The demand for lightweight, durable, and versatile aluminum profiles is skyrocketing across industries like construction, automotive, electronics, and renewable energy. From sleek architectural designs to robust industrial frameworks, aluminum profiles are essential components of modern infrastructure and technology. But how are these intricate profiles manufactured with such precision and scale? The answer lies in Aluminum Profile Roll Forming Machines—a groundbreaking technology that enables high-speed, cost-effective, and eco-friendly production.

In this comprehensive guide, we’ll delve into the features, applications, pricing, global trends, innovations, and why Wuxi Sunway Machinery is a global leader in aluminum profile roll-forming solutions. Whether you’re an industry professional or someone exploring the latest in manufacturing technology, this article will provide you with actionable insights.

What Are Aluminum Profile Roll Forming Machines?

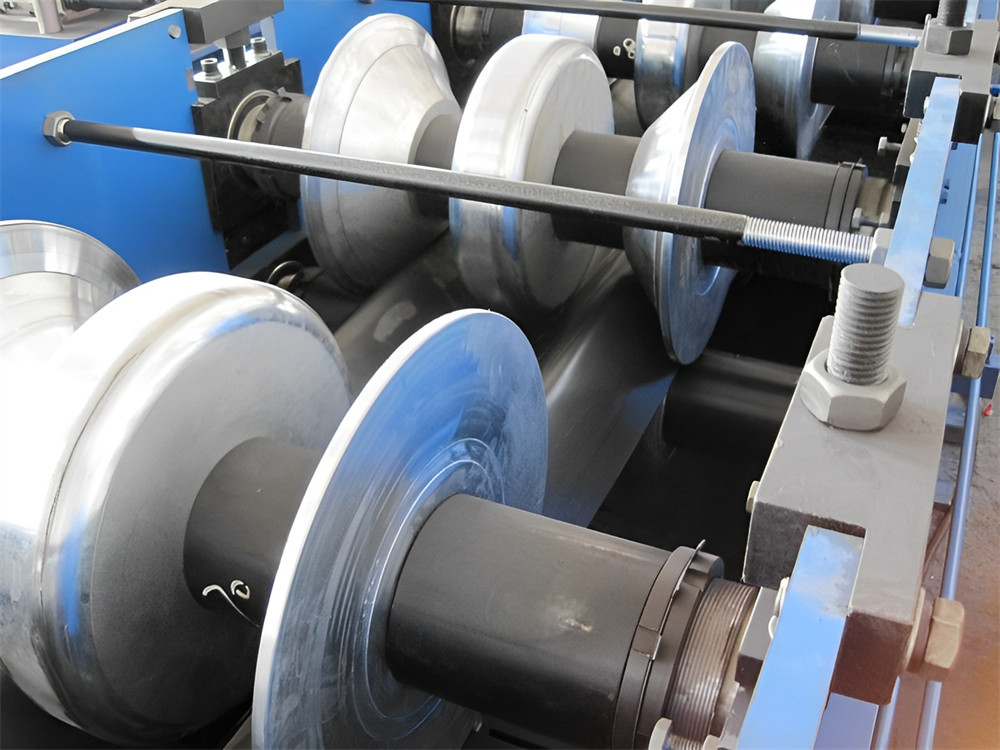

How a Pipe Roll Forming Machine Works and Why It’s Used? 10 Aluminum Profile Roll Forming Machine is a specialized piece of equipment designed to fabricate precise, custom aluminum profiles by feeding aluminum sheets or coils through a series of rollers. These rollers gradually shape the material into the desired cross-sectional profile, ensuring consistency, accuracy, and durability.

Core Features

- Material Versatility: Machines are optimized for processing various grades of aluminum, including coated, anodized, and raw aluminum.

- High-Speed Production: Capable of producing complex profiles at speeds of up to 100 meters per minute.

- Precision Engineering: Maintains tight tolerances to ensure every profile fits its intended application perfectly.

- Customizable Designs: Supports the creation of unique profiles to meet specific project requirements.

- Eco-Friendly Operations: Reduces material wastage and energy consumption, aligning with sustainability goals.

Applications of Aluminum Profile Roll Forming Machines

These machines are indispensable for manufacturing aluminum components used across a myriad of industries. Here’s a breakdown of their key applications:

1. Construction and Architecture

- Use Case: Producing aluminum profiles for curtain walls, window frames, door frames, and structural frameworks.

- Why It’s Essential: Ensures lightweight, corrosion-resistant components that are easy to install and maintain.

2. Automotive Industry

- Use Case: Manufacturing components like roof rails, crash barriers, and trim profiles.

- Why It’s Critical: Provides lightweight yet durable parts that improve vehicle performance and fuel efficiency.

3. Renewable Energy

- Use Case: Crafting mounting systems and supports for solar panels and wind turbines.

- Why It’s Relevant: Supports the renewable energy sector with durable, weather-resistant components.

4. Electronics and Appliances

- Use Case: Producing heat sinks, enclosures, and structural components for electrical devices.

- Why It’s Beneficial: Ensures precise, high-quality profiles for sensitive electronic applications.

5. Furniture and Interior Design

- Use Case: Creating profiles for modular furniture, decorative trims, and partition systems.

- Why It’s Unique: Delivers aesthetically pleasing and functional designs for modern interiors.

6. Transportation Infrastructure

- Use Case: Manufacturing profiles for railway tracks, airport walkways, and pedestrian bridges.

- Why It’s Valuable: Offers lightweight solutions that reduce installation time and costs.

Why Aluminum Profile Roll Forming Machines Are Gaining Popularity

The versatility and efficiency of aluminum make it a preferred material across industries, and Aluminum Profile Roll Forming Machines are perfectly suited to meet the rising demand. Here’s why they are indispensable:

1. Lightweight and Durable

- Why It Matters: Aluminum profiles are strong yet lightweight, making them ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

2. Corrosion Resistance

- Why It’s Critical: Aluminum profiles can withstand harsh environmental conditions, making them perfect for outdoor applications like construction and renewable energy systems.

3. Customization

- Why It’s Beneficial: Roll-forming machines can produce profiles of various shapes, sizes, and finishes, catering to diverse industry needs.

4. Eco-Friendly Manufacturing

- Why It’s Essential: Aluminum is highly recyclable, and roll-forming machines minimize waste, supporting sustainable production practices.

5. High Production Efficiency

- Why It’s Necessary: Roll-forming machines are designed for continuous operation, enabling manufacturers to meet high-volume demands without compromising quality.

Key Features of Wuxi Sunway Aluminum Profile Roll Forming Machines

Wuxi Sunway Machinery is a trusted name in the roll-forming industry, offering cutting-edge solutions for aluminum profile manufacturing. Here’s why their machines stand out:

1. Advanced Material Handling

- Supported Materials:

- Raw Aluminum

- Anodized Aluminum

- Coated Aluminum

- Why It’s Beneficial: Ensures compatibility with a range of materials for versatile applications.

2. Precision Engineering

- Performance: Achieves tolerances as low as ±0.02mm, ensuring exact dimensions.

- Why It’s Important: Guarantees seamless assembly and compatibility with other components.

3. Modular Tooling Systems

- What It Offers: Interchangeable tooling for producing multiple profiles on a single machine.

- Why It’s Valuable: Reduces downtime during tooling changes and increases production flexibility.

4. IoT and Automation Integration

- What It Enables: Real-time monitoring, automated adjustments, and predictive maintenance using IoT systems.

- Why It’s Revolutionary:

- Enhances production efficiency.

- Reduces operational costs.

5. High-Speed Operation

- Performance: Produces profiles at speeds of up to 100 meters per minute.

- Why It’s Necessary: Meets the high-volume demands of industries like construction and automotive.

6. Eco-Friendly Design

- What It Includes: Energy-efficient motors, reduced material waste, and support for recyclable aluminum.

- Why It’s Essential: Aligns with global sustainability goals and reduces the carbon footprint of manufacturing.

7. Integrated Cutting and Punching

- What It Offers: Built-in systems for cutting and punching aluminum sheets during the roll-forming process.

- Why It’s Efficient: Speeds up production and ensures ready-to-use components.

Pricing of Aluminum Profile Roll Forming Machines

The cost of an Aluminum Profile Roll Forming Machine depends on its features, capacity, and level of customization. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic aluminum profile production | 150,000–150,000–150,000–400,000 |

| Advanced Machines | High-speed, integrated cutting and punching systems | 400,000–400,000–400,000–1,000,000 |

| Fully Customizable Machines | IoT, modular tooling, and eco-friendly features | 1,000,000–1,000,000–1,000,000–2,500,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Innovations in Aluminum Profile Roll Forming Technology

The roll-forming industry is evolving rapidly, with new technologies enhancing the capabilities of Aluminum Profile Roll Forming Machines. Here are the latest innovations:

1. Digital Twin Technology

- What It Simulates: Virtual models of the roll-forming process to optimize machine settings.

- Why It’s Revolutionary:

- Reduces setup time and trial-and-error adjustments.

- Ensures consistent quality from the first production run.

2. AI-Powered Quality Control

- What It Does: Monitors dimensions, surface quality, and material thickness in real-time.

- Why It’s Game-Changing:

- Detects defects early, reducing waste.

- Improves overall product quality.

3. Multi-Profile Capability

- What It Enables: Produces multiple profiles in a single production cycle.

- Why It’s Beneficial:

- Increases production speed.

- Supports diverse manufacturing needs.

4. IoT Integration

- What It Offers: Real-time data collection, predictive maintenance, and automated adjustments.

- Why It’s Critical:

- Enhances machine uptime.

- Reduces maintenance costs.

5. Eco-Friendly Coating Systems

- What It Includes: Systems for applying protective or decorative coatings during the roll-forming process.

- Why It’s Sustainable:

- Eliminates additional coating processes.

- Reduces energy consumption.

FAQs About Aluminum Profile Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | Aluminum (raw, anodized, coated) and other lightweight metals. |

| What is the production speed? | Up to 100 meters per minute, depending on the profile complexity. |

| Are these machines eco-friendly? | Yes, they include energy-efficient motors and minimize material waste. |

| Can these machines handle custom designs? | Absolutely! Modular tooling supports bespoke profiles for diverse applications. |

| Do these machines comply with safety standards? | Yes, they meet CE, ISO, and OSHA certifications for safety and reliability. |

| Can these machines integrate with IoT systems? | Yes, IoT-enabled features allow real-time monitoring and predictive maintenance. |

Real-World Success Stories: Aluminum Profile Roll Forming Machines in Action

The versatility and efficiency of Aluminum Profile Roll Forming Machines are evident in their application across diverse industries. Here are some real-world examples that illustrate their transformative impact:

1. Case Study: Solar Energy Infrastructure

- Client: A solar energy company managing large-scale solar farms in North America.

- Challenge: The company needed lightweight yet durable mounting systems for solar panels that could withstand extreme weather conditions.

- Solution: Wuxi Sunway Machinery provided a roll-forming machine capable of processing anodized aluminum and integrating custom profiles for mounting brackets.

- Results:

- Increased production output by 35%, enabling faster installation of solar farms.

- Delivered corrosion-resistant components with precise dimensions.

- Reduced material waste by 20%, aligning with the company’s sustainability goals.

2. Case Study: Automotive Component Supplier

- Client: A leading supplier of aluminum parts for electric vehicles (EVs) in Europe.

- Challenge: The client needed high-strength, lightweight aluminum profiles for EV battery enclosures and crash barriers.

- Solution: Wuxi Sunway developed a roll-forming machine with integrated cutting and punching capabilities for high-strength alloys.

- Results:

- Reduced production lead times by 40%.

- Delivered components that improved vehicle energy efficiency and safety.

- Enabled the client to expand their product portfolio and secure new contracts.

3. Case Study: Architectural Firm

- Client: A construction company specializing in modern architectural designs in the Middle East.

- Challenge: The firm needed customized aluminum profiles for curtain walls and decorative trims that could withstand high temperatures and sand exposure.

- Solution: Wuxi Sunway supplied a roll-forming machine optimized for pre-coated aluminum with advanced surface finishes.

- Results:

- Produced elegant, weather-resistant profiles that met the aesthetic and functional requirements of the project.

- Reduced production costs by 25% compared to traditional fabrication methods.

- Enhanced the firm’s reputation for delivering high-quality architectural projects.

4. Case Study: Modular Furniture Manufacturer

- Client: A furniture manufacturer specializing in modular and customizable designs.

- Challenge: The company needed lightweight, easy-to-assemble aluminum profiles for their furniture systems.

- Solution: Wuxi Sunway provided a roll-forming machine with modular tooling for creating diverse profile designs.

- Results:

- Increased production flexibility, allowing the company to cater to evolving customer preferences.

- Delivered components with a flawless finish, enhancing the product’s market appeal.

- Reduced production waste, supporting the company’s eco-friendly initiatives.

Sustainability Practices in Aluminum Profile Manufacturing

Sustainability is a key focus in modern manufacturing, and Aluminum Profile Roll Forming Machines are designed to support eco-friendly practices. Here’s how they contribute to a greener future:

1. Energy-Efficient Operations

- How It’s Achieved: Advanced motors and optimized workflows reduce electricity consumption.

- Impact: Lowers the carbon footprint of manufacturing processes, aligning with global sustainability goals.

2. Reduced Material Waste

- How It’s Achieved: Precision cutting and forming systems minimize scrap during production.

- Impact: Conserves raw materials and reduces production costs.

3. Support for Recyclable Materials

- How It’s Achieved: Machines are designed to process recyclable aluminum materials.

- Impact: Promotes the reuse of materials, reducing waste and supporting circular economy practices.

4. Long-Lasting Components

- Why It Matters: Durable aluminum profiles require less frequent replacement, reducing overall material consumption.

- Impact: Extends the lifecycle of products, minimizing environmental impact.

5. Coating Integration

- How It’s Achieved: Machines support eco-friendly coatings that enhance the durability and aesthetics of aluminum profiles.

- Impact: Eliminates the need for additional coating processes, reducing energy usage.

Safety Standards for Aluminum Profile Roll Forming Machines

Safety is paramount in manufacturing, and Aluminum Profile Roll Forming Machines are equipped with advanced features to protect operators and ensure compliance with global standards.

1. Emergency Stop Systems

- What It Does: Allows operators to halt machine operations instantly in case of an emergency.

- Why It’s Critical: Prevents accidents and minimizes equipment damage during unforeseen incidents.

2. Safety Guards and Shields

- What It Includes: Protective barriers around moving parts to prevent accidental contact.

- Why It’s Important: Reduces the risk of injuries caused by human error or mechanical malfunctions.

3. Light Curtains

- What It Detects: Identifies objects or personnel in hazardous zones and pauses machine operations automatically.

- Why It’s Effective: Enhances safety without interrupting production workflows.

4. Noise and Vibration Reduction

- What It Reduces: Minimizes noise levels and vibrations during operation.

- Why It’s Beneficial: Creates a safer and more comfortable working environment for operators.

5. Compliance with Global Standards

- Certifications: Machines meet CE, ISO 45001, and OSHA standards for safety and environmental protection.

- Why It’s Essential: Ensures reliability and safety in diverse global markets.

Global Market Trends for Aluminum Profile Roll Forming Machines in 2025

As industries adapt to changing demands and technological advancements, the market for Aluminum Profile Roll Forming Machines continues to expand. Here are the key trends driving growth:

1. Increasing Adoption in Renewable Energy

- Trend: The renewable energy sector’s growth is fueling demand for lightweight, corrosion-resistant aluminum profiles.

- Impact: Roll-forming machines capable of producing solar panel mounting systems and wind turbine components are in high demand.

2. Expansion of the Automotive Industry

- Trend: The rise of electric vehicles (EVs) is driving the need for lightweight aluminum components.

- Impact: Manufacturers require high-capacity roll-forming machines to meet production targets.

3. Growth in Urbanization and Infrastructure Development

- Trend: Rapid urbanization is increasing demand for construction materials like aluminum frames, doors, and windows.

- Impact: Roll-forming machines designed for architectural applications are becoming essential.

4. Shift Towards Sustainable Manufacturing

- Trend: Companies are adopting eco-friendly practices to meet consumer expectations and regulatory requirements.

- Impact: Machines optimized for energy efficiency and recyclable materials are gaining traction.

5. Integration with Industry 4.0

- Trend: The adoption of IoT and AI in manufacturing is driving demand for smart roll-forming machines.

- Impact: Machines with real-time monitoring and predictive maintenance capabilities are becoming industry standards.

Why Choose Wuxi Sunway Machinery for Aluminum Profile Roll Forming Machines?

Wuxi Sunway Machinery is a global leader in roll-forming technology, trusted by manufacturers across industries. Here’s why they are the go-to partner for aluminum profile production:

- Proven Expertise: Decades of experience in designing high-performance roll-forming machines.

- Global Reach: Machines are used successfully in Asia, Europe, the Americas, and beyond.

- Innovation-Driven: Features like IoT integration, modular tooling, and AI-powered quality control set their machines apart.

- Sustainability Commitment: Machines are optimized for eco-friendly production, supporting global sustainability goals.

- Comprehensive Support: From consultation to after-sales service, Wuxi Sunway ensures a seamless experience.

Conclusion: Shaping the Future of Manufacturing with Aluminum Profiles

Aluminum Profile Roll Forming Machines are revolutionizing modern manufacturing by combining precision, efficiency, and sustainability. Their versatility makes them indispensable for industries ranging from construction and automotive to renewable energy and electronics.

Ready to transform your manufacturing processes? Partner with Wuxi Sunway Machinery and explore their innovative roll-forming solutions tailored to your needs. Together, let’s shape a smarter, more sustainable future—one aluminum profile at a time.