रोलर मशीनें विभिन्न उद्योगों में, जिसमें विनिर्माण, निर्माण और कृषि शामिल हैं, आवश्यक उपकरण हैं। ये मिट्टी, कंक्रीट और एस्फाल्ट आदि सामग्रियों को संकुचित करने के लिए उपयोग किए जाते हैं, जो मजबूत और स्थिर आधार बनाने के लिए महत्वपूर्ण हैं। हालांकि, रोलर मशीनों की कीमतें अक्सर उतार-चढ़ाव करती रहती हैं, जिससे व्यवसायों के लिए खरीदारी और बजट की योजना बनाना कठिन हो जाता है। इन मूल्य परिवर्तनों को संचालित करने वाली बाजार गतिशीलता को समझना उद्योग से जुड़े किसी भी व्यक्ति के लिए महत्वपूर्ण है। इस पोस्ट में, हम रोलर मशीन कीमतों को प्रभावित करने वाले कारकों, रोलर मशीन कीमत और गुणवत्ता के संतुलन, भविष्य की रोलर मशीन मूल्य प्रवृत्तियों और सर्वोत्तम सौदे ढूंढने के तरीकों का अन्वेषण करेंगे। तो, आइए गहराई से समझें रोलर मशीन बाजार की गतिशीलता।

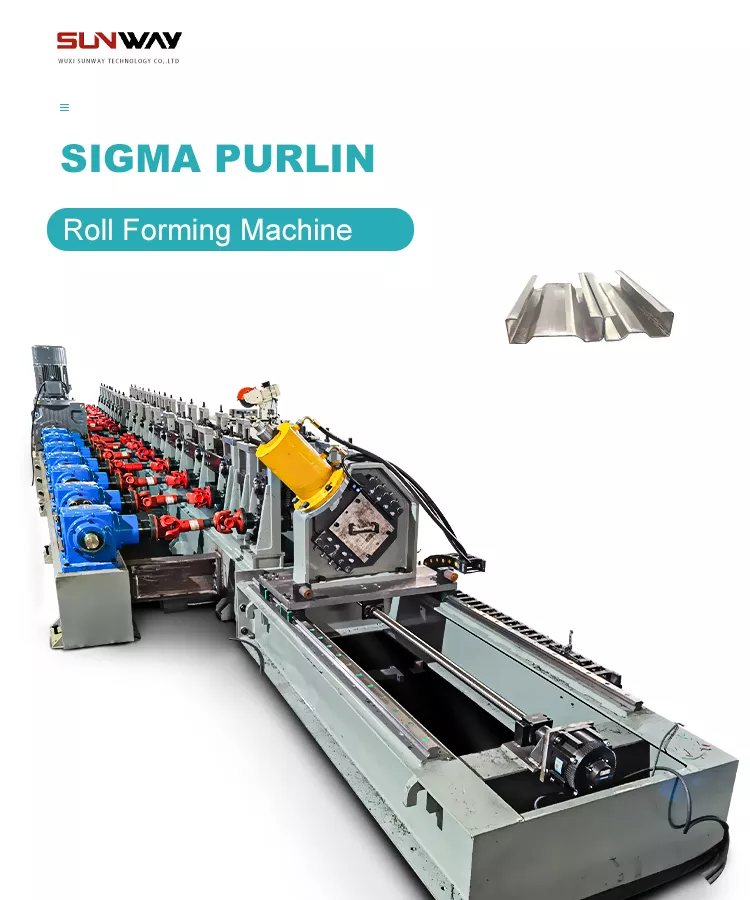

रोल फॉर्मिंग मशीन क्या है?

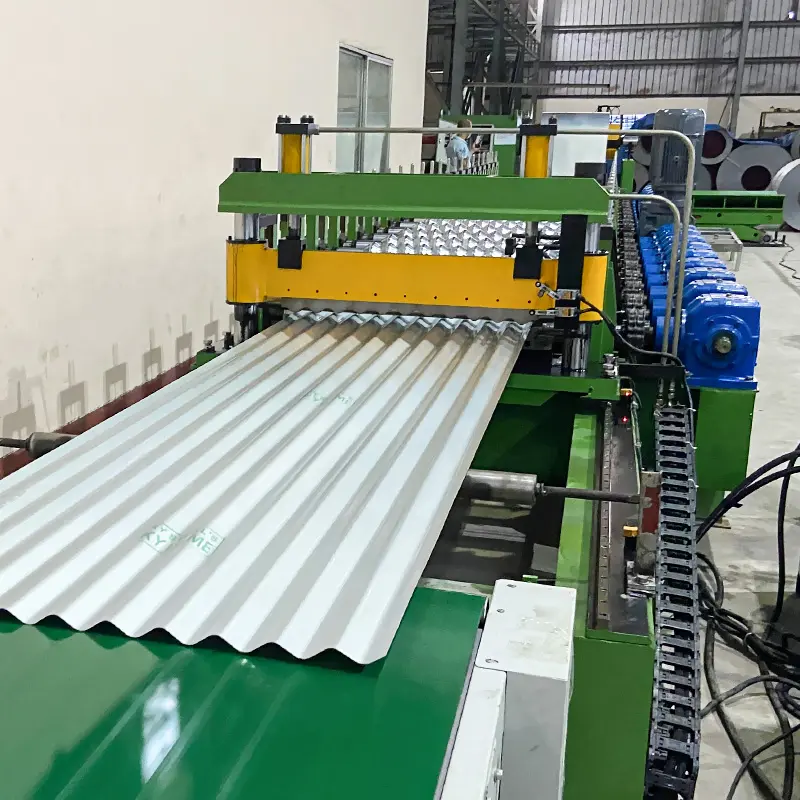

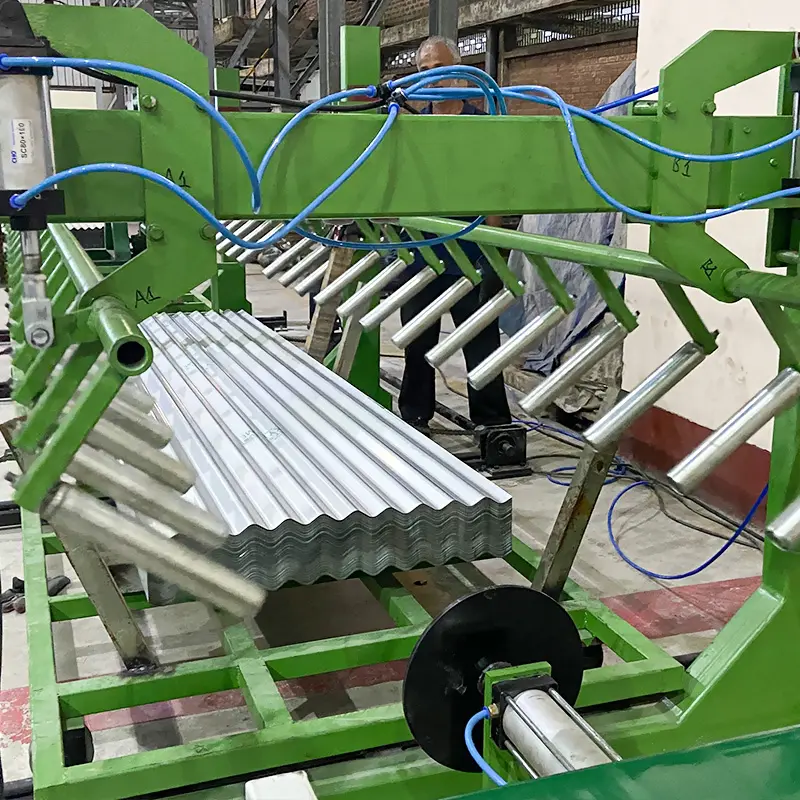

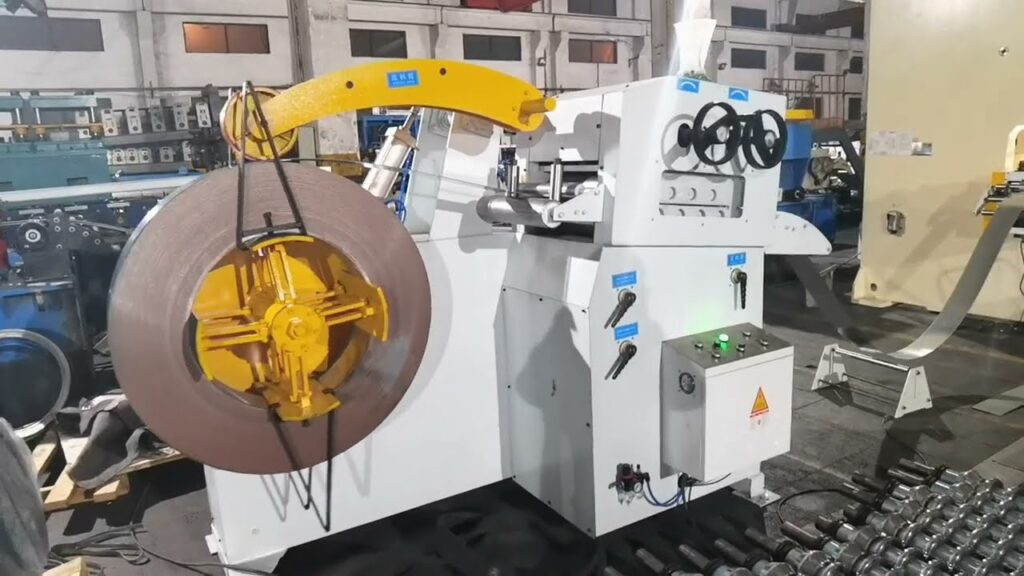

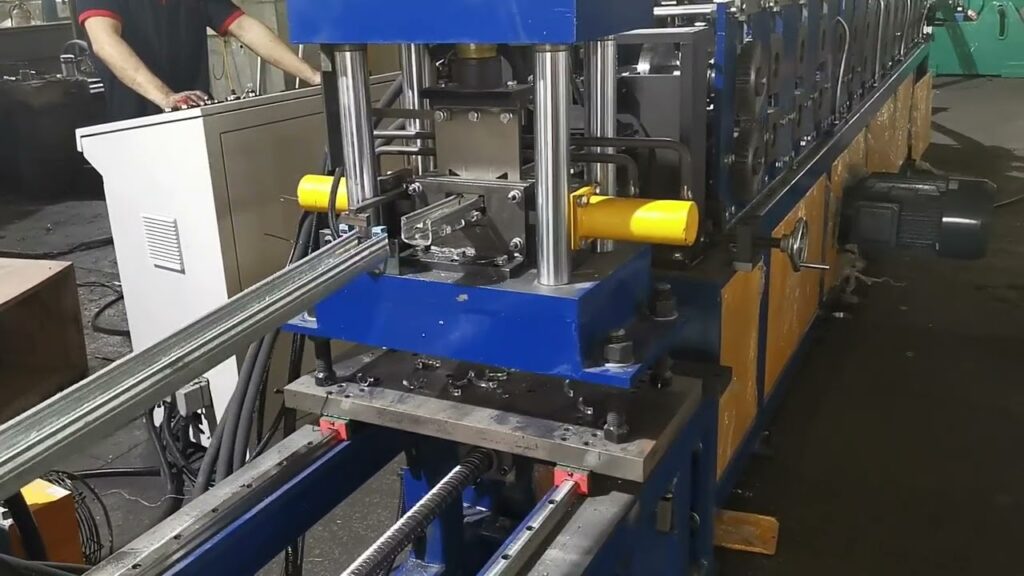

ए रोल बनाने की मशीन एक प्रकार की मशीन है जिसका उपयोग रोलर्स की एक श्रृंखला के माध्यम से धातु की शीट को पास करके धातु की चादरें बनाने के लिए किया जाता है। मशीन के रोलर्स धातु को वांछित आकार में आकार देते हैं क्योंकि यह उनके माध्यम से गुजरता है। जिस गति से धातु रोलर्स से होकर गुजरती है, साथ ही साथ धातु पर लगाए जाने वाले दबाव को विभिन्न आकार और मोटाई बनाने के लिए नियंत्रित किया जा सकता है।

रोल बनाने वाली मशीनों का उपयोग आमतौर पर छत के पैनल, गटर और खिड़कियों और दरवाजों के लिए फ्रेमिंग जैसे उत्पाद बनाने के लिए किया जाता है। उनका उपयोग मशीनरी या वाहनों के लिए कस्टम पुर्जे बनाने के लिए भी किया जा सकता है। रोल बनाने वाली मशीनें उनके आकार और क्षमताओं के आधार पर कीमत में भिन्न होती हैं।

मूल्य निर्धारण के लिए बाजार गतिशीलता को समझने का महत्व

-

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन -

दीन रेल रोल बनाने की मशीन

दीन रेल रोल बनाने की मशीन -

केबल सीढ़ी रोल बनाने की मशीन

केबल सीढ़ी रोल बनाने की मशीन -

पीवी माउंटिंग ब्रैकेट सी शेप प्रोफाइल रोल बनाने की मशीन

पीवी माउंटिंग ब्रैकेट सी शेप प्रोफाइल रोल बनाने की मशीन -

केबल ट्रे रोल बनाने की मशीन

केबल ट्रे रोल बनाने की मशीन -

पीवी माउंटिंग ब्रैकेट रोल बनाने की मशीन (एचएटी / ओमेगा प्रोफाइल)

पीवी माउंटिंग ब्रैकेट रोल बनाने की मशीन (एचएटी / ओमेगा प्रोफाइल) -

पीवी माउंटिंग ब्रैकेट जेड शेप प्रोफाइल रोल बनाने की मशीन

पीवी माउंटिंग ब्रैकेट जेड शेप प्रोफाइल रोल बनाने की मशीन -

सौर बढ़ते अकड़ चैनल रोल बनाने की मशीन

सौर बढ़ते अकड़ चैनल रोल बनाने की मशीन -

स्ट्रट चैनल रोल बनाने की मशीन

स्ट्रट चैनल रोल बनाने की मशीन

रोलर मशीनों के निर्माण या बिक्री करने वाले व्यवसायों के लिए मूल्य निर्धारण की बाजार गतिशीलता को समझना महत्वपूर्ण है। मांग, आपूर्ति, प्रतिस्पर्धा और उत्पादन लागत जैसे विभिन्न कारक रोलर मशीनों की कीमतों को प्रभावित कर सकते हैं। प्रतिस्पर्धी बने रहने के लिए, व्यवसायों को इन बाजार गतिशीलताओं से अवगत रहना चाहिए और अपनी मूल्य निर्धारण रणनीति के अनुसार समायोजन करना चाहिए।

मूल्य निर्धारण किसी भी व्यावसायिक रणनीति का एक महत्वपूर्ण तत्व है, और रोलर मशीन उद्योग भी इससे अछूता नहीं है। सही मूल्य निर्धारण रणनीति व्यवसाय को बाजार हिस्सेदारी बढ़ाने, लाभ अधिकतम करने और मजबूत ब्रांड प्रतिष्ठा बनाने में मदद कर सकती है। हालांकि, उत्पाद की कीमत बहुत अधिक या बहुत कम निर्धारित करने से बिक्री हानि या लाभ में कमी हो सकती है।

मांग और प्रतिस्पर्धा जैसी बाजार गतिशीलताएँ मूल्य निर्धारण पर महत्वपूर्ण प्रभाव डाल सकती हैं। जब रोलर मशीनों की मांग अधिक होती है, तो निर्माता अपने उत्पादों के लिए प्रीमियम मूल्य वसूल सकते हैं। इसी प्रकार, जब प्रतिस्पर्धा तीव्र होती है, तो व्यवसाय प्रतिस्पर्धी बने रहने के लिए कीमतें कम कर सकते हैं।

मूल्य निर्धारण में एक और महत्वपूर्ण कारक उत्पादन लागत है। कच्चे माल, श्रम और विनिर्माण की लागत में उतार-चढ़ाव हो सकता है, जो उत्पाद की अंतिम कीमत को प्रभावित करता है। इसके अलावा, प्रौद्योगिकी या उत्पादन प्रक्रियाओं में परिवर्तन भी उत्पादन लागत पर असर डाल सकते हैं।

संक्षेप में, मूल्य निर्धारण के लिए बाजार गतिशीलता को समझना व्यवसायों के लिए प्रतिस्पर्धी बने रहने, लाभ अधिकतम करने और मजबूत ब्रांड प्रतिष्ठा बनाने के लिए आवश्यक है। बाजार प्रवृत्तियों से अपडेट रहकर और अपनी मूल्य निर्धारण रणनीति के अनुसार समायोजन करके, व्यवसाय सुनिश्चित कर सकते हैं कि वे अपने उत्पादों की उचित कीमत निर्धारित कर रहे हैं और बाजार में प्रतिस्पर्धी बने रहें।

रोलर मशीन की कीमत को क्या प्रभावित करता है?

मशीन का प्रकार

आप जो मशीन चुनते हैं, वह मशीन की कीमत पर काफी प्रभाव डाल सकता है। उदाहरण के लिए, जटिल प्रोफाइल बनाने में सक्षम मल्टी-रोल फॉर्मिंग मशीन सामान्यतः सरल आकृतियाँ बनाने वाली सिंगल-शाफ्ट रोल फॉर्मिंग मशीन से अधिक महंगी होती है।

आकार और क्षमता

Ukuran dan kapasitas mesin roller adalah faktor kunci yang dapat secara signifikan mempengaruhi harganya. Mesin yang lebih besar yang mampu menangani lebih banyak material atau material yang lebih tebal cenderung lebih mahal daripada mesin yang lebih kecil karena beberapa alasan:

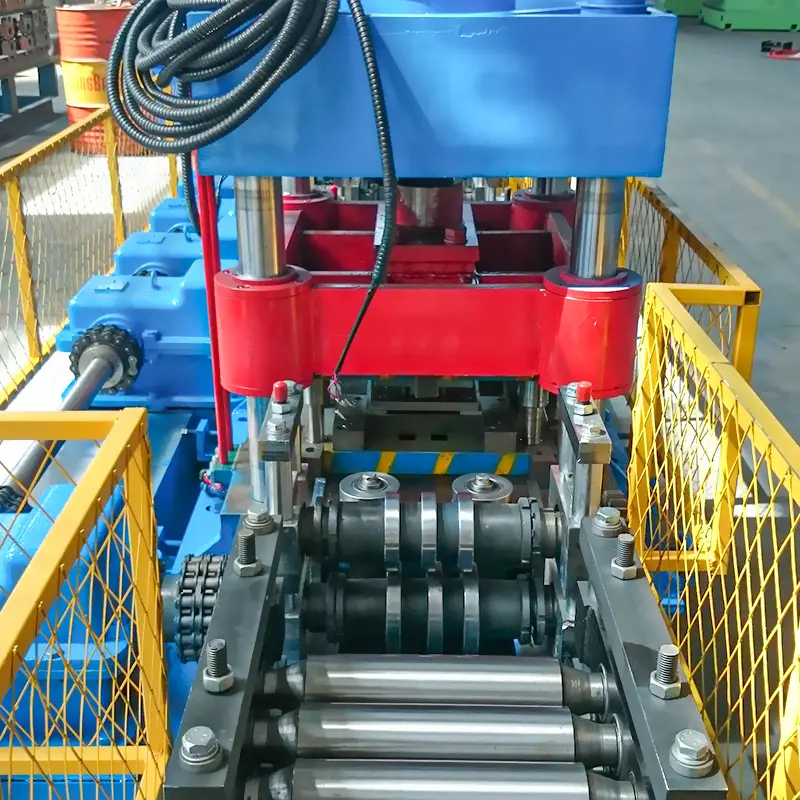

निर्माण लागत: बड़े मशीनों को बनाने के लिए अधिक सामग्री, संसाधनों और निर्माण प्रक्रियाओं की आवश्यकता होती है, जो उनकी उत्पादन लागत को बढ़ा सकती है। उदाहरण के लिए, अधिक रोलर्स वाली या उच्च मोटर पावर वाली रोलर मशीन को अधिक स्टील, बेयरिंग्स, मोटर्स और अन्य घटकों की आवश्यकता होगी, जो इसकी कीमत बढ़ा देगी।

विशेषताएं और क्षमताएं: बड़े मशीनें आमतौर पर छोटी मशीनों की तुलना में अधिक उन्नत विशेषताओं और क्षमताओं वाली होती हैं। उदाहरण के लिए, उनमें अधिक सटीक नियंत्रण, उच्च गति, बेहतर सामग्री हैंडलिंग सिस्टम या अधिक स्वचालन हो सकता है, जो उनकी दक्षता, सटीकता और उत्पादकता को सुधारता है। हालांकि, ये उन्नत विशेषताएं अधिक लागत पर आती हैं, क्योंकि इनके लिए अधिक परिष्कृत इंजीनियरिंग और प्रौद्योगिकी की आवश्यकता होती है।

अनुप्रयोग आवश्यकताएं: रोलर मशीन का आकार और क्षमता उपयोगकर्ता की विशिष्ट आवश्यकताओं और अनुप्रयोगों से मेल खानी चाहिए। उदाहरण के लिए, यदि आपको बड़े धातु शीट्स या मोटी सामग्रियों को संभालना है, तो आपको पर्याप्त क्षमता वाली बड़ी मशीन की आवश्यकता होगी। हालांकि, इससे मशीन की लागत भी बढ़ सकती है, क्योंकि आपको बड़े रोलर्स या कस्टम-डिज़ाइन फ्रेम जैसे अतिरिक्त एक्सेसरीज़ में निवेश करना पड़ सकता है।

सामग्री की गुणवत्ता

सामग्री गुणवत्ता रोलर मशीन की कीमत को प्रभावित करने वाला एक महत्वपूर्ण कारक है। रोलर मशीन के विनिर्माण में प्रयुक्त सामग्रियों की गुणवत्ता उसके टिकाऊपन, विश्वसनीयता और प्रदर्शन पर महत्वपूर्ण प्रभाव डाल सकती है। उच्च गुणवत्ता वाली सामग्रियों से बनी मशीनें सामान्यतः निम्न गुणवत्ता वाली सामग्रियों से बनी मशीनों से अधिक महंगी होती हैं।

उदाहरण के लिए, कुछ रोलर मशीनें प्लास्टिक या निम्न गुणवत्ता वाली स्टील जैसी सस्ती, निम्न श्रेणी की सामग्रियों का उपयोग कर सकती हैं। ये सामग्रियां घिसाव और फटाव के प्रति संवेदनशील हो सकती हैं और भारी उपयोग में अच्छी तरह टिक नहीं पातीं। दूसरी ओर, उच्च गुणवत्ता वाली रोलर मशीनें उच्च श्रेणी की स्टील, एल्यूमीनियम या अन्य मिश्र धातुओं जैसी सामग्रियों का उपयोग कर सकती हैं जो मजबूत, अधिक टिकाऊ और निरंतर उपयोग की कठोराइयों को सहन करने में सक्षम होती हैं।

रोलर मशीन में प्रयुक्त सामग्रियों की गुणवत्ता उसके परिशुद्धता और सटीकता को भी प्रभावित कर सकती है। उच्च गुणवत्ता वाली सामग्रियों से बनी मशीनें कसकर सहनशीलता, चिकनी सतहें और अधिक परिशुद्ध घटक प्रदान कर सकती हैं, जो अधिक सटीक और सुसंगत परिणामों का कारण बनते हैं। यह विनिर्माण जैसे उद्योगों में विशेष रूप से महत्वपूर्ण होता है जहां उच्च गुणवत्ता वाले उत्पादों के उत्पादन के लिए परिशुद्धता और सटीकता महत्वपूर्ण होती है।

सामग्रियों की गुणवत्ता के अलावा, मशीन के उत्पादन में प्रयुक्त विनिर्माण प्रक्रियाएं भी इसकी कीमत को प्रभावित कर सकती हैं। उन्नत तकनीकों और प्रक्रियाओं का उपयोग करके निर्मित मशीनें पारंपरिक विधियों से बनी मशीनों से अधिक महंगी हो सकती हैं।

प्रौद्योगिकीय प्रगति

Technological advancements play a significant role in roller machine pricing trends. Progress in automation, control systems, and materials can profoundly influence production costs, ultimately affecting roller machine prices.

Advancements in automation: Automation technology is advancing rapidly, and manufacturers are adopting it to streamline production processes. Automated systems can reduce labor costs and boost efficiency, ultimately lowering production costs and leading to more affordable roller machines.

नियंत्रण प्रणालियों में प्रगति: नियंत्रण प्रणालियों में प्रगति, जैसे कम्प्यूटरीकृत संख्यात्मक नियंत्रण (CNC) प्रणालियाँ, रोलर मशीन की कीमत पर भी प्रभाव डाल सकती हैं। ये प्रणालियाँ विनिर्माण प्रक्रिया की सटीकता और परिशुद्धता में सुधार कर सकती हैं, जिससे बेहतर गुणवत्ता वाले उत्पाद प्राप्त होते हैं। हालांकि, इन प्रणालियों की लागत अधिक हो सकती है, जो उत्पादन लागत बढ़ा सकती है और परिणामस्वरूप रोलर मशीनों की कीमतें बढ़ा सकती है।

Advancements in materials: New materials, such as lightweight alloys, can influence roller machine prices. While more expensive to produce, they offer enhanced characteristics like strength and durability, increasing the value of the final product.

这些技术进步可能会影响未来滚轮机价格趋势。随着更多制造商采用自动化技术,生产成本可能降低,从而导致滚轮机价格下降。然而,引入先进控制系统可能会提高生产成本,从而推高这些机器的价格。

先进材料的使用也可能影响滚轮机的成本。虽然这些材料能提供更好的性能特性,但也可能增加生产成本,导致价格上涨。

ब्रांड और प्रतिष्ठा

ब्रांड और प्रतिष्ठा रोलर मशीन की कीमत पर महत्वपूर्ण प्रभाव डाल सकती है। प्रतिष्ठित ब्रांड जो गुणवत्ता, विश्वसनीयता और ग्राहक सहायता के लिए जाने जाते हैं, वे अपनी मशीनों के लिए कम ज्ञात ब्रांडों या सामान्य मॉडलों की तुलना में अधिक शुल्क लेते हैं। ऐसा इसलिए होता है क्योंकि प्रतिष्ठित ब्रांड अनुसंधान और विकास, उच्च गुणवत्ता वाली सामग्रियों, उन्नत विनिर्माण प्रक्रियाओं तथा कठोर परीक्षण और प्रमाणीकरण में निवेश करते हैं ताकि उनकी मशीनें उद्योग मानकों और ग्राहक अपेक्षाओं को पूरा करें। इसके अतिरिक्त, प्रतिष्ठित ब्रांड ग्राहकों को वारंटी, तकनीकी सहायता और स्पेयर पार्ट्स की उपलब्धता प्रदान करते हैं, जो खरीद को मूल्य और मन की शांति प्रदान करते हैं।

दूसरी ओर, सस्ती या सामान्य रोलर मशीनें कम कीमत पर उपलब्ध हो सकती हैं, लेकिन उनमें ब्रांडेड मशीनों जितनी गुणवत्ता, प्रदर्शन और टिकाऊपन नहीं होता। ये मशीनें निम्न गुणवत्ता वाली सामग्रियां, कम उन्नत तकनीक और कम कठोर परीक्षण एवं प्रमाणीकरण प्रक्रियाओं का उपयोग कर सकती हैं, जो उच्च रखरखाव लागत, डाउनटाइम और सुरक्षा जोखिमों का कारण बन सकती हैं। इसके अलावा, सामान्य मशीनों में समर्पित ग्राहक सहायता या स्पेयर पार्ट्स की उपलब्धता नहीं होती, जिससे खराबी के मामले में मशीन की मरम्मत या रखरखाव कठिन हो जाता है।

इसलिए, रोलर मशीन चुनते समय, कीमत और विशेषताओं के अलावा ब्रांड प्रतिष्ठा और ग्राहक सहायता पर विचार करना आवश्यक है। प्रतिष्ठित ब्रांड में निवेश प्रारंभिक रूप से अधिक लागत वाला हो सकता है, लेकिन यह लंबे समय में विश्वसनीय और कुशल प्रदर्शन, न्यूनतम डाउनटाइम और उत्कृष्ट ग्राहक सेवा सुनिश्चित करके धन और समय की बचत कर सकता है।

बाजार मांग और प्रतिस्पर्धा

辊压机市场当前状况因地区与行业而异,但整体近期价格波动值得企业在采购时注意。

हाल की मूल्य उतार-चढ़ाव को बढ़ावा देने वाला एक कारक वैश्विक COVID-19 महामारी है। महामारी ने आपूर्ति श्रृंखलाओं और विनिर्माण प्रक्रियाओं को बाधित किया है, जिससे उत्पादन लागत बढ़ी है और आपूर्ति घटी है। इससे मशीन कीमतें बढ़ गई हैं, विशेष रूप से महामारी से बुरी तरह प्रभावित क्षेत्रों में।

市场竞争也影响近期波动。在制造商集中的地区,激烈竞争往往导致价格降低。而在制造商较少的地区,缺乏竞争可能推高价格。

原材料成本仍是辊压机价格重要因素。近年钢、铝和橡胶成本上涨,推动制造成本上升。此外,供应链中断与贸易紧张加剧原材料价格波动,进而影响机器价格。

建筑行业因多地建设活动增加,对辊压机需求高涨,推动价格上涨,尤其在快速增长地区。相比之下,农业行业需求下降,导致部分地区价格降低。

最后,全球经济前景也影响机器市场。贸易政策不确定性、政治不稳和经济复苏步伐均可能波及机器价格。

इन कारकों और उनके आपसी संबंधों को समझने से व्यवसायों को रोलर मशीनों की खरीदारी के बारे में सूचित निर्णय लेने में मदद मिल सकती है।

रोलर मशीन मूल्य बनाम गुणवत्ता: सही संतुलन ढूंढना

When considering purchasing a roller machine, it is crucial to balance price and quality. While a lower-priced machine may seem like a good value in the short term, it may result in long-term costs if it lacks quality and durability. Here are some reasons why it is important to balance price and quality:

- Durability: A roller machine that is constructed with high-quality materials will be more durable and require less maintenance over time. Investing in a higher-priced machine that lasts longer can ultimately result in lower long-term costs.

- Precision: High-quality roller machines are typically more precise and accurate than lower-priced machines. A machine that produces consistent and precise parts will reduce waste and improve product quality, which can result in cost savings over time.

- Efficiency: Higher-priced machines may have advanced automation features that can increase efficiency and reduce labor costs. A machine that can produce parts more quickly and with less human intervention will ultimately result in lower production costs.

- Long-term Cost Savings: Investing in a higher-priced machine can result in long-term cost savings due to its durability, precision, and efficiency. While a lower-priced machine may seem like a good value in the short term, it may result in higher maintenance costs or the need for replacement sooner than a higher-priced machine.

In conclusion, balancing price and quality when selecting a roller machine is crucial to ensure that you get the best value for your investment. While it may be tempting to select a machine based solely on its price, considering the quality and durability of the machine can ultimately result in long-term cost savings. By investing in a machine that is durable, precise, and efficient, you can streamline your production processes and maximize your return on investment.

रोलर मशीन मूल्य प्रवृत्तियाँ: आने वाले वर्षों में क्या अपेक्षा करें

机器价格未来展望取决于全球经济状况、供需、生产成本、市场竞争和新技术的诸多因素。以下是可能影响未来机器价格的情景与因素:

- 经济复苏:随着全球经济从 COVID-19 影响中复苏,机器需求可能增加,推动价格上涨。但复苏速度与潜在经济中断可能导致供需波动与价格变动。

- 原材料成本:钢、铝和橡胶等原材料成本将继续影响机器价格。未来原材料价格波动将波及生产成本,并进而影响机器价格。

- 技术进步:电动辊压机等新兴技术可能为制造商带来成本节约,推动价格下降。但新技术初始投资可能短期内增加生产成本,导致价格上涨。

- 市场竞争:更多制造商进入市场将加剧竞争,导致价格降低。但制造商较少的地区价格可能因竞争有限而维持高位。

- 行业特定因素:建筑、农业和采矿等行业独特需求模式可能影响机器价格。例如,基础设施支出增加可能推高建筑行业机器需求与价格。

- 环境法规:对环境可持续性的日益重视可能影响燃油驱动机器的生产成本,导致传统机器价格上涨,同时增加对电动机器等环保替代品的需求。

总体而言,机器价格未来展望不确定,受多因素影响。但企业可通过关注新兴趋势与市场状况做出明智采购决策。

रोलर मशीन कीमतें: सर्वोत्तम सौदे कहाँ प्राप्त करें

रोलर मशीन कीमतों की तुलना

比较压路机价格时,企业应考虑以下因素:

- 产品特性:比较每家制造商或供应商提供的特性,以识别最适合自身需求的压路机。

- 价格:比较价格,以识别满足需求的最实惠选项。

- 保修:评估 保修 每家制造商或供应商提供的保修,以确保免受制造缺陷的影响。

- 售后支持:评估每家供应商提供的售后支持质量,以确保购买后获得必要支持与协助。

- 交付时间:比较每家制造商或供应商的交付时间,以确保按需收到压路机。

通过在比较压路机价格时考虑这些因素,企业能够做出明智的采购决策,并找到满足需求的的最佳交易。

रोलर मशीन कीमतों पर बातचीत करना

与制造商和供应商谈判压路机价格,是企业节省资金并获取最佳投资价值的有效方式。以下是有效谈判的几点建议:

- 了解压路机的市场价值:在谈判前,企业应研究感兴趣压路机的市场价值。这将帮助它们更好地理解合理价格,并从强势立场进行谈判。

- 设定明确预算:企业在谈判前应设定清晰预算。这有助于它们专注于财务目标,避免在不必要特性上超支。

- 与供应商保持积极关系:与供应商维持积极关系对成功谈判至关重要。企业应清晰传达需求,并乐于妥协,以建立信任并保持良好关系。

- 准备好放弃谈判:如果供应商不愿满足需求,企业应准备好终止谈判。这将展示它们对获取最佳交易的决心,并可能促使供应商提供更优惠条件。

- 捆绑采购:企业若从同一供应商购买多台压路机或其他设备,通常能谈判出更低价格。捆绑采购有助于企业节省资金并加强与供应商的关系。

- 评估融资选项:在谈判价格时,企业还应考虑融资选项。它们可与供应商谈判融资条款,以降低压路机的初始采购成本。

谈判压路机价格可能具有挑战性,但遵循这些建议,企业能够有效谈判并节省采购资金。

रोलर मशीन खरीदने के लिए वित्तपोषण विकल्प

在为压路机采购融资方面,企业有多种选择。以下是最常见的融资选项及其优缺点:

- 租赁:租赁允许企业租用压路机一段时间,通常为12-36个月。租赁期结束时,企业可选择归还设备、延长租赁或以减价购买机器。租赁的优势包括较低的前期成本、税收优惠以及定期升级设备的灵活性。缺点包括因利息支付导致的总成本较高,且租赁期结束时企业不拥有设备。

- 分期付款计划:分期付款计划允许企业分期支付辊压机费用,通常需支付利息。付款额分摊于特定期限,通常为 12-60 个月。分期付款的优势在于可延长支付周期,且付款完成后企业即拥有设备。缺点包括因利息导致总成本增加,以及企业需自行承担维护与维修责任。

- 贷款:企业贷款允许企业借入特定金额资金用于购买辊压机,需分期偿还,通常附带利息。贷款优势包括可一次性购置设备、企业拥有设备所有权,以及潜在的税务优惠。缺点包括利息导致总成本上升,以及申请需提供担保品并具备良好信用记录。

通过评估这些选项,企业可选择最符合自身需求与预算的融资方式,用于购买辊压机。