When it comes to road safety, highway guard rails are the unsung heroes that protect lives every single day. These steel barriers are designed to absorb impact, redirect vehicles, and minimize damage during accidents. But have you ever wondered how these vital components are manufactured? Enter the Highway Guard Rail Roll Forming Machine—an industrial powerhouse that transforms steel coils into the durable and precisely engineered guard rails you see lining highways worldwide.

In this guide, we’ll explore everything you need to know about Highway Guard Rail Roll Forming Machines, including their applications, types, pricing, advanced features, and why Wuxi Sunway Machinery is a leader in this industry. If you’re manufacturing guard rails or planning to enter this market, this comprehensive guide will prepare you for success in 2025 and beyond.

Overview of Highway Guard Rail Roll Forming Machines

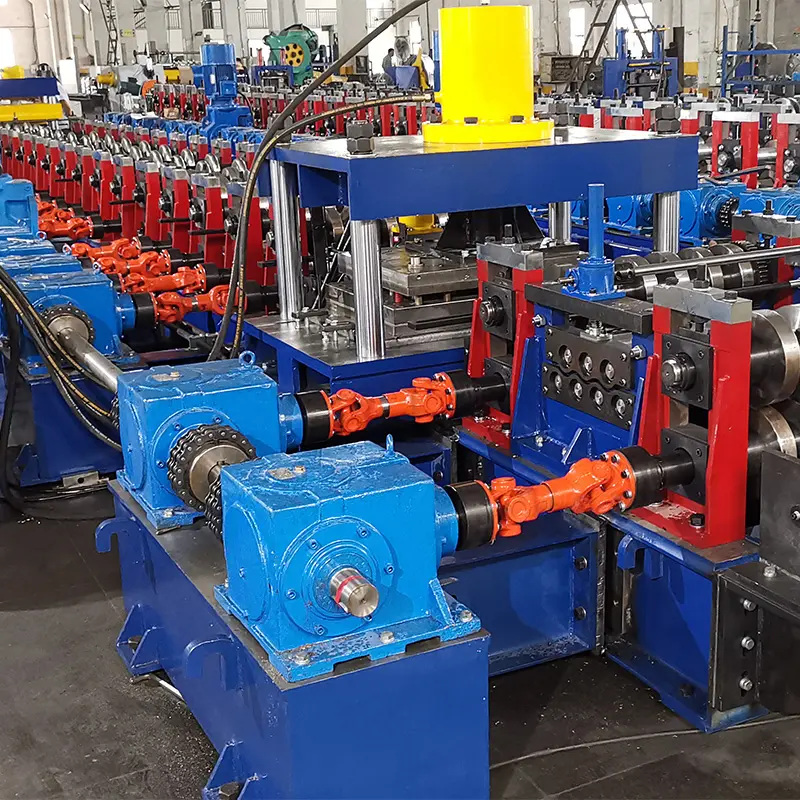

ए Highway Guard Rail Roll Forming Machine is a specialized piece of equipment designed to produce guard rail profiles from flat steel coils. These machines are engineered for high-speed production, precision, and durability, ensuring that every guard rail meets strict safety and quality standards.

The guard rails produced by these machines are typically W-beam and Thrie-beam profiles, which are widely used on highways, bridges, and roads to enhance safety. The roll-forming process involves feeding steel coils into the machine, where a series of rollers gradually shape the material into the desired profile. Additional steps like punching and cutting are often integrated into the machine, streamlining the entire production process.

With road infrastructure projects expanding globally, investing in a Highway Guard Rail Roll Forming Machine is a strategic move for manufacturers looking to meet rising demand.

Applications of Highway Guard Rails

Highway guard rails are more than just barriers—they are life-saving components engineered for safety and durability. Here’s where they are commonly used:

1. Highways and Freeways

Guard rails along highways and freeways act as a protective barrier, preventing vehicles from veering off the road and reducing the severity of accidents.

2. Bridges

On bridges, guard rails provide additional safety by preventing vehicles from plunging off the structure in case of accidents. They are designed to withstand high impact while maintaining their structural integrity.

3. Curves and Slopes

On sharp curves and steep slopes, guard rails play a critical role in guiding vehicles and preventing rollovers or falls.

4. Urban Roads

In busy urban areas, guard rails are used to separate traffic lanes, protect pedestrians, and minimize collisions.

5. Construction Zones

Temporary guard rails are often installed in construction zones to ensure the safety of workers and drivers.

With applications spanning a wide range of environments, the demand for high-quality guard rails is consistent, making Highway Guard Rail Roll Forming Machines a valuable investment.

Types of Highway Guard Rail Roll Forming Machines

The diversity of highway guard rail designs requires different types of roll-forming machines. Here’s a breakdown of the main types:

1. Standard W-Beam Roll Forming Machines

These machines are specifically designed to produce W-beam guard rails, the most common type used on highways. They are ideal for manufacturers focused on high-volume production of this profile.

2. Thrie-Beam Roll Forming Machines

Thrie-beam guard rails, which offer enhanced impact resistance, require specialized machines. These are suitable for producing guard rails for bridges and other high-risk areas.

3. Multi-Profile Roll Forming Machines

For manufacturers serving diverse markets, multi-profile machines are a versatile option. These machines can produce both W-beam and Thrie-beam profiles with quick tooling changes.

4. Fully Automated Guard Rail Machines

Fully automated machines handle every aspect of production, from material feeding to cutting and stacking. They are ideal for large-scale operations looking to maximize efficiency and minimize labor costs.

Comparison Table: Types of Highway Guard Rail Roll Forming Machines

| Machine Type | Primary Use | Profile Types | उत्पादन गति | Price Range (USD) |

|---|---|---|---|---|

| Standard W-Beam Machines | W-beam guard rails | Single Profile | 10–20 meters/min | $70,000–$100,000 |

| Thrie-Beam Machines | Thrie-beam guard rails | Single Profile | 8–15 meters/min | $80,000–$120,000 |

| Multi-Profile Machines | W-beam and Thrie-beam profiles | Multiple Profiles | 10–25 meters/min | $100,000–$150,000+ |

| Fully Automated Machines | High-volume, multi-profile | Multiple Profiles | 20–30 meters/min | $120,000–$200,000+ |

Key Features of Highway Guard Rail Roll Forming Machines

Highway guard rails must meet stringent safety standards, which means the machines producing them need to be precise, reliable, and efficient. Here are the key features to look for:

1. High-Precision Rollers

Rollers made of high-strength, chrome-coated steel ensure that every guard rail meets exact dimensions and tolerances.

2. Integrated Punching Systems

Pre-punched holes for bolts and joints are essential for installing guard rails. Integrated punching systems save time and ensure precision.

3. Servo-Driven Cutting Systems

Cutting systems powered by servo motors provide clean, burr-free cuts, ensuring the guard rails are ready for installation.

4. PLC Control Systems

Programmable Logic Controller (PLC) systems allow for automated operation, accurate adjustments, and real-time monitoring.

5. Material Compatibility

Machines should handle a variety of materials, including galvanized steel and stainless steel, to meet different project requirements.

6. Quick Tooling Changes

For multi-profile machines, quick-change tooling reduces downtime when switching between W-beam and Thrie-beam production.

Machines from Wuxi Sunway Machinery incorporate these advanced features, ensuring top-tier performance and reliability.

Specifications of Highway Guard Rail Roll Forming Machines

Understanding the technical specifications is crucial when choosing a machine. Here’s what to expect:

| Specification | विवरण |

|---|---|

| Material Thickness | 2.0mm–4.0mm |

| Material Type | Galvanized steel, stainless steel |

| बनाने की गति | 10–30 meters per minute |

| रोलर सामग्री | High-strength steel with chrome plating |

| पंचिंग सिस्टम | Hydraulic or servo punching for bolt holes |

| कटिंग सिस्टम | Hydraulic or servo cutting for precise lengths |

| नियंत्रण प्रणाली | PLC with HMI (Human-Machine Interface) |

| बिजली की आपूर्ति | Typically 380V/50Hz (customizable for regional standards) |

Pricing of Highway Guard Rail Roll Forming Machines

The cost of a Highway Guard Rail Roll Forming Machine varies based on its features, automation level, and customization. Here’s an overview:

Price Ranges

- Standard Machines: $70,000–$100,000

- Thrie-Beam Machines: $80,000–$120,000

- Multi-Profile Machines: $100,000–$150,000+

- Fully Automated Machines: $120,000–$200,000+

Factors Affecting Price

- Automation Level: Fully automated machines cost more but significantly reduce labor costs.

- Production Speed: Machines with higher speeds are generally more expensive.

- Customization: Tailored machines for unique profiles or materials come at a premium.

- Brand Quality: Reputable manufacturers like Wuxi Sunway Machinery deliver durable machines with excellent ROI.

FAQs About Highway Guard Rail Roll Forming Machines

Here are answers to some frequently asked questions:

| Question | Answer |

|---|---|

| Can these machines produce custom profiles? | Yes, custom machines can be tailored to produce unique guard rail profiles. |

| What’s the expected lifespan of these machines? | With proper maintenance, these machines can last 10–15 years or more. |

| What materials can be processed? | Most machines handle galvanized steel and stainless steel within a thickness range of 2.0mm–4.0mm. |

| Is training provided? | Yes, manufacturers like Wuxi Sunway Machinery provide training with every purchase. |

| What’s the average production capacity? | Machines can produce 5,000–10,000 meters of guard rails per day, depending on the model. |

Automation Trends in Highway Guard Rail Roll Forming Machines

Automation in manufacturing is no longer a luxury—it’s a necessity. Highway Guard Rail Roll Forming Machines are embracing cutting-edge automation technologies to meet the growing demand for high-quality guard rails while improving efficiency and reducing labor costs. Here’s how automation is revolutionizing this industry:

1. IoT-Enabled Monitoring

Imagine your machine sending you real-time performance updates via your smartphone or computer. IoT (Internet of Things) integration allows you to track production metrics, monitor component wear, and receive maintenance alerts, ensuring smooth operations.

2. Fully Automated Production Lines

Automation eliminates manual intervention in processes like material feeding, punching, cutting, and stacking. With fully automated systems, operators can oversee the entire production line with minimal effort, increasing productivity and reducing human error.

3. Adaptive Rollers

Advanced machines are equipped with self-adjusting rollers that adapt to different material thicknesses and profile dimensions automatically. This feature is crucial for manufacturers producing both W-beam and Thrie-beam profiles.

4. Real-Time Error Detection

Sensors and cameras integrated into the machine detect misalignments, roller wear, or material inconsistencies in real-time. Early detection prevents defective products and minimizes waste.

5. Predictive Maintenance

Using machine learning algorithms, predictive maintenance systems analyze data from sensors to forecast when components like rollers or cutters are likely to fail. This proactive approach reduces downtime and extends the machine’s lifespan.

At Wuxi Sunway Machinery, we incorporate these automation features into our machines to help manufacturers stay ahead of the curve.

Workflow Optimization for Highway Guard Rail Production

A well-optimized workflow can significantly enhance productivity and product quality. Here’s a detailed step-by-step guide to maximizing the efficiency of your Highway Guard Rail Roll Forming Machine:

Step 1: Material Preparation

- Raw Material Selection: Use high-quality galvanized steel or stainless steel coils with a thickness of 2.0mm–4.0mm. This ensures the durability and strength of the guard rails.

- Storage: Store steel coils in a clean, dry environment to prevent corrosion.

- Automated Decoiling: Utilize a hydraulic or motorized decoiler to feed the material into the machine. This reduces manual labor and speeds up the process.

Step 2: Precision Feeding

- संरेखण: Advanced feeding systems automatically align the material for a smooth transition into the rollers.

- Tension Control: Maintain the correct tension to prevent wrinkling or slipping during the roll-forming process.

Step 3: Roll Forming

- Gradual Shaping: The material passes through multiple roller stations, each progressively forming the W-beam or Thrie-beam profile. This ensures dimensional accuracy and structural integrity.

- Roller Calibration: Regularly inspect and calibrate the rollers to maintain consistency, especially when switching between profiles.

Step 4: Punching

- Pre-Drilled Holes: Integrated hydraulic or servo punching systems create holes for bolts and fasteners. This step is critical for assembly and installation.

- Custom Patterns: Machines allow you to program punching patterns to meet specific project requirements, such as guard rails for bridges or steep slopes.

चरण 5: कटिंग

- Clean Cuts: Hydraulic or servo-driven cutters trim the guard rails to the desired length with burr-free edges. This ensures they are ready for immediate installation.

- Length Adjustment: Use the PLC system to easily adjust cutting lengths for different orders or applications.

Step 6: Stacking and Packaging

- Automated Stacking: Finished guard rails are automatically stacked and arranged for easy transport.

- Protective Packaging: Use protective materials to prevent damage during shipping, especially for export orders.

Real-Time Monitoring

Machines from Wuxi Sunway Machinery come with HMI (Human-Machine Interface) panels, allowing operators to monitor and adjust production parameters in real-time for maximum efficiency.

Troubleshooting Common Issues in Highway Guard Rail Machines

Even the most advanced machines can face operational challenges. Here’s a quick troubleshooting guide for common issues:

1. Material Slippage

- Cause: Improper tension or misaligned feeding system.

- Solution: Adjust tension settings and realign the feeding system. Clean any debris from the rollers or feeding path.

2. Inconsistent Profile Dimensions

- Cause: Worn rollers or incorrect roller calibration.

- Solution: Inspect the rollers for wear and recalibrate the machine. Replace worn rollers if necessary.

3. Misaligned Punching

- Cause: Incorrect programming or dull punching dies.

- Solution: Reprogram the punching pattern and inspect the dies for wear. Replace or sharpen the dies if needed.

4. Uneven Cutting

- Cause: Dull cutting blades or misaligned cutting system.

- Solution: Replace the blades and ensure proper alignment of the cutting mechanism.

5. Machine Downtime

- Cause: Lack of maintenance or unaddressed wear on critical components.

- Solution: Follow a strict maintenance schedule, including regular lubrication, cleaning, and inspections. Use predictive maintenance features to identify and resolve issues early.

If problems persist, contact Wuxi Sunway Machinery for expert troubleshooting and spare parts support.

Environmental Benefits of Highway Guard Rail Roll Forming Machines

Sustainability is becoming an increasingly important factor in manufacturing, and Highway Guard Rail Roll Forming Machines play a role in eco-friendly production practices. Here’s how:

1. Minimal Material Waste

The roll-forming process is highly efficient, using nearly all of the raw material and generating minimal scrap. What little scrap is produced can often be recycled.

2. Energy-Efficient Design

Modern machines are designed to consume less energy while maintaining high production speeds. Features like servo motors and optimized hydraulic systems contribute to lower power consumption.

3. Recyclable Materials

Guard rails are typically made of galvanized steel or stainless steel, both of which are 100% recyclable. This aligns with global sustainability goals.

4. Long Product Lifespan

Durable and corrosion-resistant guard rails require fewer replacements, reducing the overall environmental footprint of road safety infrastructure.

By investing in energy-efficient machines, manufacturers can align with environmental standards while also reducing operational costs. At Wuxi Sunway Machinery, we prioritize sustainability in our machine designs.

FAQs About Highway Guard Rail Roll Forming Machines

Let’s answer some additional frequently asked questions to help you make an informed decision:

| Question | Answer |

|---|---|

| Can these machines produce custom profiles? | Yes, custom machines can be designed to produce unique guard rail profiles for specialized applications. |

| What’s the average lead time for delivery? | Delivery times vary but typically range from 30–90 days, depending on customization requirements. |

| What’s the lifespan of these machines? | With proper maintenance, these machines can last 10–15 years or more. |

| Do these machines require a large workspace? | Machines typically require 20–30 meters in length and 5–7 meters in width for optimal operation. |

| What kind of training is provided? | Manufacturers like Wuxi Sunway Machinery offer on-site installation and operator training. |

| Are there financing options available? | Yes, many manufacturers provide flexible payment plans to accommodate your budget. |

Why Choose Wuxi Sunway Machinery for Highway Guard Rail Machines?

When it comes to roll-forming technology, Wuxi Sunway Machinery is the industry leader. Here’s why:

- Proven Expertise: Decades of experience in designing and manufacturing roll-forming machines for diverse industries.

- Custom Solutions: Tailored machines to meet your specific requirements, whether for standard or custom guard rail profiles.

- Global Reach: A trusted partner for manufacturers across Asia, Europe, Africa, and beyond.

- Quality Assurance: Machines built to international quality standards, ensuring durability and performance.

- Comprehensive Support: From installation to maintenance and spare parts, Wuxi Sunway Machinery has you covered every step of the way.

Conclusion: Investing in a Highway Guard Rail Roll Forming Machine

As global infrastructure projects expand, the demand for high-quality highway guard rails is surging. A Highway Guard Rail Roll Forming Machine is an investment in precision, efficiency, and scalability, ensuring you can meet market demand while maintaining the highest standards of safety and quality.

When it comes to choosing a supplier, Wuxi Sunway Machinery stands out for its innovation, reliability, and commitment to customer satisfaction. Ready to take your guard rail manufacturing to the next level? Let’s roll into a safer and more profitable future—together!