With the global push toward sustainability, circular economy initiatives, and waste reduction, the demand for efficient recycling infrastructure has never been higher. Recycling plants require high-strength, corrosion-resistant, and precision-engineered metal components to build waste processing facilities, conveyor systems, and structural enclosures.

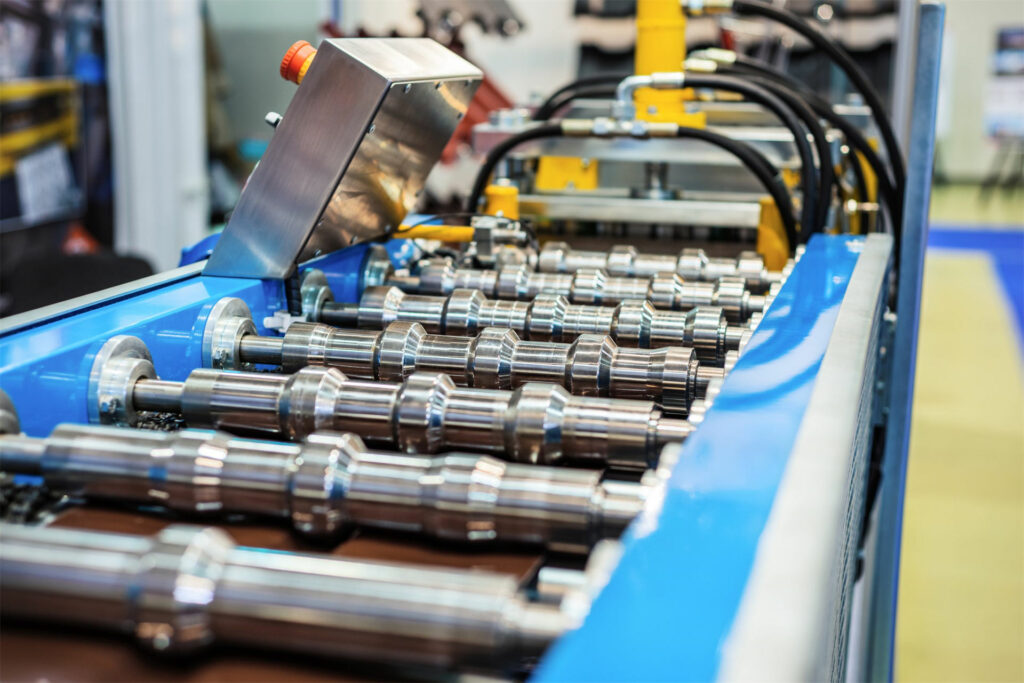

To meet these needs, manufacturers are turning to Recycling Plant Roll Forming Machines—advanced industrial systems that enable automated, high-speed production of metal recycling plant components with exceptional efficiency and durability.

In this guide, we’ll explore the applications, pricing, key features, industry trends, and why Wuxi Sunway Machinery is leading the industry in recycling plant roll-forming solutions.

What Are Recycling Plant Roll Forming Machines?

ए Recycling Plant Roll Forming Machine is a specialized industrial system designed to manufacture metal components for waste processing plants, recycling centers, and material recovery facilities. These machines provide high-speed, precision-driven, and cost-effective production, making them essential for modern recycling infrastructure projects.

Key Features of Recycling Plant Roll Forming Machines

- Customizable Structural Components – Supports modular conveyor frames, sorting enclosures, and support beams.

- High-Tensile Steel and Galvanized Processing – Ensures long-term durability for heavy-duty recycling operations.

- Corrosion-Resistant Coatings – Protects against moisture, chemicals, and environmental wear.

- Automated Hole Punching and Cutting – Facilitates quick installation and assembly.

- Smart Monitoring and IoT Integration – Allows for real-time defect detection and predictive maintenance.

- High-Speed Production – Enables mass production with minimal material waste.

- Fire-Resistant and Impact-Resistant Components – Meets global safety and durability standards for industrial recycling plants.

Applications of Recycling Plant Roll Forming Machines

Recycling facilities require strong, durable, and precision-engineered structural components to handle large-scale waste processing and material sorting operations. Recycling Plant Roll Forming Machines enable manufacturers to produce specialized components for various applications:

1. Conveyor Frame and Support Structures

- Use Case: Manufacturing high-strength metal frames for conveyor belts in recycling plants.

- Why It’s Essential: Provides support for high-speed waste sorting and transportation systems.

2. Waste Sorting Enclosures and Bins

- Use Case: Producing metal sorting enclosures and bins for recycling centers.

- Why It’s Beneficial: Ensures efficient separation of recyclable materials.

3. Machinery Casings and Protective Covers

- Use Case: Fabricating protective metal casings for recycling plant machinery.

- Why It’s Important: Enhances equipment longevity and operator safety.

4. Structural Beams and Supports

- Use Case: Manufacturing steel beams and columns for recycling plant buildings.

- Why It’s Necessary: Provides structural integrity and earthquake resistance.

5. Automated Recycling System Components

- Use Case: Producing modular panels for automated waste sorting systems.

- Why It’s Innovative: Enables smart recycling technology with integrated AI sorting.

6. Fireproof and Corrosion-Resistant Storage Units

- Use Case: Developing fire-resistant metal storage enclosures for hazardous waste recycling.

- Why It’s Critical: Meets safety and environmental compliance standards.

Key Features of Wuxi Sunway Recycling Plant Roll Forming Machines

Wuxi Sunway Machinery is a global leader in recycling plant roll-forming technology, offering high-performance, precision-engineered solutions for waste management and recycling infrastructure manufacturers.

1. Customizable Conveyor and Sorting Structures

- What It Offers: Machines equipped with adjustable tooling for producing conveyor frames, support beams, and sorting enclosures.

- Why It’s Critical: Supports various recycling plant applications, from waste sorting to material recovery.

2. Multi-Material Processing Capabilities

- What It Processes:

- High-Tensile Steel – Provides long-lasting durability and impact resistance.

- गैल्वेनाइज्ड स्टील – Ensures corrosion resistance in humid and chemical-heavy environments.

- एल्यूमीनियम Alloys – Lightweight and rust-proof for recycling machinery casings.

- Why It’s Essential: Accommodates diverse recycling industry requirements and environmental conditions.

3. High-Speed, Automated Production

- What It Achieves: Processes up to 70 meters of metal per minute with minimal manual intervention.

- Why It’s Efficient: Meets high-volume production demands while maintaining consistent quality.

4. Integrated Hole Punching and Slot Cutting

- What It Enables: Pre-drilled mounting points for quick assembly of recycling plant structures.

- Why It’s Beneficial: Reduces manual labor and enhances modular equipment installation.

5. Fire-Resistant and Chemical-Resistant Coatings

- What It Delivers: Machines capable of applying protective coatings during production.

- Why It’s Beneficial: Ensures longer lifespan and compliance with environmental safety regulations.

6. Smart Monitoring and IoT-Enabled Quality Control

- What It Integrates: Real-time defect detection, predictive maintenance, and remote machine monitoring.

- Why It’s Innovative: Reduces waste, minimizes downtime, and enhances operational efficiency.

Pricing of Recycling Plant Roll Forming Machines

The cost of a Recycling Plant Roll Forming Machine depends on features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic conveyor frame and enclosure production | 400,000–400,000–400,000–1,200,000 |

| Advanced Machines | High-speed production with automated hole punching | 1,200,000–1,200,000–1,200,000–3,500,000 |

| Customizable Smart Machines | Fully automated, IoT-connected Industry 4.0 solutions | 3,500,000–3,500,000–3,500,000–7,000,000 |

For personalized pricing and financing options, reach out to Wuxi Sunway Machinery.

Real-World Success Stories: How Recycling Plant Roll Forming Machines Are Transforming Waste Management

From municipal recycling centers to industrial waste processing facilities, Recycling Plant Roll Forming Machines are playing a critical role in building the infrastructure needed for a greener future. Below are real-world applications showcasing the impact of these machines in the waste management industry.

1. Smart Recycling Facility in Germany

Client: ए municipal recycling center upgrading its infrastructure to support smart waste management.

Challenge: Required modular conveyor frames, sorting enclosures, and heavy-duty support structures for automated waste sorting systems.

Solution: Wuxi Sunway Machinery supplied a custom roll-forming system designed for precision-engineered, high-strength steel components.

Outcome:

✅ Reduced material waste by 40%, optimizing cost efficiency.

✅ Increased plant efficiency by 50%, enabling faster sorting and processing of recyclables.

✅ Enhanced durability, ensuring corrosion-resistant, long-lasting structures.

2. Industrial Waste Processing Plant in Canada

Client: ए waste management company handling industrial and hazardous waste disposal.

Challenge: Needed fireproof, chemical-resistant metal enclosures and conveyor support systems.

Solution: Wuxi Sunway delivered a high-speed roll-forming machine optimized for galvanized and stainless steel components.

Outcome:

✅ Improved plant safety, meeting fireproofing and chemical resistance standards.

✅ Reduced maintenance costs, ensuring long-term operational reliability.

✅ Faster component production, reducing lead times for plant upgrades.

3. E-Waste Recycling Center in the United States

Client: How a Pipe Roll Forming Machine Works and Why It’s Used? 10 electronics recycling firm specializing in e-waste recovery and metal extraction.

Challenge: Required customized sorting enclosures and impact-resistant conveyor systems.

Solution: Wuxi Sunway provided a flexible roll-forming solution for modular, easy-to-install plant components.

Outcome:

✅ Standardized modular construction, simplifying recycling plant expansion.

✅ Reduced setup time by 45%, allowing for faster deployment of recycling systems.

✅ Enhanced worker safety, ensuring secure enclosures for handling hazardous materials.

4. Plastic Waste Processing Plant in South America

Client: ए plastic recycling company converting waste plastics into reusable materials.

Challenge: Needed lightweight, corrosion-resistant conveyor structures and support frames.

Solution: Wuxi Sunway supplied a roll-forming machine optimized for aluminum and galvanized steel components.

Outcome:

✅ Improved plant efficiency, allowing faster plastic waste sorting and processing.

✅ Reduced environmental impact, by utilizing recyclable, sustainable materials.

✅ Lowered installation costs, making recycling plant expansion more affordable.

Future Trends in Recycling Plant Manufacturing for 2025

With sustainability and environmental regulations tightening, manufacturers are adopting new materials, automation, and modular designs to enhance recycling plant production. Below are the key trends shaping the future of Recycling Plant Roll Forming Machines.

1. AI-Optimized Recycling Plant Infrastructure

- Trend: The rise of AI-powered waste sorting systems that optimize material recovery and defect detection.

- Impact on Machines: Roll-forming systems will feature automated quality control and predictive maintenance.

2. Lightweight, High-Strength Materials for Waste Processing Facilities

- Trend: Increased use of lightweight composites and high-tensile steel for plant structures.

- Impact on Machines: Machines will be optimized for multi-material processing.

3. Modular and Pre-Assembled Recycling Systems

- Trend: Enhanced focus on pre-fabricated conveyor systems and modular plant components.

- Impact on Machines: Roll-forming systems will prioritize easy assembly, interlocking designs.

4. Corrosion-Resistant and Fireproof Coatings

- Trend: Stricter fire safety and corrosion resistance requirements for recycling facilities.

- Impact on Machines: Machines will integrate coating application systems for durability.

5. Smart Waste Management and IoT-Enabled Tracking

- Trend: Growth in IoT-connected recycling plants with real-time operational monitoring.

- Impact on Machines: Machines will produce smart plant components with integrated tracking technology.

Innovations in Recycling Plant Roll Forming Machines for 2025

The next generation of Recycling Plant Roll Forming Machines is set to revolutionize how waste management infrastructure is built and maintained. Below are some of the latest innovations:

1. AI-Guided Precision Manufacturing

- What It Enables: AI-driven systems automatically adjust forming parameters for optimal production.

- Why It’s Revolutionary: Reduces scrap rates and ensures consistent component quality.

2. Fireproof and Chemical-Resistant Coatings

- What It Adds: Machines capable of applying protective coatings for fire and chemical resistance.

- Why It’s Valuable: Extends the lifespan of recycling plant components.

3. Mobile, On-Site Manufacturing Units

- What It Offers: Portable roll-forming machines for on-site recycling plant infrastructure production.

- Why It’s Game-Changing: Reduces transportation costs and accelerates plant setup.

4. Smart Monitoring and Predictive Maintenance

- What It Integrates: IoT-enabled systems for real-time defect detection and predictive maintenance scheduling.

- Why It’s Essential: Minimizes downtime and ensures continuous plant efficiency.

Why Wuxi Sunway Machinery Leads the Recycling Industry

1. Decades of Expertise

With years of experience, Wuxi Sunway has a proven track record of excellence in recycling plant roll-forming solutions.

2. Cutting-Edge Technology

Incorporates advanced features like AI, IoT-driven automation, and high-speed roll-forming.

3. Customization Excellence

Offers tailored solutions for waste processing facilities, recycling companies, and sustainability initiatives.

4. Global Industry Leadership

Trusted by municipalities, industrial waste management firms, and recycling equipment suppliers worldwide.

5. Comprehensive Support

Provides consultation, installation, training, and after-sales services for seamless operation.

Visit their official website to explore their offerings or request a customized recycling plant roll-forming solution tailored to your needs.

Final Thoughts: The Future of Recycling Plant Manufacturing with Roll Forming Technology

With global sustainability initiatives expanding, Recycling Plant Roll Forming Machines are transforming how waste processing facilities are designed, manufactured, and deployed. Whether for municipal recycling centers, industrial plants, or e-waste processing facilities, these machines provide efficient, scalable, and high-quality solutions.

Looking to enhance your recycling plant infrastructure production capabilities? Partner with Wuxi Sunway Machinery and take your sustainable manufacturing to the next level.