Pipe selection challenges new businesses; this explores pipe roll forming machine operations and uses.

什么是管材辊压成型机?

ए 管材辊压成型机 是一种用于成型管材卷的设备。管材卷是用于各行业传输流体和气体的金属管件。该机通过一系列模具创建所需的管材卷形状。

管材辊压成型机是创建定制或特定管材形状的理想选择。它可用于生产各种部件,如集管和集管组件、法兰及其他零件、弯头及三通等。

How does a pipe roll forming machine work?

A pipe roll forming machine is used to create pipe rolls. The machine features two rolls mounted on a rotating frame. These rolls are connected by a series of bars extending between them. As the frame rotates, the bars cause the rolls to move around and form the desired shape. This process produces pipes, tubes, and other small shapes from metal sheets.

The pipe roll forming machine is an essential tool in producing custom-made pipes and tubes. It is commonly used to create pipes for water, gas, and oil pipelines. Additionally, it produces other small round objects, such as caps and buttons.

The main reason why pipe रोल बनाना machines are so popular is their extreme versatility. They can produce a wide variety of shapes and sizes. Moreover, they are relatively easy to operate and maintain.

-

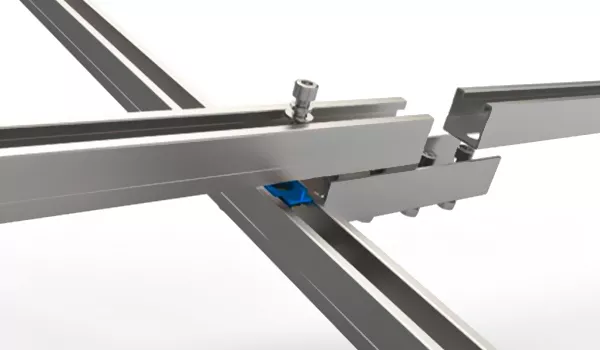

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line -

डाउनस्पॉट पाइप रोल बनाने की मशीन

डाउनस्पॉट पाइप रोल बनाने की मशीन -

梯形板滚压成型机

梯形板滚压成型机 -

रूफ टाइल पैनल रोल बनाने की मशीन

रूफ टाइल पैनल रोल बनाने की मशीन -

शेल्फ कॉलम के लिए बॉक्स बीम स्टील रोल बनाने की मशीन

शेल्फ कॉलम के लिए बॉक्स बीम स्टील रोल बनाने की मशीन -

समलम्बाकार पैनल रोल बनाने की मशीन

समलम्बाकार पैनल रोल बनाने की मशीन -

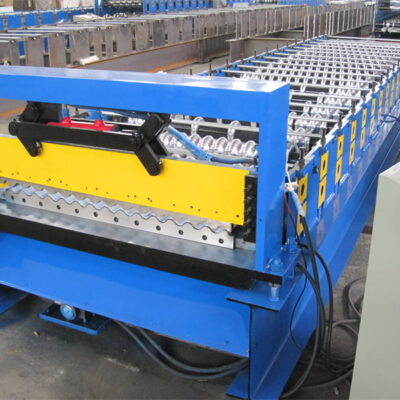

रूफ पैनल डबल लेयर मशीन丨टाइल और

रूफ पैनल डबल लेयर मशीन丨टाइल और -

रूफ टाइल रोल बनाने की मशीन

रूफ टाइल रोल बनाने की मशीन -

डाउनपाइप रोल बनाने की मशीन

डाउनपाइप रोल बनाने की मशीन

Why is it used?

The pipe roll forming machine is specialized equipment that forms smooth, round pipes from metal sheet stock. It employs rotating drums to deform the metal sheet into the desired shape, then returns it to form as it progresses along the drums.

The pipe roll forming machine offers numerous advantages over other pipe production methods. The process is straightforward and rapid. The finished products are highly precise and uniform, ensuring identical size and shape for each pipe. Furthermore, its ability to produce multiple pieces simultaneously suits tasks like fabricating large piping sections or complex shapes unattainable by other means.

Types of pipe roll forming machines

Pipe roll forming machines produce pipes, tubes, and hoses using a rotating mandrel to achieve the desired shape. The three primary types are hydraulic, pneumatic, and contact.

Hydraulic pipe roll forming machines use hydraulic pressure to shape the pipe. They feature a large pressurized chamber that forces the metal around the rotating mandrel. Pneumatic models employ air pressure similarly, with a smaller chamber achieving the same effect. Contact machines rely on metal-on-metal friction, where two metal pieces rotate together to form the shape.

Why should you invest in a roll forming machine?

Roll forming machines are highly versatile tools suitable for diverse applications. They can form pipes of virtually any diameter, from small to large. Key reasons to invest include:

- Speed and efficiency: These machines rapidly produce large quantities of pipe, ideal for high-volume needs.

- Versatility: They adapt to various applications, perfect for producing multiple pipe types.

- Durability: Built to withstand heavy use, ensuring long-term reliability.

निष्कर्ष

As manufacturing shifts toward automation, pipe roll forming machines will play a key role in streamlining production. They reduce time for complex parts or enable custom designs impossible with traditional methods. To explore their potential impact on your business, read on.

सामान्य प्रश्न

What are the applications for roll forming?

Common roll forming applications/products: door and window hardware, metal fencing, computer casings and components, metal furniture components, rain gutters and house siding, desk drawer slides, steel support framing, metal tubing.