As urbanization accelerates and cities expand, the demand for robust and aesthetically pleasing street light poles has reached unprecedented heights. At the heart of modern streetlight manufacturing lies the Street Light Pole Roll Forming Machine, a sophisticated tool designed to produce high-strength, customizable, and cost-effective poles that illuminate roads, parks, and public spaces.

In this guide, we’ll delve into the Street Light Pole Roll Forming Machine, its critical applications, advanced features, pricing insights, and why Wuxi Sunway Machinery stands out as a global leader in roll-forming technology. Whether you’re a manufacturer, contractor, or urban planner, this article will guide you through the transformative potential of these machines.

What is a Street Light Pole Roll Forming Machine?

ए Street Light Pole Roll Forming Machine is an industrial-grade machine used to manufacture high-quality street light poles through a cold roll-forming process. These machines take raw metal sheets or coils and transform them into durable, hollow poles with tapered or cylindrical shapes. The result is a seamless, high-strength product that meets the structural and aesthetic needs of urban infrastructure.

The roll-forming process ensures precision, repeatability, and efficiency, making it possible to produce poles that are not only structurally reliable but also visually appealing. Whether for highways, residential areas, or urban parks, Street Light Pole Roll Forming Machines provide manufacturers with the tools to meet diverse customer demands while optimizing production costs.

Applications of Street Light Pole Roll Forming Machines

Street light poles are a vital component of urban infrastructure, providing safety, aesthetics, and functionality in public spaces. Below are the primary applications of roll-formed street light poles:

1. Highway Lighting

- Use Case: Tall poles with high-lumen lights are used to illuminate highways and expressways.

- Why It Matters: Roll-formed poles ensure structural integrity, even under harsh weather conditions, ensuring consistent lighting for drivers.

2. Urban Street Lighting

- Use Case: Poles designed for residential streets and city centers provide both functionality and visual appeal.

- Why It Matters: Customizable designs help cities create an inviting atmosphere while maintaining safety.

3. Park and Landscape Lighting

- Use Case: Ornamental poles with unique shapes and finishes are used in parks and recreational areas.

- Why It Matters: Roll-forming technology allows manufacturers to produce poles with intricate designs and decorative features.

4. Smart Poles for IoT Integration

- Use Case: Smart poles equipped with IoT sensors, cameras, and 5G infrastructure enhance urban connectivity.

- Why It Matters: Roll-forming machines can produce hollow poles with integrated compartments for housing smart technology.

5. Solar Street Lighting

- Use Case: Poles designed to support solar panels for energy-efficient outdoor lighting.

- Why It Matters: Roll-formed poles are lightweight yet sturdy, ideal for supporting renewable energy systems.

6. Industrial and Commercial Areas

- Use Case: Heavy-duty poles illuminate industrial zones, factories, and commercial spaces.

- Why It Matters: High-strength poles ensure durability and performance in demanding environments.

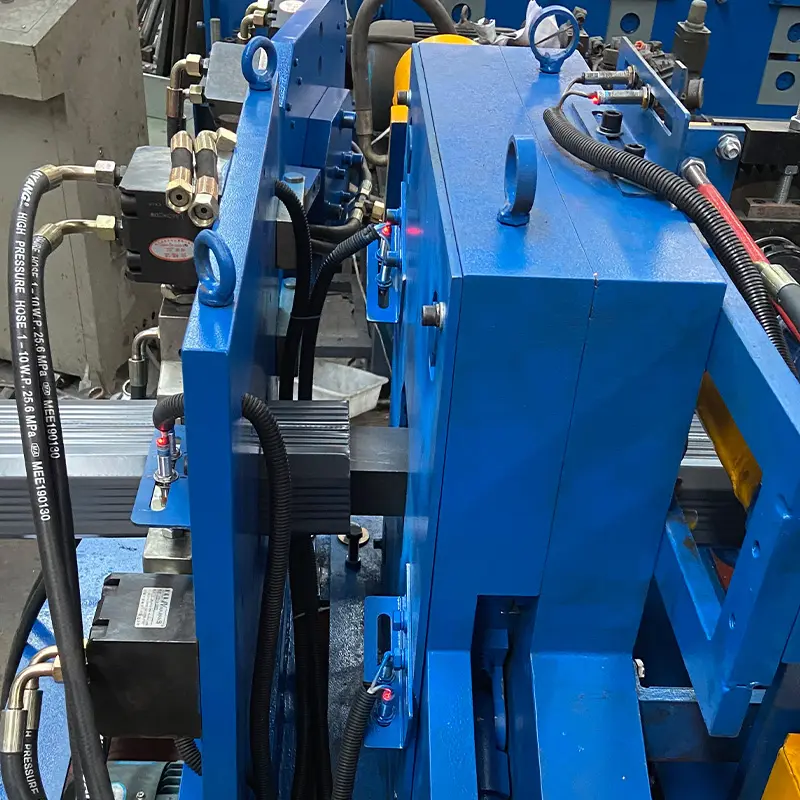

Key Features of Wuxi Sunway Street Light Pole Roll Forming Machines

When it comes to manufacturing premium street light poles, Wuxi Sunway Machinery offers cutting-edge roll-forming machines that stand out for their precision, efficiency, and customization capabilities. Here’s what makes their machines exceptional:

1. Customizable Pole Designs

- What It Offers: Machines can produce both tapered and cylindrical poles, with options for single or multi-segment designs.

- Why It’s Revolutionary: Supports diverse applications, from standard highway poles to decorative urban designs.

2. Material Versatility

- Supported Materials:

- Galvanized steel

- Stainless steel

- Aluminum alloys

- High-strength steel

- Why It’s Crucial: Enables manufacturers to produce poles that meet specific durability and aesthetic requirements.

3. High-Precision Forming

- What It Does: Produces poles with uniform thickness, smooth seams, and tight tolerances.

- Why It’s Important: Ensures structural integrity and a flawless finish, reducing rework and waste.

4. Integrated Welding and Seam Optimization

- Features: Automatic welding systems ensure seamless joints for hollow poles.

- Why It Matters: Eliminates the need for secondary welding operations, saving time and improving quality.

5. High-Speed Production

- Performance: Capable of producing up to 10 meters of poles per minute, depending on the design complexity.

- Why It Matters: Meets the high-volume demands of urban infrastructure projects.

6. PLC-Controlled Automation

- Features:

- Fully programmable logic controllers (PLC) with an intuitive touchscreen interface.

- Stores multiple pole designs for quick setup.

- Real-time monitoring and diagnostics.

- Why It’s Revolutionary: Simplifies operation and ensures consistent quality across production runs.

7. Eco-Friendly Operation

- What It Includes: Energy-efficient motors and waste-reducing technologies.

- Why It Matters: Supports sustainable manufacturing practices, reducing operational costs and environmental impact.

8. Compact and Modular Design

- What It Does: Offers a space-saving design that integrates seamlessly into existing production lines.

- Why It Matters: Optimizes factory floor space and allows for easy upgrades.

Production Workflow of a Street Light Pole Roll Forming Machine

The production process for street light poles is streamlined to maximize efficiency and precision. Below is an overview of the workflow:

1. Decoiling

- Large coils of raw material are loaded onto the decoiler, which feeds the material into the machine.

2. Leveling

- A leveling system flattens the material and removes any warping before it enters the roll-forming section.

3. Roll Forming

- The material passes through a series of rollers that gradually shape it into the desired pole profile.

4. Welding

- Automatic welding systems create a seamless joint, forming the hollow pole structure.

5. Cutting and Punching

- Servo-controlled cutting units trim the poles to the required length, while punching systems create holes for mounting brackets and fixtures.

6. Surface Treatment

- Optional processes like galvanization or powder coating enhance corrosion resistance and aesthetics.

7. Stacking

- Finished poles are automatically stacked for easy packaging and transportation.

Pricing of Street Light Pole Roll Forming Machines

The cost of a Street Light Pole Roll Forming Machine depends on its features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic pole production for standard designs | $150,000–$250,000 |

| High-Precision Machines | Advanced tolerances and automated welding | $250,000–$400,000 |

| Fully Customizable Machines | Multi-profile and material capability | $400,000–$600,000 |

For tailored pricing and financing options, contact Wuxi Sunway Machinery.

Advantages of Using Street Light Pole Roll Forming Machines

Investing in a Street Light Pole Roll Forming Machine offers numerous benefits for manufacturers:

1. Increased Efficiency

- High-speed production reduces lead times and increases output.

2. Precision and Consistency

- Ensures uniform quality across all poles, minimizing rework and defects.

3. Material Flexibility

- Supports a wide range of materials, including corrosion-resistant alloys.

4. Cost Savings

- Reduces material waste and labor costs, improving overall profitability.

5. Scalability

- High production capacity allows manufacturers to meet the growing demands of urban infrastructure projects.

FAQs About Street Light Pole Roll Forming Machines

| Question | Answer |

|---|---|

| What is the production speed? | Machines can produce up to 10 meters of poles per minute, depending on the design. |

| Can the machine handle decorative designs? | Yes, it can produce custom shapes and profiles for ornamental poles. |

| What is the maximum pole length? | Machines can produce poles up to 12 meters long, depending on the model. |

| Does Sunway provide installation support? | Absolutely! Sunway offers on-site installation and commissioning services. |

| What is the machine’s lifespan? | With proper maintenance, the machine can last 10–15 years or more. |

| Is training included with the purchase? | Yes, comprehensive training is provided with every machine purchase. |

Global Trends Driving the Demand for Street Light Pole Roll Forming Machines

The global push for smarter, greener, and more connected urban environments is transforming how cities are built and maintained. These trends are directly influencing the adoption of Street Light Pole Roll Forming Machines in 2025:

1. Rise of Smart Cities

- The Context: Governments worldwide are investing in smart city projects, where technologies like IoT, 5G, and AI are integrated into urban infrastructure.

- Impact on Street Lighting: Smart street light poles are equipped with sensors, cameras, and communication devices, requiring precise, multi-functional designs.

- Why It Matters: Roll-forming machines enable the production of hollow, compartmentalized poles that can house smart technologies seamlessly.

2. Shift Toward Renewable Energy

- The Push: Many countries are transitioning to solar-powered street lights to reduce reliance on fossil fuels.

- Impact on Pole Design: Solar street lights require lightweight yet sturdy poles to support solar panels and batteries.

- Why It’s Exciting: Machines capable of processing aluminum and other lightweight materials are crucial for producing these modern poles.

3. Infrastructure Development in Emerging Economies

- The Numbers: Emerging markets in Asia, Africa, and South America are investing heavily in road and public lighting infrastructure.

- Impact on Manufacturing: High demand for affordable and durable lighting solutions is driving the need for efficient roll-forming technologies.

- Why It Matters: Roll-forming machines produce cost-effective poles at high speeds, meeting the needs of large-scale projects.

4. Focus on Aesthetic Urban Design

- The Trend: Cities are prioritizing the visual appeal of urban infrastructure to enhance tourism and public satisfaction.

- Impact on Poles: Ornamental and custom-designed light poles are becoming increasingly popular.

- Machine Relevance: Roll-forming machines with multi-profile capabilities allow manufacturers to produce decorative poles without compromising structural integrity.

5. Increasing Safety Standards

- What’s Happening: Regulatory bodies are enforcing stricter safety and durability standards for street lighting infrastructure.

- Impact on Production: Poles must meet higher standards for wind resistance, corrosion resistance, and load capacity.

- Why It’s Important: High-precision roll-forming machines ensure compliance with global safety standards.

Technological Advancements in Street Light Pole Roll Forming Machines

The evolution of Street Light Pole Roll Forming Machines is being driven by groundbreaking innovations that enhance performance, efficiency, and sustainability. Let’s explore the latest technological advancements making waves in 2025:

1. Artificial Intelligence (AI) for Quality Assurance

- What It Does: AI-powered cameras and sensors monitor the production process in real-time, identifying defects and ensuring consistent quality.

- Benefits:

- Reduces material waste by catching errors early.

- Improves overall product reliability.

- Enhances customer satisfaction with defect-free outputs.

2. IoT-Enabled Smart Machines

- How It Works: IoT sensors collect real-time data on machine performance, material usage, and output quality.

- Advantages:

- Enables remote monitoring and diagnostics.

- Provides predictive maintenance alerts to prevent downtime.

- Optimizes production efficiency through data-driven insights.

3. Advanced Welding Technologies

- The Innovation: Integrated welding systems use laser or TIG (Tungsten Inert Gas) welding for seamless joints.

- Why It’s Revolutionary:

- Produces stronger, more aesthetically pleasing seams.

- Reduces post-welding treatments, saving time and costs.

- Ensures durability, particularly for poles exposed to extreme weather.

4. Multi-Material Processing

- What It Offers: Machines can switch between materials like galvanized steel, stainless steel, and aluminum alloys.

- Why It’s Crucial: Supports the production of poles for diverse applications, from robust highway poles to lightweight solar pole designs.

5. Servo-Driven Punching and Cutting

- How It Works: Servo motors control punching and cutting units with exceptional precision.

- Benefits:

- Creates uniform holes for brackets and fixtures.

- Ensures clean cuts, reducing the need for secondary processes.

- Enhances the overall aesthetic and structural quality of the poles.

6. Modular Design with Scalability

- What It Does: Modular machine designs allow manufacturers to add or remove features as needed.

- Why It Matters: Provides flexibility for manufacturers to adapt to changing market demands and production scales.

Environmental Impact of Street Light Pole Roll Forming Machines

Sustainability is at the forefront of modern manufacturing. Here’s how Street Light Pole Roll Forming Machines contribute to eco-friendly production:

1. Reduced Material Waste

- How It Works: Optimized roll-forming processes minimize scrap and offcuts.

- Impact: Conserves raw materials and lowers production costs.

2. Energy Efficiency

- The Innovation: Machines are equipped with energy-efficient motors and controls that consume less electricity.

- Why It Matters: Reduces the carbon footprint of manufacturing operations.

3. Recyclable Outputs

- The Advantage: Poles made from aluminum and steel are fully recyclable, encouraging a circular economy.

- Why It’s Important: Aligns with global sustainability goals and reduces landfill waste.

4. Localized Production

- What It Does: Enables manufacturers to produce components locally, reducing the environmental impact of transportation.

- Outcome: Enhances regional sustainability while supporting local economies.

Comparison: Street Light Pole Roll Forming Machines vs. Traditional Methods

Let’s compare Street Light Pole Roll Forming Machines with conventional methods like manual welding or stamping:

| विशेषता | रोल बनाने की मशीन | Traditional Methods |

|---|---|---|

| Precision | High; ensures consistent dimensions | Moderate; prone to human error |

| उत्पादन गति | High; up to 10 meters per minute | Slow; labor-intensive processes |

| Automation | Fully automated with IoT integration | Mostly manual or semi-automated |

| Material Waste | Minimal; optimized processes reduce scrap | Higher; less efficient material usage |

| अनुकूलन | Easily customizable for various profiles | Limited flexibility; requires separate tooling |

| 成本效益 | Higher initial cost, lower operational costs | Lower initial cost, higher long-term costs |

| Scalability | Ideal for mass production | Limited scalability for high-volume demand |

Additional FAQs About Street Light Pole Roll Forming Machines

| Question | Answer |

|---|---|

| What is the maximum pole diameter? | Machines can produce poles with diameters of up to 500mm, depending on the design. |

| Can the machine handle tapered poles? | Yes, it can produce both tapered and cylindrical poles. |

| What is the typical lead time for delivery? | Delivery takes 3–6 months, depending on customization requirements. |

| Does Sunway offer financing options? | Yes, Sunway provides flexible financing solutions to meet customer needs. |

| Is operator training included? | Absolutely, comprehensive training is provided with every machine purchase. |

| Can the machine process corrosion-resistant materials? | Yes, it is designed to handle materials like galvanized and stainless steel. |

Why Choose Wuxi Sunway Machinery for Street Light Pole Roll Forming Machines?

Here’s why Wuxi Sunway Machinery is the preferred partner for manufacturers worldwide:

- Proven Expertise: Decades of experience in designing and delivering innovative roll-forming solutions.

- Global Reach: Trusted by customers across Asia, Europe, the Americas, and beyond.

- Customization Excellence: Machines tailored to meet specific pole designs and material requirements.

- Sustainability Commitment: Eco-friendly designs that minimize waste and energy consumption.

- Innovation Leadership: Features like IoT integration, servo-driven systems, and advanced welding technologies.

- Comprehensive Support: From installation to troubleshooting, Sunway ensures seamless operations and customer satisfaction.

Conclusion: Lighting the Future with Roll Forming Innovation

The Street Light Pole Roll Forming Machine is revolutionizing urban infrastructure by enabling the efficient production of durable, customizable, and sustainable poles. Whether for highways, smart cities, or solar projects, these machines deliver the precision and scalability needed to meet modern demands.

Ready to upgrade your production line? Contact Wuxi Sunway Machinery today to explore their advanced roll-forming solutions. Together, let’s illuminate the future of urban infrastructure—one pole at a time!