परिचय

Pallet Rack Roll Forming Machines essential for organizing and storing goods in warehouses and distribution centers. Designed for efficiency, they produce pallet racking systems that provide optimal storage solutions across industries. This article explores pallet rack roll forming machines, their advantages, types, selection criteria, installation and maintenance procedures, and leading manufacturers.

Understanding Pallet Rack Roll Forming Machines

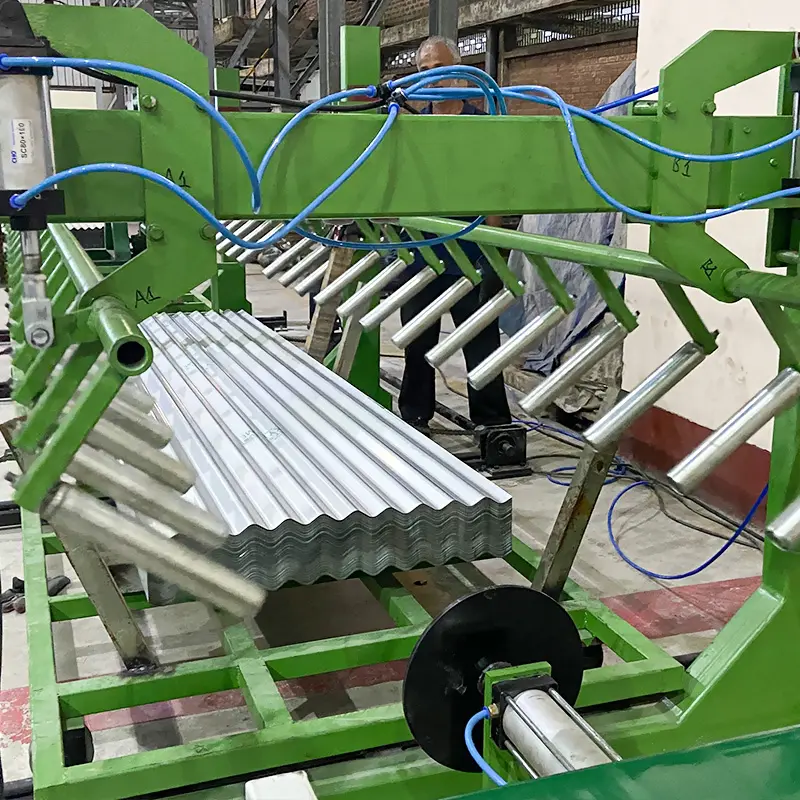

Pallet rack roll forming machines are specialized equipment for manufacturing pallet racking systems. Employing roll forming technology, they feed flat metal coils through sequential rollers to create precise profiles, which are then cut, punched, and assembled into components like uprights, beams, and connectors.

This roll forming process surpasses traditional methods with superior precision, uniformity, and cost efficiency. These machines produce high volumes of racking parts with minimal waste and exceptional accuracy.

Benefits of Pallet Rack Roll Forming Machines

बढ़ी हुई दक्षता

Pallet rack roll forming machines significantly enhance manufacturing efficiency. Through their automated features, these machines deliver consistent, precise racking components at high speeds. Automation reduces dependence on manual labor, minimizing errors and boosting productivity.

定制选项

A key advantage of pallet rack roll forming machines is their capacity for customization. They produce racking components in diverse sizes, shapes, and configurations, enabling businesses to adapt storage systems to precise needs. Whether adjusting beam lengths or incorporating extra connectors, their versatility optimizes warehouse space utilization.

耐用性和强度

Pallet rack roll forming machines yield racking components of superior durability and strength. The roll forming process compacts the metal, enhancing load-bearing capacity and resistance to bending or warping. This robustness ensures safe, secure storage of goods under heavy loads.

High speed for volume.

Investing in a pallet rack roll forming machine delivers substantial long-term cost savings. Engineered for high-volume output, these machines lower per-unit production costs. The precision and uniformity of roll forming also curb material waste, trimming expenses further. Moreover, the longevity of the components reduces maintenance and replacement costs over time.

Types of Pallet Rack Roll Forming Machines

Various types of pallet rack roll forming machines are available, each tailored to specific storage needs. Here are some common varieties:

Selective Pallet Rack Roll Forming Machines

Selective pallet rack roll forming machines are prevalent across industries. They manufacture standard pallet racking systems that provide individual access to each pallet. Ideal for warehouses managing diverse SKUs, they facilitate straightforward pallet retrieval.

Drive-In Pallet Rack Roll Forming Machines

Drive-in pallet rack roll forming machines suit high-density storage. Forklifts enter the racks directly, eliminating aisles and maximizing space, though selectivity is limited by last-in, first-out (LIFO) retrieval.

Push Back Pallet Rack Roll Forming Machines

Push-back pallet rack roll forming machines excel in high-density storage with selectivity. Employing gravity flow, pallets load onto nested carts on inclined rails; removing one advances the next automatically.

Cantilever Pallet Rack Roll Forming Machines

Cantilever pallet rack roll forming machines produce cantilever racks for long, bulky items like pipes, lumber, and steel bars. Featuring arms extending from uprights, they offer easy access and loading flexibility.

Factors to Consider When Choosing a Pallet Rack Roll Forming Machine

Selecting a pallet rack roll forming machine requires evaluating key factors to match specific needs. Key considerations include:

Required Load Capacity

Load capacity depends on material thickness and quality. Select a machine producing components that safely bear expected loads.

Warehouse Space and Layout

Warehouse dimensions and layout dictate rack type and size. Ceiling height, aisle width, and capacity needs guide machine selection.

Product Dimensions and Weight

Product size and weight inform efficient storage design. The machine must produce compatible racking components.

Material Handling Equipment Compatibility

Ensure compatibility with forklifts and reach trucks for seamless goods movement.

Fitur Keselamatan

Prioritize safety with features like reinforced bases, secure beams, and load distribution for system stability.

Budget Considerations

Balance budget with machine cost, installation, training, and maintenance. Weigh long-term ROI.

Installation and Maintenance of Pallet Rack Roll Forming Machines

Proper installation and maintenance ensure efficient, safe operation. Overview of processes:

स्थापना प्रक्रिया

Installation begins with a sturdy, level foundation, followed by assembly per manufacturer guidelines: main frame, rollers, electrical, and hydraulics. Final testing and adjustments confirm functionality.

Regular Maintenance and Inspections

Routine upkeep sustains peak performance: inspections, cleaning, lubrication, and calibration per manufacturer schedules.

Inspect rollers, guides, and cutters for wear, damage, or misalignment. Clean to remove debris, dust, and shavings.

Lubricate per guidelines to minimize friction. Regularly calibrate roll gaps and cut lengths for precision.

Troubleshooting and Repairs

Systematically diagnose issues: check connections, damage, noises, or vibrations. Consult manual or manufacturer.

Engage qualified technicians for repairs to avoid risks. Proactive maintenance prevents downtime and expenses.

निष्कर्ष

Pallet rack roll forming machines are vital for efficient, economical storage in warehouses and distribution centers. Grasping benefits, types, selection factors, installation, and maintenance maximizes their value.

The right machine streamlines operations, boosts productivity, and elevates warehouse efficiency. Prioritize load capacity, layout, specs, safety, and cost-effectiveness.

Research reputable manufacturers for tailored solutions. Routine maintenance ensures optimal performance and minimal disruptions.

常见问题解答

1. Are pallet rack roll forming machines suitable for all industries?

Versatile for warehousing, logistics, manufacturing, retail, and beyond, they offer customizable storage.

2. Can pallet rack roll forming machines accommodate different sizes of pallets?

Yes, they customize components for various pallet sizes.

3. How long does it take to install a pallet rack roll forming machine?

Time varies by complexity and site readiness, typically days to weeks. Consult manufacturer for estimates.

4. What safety features should I look for in a pallet rack roll forming machine?

Seek reinforced bases, secure connections, load distribution, sensors, and guards.

5. Can I retrofit an existing pallet rack system with a roll forming machine?

Generally for new components; consult experts for retrofit feasibility.