When it comes to roofing, wall cladding, or even decorative architectural designs, corrugated panels are a go-to choice. These lightweight yet strong panels are widely used in residential, industrial, and commercial projects due to their durability, aesthetic appeal, and cost-effectiveness. But how do manufacturers produce these panels efficiently and at scale? That’s where the नालीदार पैनल रोल बनाने की मशीन steps in—a marvel of engineering that transforms metal coils into perfectly shaped corrugated panels.

In this comprehensive guide, we’ll explore everything you need to know about Corrugated Panel Roll Forming Machines in 2025. From applications and types to pricing, troubleshooting, and automation trends, we’ll cover it all. Additionally, we’ll dive into why Wuxi Sunway Machinery, a trusted global leader in roll-forming technology, is the ideal choice for your manufacturing needs.

Overview of Corrugated Panel Roll Forming Machines

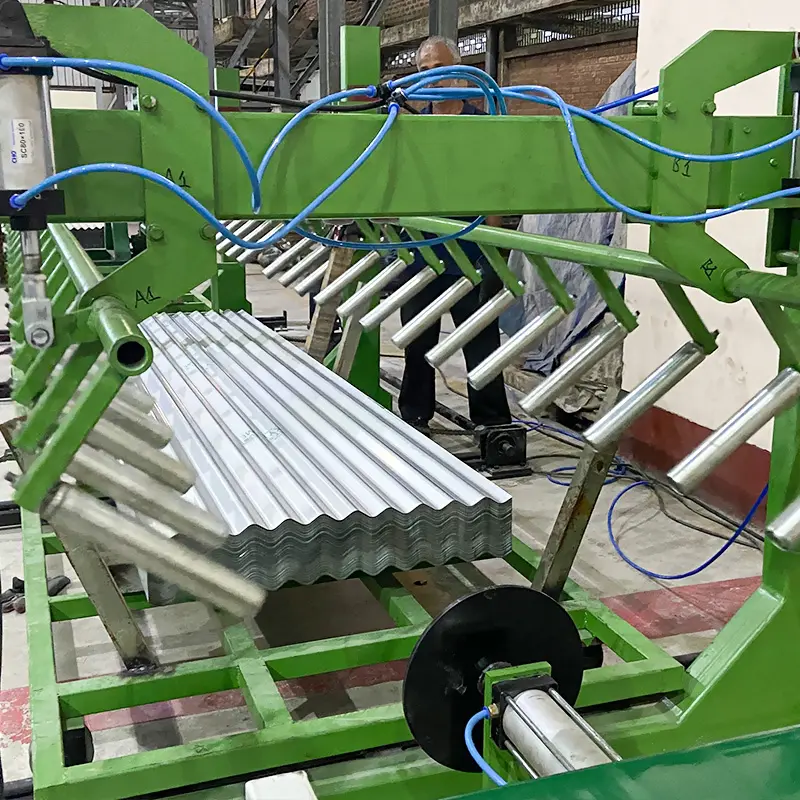

ए नालीदार पैनल रोल बनाने की मशीन is a specialized piece of equipment designed to produce corrugated metal sheets from flat metal coils. These machines take raw materials like galvanized steel, pre-painted steel, or aluminum and transform them into corrugated panels through a series of rollers that gradually shape the material into its signature wavy profile.

The roll-forming process ensures precision, uniformity, and high production efficiency, making these machines indispensable for manufacturers serving industries such as construction, agriculture, and transportation. With the increasing demand for durable, lightweight, and eco-friendly building materials, corrugated panels are more relevant than ever.

Applications of Corrugated Panel Roll Forming Machines

Corrugated panels are incredibly versatile, making them a cornerstone in various industries. Here’s where corrugated panels—and the machines that produce them—shine:

1. Roofing Systems

Corrugated metal sheets are a popular choice for roofing due to their strength, weather resistance, and ease of installation. They’re commonly used in:

- Residential homes

- Warehouses

- Industrial buildings

- Agricultural structures like barns and greenhouses

2. Wall Cladding

Corrugated panels provide an aesthetically pleasing and durable solution for exterior and interior wall cladding. They’re often used in commercial buildings, factories, and even modern architectural designs.

3. Fencing

Corrugated panels are used to create sturdy, weather-resistant fences for residential, commercial, and agricultural properties.

4. Decorative Applications

Thanks to their unique texture, corrugated panels are increasingly being used in decorative applications, such as feature walls in homes, restaurants, or retail spaces.

5. Transportation

In the automotive and logistics industries, corrugated metal sheets are used for truck beds, cargo containers, and storage units due to their lightweight yet strong properties.

By investing in a नालीदार पैनल रोल बनाने की मशीन, manufacturers can cater to these diverse applications, tapping into a growing market for corrugated metal products.

Types of Corrugated Panel Roll Forming Machines

Not all corrugated panels are created equal, and neither are the machines that produce them. Here’s a breakdown of the main types of Corrugated Panel Roll Forming Machines:

1. Standard Corrugated Roll Forming Machines

These machines are designed to produce traditional corrugated profiles with uniform wave patterns. They are ideal for high-volume production of roofing and cladding sheets.

2. Multi-Profile Roll Forming Machines

For manufacturers serving diverse markets, multi-profile machines offer the flexibility to produce various corrugated panel designs. These machines come with interchangeable tooling systems, allowing for quick profile changes.

3. High-Speed Corrugated Roll Forming Machines

Time is money, and high-speed machines are perfect for manufacturers looking to maximize output. These machines deliver higher production speeds without compromising on quality.

4. Custom Corrugated Roll Forming Machines

If you need unique corrugated profiles for specialized applications, custom machines can be designed to meet your specific requirements.

Comparison Table: Types of Corrugated Panel Roll Forming Machines

| Machine Type | Primary Use | Profiles Produced | उत्पादन गति | Price Range (USD) |

|---|---|---|---|---|

| Standard Machines | Traditional corrugated profiles | 1 Profile | 10–15 meters/min | $50,000–$80,000 |

| Multi-Profile Machines | Versatile, multi-design production | Multiple Profiles | 10–20 meters/min | $80,000–$120,000+ |

| High-Speed Machines | Large-scale production | 1 Profile | 20–30 meters/min | $100,000–$150,000 |

| Custom Machines | Specialized or unique profiles | Variable | Variable | Based on design specs |

Key Features of Corrugated Panel Roll Forming Machines

When investing in a नालीदार पैनल रोल बनाने की मशीन, it’s essential to look for features that ensure high-quality output, operational efficiency, and durability. Here’s what to prioritize:

1. High-Precision Rollers

The rollers are the heart of the machine. High-strength, chrome-plated steel rollers ensure precision shaping and long-term durability.

2. Advanced PLC Control Systems

ए Programmable Logic Controller (PLC) system allows operators to automate production settings, monitor performance, and make real-time adjustments.

3. Material Compatibility

Ensure the machine can handle a variety of materials, including:

- Galvanized steel

- Pre-painted steel

- एल्यूमीनियम

- Stainless steel

4. Cutting Systems

Servo-driven or hydraulic cutting systems provide clean, burr-free cuts, ensuring panels meet exact length specifications.

5. Noise Reduction

Modern machines are equipped with noise-dampening features to ensure a quieter production environment.

6. Quick-Change Tooling

For multi-profile machines, quick-change tooling systems minimize downtime when switching between profiles.

Machines from Wuxi Sunway Machinery incorporate all these features, ensuring high-quality output and reliable performance.

Specifications of Corrugated Panel Roll Forming Machines

Here’s a quick overview of the technical specifications to expect:

| Specification | विवरण |

|---|---|

| Material Thickness | 0.3mm–1.2mm |

| Material Type | Galvanized steel, pre-painted steel, aluminum |

| बनाने की गति | 10–30 meters per minute |

| रोलर सामग्री | High-strength steel with chrome plating |

| कटिंग सिस्टम | Servo or hydraulic cutting |

| नियंत्रण प्रणाली | PLC with HMI (Human-Machine Interface) |

| बिजली की आपूर्ति | Typically 380V/50Hz (customizable for regional standards) |

Pricing of Corrugated Panel Roll Forming Machines

The cost of a नालीदार पैनल रोल बनाने की मशीन depends on its features, automation level, and production capacity. Here’s a general pricing guide:

Price Ranges

- Standard Machines: $50,000–$80,000

- Multi-Profile Machines: $80,000–$120,000+

- High-Speed Machines: $100,000–$150,000

- Custom Machines: Pricing depends on specific requirements.

Automation Trends in Corrugated Panel Roll Forming Machines

As industries demand faster production and higher precision, automation is transforming the roll-forming landscape. Here are the latest trends:

1. IoT Integration

IoT-enabled machines allow manufacturers to monitor production metrics in real time, receive maintenance alerts, and optimize workflows remotely.

2. Predictive Maintenance

Using AI-powered sensors, predictive maintenance systems can identify potential issues before they cause downtime, saving manufacturers time and money.

3. Fully Automated Production Lines

Advanced machines now handle every step of the process—from material feeding to cutting and stacking—reducing labor costs and improving efficiency.

FAQs About Corrugated Panel Roll Forming Machines

Here are answers to some common questions:

| Question | Answer |

|---|---|

| Can these machines produce custom profiles? | Yes, custom machines can be designed to produce unique corrugated panel designs. |

| What’s the average production speed? | Depending on the machine type, production speeds range from 10 to 30 meters per minute. |

| What materials can be processed? | Most machines handle galvanized steel, pre-painted steel, and aluminum within specified thicknesses. |

| Do these machines require skilled operators? | Advanced PLC systems make these machines user-friendly, requiring minimal operator training. |

| What’s the lifespan of these machines? | With proper maintenance, these machines can last 10–15 years or more. |

| Can I switch between profiles easily? | Yes, multi-profile machines allow for quick and seamless profile changes. |

Automation Trends in Corrugated Panel Roll Forming Machines

Automation is no longer a luxury—it’s a necessity for manufacturers looking to stay competitive in today’s fast-paced markets. Modern Corrugated Panel Roll Forming Machines are leveraging the latest technologies to reduce costs, enhance efficiency, and boost product quality. Here’s how automation is shaping the future:

1. IoT-Enabled Smart Factories

Imagine your roll-forming machine sending you real-time updates about its performance, maintenance needs, and production metrics—all to your smartphone or laptop. That’s the power of IoT (Internet of Things). With IoT integration, manufacturers can:

- Monitor Remotely: Track production output, energy consumption, and machine status from anywhere.

- Receive Alerts: Get instant notifications about issues like roller misalignment or material feed disruptions.

- Analyze Data: Use cloud-based analytics to identify bottlenecks, optimize production schedules, and improve efficiency.

2. Fully Automated Profile Changes

Gone are the days of manual tooling changes that slow down production. Advanced machines now feature automated profile-switching systems, allowing operators to switch between profiles in minutes through a simple command in the PLC (Programmable Logic Controller) interface. This feature is a game-changer for manufacturers producing multiple panel designs.

3. Real-Time Quality Control

Advanced sensors and cameras are being integrated into roll-forming machines to ensure real-time quality assurance. These systems can:

- Detect imperfections in the panel surface.

- Measure dimensions to ensure they meet exact specifications.

- Automatically halt production if an issue arises, reducing waste.

4. Predictive Maintenance with AI

Predictive maintenance systems use AI to analyze data from machine sensors and forecast when components like rollers or cutters might fail. This allows manufacturers to:

- Schedule maintenance proactively.

- Avoid unplanned downtime.

- Extend the lifespan of critical machine components.

5. Servo-Driven Precision

Servo motors are becoming a standard feature in high-end machines. They ensure:

- Accurate Cutting: Clean, burr-free cuts every time.

- Precise Profiling: Consistent corrugation shapes, even at high speeds.

- Energy Efficiency: Reduced power consumption compared to traditional motors.

At Wuxi Sunway Machinery, we integrate these advanced automation features into our machines, ensuring that our clients stay ahead of the curve.

Troubleshooting Common Issues in Corrugated Panel Roll Forming Machines

Even the most advanced machines can encounter operational challenges. Knowing how to troubleshoot these issues can save you time and money. Here are some common problems and their solutions:

1. Uneven Corrugations

- Cause: Misaligned rollers or inconsistent material feeding.

- Solution: Inspect the rollers for alignment issues and recalibrate the machine. Ensure the material is fed consistently without slack or tension imbalances.

2. Material Jamming

- Cause: Improper material feeding or debris in the machine.

- Solution: Check the feeding system for obstructions and clean the rollers and guides regularly. Use high-quality coils to reduce the risk of material jamming.

3. Burrs on Panel Edges

- Cause: Dull cutting blades or incorrect cutting pressure.

- Solution: Replace or sharpen the cutting blades. Adjust the cutting pressure in the PLC system for cleaner cuts.

4. Inconsistent Panel Lengths

- Cause: Faulty PLC programming or worn servo motors.

- Solution: Verify the length settings in the PLC system and recalibrate the servo motor. Replace worn components if needed.

5. Machine Downtime

- Cause: Neglected maintenance or wear on critical parts.

- Solution: Follow a strict maintenance schedule, including lubrication, cleaning, and inspections. Use predictive maintenance tools if available.

For expert troubleshooting and professional assistance, contact Wuxi Sunway Machinery. Our team provides comprehensive support to keep your machines running smoothly.

Environmental Benefits of Corrugated Panel Roll Forming Machines

Sustainability is no longer optional—it’s a business imperative. Modern Corrugated Panel Roll Forming Machines are designed with eco-friendly practices in mind, helping manufacturers reduce their environmental footprint. Here’s how:

1. Minimal Material Waste

The roll-forming process is highly efficient, utilizing nearly all of the raw material. Any scraps generated are minimal and can often be recycled, reducing waste.

2. Energy-Efficient Operations

Modern machines are designed to consume less energy while maintaining high production speeds. Features like servo motors and optimized hydraulics ensure lower power consumption, aligning with global energy conservation goals.

3. Recyclable Materials

Corrugated panels produced by these machines are typically made from materials like galvanized steel, aluminum, and stainless steel—all of which are 100% recyclable.

4. Long Product Lifespan

Corrugated panels are durable and resistant to corrosion, reducing the need for frequent replacements. This extends the lifecycle of structures and minimizes resource consumption over time.

By investing in energy-efficient machinery, manufacturers can align with environmental standards while reducing operational costs. At Wuxi Sunway Machinery, we prioritize sustainability in our machine designs.

FAQs About Corrugated Panel Roll Forming Machines

Here are some frequently asked questions to address any lingering doubts:

| Question | Answer |

|---|---|

| What is the typical production speed? | Production speeds range from 10–30 meters per minute, depending on the machine model and material. |

| Can I produce custom corrugated profiles? | Yes, custom machines can be designed to produce unique corrugated profiles for specialized applications. |

| What materials can these machines process? | Common materials include galvanized steel, pre-painted steel, aluminum, and stainless steel. |

| How long does it take to switch profiles? | Automated profile switching takes just a few minutes, while manual changes may take longer. |

| Do these machines require skilled operators? | Advanced PLC systems make these machines user-friendly, requiring minimal operator training. |

| What’s the lifespan of these machines? | With proper maintenance, these machines can last 10–15 years or more. |

| Are financing options available? | Yes, manufacturers like Wuxi Sunway Machinery offer flexible financing plans. |

Why Choose Wuxi Sunway Machinery for Corrugated Panel Roll Forming Machines?

When it comes to roll-forming technology, Wuxi Sunway Machinery is a global leader. Here’s why manufacturers worldwide trust us:

- Proven Expertise: Decades of experience in designing and manufacturing roll-forming machines for diverse applications.

- Custom Solutions: Machines tailored to your specific production needs, whether for roofing, cladding, or decorative panels.

- Global Reputation: Trusted by clients across Asia, Europe, Africa, and beyond for reliability and quality.

- Top-Notch Quality: Our machines are built to international standards, ensuring exceptional performance and durability.

- Comprehensive Support: From installation to maintenance, spare parts, and troubleshooting, we’re with you every step of the way.

- Innovative Features: We incorporate cutting-edge technologies like IoT, servo-driven systems, and predictive maintenance to future-proof your production line.

Conclusion: Is a Corrugated Panel Roll Forming Machine Worth It?

If your business is in the construction, agriculture, or transportation industries, investing in a नालीदार पैनल रोल बनाने की मशीन is a no-brainer. These machines provide unmatched efficiency, precision, and scalability, enabling you to meet the rising demand for high-quality corrugated panels.

For a reliable partner in roll-forming technology, look no further than Wuxi Sunway Machinery. With a commitment to innovation, quality, and customer satisfaction, we’re here to help you shape the future of manufacturing. Ready to elevate your production capabilities? Let’s roll into a more profitable and sustainable tomorrow—together!