Customizing metal production is essential for businesses across various industries to meet unique production needs and maintain competitiveness. रोल बनाने की मशीनें Roll forming machines are versatile tools for custom metal production, providing numerous customization options that benefit businesses in many ways. In this post, we explore the advantages of customizing metal production with a roll forming machine, including available options, key benefits, and diverse applications. Let’s dive in.

Understanding Roll Forming Machines

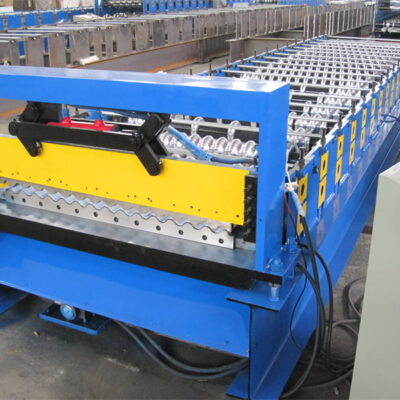

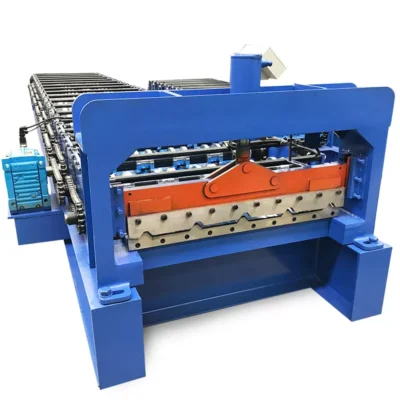

Roll forming machines are vital equipment for custom metal fabrication. They process various metals, such as steel, aluminum, copper, and brass, typically supplied in coils that are fed into the machine.

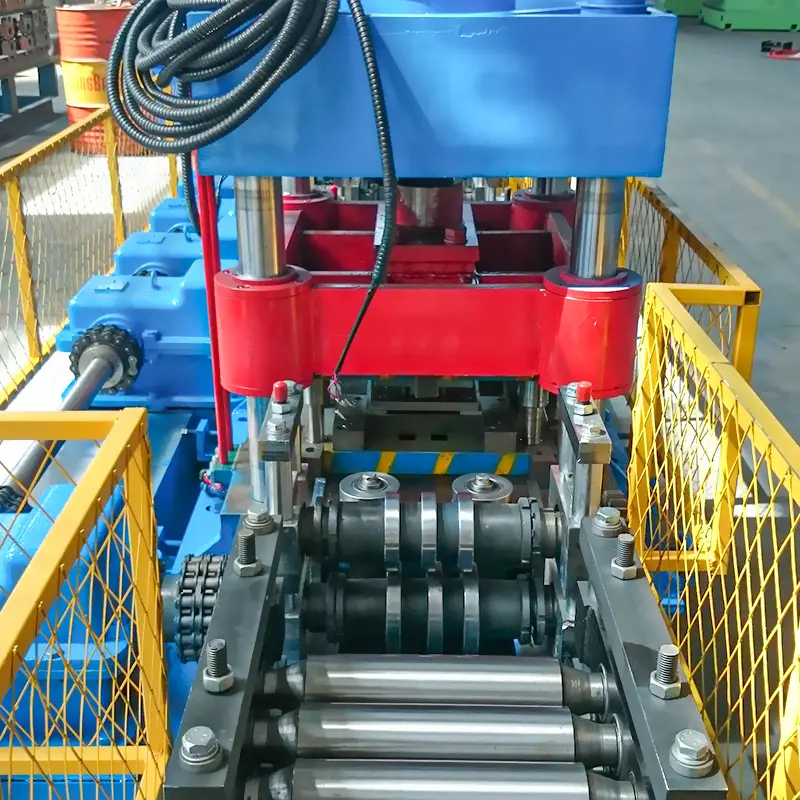

These machines employ a continuous process to shape metal into precise profiles. The material passes through a series of rollers that progressively bend and form it to the required specifications. The rollers are often custom-engineered for specific product shapes and dimensions.

Roll forming machines provide numerous advantages for custom metal fabrication, including:

- High efficiency: These machines produce metal profiles rapidly and effectively, making them perfect for large-scale production.

- Precision: They deliver metal profiles with exceptional accuracy and uniformity, guaranteeing compliance with exact specifications.

- Reduced waste: By utilizing the minimal material necessary for the desired profile, these machines significantly cut down on scrap.

- Versatility: Capable of creating diverse metal profiles, they suit a broad array of industries and uses.

- Cost-effectiveness: Compared to alternative forming techniques, they yield substantial savings through superior efficiency and less waste.

In essence, roll forming machines employ a continuous process to shape metal into precise forms, delivering key benefits for bespoke metal production. They generate profiles swiftly and precisely, with unwavering consistency, while curtailing waste and lowering costs relative to other methods.

Customization Capabilities of Roll Forming Machines

Roll forming machines provide extensive customization options for companies seeking tailored metal profiles. Among the most prevalent are:

- Metal thickness: These machines handle coils of varying thicknesses, enabling profiles customized for specific strength and longevity needs.

- Shape: They craft profiles in diverse forms—flat, curved, round, or bespoke—ideal for unique design demands.

- Size: Ranging from petite and detailed to expansive and intricate, they accommodate precise dimensional requirements.

- Finish: Options include painted, galvanized, or coated surfaces, fulfilling both aesthetic and functional criteria.

- Secondary operations: The machines also execute add-ons such as punching, notching, and welding to meet bespoke specifications.

These customization features grant businesses the adaptability to create tailored metal profiles, fostering innovation, boosting efficiency, and maintaining market edge.

Benefits of Tailoring Metal Production via Roll Forming

Customizing metal output with a roll forming machine yields distinct advantages. Key among them:

- Enhanced efficiency: With rapid, accurate production, these machines slash time and expenses. Tailoring optimizes workflows for peak performance.

- Minimal waste: Precision material use curtails scraps, trimming costs and advancing eco-friendly practices.

- Superior quality: Consistent precision ensures products adhere to stringent standards.

- Cost reductions: Greater efficiency and less waste outperform traditional methods economically.

- Adaptability: Bespoke shapes, sizes, and finishes enable one-of-a-kind solutions.

Tailored production via roll forming confers efficiency gains, waste reduction, quality elevation, savings, and versatility—empowering superior profiles, competitiveness, and sustainability.

Uses for Custom Roll Forming Machines

Custom metal fabrication with roll forming spans construction, automotive, and manufacturing. Notable examples:

- Construction: Employed for roofing, siding, and panels, customization yields innovative, performance-optimized designs.

- Automotive: Produces lightweight, resilient components for bodies, frames, and structures meeting safety norms.

- Manufacturing: Crafts parts for appliances, furniture, and electronics with tailored form, scale, and finish.

A furniture maker, for instance, might fashion unique legs or frames, blending style and utility.

Ultimately, these versatile machines enable bespoke, high-performing products across sectors, driving success.

Roll forming customization boosts efficiency, quality, waste control, savings, and flexibility. Varied options yield innovative profiles for construction, automotive, and manufacturing, delivering excellence.