स्टील स्टड रोल फॉर्मिंग मशीन स्टील प्रोफाइल और शीट मेटल उत्पादों के निर्माण में उपयोग की जाने वाली सबसे महत्वपूर्ण उपकरणों में से एक है। यह लेख स्टील स्टड रोल फॉर्मिंग मशीन का एक गाइड है। इसमें कार्य सिद्धांत, डिजाइन और स्टील स्टड रोल फॉर्मिंग मशीन के विभिन्न निर्माताओं का वर्णन किया गया है।

स्टील स्टड रोल फॉर्मिंग मशीन क्या है?

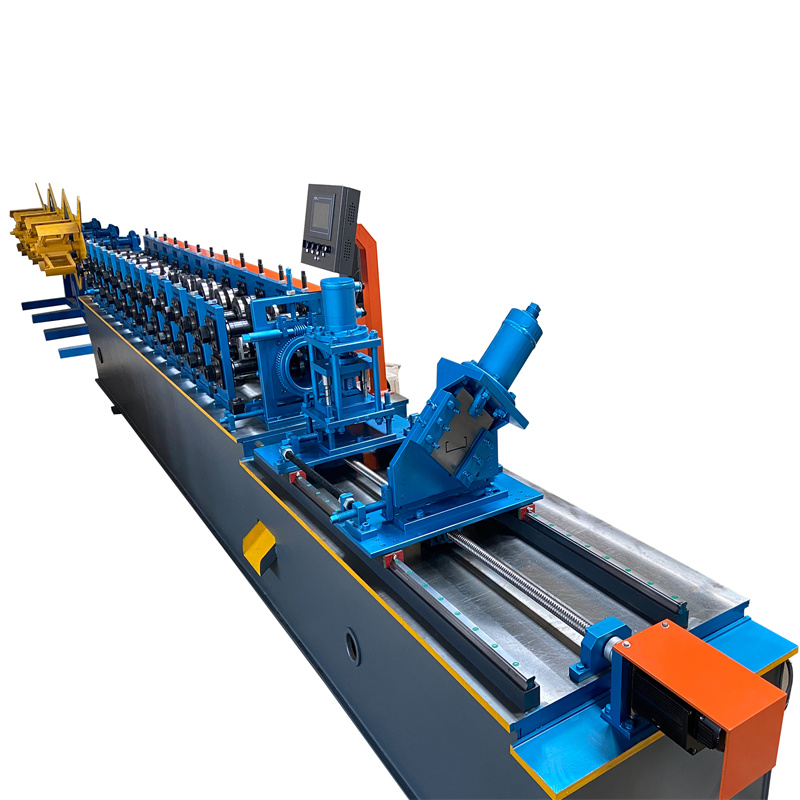

स्टील स्टड रोल फॉर्मिंग मशीन दीवारों के लिए स्टील फ्रेमिंग बनाने के लिए उपयोग किया जाने वाला निर्माण उपकरण का एक प्रकार है। इस मशीन का उपयोग आंतरिक और बाहरी दोनों दीवार फ्रेमिंग बनाने के लिए किया जा सकता है। रोल फॉर्मिंग मशीन से स्टील फ्रेमिंग बनाने की प्रक्रिया को “रोल फॉर्मिंग” के नाम से जाना जाता है।

स्टील स्टड्स का उपयोग व्यावसायिक और आवासीय दोनों निर्माण परियोजनाओं में आमतौर पर किया जाता है। वे मजबूत और टिकाऊ होते हैं, जो उन्हें लोड-बेयरिंग अनुप्रयोगों के लिए आदर्श बनाते हैं। स्टील स्टड्स अग्नि प्रतिरोधी और दीमक प्रतिरोधी भी होते हैं, जो उन्हें इन कीटों वाले क्षेत्रों में उपयोग के लिए लोकप्रिय विकल्प बनाते हैं।

स्टील स्टड रोल फॉर्मिंग मशीन कैसे काम करती है?

स्टील स्टड रोल फॉर्मिंग मशीन दीवारों के लिए स्टील फ्रेमिंग बनाने के लिए उपयोग किया जाने वाला निर्माण उपकरण का एक प्रकार है। मशीन स्टील शीट्स को आवश्यक आकार और साइज में मोड़ने और काटने का काम करती है।

स्टील स्टड रोल फॉर्मिंग मशीन का उपयोग करने का पहला चरण स्टील शीट्स को मशीन पर लोड करना है। फिर शीट्स को वांछित आकार में मोड़ने वाली रोलर्स की एक श्रृंखला से गुजारा जाता है। एक बार शीट्स वांछित आकार में आ जाने पर, उन्हें साइज के अनुसार काटा जाता है और फिर निर्माण स्थल पर पहुंचाया जाता है।

स्टील स्टड रोल फॉर्मिंग मशीन कैसे खरीदें

स्टील स्टड रोल बनाना मशीन चुनते समय, आपको कुछ बातों का ध्यान रखना चाहिए। यहां स्टील स्टड रोल फॉर्मिंग मशीन खरीदने का एक त्वरित गाइड दिया गया है:

- सबसे पहले मशीन के आकार पर विचार करें। छोटी परियोजनाओं के लिए डिजाइन की गई मशीनें हैं और बड़ी परियोजनाओं के लिए भी। अपनी आवश्यकताओं के लिए सबसे उपयुक्त चुनें।

- दूसरी बात मशीन की गति है। यदि आप मशीन का व्यावसायिक उद्देश्यों के लिए उपयोग करेंगे, तो तेज मॉडल चुनें। अन्यथा, धीमी मॉडल पर्याप्त होगी।

- मशीन की कीमत पर भी विचार करें। कुछ मशीनें बहुत किफायती हैं जबकि कुछ काफी महंगी। अपने बजट के अनुकूल चुनें।

- स्टील स्टड रोल फॉर्मिंग मशीन खरीदते समय, इसकी वारंटी और रिटर्न पॉलिसी की जांच करें ताकि यदि कुछ गड़बड़ हो जाए तो आप पैसे वापस ले सकें या इसे बदलवा सकें।

स्टील स्टड रोल फॉर्मिंग मशीन उपयोग करने के टिप्स

यदि आप स्टील स्टड रोल फॉर्मिंग मशीन की तलाश में हैं, तो अपने निवेश से अधिकतम लाभ सुनिश्चित करने के लिए कुछ बातों का ध्यान रखें। यहां कुछ टिप्स दिए गए हैं:

- सुनिश्चित करें कि आपके पास कार्य के लिए सही मशीन हो। विभिन्न अनुप्रयोगों के लिए विभिन्न मशीनें हैं, इसलिए अपनी आवश्यकताओं के लिए उपयुक्त चुनें।

- मशीन चलाने से पहले मैनुअल ध्यान से पढ़ें। इससे आपको मशीन का सही उपयोग और रखरखाव समझ आएगा तथा दुर्घटनाओं से बचा जा सकेगा।

- मशीन के आसपास के क्षेत्र को साफ और अव्यवस्थित रखें। इससे दुर्घटनाओं को रोका जा सकेगा और मशीन की आयु बढ़ेगी।

- सभी भागों की अच्छी स्थिति सुनिश्चित करने के लिए मशीन की नियमित जांच करें। इससे डाउनटाइम रोका जा सकेगा और उत्पादन सुचारू रहेगा।

- मशीन चलाते समय सभी सुरक्षा दिशानिर्देशों का पालन करें। यह आपकी और आसपास वालों की सुरक्षा के लिए महत्वपूर्ण है।

स्टील स्टड रोल फॉर्मिंग मशीन के शीर्ष 5 सर्वश्रेष्ठ निर्माता

1. फॉर्मटेक ग्रुप

फॉर्मटेक लंबे समय से स्थापित ब्रांडों का एक समूह है, जिनमें से प्रत्येक एक प्रसिद्ध नाम और धातु बनाने और धातु प्रसंस्करण उद्योगों को नवीन और विश्वसनीय उपकरण प्रदान करने का इतिहास है। फॉर्मटेक अपने ब्रांडों की "सर्वश्रेष्ठ श्रेणी" तकनीक और उपकरणों को एकीकृत विनिर्माण प्रणालियों में जोड़ता है जो शीट धातु से सटीक उत्पाद बनाने की उत्पादकता में सुधार करते हैं।

2. सैमको मशीनरी

सैमको मशीनरी दुनिया भर में उद्योगों की एक विस्तृत श्रृंखला की सेवा के लिए रोलफॉर्मिंग मशीनों का डिजाइन और निर्माण करती है। आपकी विशिष्ट धातु झुकने की जरूरतों को पूरा करने वाले अंतिम उत्पादों को अनुकूलित और बनाना, वे भवन और निर्माण, रैकिंग और ठंडे बस्ते, परिवहन और सौर सहित कई उद्योगों के लिए समाधान प्रदान करते हैं।

3. योदर मशीनरी

योडर मशीनरी एक अग्रणी रोल बनाने की मशीन आपूर्तिकर्ता है। वे मशीनों की एक विस्तृत श्रृंखला पेश करते हैं जो विभिन्न प्रकार के बजट के लिए उपयुक्त हैं। उनकी ग्राहक सेवा उत्कृष्ट है, और उच्च गुणवत्ता वाली मशीनें प्रदान करने के लिए उनकी अच्छी प्रतिष्ठा है।

4. विंटन मशीन

विंटन मशीन रोल बनाने वाली मशीनों की एक और शीर्ष आपूर्तिकर्ता है। वे ऑटोमोटिव, निर्माण और उपकरण निर्माण सहित विभिन्न उद्योगों के लिए मशीनों की पेशकश करते हैं। विंटन मशीन मशीन की मरम्मत और प्रतिस्थापन सहित सेवाओं की एक विस्तृत श्रृंखला भी प्रदान करती है।

Prioritize manufacturers with strong reputations, longevity, and proven track records.

-

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन -

दीन रेल रोल बनाने की मशीन

दीन रेल रोल बनाने की मशीन -

एल कोण रोल बनाने की मशीन

एल कोण रोल बनाने की मशीन -

केबल सीढ़ी रोल बनाने की मशीन

केबल सीढ़ी रोल बनाने की मशीन -

केबल ट्रे रोल बनाने की मशीन

केबल ट्रे रोल बनाने की मशीन -

लाइट गेज कील स्टड ट्रैक सी चैनल स्टील रोल बनाने की मशीन ड्राईवॉल मेटल सी स्टड मशीनरी

लाइट गेज कील स्टड ट्रैक सी चैनल स्टील रोल बनाने की मशीन ड्राईवॉल मेटल सी स्टड मशीनरी -

स्टील का तार लंबाई लाइन मशीन में कटौती

स्टील का तार लंबाई लाइन मशीन में कटौती -

स्टील का तार लंबाई लाइन मशीन में कटौती

स्टील का तार लंबाई लाइन मशीन में कटौती -

स्टील का तार लंबाई लाइन मशीन में कटौती

स्टील का तार लंबाई लाइन मशीन में कटौती

निष्कर्ष

स्टील स्टड रोल फॉर्मिंग मशीनें किसी भी निर्माण परियोजना का आवश्यक हिस्सा हैं। इस गाइड में हमने इन मशीनों के बारे में सब कुछ कवर किया है, उनके कार्य सिद्धांत से लेकर लाभ तक। हम आशा करते हैं कि इस गाइड ने आपको स्टील स्टड रोल फॉर्मिंग मशीनों और निर्माण परियोजनाओं में उनकी भूमिका के बारे में बेहतर समझ दी होगी। यदि आप अपने निर्माण व्यवसाय के लिए मशीन खरीदने पर विचार कर रहे हैं, तो हमारी स्टील स्टड रोल फॉर्मिंग मशीनों की चयन देखें।

Frequently Asked Questions (FAQ)

1) What profiles can a Steel Stud Roll Forming Machine produce for drywall systems?

- Common profiles include C studs, U tracks, resilient channels, furring channels, and custom knock-out patterns for MEP. Typical gauges are 0.4–1.2 mm (26–18 ga) galvanized steel meeting ASTM C645/C754 or EN 14195.

2) What tolerances are realistic for interior steel studs and tracks?

- Best-practice targets: width ±0.5 mm, flange height ±0.4 mm, web bow ≤1 mm/m, twist ≤1°/m, knockout pitch ±0.5 mm, cut length ±0.8 mm over 3–4 m, when using servo flying shear and laser length encoders.

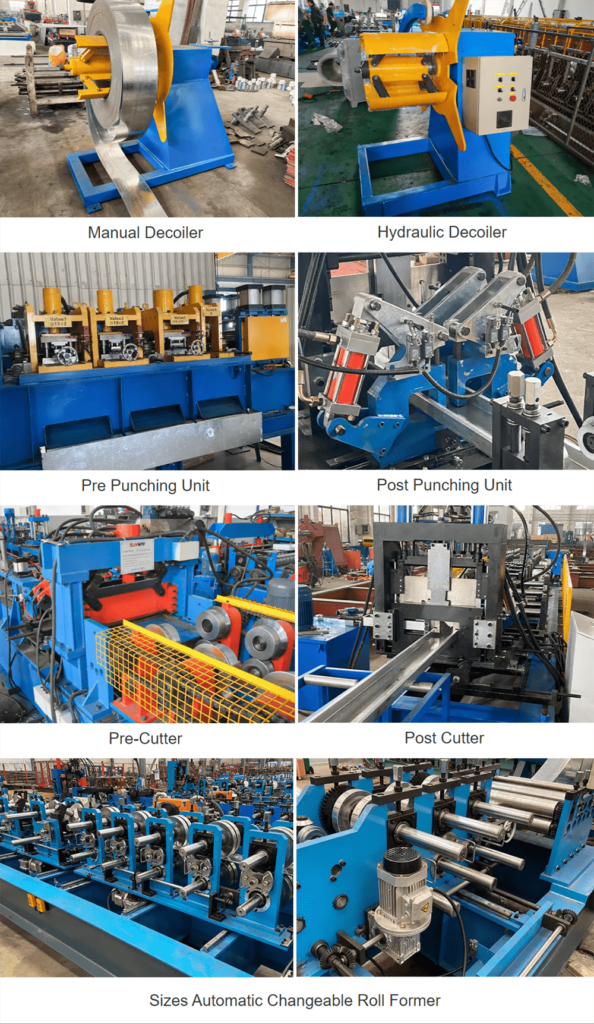

3) How does pre-punching integrate with stud roll forming?

- A servo-controlled pre-punch press upstream of the forming stands handles service holes, knockouts, and identification slots. Pattern changes are recipe-driven via the HMI; vision inspection can close the loop to maintain hole pitch at speed.

4) Can the same line run both studs and tracks efficiently?

- Yes, via cassette/tooling change systems and automatic stand positioning. Changeovers drop from 45–90 minutes to 10–25 minutes on modern lines, enabling mixed C stud/U track production in short runs.

5) What affects surface finish when running pre-painted or galvanized coils?

- Roll hardness and polish, correct roll-gap, micro-lubrication, felt wipers, crowned guides, and clean entry tables. Maintain coil tension and edge guiding to prevent scuffing or zinc pick-up.

2025 Industry Trends

- Digital recipes and auto setup: Barcode-scanned coil + profile recipe triggers auto stand positioning and roll-gap settings, reducing first‑piece scrap.

- Higher throughput with precision: Flying shear plus laser encoding supports 40–70 m/min on simple studs/tracks while holding ±0.8 mm cut length on 3–4 m parts.

- Inline QA: Vision systems verify knockout geometry and burrs at line speed, logging to MES for traceability.

- Energy reductions: IE5 motors, regenerative VFDs, and smart lubrication lower energy intensity by 15–25% vs. 2022.

- Sustainability and EPDs: Builders increasingly demand EPD-backed stud products; mills and fabricators standardize coil-to-part traceability and recycled content reporting.

2025 benchmarks for Steel Stud Roll Forming Machines

| Metric | 2022 Typical | 2025 Best-in-class | Notes |

|---|---|---|---|

| Line speed (m/min) | 15–35 | 40–70 | Simple studs/tracks with flying shear |

| Changeover time (min) | 45–90 | 10–25 | Cassette tooling + auto stands |

| Cut length tolerance (mm over 3–4 m) | ±1.5–2.0 | ±0.5–0.8 | Laser encoder + servo shear |

| Knockout pitch tolerance (mm) | ±1.0 | ±0.5 | Vision-assisted closed loop |

| First-pass yield after changeover (%) | 93–96 | 98–99.5 | Recipe control + SMED |

| Energy intensity (kWh/ton) | 120–160 | 90–115 | IE5 + regen drives |

| OEE (%) | 60–70 | 75–85 | Higher uptime/quality |

Selected references:

- ASTM C645/C754 (non-structural steel framing): https://www.astm.org

- EN 14195 (metal framing components): https://standards.iteh.ai

- The Fabricator—roll forming best practices: https://www.thefabricator.com

- NIST MEP—SMED/OEE resources: https://www.nist.gov/mep

- ISO 50001—energy management: https://www.iso.org

Latest Research Cases

Case Study 1: Vision-Guided Knockout Control for Drywall Studs (2025)

Background: A EU drywall supplier had variable knockout pitch at 50 m/min on 0.55 mm G90 coils, increasing field rework.

Solution: Integrated camera-based inspection with encoder-synced corrections to the servo pre-punch; added auto stand positioning and digital recipes.

Results: Knockout pitch Cpk improved from 1.05 to 1.78; scrap reduced from 3.2% to 0.9%; first-piece approval time fell by 60%.

Case Study 2: Energy Optimization on Multi-SKU Stud/Track Line (2024)

Background: A North American fabricator sought energy savings and higher OEE during frequent changeovers.

Solution: Upgraded to IE5 motors with regenerative drives, implemented micro-lube, and adopted cassette tooling with standardized SMED procedures.

Results: Energy intensity down 22% (kWh/ton); average changeover reduced from 62 to 21 minutes; OEE increased from 67% to 81%.

Expert Opinions

- Rob Dietrich, Director of Engineering, Formtek

Viewpoint: “For light-gauge stud lines, knockout precision is won or lost at the pre-punch. Encoder sync and vision feedback are now table stakes for holding ±0.5 mm pitch at high speed.” - Dr. Daniel Schaeffler, President, Engineering Quality Solutions

Viewpoint: “Pass design and roll-gap control are critical to minimize camber and twist on thin gauges. Consistent coil mechanicals and proper lubrication prevent edge wave that shows up as drywall fit issues.” - Maria Alvarez, Operations Manager, Samco Machinery

Viewpoint: “Cassette tooling with automatic stand positioning routinely halves changeover time on stud/track families. Most customers see sub‑12‑month ROI when running multi-SKU programs.”

Practical Tools/Resources

- Roll design and simulation: COPRA RF / COPRA FEA RF (https://www.data-m.de), AutoForm (https://www.autoform.com)

- Inline metrology/vision: Keyence (https://www.keyence.com), Cognex (https://www.cognex.com)

- Standards and compliance: ASTM C645/C754 (https://www.astm.org), EN 14195 (https://standards.iteh.ai), ISO 9001 (https://www.iso.org)

- Maintenance/Energy: Fiix CMMS (https://www.fiixsoftware.com), UpKeep (https://www.upkeep.com), ISO 50001 (https://www.iso.org)

- Industry learning: The Fabricator—roll forming (https://www.thefabricator.com), NIST MEP (https://www.nist.gov/mep)

Last updated: 2025-10-20

Changelog: Added 5 FAQs tailored to Steel Stud Roll Forming Machine users; introduced 2025 benchmarks table and key trends; added two recent case studies; included expert viewpoints; curated practical tools/resources with authoritative links

Next review date & triggers: 2026-04-15 or earlier if ASTM/EN framing standards are revised, major OEMs release sub-10-minute cassette changeover systems, or new energy regulations mandate IE5/regenerative drives