ensure each subsequent panel overlaps the previous one to prevent water ingress.

- Flashing and Trim Installation: Install flashing and trim pieces to cover joints and edges. This not only enhances the aesthetic appeal but also provides additional protection against the elements.

- Final Inspection: After all panels are installed, conduct a thorough inspection to ensure everything is securely fastened and properly aligned.

Operation and Maintenance

Corrugated metal siding is relatively low-maintenance, but regular checks can help extend its lifespan. Here’s what to keep in mind:

- 定期检查: Periodically inspect your siding for any signs of rust, corrosion, or damage. Addressing these issues early can prevent more extensive damage.

- Cleaning: Clean the siding with a mild detergent and water to remove dirt, grime, and any buildup that might affect the siding’s finish.

- Re-Sealing: Depending on the material, you may need to re-seal joints and edges to maintain water resistance. This is particularly important for galvanized steel and aluminum.

- Repainting: If you have pre-painted steel, consider repainting every few years to maintain the aesthetic appeal and protect against corrosion.

常见问题解答

| Question | Answer |

|---|---|

| What is the lifespan of corrugated metal siding? | Depending on the material, corrugated metal siding can last between 40 to 70 years with proper maintenance. |

| Can corrugated metal siding be installed over existing siding? | Yes, but the existing siding must be in good condition and properly prepared before installation. |

| Is corrugated metal siding energy-efficient? | Yes, metal siding can reflect sunlight, which helps keep your building cooler in hot climates. |

| How does corrugated metal siding perform in extreme weather? | It’s highly resistant to wind, rain, and snow, making it ideal for areas prone to extreme weather. |

| Does corrugated metal siding require special maintenance? | While it’s low-maintenance, regular inspections and occasional cleaning will help maintain its longevity. |

| Can I paint corrugated metal siding? | Yes, many types of corrugated metal siding can be painted or come pre-painted. |

| Is it environmentally friendly? | Corrugated metal siding is often made from recycled materials and can be recycled at the end of its life. |

निष्कर्ष

Corrugated metal siding offers a blend of durability, aesthetics, and versatility that’s hard to beat. Whether you’re looking to add a modern touch to your home or seeking a resilient material for an industrial project, corrugated metal is a fantastic choice. With the right knowledge and careful planning, you can select the best type for your needs, ensure proper installation, and enjoy its benefits for decades.

In choosing the right supplier and material, considering factors like climate, aesthetics, and budget will help you make an informed decision. Remember, investing in high-quality materials and professional installation will pay off in the long run, offering you a siding solution that not only looks great but also stands the test of time.