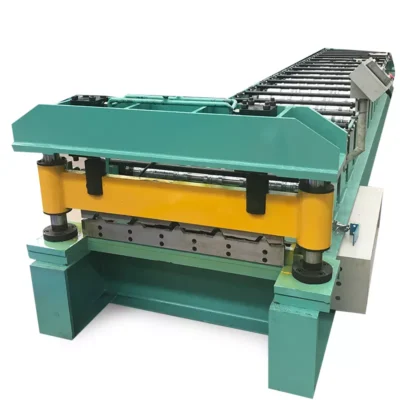

Corrugated sheet roll forming machines ने रूफिंग उद्योग में क्रांति ला दी है, जिससे उच्च गुणवत्ता वाली रूफिंग सामग्री उत्पादित करना पहले से कहीं अधिक सरल तथा लागत प्रभावी हो गया है। इनकी उच्च परिशुद्धता तथा एकरूपता के साथ रूफिंग पैनल उत्पादित करने की क्षमता के कारण, कोरुगेटेड शीट रोल फॉर्मिंग मशीनें रूफिंग निर्माताओं के लिए एक आवश्यक उपकरण बन गई हैं। इस पोस्ट में, हम रूफिंग के लिए कोरुगेटेड शीट रोल फॉर्मिंग मशीनों के लाभों का अन्वेषण करेंगे, उनकी गति तथा दक्षता से लेकर उनकी टिकाऊपन तथा स्थिरता तक। तो आइए रूफिंग निर्माण की दुनिया में उतरें तथा जानें कि ये मशीनें उद्योग के लिए कैसे खेल बदल रही हैं।

कोरुगेटेड शीट रोल फॉर्मिंग मशीनों की परिशुद्धता तथा एकरूपता

रूफिंग के लिए कोरुगेटेड शीट रोल फॉर्मिंग मशीनों का उपयोग करने का एक प्रमुख लाभ उच्च गुणवत्ता वाली रूफिंग सामग्री को उच्च परिशुद्धता तथा एकरूपता के साथ उत्पादित करने की उनकी क्षमता है। कंप्यूटर नियंत्रित प्रौद्योगिकी का उपयोग करके, ये मशीनें पूर्णतः आकारबद्ध तथा आकार की रूफिंग पैनल उत्पादित कर सकती हैं, जिसमें एकसमान कोरुगेशन तथा मोटाई होती है।

यह परिशुद्धता तथा एकरूपता प्रत्येक रूफिंग पैनल को पूर्णतः फिट होने सुनिश्चित करने में महत्वपूर्ण है, जिससे रिसाव तथा अन्य समस्याओं का जोखिम कम हो जाता है जो खराब फिटिंग वाले पैनलों से उत्पन्न हो सकती हैं। इसके अलावा, इन मशीनों द्वारा उत्पादित पैनलों की एकसमान गुणवत्ता प्रत्येक पैनल में समान टिकाऊपन तथा मजबूती सुनिश्चित करती है, जो रूफ की दीर्घायु सुनिश्चित करने तथा मरम्मत तथा प्रतिस्थापन की आवश्यकता कम करने में सहायक हो सकती है।

उच्च परिशुद्धता तथा एकरूपता के साथ उच्च गुणवत्ता वाली रूफिंग सामग्री उत्पादित करके, कोरुगेटेड शीट रोल फॉर्मिंग मशीनें रूफिंग परियोजनाओं की समग्र गुणवत्ता सुधारने में सहायक हैं, समस्याओं का जोखिम कम करती हैं तथा प्रत्येक परियोजना को सर्वोच्च संभव मानक पर पूर्ण करने सुनिश्चित करती हैं। चाहे आप ठेकेदार हों या गृहस्वामी, यह परिशुद्धता तथा एकरूपता निश्चिंतता प्रदान कर सकती है, यह जानते हुए कि आपका रूफ टिकाऊ ढंग से निर्मित है तथा वर्षों तक विश्वसनीय सुरक्षा प्रदान करेगा।

कोरुगेटेड शीट रोल फॉर्मिंग मशीनों की गति तथा दक्षता

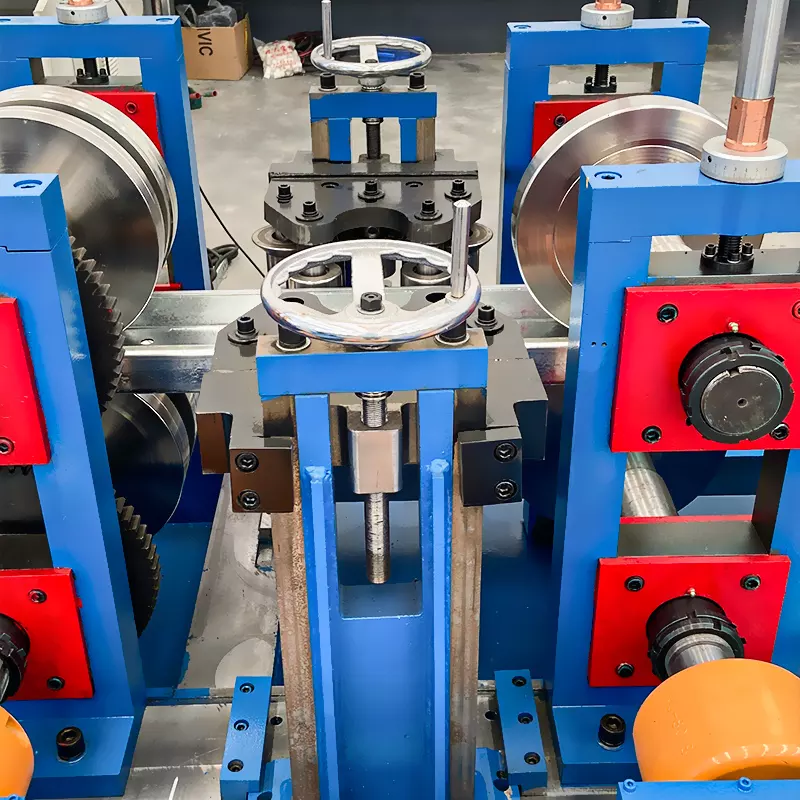

रूफिंग के लिए कोरुगेटेड शीट रोल फॉर्मिंग मशीनों का उपयोग करने का एक अन्य लाभ रूफिंग सामग्री को तीव्रता से तथा दक्षतापूर्वक उत्पादित करने की उनकी क्षमता है। ये मशीनें उच्च गति पर रूफिंग पैनल उत्पादित करने के लिए डिज़ाइन की गई हैं, जिससे निर्माता बड़े ऑर्डर को तीव्रता से तथा दक्षतापूर्वक पूर्ण कर सकते हैं। इससे निर्माण परियोजनाओं को गति मिल सकती है, ठेकेदारों को कार्य तीव्रता से पूर्ण करने तथा अगली परियोजना पर शीघ्र आगे बढ़ने में सहायता मिल सकती है।

रूफिंग पैनल को तीव्रता से तथा दक्षतापूर्वक उत्पादित करके, कोरुगेटेड शीट रोल फॉर्मिंग मशीनें स्थापना के लिए आवश्यक समय को भी कम करने में सहायक हो सकती हैं। एकसमान आकार तथा आकृति वाले रूफिंग पैनलों के साथ, स्थापना अधिक तीव्रता से तथा अधिक परिशुद्धता के साथ पूर्ण की जा सकती है, त्रुटियों तथा गलतियों का जोखिम कम हो जाता है। इससे ठेकेदारों तथा गृहस्वामियों दोनों के लिए समय तथा धन की बचत हो सकती है, साथ ही लंबी निर्माण परियोजनाओं से दैनिक गतिविधियों में होने वाले व्यवधान को भी कम किया जा सकता है।

समग्र रूप से, कोरुगेटेड शीट रोल फॉर्मिंग मशीनों की गति तथा दक्षता उन्हें उन रूफिंग निर्माताओं के लिए आदर्श विकल्प बनाती है जिन्हें उच्च गुणवत्ता वाली रूफिंग सामग्री को तीव्रता से तथा दक्षतापूर्वक उत्पादित करने की आवश्यकता है। चाहे आप ठेकेदार हों या गृहस्वामी, इन मशीनों की गति तथा दक्षता आपकी रूफिंग परियोजना को समय पर तथा बजट में पूर्ण करने में सहायक हो सकती है, आपके दैनिक जीवन में न्यूनतम व्यवधान के साथ।

कोरुगेटेड शीट रोल फॉर्मिंग मशीनों की अनुकूलन क्षमता

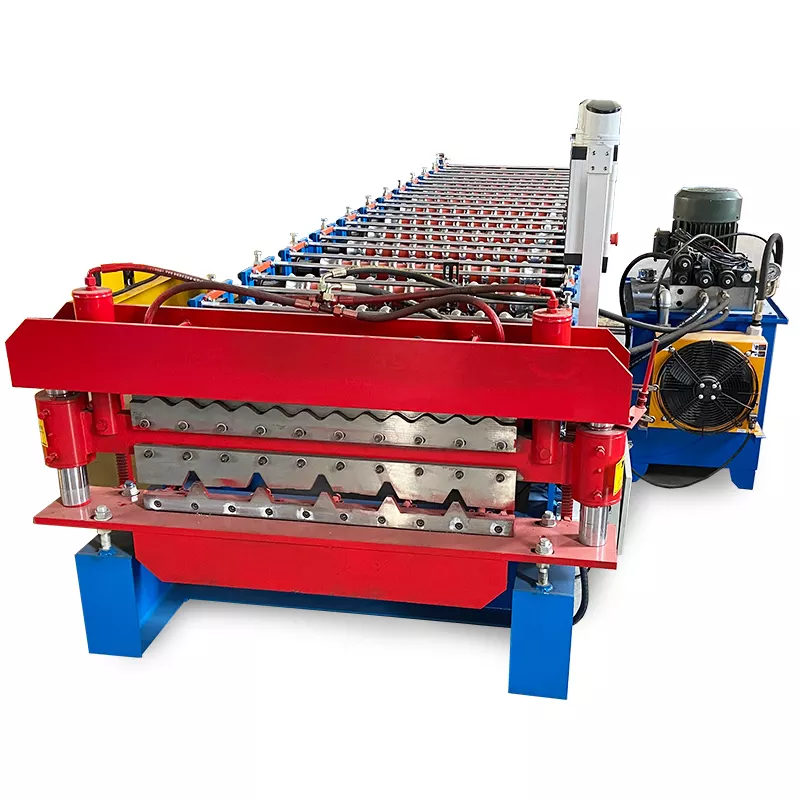

कोरुगेटेड शीट रोल फॉर्मिंग मशीनें अत्यधिक अनुकूल्य हैं, जो निर्माताओं को उनकी परियोजनाओं की विशिष्ट आवश्यकताओं के अनुरूप रूफिंग पैनल बनाने की अनुमति देती हैं। ये मशीनें विविध सामग्रियों, आकारों तथा प्रोफाइलों को समायोजित करने के लिए कॉन्फ़िगर की जा सकती हैं, जिससे ठेकेदार अपनी परियोजनाओं के लिए अद्वितीय रूफिंग पैनल बना सकते हैं।

यह अनुकूलन महत्वपूर्ण है क्योंकि इससे ठेकेदार अपनी परियोजना की आवश्यकताओं के अनुरूप पूर्णतः अनुकूलित रूफिंग पैनल बना सकते हैं। कोरुगेटेड शीट रोल फॉर्मिंग मशीन का उपयोग करके, ठेकेदार सुनिश्चित कर सकते हैं कि वे उत्पादित पैनल उनकी परियोजना के लिए आवश्यक सटीक आकार तथा प्रोफाइल के हों, जिससे साइट पर कटाई तथा ट्रिमिंग की आवश्यकता कम हो जाती है। इससे समग्र परियोजना दक्षता में सुधार होता है, स्थापना के लिए आवश्यक समय तथा श्रम कम होता है तथा अपशिष्ट न्यूनतम हो जाता है।

इसके अलावा, कोरुगेटेड शीट रोल फॉर्मिंग मशीनों का अनुकूलन विभिन्न डिज़ाइन विकल्प प्रदान करता है, जिसमें विभिन्न पैटर्न, रंग तथा फिनिश शामिल हैं। इससे ठेकेदार भवन के समग्र डिज़ाइन के पूरक दृश्य रूप से आकर्षक रूफिंग पैनल बना सकते हैं।

कुल मिलाकर, कॉरुगेटेड शीट रोल फॉर्मिंग मशीनों का अनुकूलन रूफिंग निर्माताओं के लिए एक महत्वपूर्ण लाभ है। अपने प्रोजेक्ट की आवश्यकताओं के अनुरूप सटीक रूप से तैयार किए गए पैनलों का निर्माण करके, ठेकेदार समग्र प्रोजेक्ट दक्षता में सुधार कर सकते हैं, अपशिष्ट को न्यूनतम कर सकते हैं तथा भवन के डिजाइन के अनुरूप आकर्षक रूफिंग प्रणालियाँ तैयार कर सकते हैं।

कॉरुगेटेड शीट रोल फॉर्मिंग मशीनों की लागत प्रभावशीलता

रूफिंग निर्माताओं के लिए कॉरुगेटेड शीट रोल फॉर्मिंग मशीनें अत्यधिक लागत प्रभावी हो सकती हैं। ये मशीनें न्यूनतम श्रम के साथ रूफिंग सामग्री का तीव्र और कुशल उत्पादन करने के लिए डिज़ाइन की गई हैं। इससे श्रम लागत में कमी आती है तथा निर्माताओं की लाभप्रदता बढ़ती है, क्योंकि उच्च गुणवत्ता वाले रूफिंग पैनलों के उत्पादन के लिए कम श्रमिकों की आवश्यकता होती है।

इसके अतिरिक्त, कॉरुगेटेड शीट रोल फॉर्मिंग मशीनों की गति और दक्षता समग्र उत्पादन लागत को कम करने में सहायक होती है। तीव्र और कुशल ढंग से रूफिंग पैनलों का उत्पादन करके, निर्माता बड़े ऑर्डरों को शीघ्र पूरा कर सकते हैं तथा अपशिष्ट को कम कर सकते हैं, जिससे सामग्री की लागत घटती है और समग्र लाभप्रदता में वृद्धि होती है।

इसके अलावा, कॉरुगेटेड शीट रोल फॉर्मिंग मशीनों द्वारा उत्पादित रूफिंग पैनलों की सुसंगत गुणवत्ता मरम्मत और प्रतिस्थापन की लागत को कम करने में मदद करती है, क्योंकि ये पैनल दोषों या त्रुटियों के कारण रखरखाव या प्रतिस्थापन की कम आवश्यकता रखते हैं।

कुल मिलाकर, कॉरुगेटेड शीट रोल फॉर्मिंग मशीनों की लागत प्रभावशीलता उन्हें उच्च गुणवत्ता वाली रूफिंग सामग्री का कुशल और किफायती उत्पादन करने वाले रूफिंग निर्माताओं के लिए आदर्श विकल्प बनाती है। श्रम लागत में कमी, उत्पादन दक्षता में सुधार तथा मरम्मत और प्रतिस्थापन की आवश्यकता में कमी लाकर, ये मशीनें निर्माताओं की लाभप्रदता बढ़ाने तथा उपभोक्ताओं के लिए लागत घटाने में सहायक होती हैं।

कॉरुगेटेड शीट रोल फॉर्मिंग मशीनों की टिकाऊपन और दीर्घायु

कॉrugेटेड शीट रोल फॉर्मिंग मशीनें असाधारण रूप से टिकाऊ और लंबे समय तक चलने वाली छत सामग्री का उत्पादन कर सकती हैं। ये मशीनें ऐसी छत पैनलों का निर्माण करने के लिए डिज़ाइन की गई हैं जो कठोर मौसम की स्थितियों, चरम तापमानों और अन्य पर्यावरणीय कारकों का सामना कर सकें, भवनों के लिए वर्षों तक विश्वसनीय सुरक्षा प्रदान करें।

इसके अतिरिक्त, उच्च-गुणवत्ता वाली सामग्रियों और उन्नत विनिर्माण प्रक्रियाओं का उपयोग करके,

स्थिरता और कॉrugेटेड शीट रोल फॉर्मिंग मशीनों की सटीकता समग्र छत पैनलों की गुणवत्ता में सुधार करने में मदद कर सकती है। इसका अर्थ है कि प्रत्येक पैनल समान उच्च गुणवत्ता का होगा और पर्यावरणीय कारकों के खिलाफ समान स्तर की सुरक्षा प्रदान करेगा, जिससे रिसाव, दरारें या अन्य प्रकार की क्षति का जोखिम कम हो जाएगा। कुल मिलाकर, कॉrugेटेड शीट रोल फॉर्मिंग मशीनों की टिकाऊता और दीर्घायु उन्हें छत निर्माताओं के लिए एक उत्कृष्ट विकल्प बनाती है जो उच्च-गुणवत्ता वाली और लंबे समय तक चलने वाली छत सामग्री उत्पादित करना चाहते हैं। मरम्मत और प्रतिस्थापन की आवश्यकता को कम करके, ये मशीनें निर्माताओं और उपभोक्ताओं दोनों के लिए धन की बचत करने में मदद कर सकती हैं, साथ ही कठोर मौसम की स्थितियों और अन्य पर्यावरणीय कारकों के खिलाफ विश्वसनीय सुरक्षा प्रदान करती हैं।

कॉrugेटेड शीट रोल फॉर्मिंग मशीनें छत निर्माताओं के लिए एक आवश्यक उपकरण हैं। ये मशीनें सटीक, सुसंगत और अनुकूलन योग्य छत पैनल प्रदान करती हैं, जिन्हें तेजी से और लागत-प्रभावी ढंग से उत्पादित किया जा सकता है। पैनल टिकाऊ और लंबे समय तक चलने वाले होते हैं, जो कठोर मौसम की स्थितियों और अन्य पर्यावरणीय कारकों का सामना कर सकते हैं। अंततः, ये मशीनें छत परियोजनाओं की समग्र गुणवत्ता और दक्षता में सुधार कर सकती हैं, मरम्मत और प्रतिस्थापन की आवश्यकता को कम करके तथा निर्माताओं और उपभोक्ताओं दोनों के लिए धन की बचत करके।

छत के लिए कॉrugेटेड शीट रोल फॉर्मिंग मशीनों के उपयोग के लाभ 1

Frequently Asked Questions (FAQ)

1) What line speeds are typical for corrugated sheet roll forming machines in roofing production?

- For 0.35–0.6 mm GI/PPGI: 25–60 m/min with flying cutoff; 15–35 m/min when inline embossing or punching is included. Actual speed depends on coil thickness, profile pitch, and cutoff type.

2) Which substrates and coatings perform best for corrugated roofing in diverse climates?

- Galvanized steel (ASTM A653 Z180–Z275) for general use; zinc–magnesium (EN 10346 ZM90–120) for improved cut-edge corrosion; Al–Zn (AZ150–AZ200) for heat-reflective durability; PVDF or SMP per EN 10169 for high UV exposure; 3000/5000 series aluminum for coastal zones.

3) How can manufacturers minimize oil-canning and panel waviness on corrugated profiles?

- Ensure coil flatness via tension leveling, maintain symmetrical roll gaps, use crowned rolls where appropriate, stabilize line tension, and control lube film thickness. Keep forming strain below ~2–3% in critical radii on prepainted stock.

4) What tolerances are realistic for panel length and corrugation pitch?

- Best-in-class: length tolerance ±1.0 mm (3σ) at 40 m/min with encoder + thermal compensation; corrugation pitch ±0.5 mm using servo feed synchronization and inline vision verification.

5) What’s the most cost-effective automation upgrade for SME plants?

- Add servo flying cutoff with recipe-based length control and auto stacker. Typical ROI: 9–15 months from reduced scrap (<1.5%), faster changeovers (30–50%), and lower labor per m².

2025 Industry Trends

- Electrification of cutoffs and presses reduces hydraulic maintenance and energy use.

- Inline vision/lidar checks corrugation pitch, panel width, and squareness in real time.

- Wider adoption of Zn–Mg and Al–Zn substrates to meet longer corrosion warranties.

- Quick-change cassettes and digital recipes bring changeovers under 20–30 minutes.

- Machine data via OPC UA/MQTT feeds MES/ERP for traceability and warranty documentation.

2025 Benchmarks for Corrugated Sheet Roll Forming Machines (Roofing)

| KPI (0.35–0.6 mm GI/PPGI/Al-Zn) | 2023 Typical | 2025 Best-in-Class | Key Enablers |

|---|---|---|---|

| Line speed (m/min) | 20–40 | 35–60 | Servo drives, flying cutoff |

| Length tolerance (3σ, mm) | ±2.0 | ±0.8–1.0 | Encoders, thermal comp |

| Pitch accuracy (mm) | ±1.0–1.5 | ±0.4–0.6 | Vision feedback, servo sync |

| Changeover time (min) | 60–120 | 20–30 | Cassettes, auto presets |

| Startup scrap (%) | 3–5 | 0.8–1.5 | Digital recipes, SPC |

| Energy (kWh/1,000 m) | 60–85 | 38–55 | IE4 motors, VFDs, smart idle |

| Zn–Mg share (EU roofing coils) | 10–15% | 20–30% | Corrosion + sustainability |

Authoritative references:

- EN 10346 (continuous hot-dip coated steel): https://standards.cen.eu

- EN 10169 (organic coated steels): https://standards.cen.eu

- ASTM A653 (galvanized), ASTM A755/A755M (prepainted): https://www.astm.org

- World Steel Association corrosion/sustainability: https://worldsteel.org

- OPC Foundation (OPC UA): https://opcfoundation.org

- U.S. DOE AMO (motor systems efficiency): https://www.energy.gov/eere/amo

Latest Research Cases

Case Study 1: Vision-Guided Pitch Control on Corrugated Roofing Line (2025)

Background: A regional roofing manufacturer saw variable corrugation pitch causing overlap mismatch on site, increasing installation time and leak risk.

Solution: Installed inline camera vision to measure pitch and panel width; closed-loop correction to roll former speed and flying cutoff timing; added thermal compensation in PLC.

Results: Pitch accuracy improved from ±1.2 mm to ±0.5 mm; length tolerance to ±0.9 mm (3σ) at 42 m/min; startup scrap reduced 52%; installation complaints dropped 41% YoY.

Case Study 2: Transition to Zn–Mg Coils and All-Electric Cutoff (2024)

Background: Coastal projects experienced cut-edge rust on galvanized corrugated sheets within 18–24 months.

Solution: Switched from GI Z275 to ZM120 (EN 10346) and replaced hydraulic cutoff with all-electric servo unit; optimized lube to minimize paint scuffing.

Results: Neutral salt spray edge creep improved 30–40%; warranty claims reduced 38%; energy per 1,000 m decreased 16%; unplanned maintenance downtime decreased 3%.

Expert Opinions

- Dr. Maria Jensen, Materials Scientist, European Coil Coaters Association

- “Zinc–magnesium substrates paired with high-durability PVDF systems deliver exceptional cut-edge protection for corrugated roofing, enabling longer warranties with lower coating mass.”

- Kenji Sato, Chief Engineer, Nidec Press & Automation

- “All-electric flying cutoffs provide tighter repeatability at high speeds. For corrugated profiles, that precision translates directly into fewer onsite fit-up issues.”

- Prof. Alan McBride, Director, Advanced Roll Forming Lab, University of Strathclyde

- “Vision-in-the-loop metrology is now mature enough for painted corrugated lines—sub-millimetre control is achievable without increasing paint marring when lubrication is well managed.”

Practical Tools/Resources

- COPRA RF / COPRA RF Vision (roll design + inline measurement): https://www.datam.de

- UBECO PROFIL (roll forming design software): https://www.ubeco.com

- NIST Engineering Statistics Handbook (SPC/DOE for process control): https://www.itl.nist.gov/div898/handbook

- ASTM A653, A755/A755M (material standards): https://www.astm.org

- European Coil Coaters Association (best practices for prepainted metals): https://www.prepaintedmetal.eu

- OPC Foundation (OPC UA specs and examples): https://opcfoundation.org

- DOE Motor Systems Tool (energy optimization): https://www.energy.gov/eere/amo

Note: Validate benchmarks for your specific corrugation geometry, substrate, paint system, and local building code requirements before procurement or process changes.

Last updated: 2025-10-21

Changelog: Added 5 FAQs; introduced 2025 trends with KPI table; included two recent case studies; added expert commentary; compiled practical tools/resources with authoritative links

Next review date & triggers: 2026-04-21 or earlier if EN/ASTM standards are revised, major OEMs release all-electric cutoff upgrades, or Zn–Mg coil adoption guidance changes