As the world shifts towards renewable energy, solar trackers have become a game-changer in maximizing solar energy efficiency. These systems, which adjust the orientation of 太阳能电池板s to follow the sun’s path, require high-quality frames and components to ensure durability and performance. At the heart of their production lies the Solar Tracker Roll Forming Machine—a cutting-edge solution crafted to manufacture precise and robust steel profiles for solar tracker systems.

In this comprehensive guide, we’ll deep dive into Solar Tracker Roll Forming Machines, exploring their features, applications, benefits, pricing, and how Wuxi Sunway Machinery leads the industry with its advanced solutions. Whether you’re a manufacturer in renewable energy or curious about the technology behind solar trackers, this guide is your ultimate resource.

What is a Solar Tracker Roll Forming Machine?

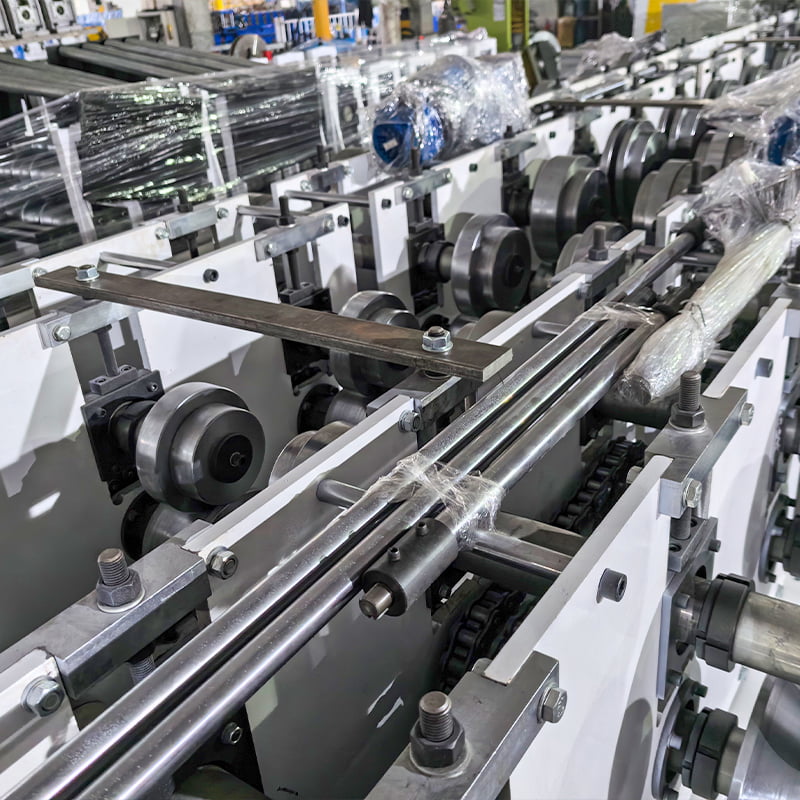

ए Solar Tracker Roll Forming Machine is a specialized industrial machine designed to produce steel profiles used in solar tracker systems. These profiles serve as the structural backbone for solar panels, ensuring stability, durability, and precision in alignment.

The roll-forming machine transforms flat steel coils into intricate profiles through a continuous process involving multiple rollers. With advanced automation, integrated punching systems, servo-driven cutting, and customization capabilities, these machines enable manufacturers to meet the growing global demand for solar energy infrastructure.

In an era where renewable energy is reshaping industries, Solar Tracker Roll Forming Machines play a pivotal role in supporting sustainable energy solutions.

Applications of Solar Tracker Profiles

Solar tracker profiles are essential components in solar energy systems. Below are the primary applications:

1. Single-Axis Solar Trackers

- Use Case: Profiles are used to support solar panels that rotate along a single axis (east to west).

- Why It Matters: Single-axis trackers are widely used in large-scale solar farms due to their efficiency and cost-effectiveness.

2. Dual-Axis Solar Trackers

- Use Case: Frames are used in advanced trackers that follow the sun’s movement on both horizontal and vertical axes.

- Why It Matters: Dual-axis trackers maximize solar energy capture, ideal for high-efficiency solar projects.

3. Fixed Tilt Solar Systems

- Use Case: Profiles are used for fixed-position solar panel systems, popular in smaller installations.

- Why It Matters: These systems offer a simpler and cost-effective alternative to trackers, but still require durable frames.

4. Solar Carports

- Use Case: Profiles are used in solar carports, which combine parking structures with solar panel installations.

- Why It Matters: Solar carports provide dual benefits—energy generation and vehicle protection.

5. Floating Solar Farms

- Use Case: Profiles are used in floating solar installations on water bodies.

- Why It Matters: Floating solar systems require corrosion-resistant profiles for long-lasting performance.

6. Roof-Mounted Solar Systems

- Use Case: Tracker profiles are also used for residential and commercial roof-mounted solar systems.

- Why It Matters: Lightweight yet durable profiles ensure safety and efficiency in rooftop installations.

Key Features of Wuxi Sunway Solar Tracker Roll Forming Machines

When it comes to producing high-quality solar tracker profiles, Wuxi Sunway Machinery offers cutting-edge roll-forming solutions. Here’s what sets their machines apart:

1. Customizable Profile Designs

- What It Does: Produces solar tracker profiles in various shapes, including U-channels, Z-profiles, and C-sections.

- Why It’s Important: Provides flexibility to meet the specific requirements of diverse solar tracker systems.

2. High-Speed Production

- Performance: Capable of producing up to 20 meters of profiles per minute, depending on material and design.

- Why It Matters: Enables manufacturers to scale up production to meet growing global demand.

3. Integrated Pre-Punching Systems

- Features: Hydraulic or servo-driven punching systems create holes and slots for assembly components.

- Why It’s Important: Streamlines the production process by eliminating the need for secondary operations.

4. Precision Cutting Technology

- Technology Used: Servo-controlled cutting systems ensure clean, burr-free edges.

- Why It Matters: Enhances product quality and reduces material waste.

5. Material Versatility

- Supported Materials:

- Galvanized steel

- Stainless steel

- एल्यूमीनियम

- Thickness Range: 1.5mm–4.0mm

- Why It’s Crucial: Ensures compatibility with lightweight and heavy-duty solar tracker systems.

6. PLC-Controlled Automation

- Features:

- Fully programmable logic controllers (PLC) with an intuitive touchscreen interface.

- Stores multiple profile designs and production parameters.

- Real-time monitoring and error detection.

- Why It’s Revolutionary: Simplifies operation and ensures consistent quality across production runs.

7. Eco-Friendly Design

- What It Offers: Energy-efficient motors and systems reduce electricity consumption.

- Why It Matters: Supports sustainable manufacturing practices, aligning with the renewable energy ethos.

8. Enhanced Safety Features

- Highlights:

- Emergency stop buttons for immediate shutdown.

- Overload protection to prevent mechanical damage.

- Safety shields for moving parts to ensure operator safety.

- Why It’s Critical: Guarantees safe working conditions while maintaining machine reliability.

Production Workflow of a Solar Tracker Roll Forming Machine

The production process of solar tracker profiles is seamless and efficient. Below is an outline of the workflow:

1. Decoiling

- Steel or aluminum coils are loaded onto the decoiler, which feeds the material into the machine.

2. Leveling

- A leveling system ensures the material is flat and free from warping before entering the roll-forming section.

3. Pre-Punching

- Hydraulic or servo-driven punching systems create holes and slots for components like bolts, nuts, and mounting brackets.

4. Roll Forming

- The material passes through multiple precision-engineered rollers, gradually shaping it into the desired profile.

5. Cutting

- A servo-controlled cutting system trims the profiles to the specified lengths with clean, burr-free edges.

6. Stacking

- Finished profiles are automatically stacked for packaging and transportation.

Pricing of Solar Tracker Roll Forming Machines

The cost of a Solar Tracker Roll Forming Machine depends on its features, production capacity, and level of customization. Here’s a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Basic Machines | Standard solar tracker profile production | $100,000–$150,000 |

| High-Speed Machines | Enhanced speed and precision | $150,000–$200,000 |

| Fully Customizable Machines | Advanced features with multi-profile capability | $200,000–$300,000 |

For customized quotes and financing options, contact Wuxi Sunway Machinery.

Advantages of Using a Solar Tracker Roll Forming Machine

Investing in a Solar Tracker Roll Forming Machine offers numerous advantages:

1. Efficiency

- High-speed production and integrated punching systems reduce lead times and labor costs.

2. Precision

- Advanced automation ensures consistent quality, minimizing defects and rework.

3. Versatility

- Supports the production of profiles for various solar tracker systems, catering to diverse project requirements.

4. Sustainability

- Reduces material waste and energy consumption, supporting green manufacturing practices.

5. Scalability

- High production capacity allows manufacturers to scale operations as demand grows.

FAQs About Solar Tracker Roll Forming Machines

| Question | Answer |

|---|---|

| What is the production speed? | Machines can produce up to 20 meters per minute, depending on material and profile. |

| Can the machine handle custom designs? | Yes, programmable settings allow for custom dimensions and configurations. |

| What materials are compatible? | Galvanized steel, stainless steel, and aluminum. |

| Is operator training included? | Yes, comprehensive training is provided with every machine purchase. |

| What is the warranty period? | All Sunway machines come with a 12-month warranty, with extended options available. |

| How long does installation take? | Installation and commissioning typically take 5–10 days, depending on factory setup. |

| Does Sunway provide after-sales support? | Absolutely! Sunway offers full technical support, including spare parts and troubleshooting. |

Global Market Trends Driving the Demand for Solar Tracker Roll Forming Machines

The renewable energy sector is booming, and solar trackers are at the forefront of maximizing energy efficiency. Let’s take a closer look at the global trends influencing the demand for Solar Tracker Roll Forming Machines in 2025:

1. Rapid Growth of Solar Energy Projects

- The Numbers: Global solar energy capacity is projected to surpass 3,000 GW by 2030, driven by government incentives and corporate sustainability goals.

- Impact on Solar Trackers: The demand for solar trackers is surging as they increase energy output by up to 25–35% compared to fixed-tilt systems.

- Machine Relevance: Roll-forming machines are essential to meet the large-scale production requirements of solar tracker components.

2. Expansion of Utility-Scale Solar Farms

- What’s Happening: Massive solar farms are being developed in regions like the Middle East, Africa, and the Americas to meet growing energy needs.

- Impact on Solar Tracker Profiles: Utility-scale projects require heavy-duty, corrosion-resistant profiles to withstand harsh environmental conditions.

- Why It Matters: Roll-forming machines ensure the production of high-quality, weather-resistant profiles.

3. Focus on Decentralized and Off-Grid Solar Systems

- The Trend: Decentralized solar systems are gaining popularity in rural and remote areas, providing reliable electricity without grid dependency.

- Impact on Solar Trackers: Lightweight and modular tracker profiles are ideal for off-grid installations.

- Machine Relevance: Advanced roll-forming machines can produce customized profiles suited for these specialized applications.

4. Integration of AI and IoT in Solar Trackers

- The Context: Smart solar trackers equipped with sensors and IoT systems are becoming the industry standard for optimizing energy efficiency.

- Impact on Profile Design: Profiles need to accommodate additional components like sensors, actuators, and wiring.

- Why It’s Exciting: Roll-forming machines with integrated punching systems enable precise placement of holes and slots for these components.

5. Push for Sustainability in Manufacturing

- The Shift: Solar energy companies are prioritizing eco-friendly manufacturing processes to reduce their carbon footprint.

- Impact on Roll-Forming Machines: There’s a growing demand for machines that minimize material waste and energy consumption.

- Why It’s Important: Wuxi Sunway’s roll-forming machines are designed with sustainability in mind, aligning with the green goals of the solar industry.

Technological Advancements in Solar Tracker Roll Forming Machines

As the renewable energy market evolves, so does the technology behind Solar Tracker Roll Forming Machines. Here are some of the latest innovations transforming the industry:

1. IoT-Enabled Smart Machines

- What It Does: IoT integration allows machines to connect to a centralized platform for real-time monitoring and diagnostics.

- Benefits:

- Predictive maintenance reduces downtime.

- Operational data helps optimize production efficiency.

- Remote access enables operators to control and monitor machines from anywhere.

2. Quick Changeover Systems

- What It Offers: Enables seamless switching between different profile designs without manual adjustments.

- Why It’s Game-Changing: Reduces downtime and increases productivity, especially for manufacturers handling diverse orders.

3. Advanced Servo Motor Technology

- How It Works: Servo motors control punching, cutting, and forming systems with unmatched precision.

- Advantages:

- Ensures burr-free cuts and perfectly aligned holes.

- Enhances product quality and reduces material waste.

4. Automated Quality Control

- What It Is: Integrated sensors and cameras inspect profiles for defects during production.

- Why It’s Revolutionary:

- Detects issues in real-time, ensuring consistent quality.

- Reduces the need for manual inspections, saving time and labor.

5. Digital Twin Technology

- What It Does: Creates a virtual replica of the machine and production line for testing and optimization.

- Why It’s Important:

- Allows manufacturers to simulate new profile designs without wasting materials.

- Speeds up the prototyping process, bringing products to market faster.

6. Eco-Efficient Design

- The Innovation: Machines are engineered to consume less energy and generate minimal waste.

- Why It Matters: Supports manufacturers in achieving their sustainability goals while reducing operational costs.

Environmental Benefits of Solar Tracker Roll Forming Machines

The renewable energy sector is inherently focused on sustainability, and Solar Tracker Roll Forming Machines align perfectly with this ethos. Here’s how:

1. Efficient Material Usage

- What It Does: Optimizes material usage, minimizing scrap and waste.

- Impact: Reduces production costs and the environmental footprint of manufacturing.

2. Energy Conservation

- The Innovation: Equipped with energy-efficient motors and systems, these machines consume significantly less electricity.

- Outcome: Supports manufacturers in reducing their carbon footprint.

3. Recyclability

- The Advantage: Profiles produced from galvanized steel or aluminum are fully recyclable, aligning with circular economy principles.

- Why It’s Important: Encourages responsible manufacturing and reduces landfill waste.

4. Localized Production

- What It Does: Enables manufacturers to produce solar tracker components locally, reducing the need for long-distance transportation.

- Impact: Lowers greenhouse gas emissions associated with logistics.

Comparison: Solar Tracker Roll Forming Machines vs. Traditional Manufacturing Methods

Let’s compare Solar Tracker Roll Forming Machines with conventional methods like extrusion or manual fabrication:

| विशेषता | Solar Tracker Roll Forming Machine | Traditional Methods |

|---|---|---|

| Precision | High; ensures consistent dimensions | Moderate; prone to human or mechanical errors |

| उत्पादन गति | High; up to 20 meters per minute | Slow; dependent on manual labor |

| Automation | Fully automated with PLC and IoT control | Mostly manual or semi-automated |

| Material Waste | Minimal; optimized processes reduce scrap | Higher; less efficient material usage |

| अनुकूलन | Easily customizable for various profiles | Limited flexibility; requires separate tooling |

| 成本效益 | Higher initial cost, lower long-term costs | Lower initial cost, higher operational costs |

| Scalability | Ideal for large-scale production | Not suitable for high-volume manufacturing |

Additional FAQs About Solar Tracker Roll Forming Machines

| Question | Answer |

|---|---|

| What types of profiles can this machine produce? | U-channels, Z-profiles, C-sections, and custom designs. |

| What is the material thickness range? | Compatible with thicknesses ranging from 1.5mm to 4.0mm. |

| Can the machine handle lightweight materials? | Yes, it supports lightweight materials like aluminum for specialized applications. |

| What is the warranty period? | All Sunway machines come with a 12-month warranty, with extended options available. |

| How long does it take to install the machine? | Installation and commissioning typically take 5–10 days, depending on factory setup. |

| What after-sales support is available? | Sunway offers full technical support, including spare parts, troubleshooting, and training. |

| Can Sunway customize the machine for specific needs? | Absolutely! Sunway specializes in tailoring machines to meet unique production requirements. |

Why Choose Wuxi Sunway Machinery for Solar Tracker Roll Forming Machines?

Here’s why Wuxi Sunway Machinery is the trusted choice for roll-forming solutions:

- Industry Expertise: Decades of experience in delivering innovative roll-forming solutions for renewable energy projects.

- Global Presence: Trusted by clients across Asia, Europe, Africa, and the Americas.

- Customization: Machines tailored to meet specific production and design needs.

- Sustainability: Designed with eco-friendly features to support green manufacturing.

- Cutting-Edge Technology: Equipped with IoT, servo systems, and advanced automation features.

- Comprehensive Support: Offers end-to-end service, from installation to troubleshooting and operator training.

Conclusion: Shaping the Future of Solar Energy

The Solar Tracker Roll Forming Machine is a cornerstone in the renewable energy industry, enabling the efficient production of high-quality components essential for solar tracker systems. As the world continues to embrace solar energy, investing in this advanced machinery is a strategic move for manufacturers looking to lead in 2025 and beyond.

Ready to power the renewable energy revolution? Contact Wuxi Sunway Machinery today to explore their cutting-edge roll-forming solutions. Together, let’s transform solar energy production—one profile at a time!