Introduction to Roll Forming

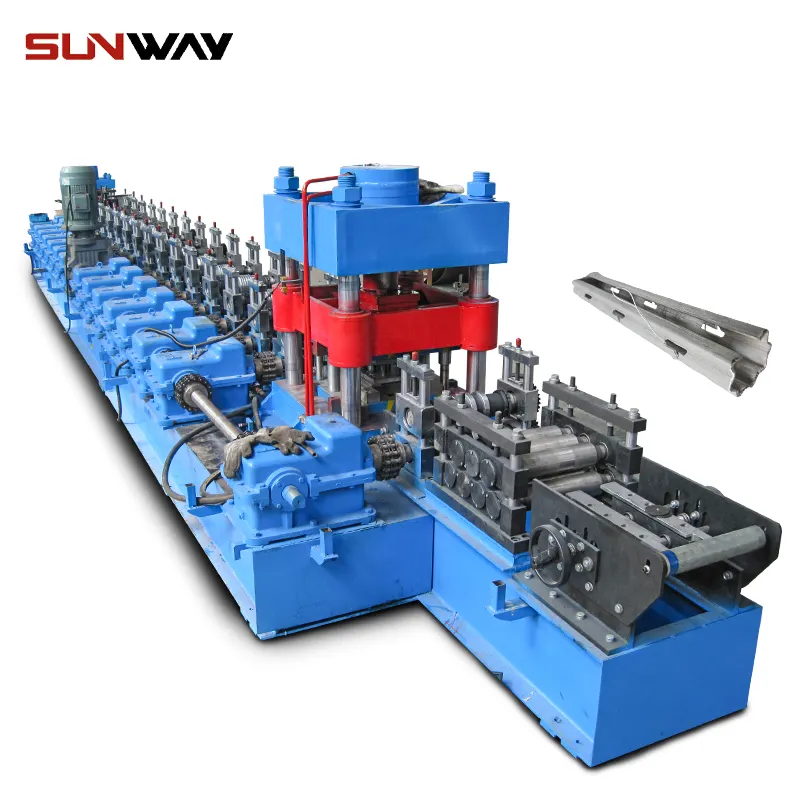

Roll forming shapes metal into specific profiles. A long metal strip is fed through rollers in the machine, gradually forming the desired shape.

Basic components include entry, forming, cut-off, and exit sections. The entry guides the strip for consistent width and thickness. Forming shapes it via rollers. Cut-off severs to length, and exit collects the product.

After forming, the piece is cut to length in the cut-off section, then exits for collection and packaging.

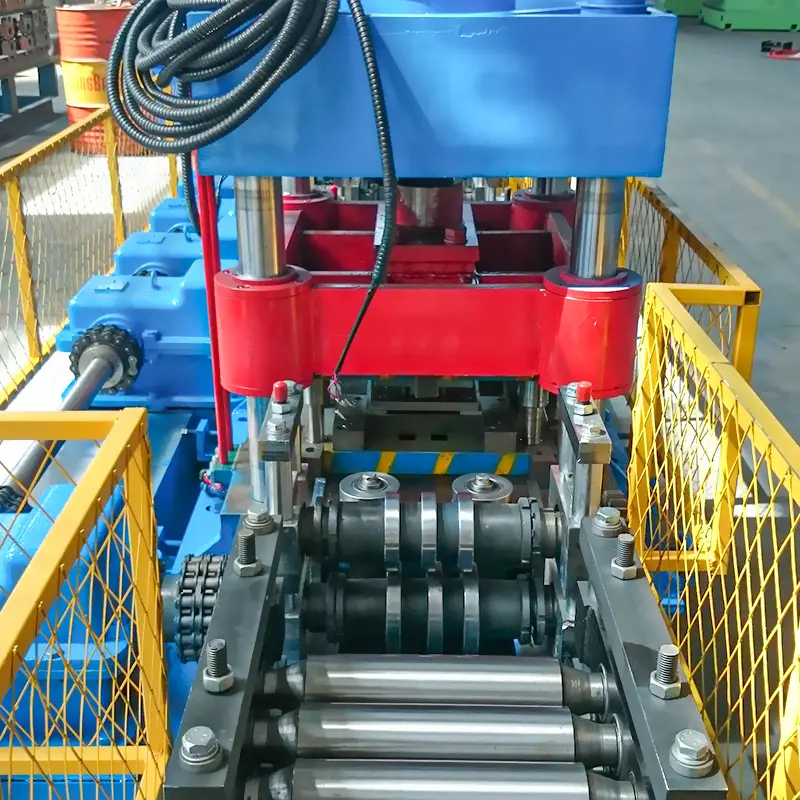

Custom rollers, working in pairs, determine the profile by applying pressure and support.

Roll forming’s versatility produces diverse profiles with consistent quality, ideal for many industries.

रोल बनाने की मशीन के प्रकार

-

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन -

दीन रेल रोल बनाने की मशीन

दीन रेल रोल बनाने की मशीन -

केबल सीढ़ी रोल बनाने की मशीन

केबल सीढ़ी रोल बनाने की मशीन -

पीवी माउंटिंग ब्रैकेट सी शेप प्रोफाइल रोल बनाने की मशीन

पीवी माउंटिंग ब्रैकेट सी शेप प्रोफाइल रोल बनाने की मशीन -

केबल ट्रे रोल बनाने की मशीन

केबल ट्रे रोल बनाने की मशीन -

पीवी माउंटिंग ब्रैकेट रोल बनाने की मशीन (एचएटी / ओमेगा प्रोफाइल)

पीवी माउंटिंग ब्रैकेट रोल बनाने की मशीन (एचएटी / ओमेगा प्रोफाइल) -

पीवी माउंटिंग ब्रैकेट जेड शेप प्रोफाइल रोल बनाने की मशीन

पीवी माउंटिंग ब्रैकेट जेड शेप प्रोफाइल रोल बनाने की मशीन -

सौर बढ़ते अकड़ चैनल रोल बनाने की मशीन

सौर बढ़ते अकड़ चैनल रोल बनाने की मशीन -

स्ट्रट चैनल रोल बनाने की मशीन

स्ट्रट चैनल रोल बनाने की मशीन

रोल बनाने की मशीनें Roll forming machines come in various types tailored to production needs. Main types include:

Single-Level Roll Forming Machines: Produce one profile at a time; ideal for simple shapes or low-volume runs.

Duplex Roll Forming Machines: Produce two profiles simultaneously for greater efficiency.

Triplex Roll Forming Machines: Produce three profiles at once, handling wider ranges.

Multi-Level Roll Forming Machines: Produce multiple profiles with four or more tooling levels; suited for high-volume, complex work.

Differences lie in tooling levels and simultaneous profiles. Single-level are simplest and cheapest but limited; others boost efficiency at higher cost. multi-level machines offer more profiles at once, enhancing efficiency.

Select based on material, part complexity, output volume, budget, and needs.

Roll Forming Machine Components

Main components: entry, forming, cut-off, exit. Overview:

Entry Section: Feeds and straightens strip via uncoiler, rollers, leveler.

Forming Section: Shapes strip through sequential rollers applying precise bends.

Cut-Off Section: Shears or saws to length.

Exit Section: Conveys finished parts for packaging.

Sections collaborate: forming shapes progressively, cut-off sizes, exit handles output.

Applications of Roll Forming Machines

Used across industries; examples in automotive, construction, HVAC:

Automotive: Bumpers, rails, beams, chassis from high-strength steel.

Construction: Panels, framing, gutters from galvanized steel/aluminum.

HVAC: Ducts, vents, components from galvanized/stainless steel.

Valued for consistent, accurate parts meeting standards.

Also for furniture, lighting, consumer goods; versatile for efficiency.

In conclusion, diverse types serve automotive, construction, HVAC with efficiency and versatility. Informed selection enhances manufacturing.

Frequently Asked Questions (FAQ)

- What materials can a roll forming machine process?

- Common: galvanized steel, cold-rolled steel, stainless steel, aluminum, copper. Advanced lines in 2025 also handle high-strength steels (800–1180 MPa) and pre-painted coils with scratch-resistant guides.

- How is roll forming different from press braking or extrusion?

- Roll forming is continuous and best for long, consistent profiles with tight tolerances and high throughput. Press brakes suit short runs and simple bends; extrusion is for non-ferrous metals and complex hollow shapes but with different mechanical properties.

- What factors determine the number of forming stations?

- Profile complexity, material yield strength, thickness, desired line speed, and surface finish. As a rule of thumb: 0.8–1.2 stations per bend feature for mild steel; add ~20–30% for AHSS.

- How do I calculate required motor power for a roll forming line?

- Power ≈ (Forming force × strip speed × safety factor) ÷ efficiency. Vendors often estimate from profile geometry and material properties; include 15–25% reserve for acceleration and cut-off cycles.

- What QA methods are standard in modern roll forming?

- In-line laser profile measurement, vision systems for hole/slot inspection, torque monitoring per stand, SPC charts on critical dimensions, and periodic coupon tensile or hardness tests.

2025 Industry Trends for Roll Forming Machines

- Shift to high-strength and ultra-high-strength steel (UHSS) profiles for automotive lightweighting with springback compensation built into digital tooling.

- Adoption of AI-driven closed-loop quality control (vision + laser scanning) reducing scrap by 10–25% in high-volume lines.

- Faster changeovers via cassette/tooling cart systems and servo-adjustable stands; typical changeover times now 15–30 minutes for C/Z channels.

- Integration of roll forming with downstream punching, welding, and packaging cells to create single-pass “coil-to-box” lines.

- Increased demand for solar PV mounting hardware, EV battery enclosure components, and data center cable management profiles.

- Energy efficiency upgrades: regenerative drives and variable-frequency motors cut energy use by 8–15% per line.

- Standards and safety: growth in ISO 21920 (profile tolerancing) adoption and enhanced CE/OSHA-compliant guarding with light curtains.

2025 Market Snapshot and Benchmarks

| Metric (2025) | Value/Range | Notes/Source |

|---|---|---|

| Global roll forming equipment market size | ~$8.6–9.2B | Industry analyst consensus (2025) from Grand View Research, MarketsandMarkets |

| CAGR forecast (2025–2030) | 6–7% | Driven by construction, PV mounting, automotive UHSS |

| Typical line speed (construction panels) | 30–80 m/min | With integrated punching up to 50 m/min |

| Typical line speed (automotive structural) | 10–30 m/min | Tighter tolerances, thicker/high-strength steels |

| Scrap reduction via in-line AI inspection | 10–25% | Vendor case data (Keyence, Cognex deployments) |

| Average changeover time (cassette tooling) | 15–30 min | For C/Z channel systems |

| Energy savings (regen drives/VFDs) | 8–15% | OEM energy audits (2023–2025) |

Citations:

- MarketsandMarkets, “Roll Forming Machine Market—Forecast to 2030” (2025)

- Grand View Research, “Metal Forming Machine Tools Market” (2025)

- Keyence and Cognex application notes on in-line profile and defect inspection (2024–2025)

Latest Research Cases

Case Study 1: AI-Guided Closed-Loop Roll Forming for AHSS Door Beams (2025)

- Background: An automotive Tier-1 supplier needed to form 980 MPa AHSS door intrusion beams with ±0.3 mm tolerance while reducing scrap.

- Solution: Implemented laser profile scanners, camera-based edge tracking, and a machine-learning controller that adjusted stand gaps/angles in real time. Upgraded to servo-driven stands and added predictive tool wear analytics.

- Results: Scrap rate cut from 8.7% to 2.9%; Cp/Cpk improved from 1.11/1.02 to 1.52/1.43; overall equipment effectiveness (OEE) increased by 11%. Energy per part reduced 9% due to adaptive speed control.

Case Study 2: Coil-to-Rack Cable Tray Line with 18-Min Changeovers (2024)

- Background: An electrical infrastructure manufacturer faced short-run variability across cable tray widths and perforation patterns.

- Solution: Deployed a duplex roll forming machine with quick-change cassettes, servo hole punching, and automated recipe management tied to ERP.

- Results: Changeover time dropped from 55 minutes to 18 minutes; throughput up 22%; first-pass yield rose from 93% to 98.5%. Inventory of WIP reduced by 30% through schedule-driven recipes.

Expert Opinions

- Dr. Taylan Altan, Professor Emeritus and Director, ERC for Net Shape Manufacturing (The Ohio State University)

- Viewpoint: “For UHSS roll forming, control of incremental strain and stand alignment is paramount. Springback compensation must be designed into tooling and validated by simulation before first coil.”

- Source: ERC/NSM technical notes and conference presentations (2024–2025)

- Mark Thompson, VP Engineering, Formtek Group

- Viewpoint: “Quick-change cassettes and servo-adjustable tooling have turned high-mix C/Z production into a competitive advantage—if paired with standardized coil data and digital setup sheets.”

- Source: Formtek webinars and application briefs (2025)

- Dr. Zhiming Wang, Senior Materials Engineer, WorldAutoSteel

- Viewpoint: “980–1180 MPa steels are mainstream in 2025 chassis and BIW components; roll forming excels when combined with in-line hole expansion management and edge quality control.”

- Source: WorldAutoSteel technical releases (2024–2025)

Practical Tools and Resources

- COPRA RF (Data M / UBECO): Roll forming design, flower pattern development, and stress analysis

- https://www.ubeco.com

- FormingSuite by FTI: Material utilization and cost modeling for metal forming

- https://www.forming.com

- MSC Simufact Forming: Process simulation for roll forming and metal forming

- https://www.mscsoftware.com/product/simufact-forming

- Keyence LJ-V and Cognex 3D-A1000: In-line profile and defect inspection systems

- https://www.keyence.com and https://www.cognex.com

- WorldAutoSteel AHSS Guidelines: Material data and forming guidance for high-strength steels

- https://www.worldautosteel.org

- ISO Standards

- ISO 21920 (Geometrical product specifications—surface texture)

- ISO 12100 (Machine safety—risk assessment)

- https://www.iso.org

- OSHA Machine Guarding eTool (for U.S. compliance)

- https://www.osha.gov/etools/machine-guarding

Last updated: 2025-10-21

Changelog: Added FAQ, 2025 trends with data table, two recent case studies, expert opinions with sources, and practical tools/resources aligned to roll forming machine selection and operation

Next review date & triggers: 2026-04-21 or earlier if new UHSS grades or AI QC standards are released, or if PV mounting hardware standards (UL/IEC) update impacting profile tolerances