With the increasing demand for secure, durable, and cost-effective packaging frames in industries like logistics, warehousing, and heavy equipment transportation, manufacturers need high-speed, precision-driven production methods to keep up with market needs.

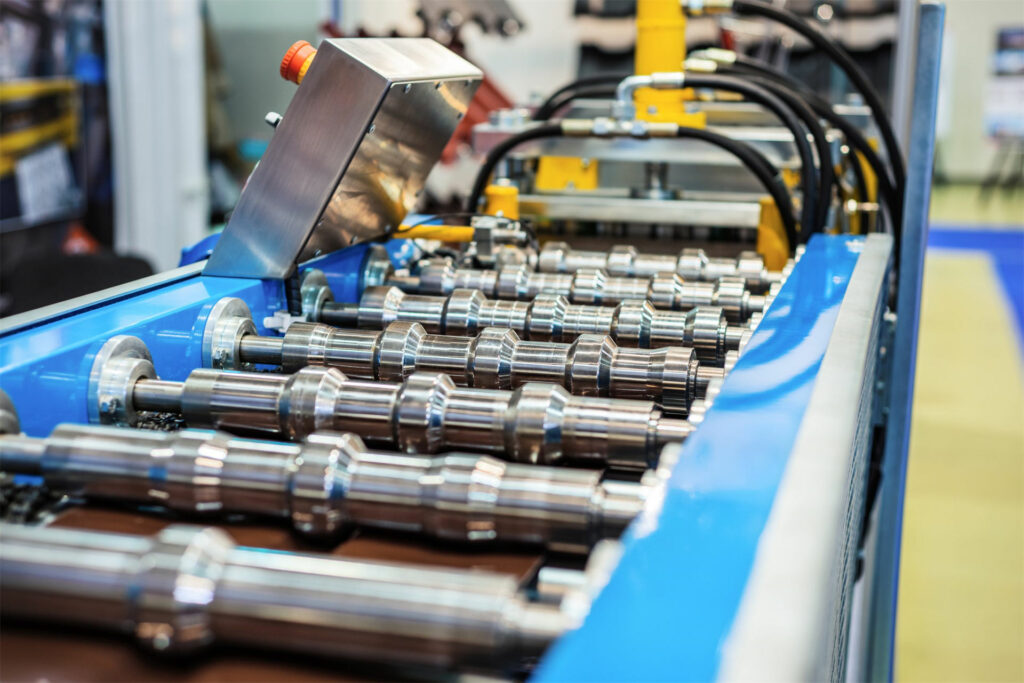

Enter Packaging Frame Roll Forming Machines—advanced production systems that automate the manufacturing of steel and aluminum packaging frames, support structures, and reinforcement panels. These machines ensure structural integrity, weight optimization, and cost savings, making them essential for modern packaging and shipping industries.

In this guide, we’ll explore the applications, pricing, key features, industry trends, and why Wuxi Sunway Machinery is leading the industry in packaging frame roll-forming solutions.

What Are Packaging Frame Roll Forming Machines?

ए Packaging Frame Roll Forming Machine is an industrial-grade system designed to manufacture metal packaging frames, protective supports, and reinforcement structures used in logistics, shipping, and industrial packaging. These machines ensure high-speed, automated production with precise cuts, bends, and hole punching, optimizing packaging strength and durability.

Key Features of Packaging Frame Roll Forming Machines

- Customizable Frame Profiles – Supports various packaging frame sizes, reinforcement bars, and load-bearing structures.

- High-Tensile Steel and Aluminum Processing – Ensures durability, strength, and corrosion resistance.

- Automated Hole Punching and Precision Cutting – Facilitates quick assembly and modular integration.

- Powder Coating and Surface Treatment Integration – Provides scratch-resistant, anti-corrosion finishes.

- Smart Monitoring and IoT Integration – Allows for real-time defect detection and predictive maintenance.

- High-Speed Production – Enables mass manufacturing with minimal material waste.

- Impact-Resistant and Anti-Corrosion Coatings – Meets global packaging and transportation safety standards.

Applications of Packaging Frame Roll Forming Machines

With increasing global trade, e-commerce, and industrial shipping, manufacturers need high-precision, automated systems to produce packaging frames efficiently. Packaging Frame Roll Forming Machines enable manufacturers to produce specialized components for various applications:

1. Heavy-Duty Industrial Packaging Frames

- Use Case: Manufacturing reinforced steel frames for packaging heavy machinery, automotive parts, and industrial equipment.

- Why It’s Essential: Provides structural protection during transportation and storage.

2. Shipping Container Reinforcement Structures

- Use Case: Producing metal reinforcement beams for packaging containers.

- Why It’s Beneficial: Ensures stability and load-bearing capacity in transit.

3. Warehouse Storage and Pallet Racking Frames

- Use Case: Fabricating sturdy frames for industrial shelving and pallet racks.

- Why It’s Important: Enhances warehouse efficiency and inventory management.

4. Modular and Stackable Packaging Supports

- Use Case: Developing customizable, reusable packaging frames for logistics and distribution.

- Why It’s Necessary: Reduces packaging waste and improves reusability.

5. Corrosion-Resistant Packaging Frames for Outdoor Storage

- Use Case: Producing weatherproof packaging frames for outdoor equipment storage.

- Why It’s Innovative: Protects goods from environmental damage.

6. Smart Packaging Frames with IoT-Enabled Tracking

- Use Case: Manufacturing packaging frames embedded with smart sensors for tracking and asset management.

- Why It’s Critical: Enhances supply chain visibility and security.

Key Features of Wuxi Sunway Packaging Frame Roll Forming Machines

Wuxi Sunway Machinery is a global leader in packaging frame roll-forming technology, offering high-performance, precision-engineered solutions for logistics and industrial packaging manufacturers. Their machines are designed to enhance productivity, reduce costs, and improve structural durability.

1. Customizable Packaging Frame Profiles and Sizes

- What It Offers: Machines equipped with adjustable tooling for producing packaging frames, support beams, and reinforcement bars.

- Why It’s Critical: Supports various packaging configurations, from heavy-duty transport packaging to lightweight modular designs.

2. Multi-Material Processing Capabilities

- What It Processes:

- गैल्वेनाइज्ड स्टील – Provides high tensile strength and anti-corrosion properties.

- एल्यूमीनियम Alloys – Lightweight and rust-resistant for modern packaging solutions.

- Powder-Coated Steel – Ensures scratch-proof, aesthetic finishes for professional-grade packaging.

- Why It’s Essential: Accommodates diverse packaging materials for different industries.

3. High-Speed, Automated Production

- What It Achieves: Processes up to 75 meters of metal per minute with minimal manual intervention.

- Why It’s Efficient: Meets high-volume production demands while maintaining consistent quality.

4. Integrated Hole Punching, Slot Cutting, and Bending

- What It Enables: Pre-drilled mounting points and precision bending for easy packaging assembly.

- Why It’s Beneficial: Reduces manual labor and enhances modular packaging frame design.

5. Corrosion-Resistant and Impact-Proof Coatings

- What It Delivers: Machines capable of applying protective coatings during production.

- Why It’s Beneficial: Ensures longer product lifespan and compliance with international logistics standards.

6. Smart Monitoring and IoT-Enabled Quality Control

- What It Integrates: Real-time defect detection, predictive maintenance, and remote machine monitoring.

- Why It’s Innovative: Reduces waste, minimizes downtime, and enhances operational efficiency.

Pricing of Packaging Frame Roll Forming Machines

The cost of a Packaging Frame Roll Forming Machine depends on features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic packaging frame production | 350,000–350,000–350,000–900,000 |

| Advanced Machines | High-speed production with automated hole punching | 900,000–900,000–900,000–2,500,000 |

| Customizable Smart Machines | Fully automated, IoT-connected Industry 4.0 solutions | 2,500,000–2,500,000–2,500,000–6,000,000 |

For personalized pricing and financing options, reach out to Wuxi Sunway Machinery.

Real-World Success Stories: How Packaging Frame Roll Forming Machines Are Transforming Industrial Logistics

From automotive component packaging to heavy-duty shipping solutions, Packaging Frame Roll Forming Machines help manufacturers scale production, reduce costs, and improve packaging efficiency. Below are real-world applications showcasing the impact of these machines in packaging frame manufacturing.

1. Heavy Equipment Packaging Solutions in the United States

Client: ए heavy machinery manufacturer specializing in export packaging solutions.

Challenge: Required high-strength steel frames for packaging large industrial machines.

Solution: Wuxi Sunway Machinery supplied a custom roll-forming machine with reinforced steel processing capabilities.

Outcome:

✅ Increased packaging frame durability, ensuring safe transportation of heavy loads.

✅ Reduced material costs by 30%, improving profit margins.

✅ Faster production cycles, meeting high-volume export demands.

2. Sustainable Packaging Frames for Electronics in Europe

Client: ए consumer electronics company focused on eco-friendly packaging solutions.

Challenge: Needed lightweight, recyclable metal frames for secure electronics packaging.

Solution: Wuxi Sunway provided a roll-forming system optimized for aluminum processing with minimal material waste.

Outcome:

✅ Reduced environmental impact, supporting sustainability goals.

✅ Improved structural integrity, ensuring electronic devices remain undamaged.

✅ Enhanced customization, allowing for multiple frame sizes and designs.

3. Automotive Parts Packaging for Global Shipping in Canada

Client: ए tier-1 automotive supplier exporting engine components and vehicle parts.

Challenge: Needed modular, stackable packaging frames for efficient container shipping.

Solution: Wuxi Sunway delivered a high-speed roll-forming machine designed for modular, interlocking frame profiles.

Outcome:

✅ Optimized space utilization, reducing shipping costs by 20%.

✅ Enhanced reusability, leading to long-term cost savings.

✅ Faster assembly, improving packaging facility workflow.

4. Aerospace Component Packaging Frames in Asia

Client: How a Pipe Roll Forming Machine Works and Why It’s Used? 10 aerospace manufacturing company producing high-value aircraft components.

Challenge: Required impact-resistant packaging frames for delicate aerospace parts.

Solution: Wuxi Sunway provided a reinforced roll-forming machine with precision hole punching and custom bending.

Outcome:

✅ Improved shock absorption, ensuring safe transportation of fragile aerospace components.

✅ Reduced production time by 40%, accelerating supply chain operations.

✅ Enhanced security features, preventing tampering and damage.

5. Smart Logistics Packaging Frames for E-Commerce in the Middle East

Client: ए large-scale e-commerce logistics provider.

Challenge: Needed customized, reusable metal frames for high-volume warehouse storage and shipping.

Solution: Wuxi Sunway delivered a roll-forming machine capable of producing smart, RFID-enabled packaging frames.

Outcome:

✅ Improved inventory tracking, enhancing supply chain visibility.

✅ Reduced packaging waste, supporting sustainability initiatives.

✅ Modular design, allowing easy adaptation for different product sizes.

Future Trends in Packaging Frame Manufacturing for 2025

With logistics and supply chain management evolving, manufacturers are adopting new materials, automation, and smart packaging technologies to enhance efficiency. Below are the key trends shaping the future of Packaging Frame Roll Forming Machines.

1. AI-Driven Packaging Optimization

- Trend: AI-powered logistics systems are influencing packaging frame designs for better space utilization and cost reduction.

- Impact on Machines: Roll-forming systems will integrate real-time AI adjustments for material efficiency and strength optimization.

2. Lightweight, High-Strength Packaging Frame Materials

- Trend: Increased use of aluminum alloys and composite metals for lighter yet durable packaging solutions.

- Impact on Machines: Machines will be optimized for multi-material processing to improve strength-to-weight ratios.

3. Modular and Customizable Packaging Frames

- Trend: Growth in adjustable, reusable packaging frames for cost-effective shipping solutions.

- Impact on Machines: Roll-forming systems will prioritize interlocking, stackable, and modular frame designs.

4. Corrosion-Resistant and Weatherproof Coatings

- Trend: Stricter durability and resistance standards for packaging frames used in harsh environments.

- Impact on Machines: Machines will integrate coating application systems to enhance longevity.

5. Smart Packaging Frames with IoT Tracking and RFID Integration

- Trend: Companies are investing in smart logistics solutions with real-time tracking and automated sorting.

- Impact on Machines: Increased demand for packaging frames with RFID and IoT sensor integration.

Innovations in Packaging Frame Roll Forming Machines for 2025

The next generation of Packaging Frame Roll Forming Machines is set to revolutionize industrial logistics and packaging manufacturing. Below are some of the latest innovations:

1. AI-Guided Precision Manufacturing

- What It Enables: AI-driven systems automatically adjust forming parameters for optimal packaging strength.

- Why It’s Revolutionary: Reduces scrap rates and ensures consistent frame dimensions.

2. Impact-Resistant and Tamper-Proof Coatings

- What It Adds: Machines capable of applying protective coatings for added security and durability.

- Why It’s Valuable: Protects high-value goods from theft, damage, and environmental exposure.

3. Mobile, On-Site Roll Forming Units

- What It Offers: Portable roll-forming machines for on-demand packaging frame production.

- Why It’s Game-Changing: Reduces transportation costs and allows for localized frame production.

4. Smart Monitoring and Predictive Maintenance

- What It Integrates: IoT-enabled systems for real-time defect detection and predictive maintenance scheduling.

- Why It’s Essential: Minimizes downtime and ensures continuous production efficiency.

Why Wuxi Sunway Machinery Leads the Packaging Frame Manufacturing Industry

1. Decades of Expertise

With years of experience, Wuxi Sunway has a proven track record of excellence in packaging frame roll-forming solutions.

2. Cutting-Edge Technology

Incorporates advanced features like AI, IoT-driven automation, and high-speed roll-forming.

3. Customization Excellence

Offers tailored solutions for packaging frame manufacturers, logistics providers, and industrial suppliers.

4. Global Industry Leadership

Trusted by shipping companies, e-commerce logistics firms, and industrial packaging suppliers worldwide.

5. Comprehensive Support

Provides consultation, installation, training, and after-sales services for seamless operation.

Visit their official website to explore their offerings or request a customized packaging frame roll-forming solution tailored to your needs.

Final Thoughts: The Future of Packaging Frame Manufacturing with Roll Forming Technology

Looking to optimize your packaging frame production process? Partner with Wuxi Sunway Machinery and take your industrial packaging manufacturing to the next level.