Overview of Box Profile Sheets

Box profile sheets are an increasingly popular choice in the construction and industrial sector due to their strength, durability, and versatility. These metal sheets, often made from materials like galvanized steel, aluminum, or zinc-aluminum alloy, provide a strong and aesthetically pleasing roofing and cladding solution. But why choose box profile sheets over other roofing materials? The answer lies in their unique profile design that offers excellent water drainage, higher load resistance, and reduced noise during rain, making them ideal for a variety of climates and structures.

Box profile sheets come in a range of thicknesses, coatings, and designs, ensuring there’s a model suited for almost any application, from residential buildings to large-scale industrial warehouses. This article dives deep into the types, working processes, materials, key components, and maintenance procedures to guide you in making an informed choice.

Guide to Corrugated Iron Sheets and Box Profile Sheets

Corrugated iron sheets are an early precursor to box profile sheets. Unlike the box profile design, corrugated sheets have a wavy pattern and are generally used for agricultural and rural structures due to their simple appearance and limited aesthetic options. Box profile sheets, in contrast, are manufactured with a distinct, structured design that allows for better load-bearing capabilities and greater architectural flexibility.

Box Profile Sheets Compared to Corrugated Iron Sheets

Box profile sheets stand out for their ability to cover large spans without additional support, making them suitable for modern roofing and cladding needs. Below is a comparison:

| विशेषता | Box Profile Sheets | Corrugated Iron Sheets |

|---|---|---|

| Strength | High load-bearing capacity, suitable for wide spans | Moderate strength, requires closer support |

| Water Drainage | Excellent due to profile design | Moderate due to wavy pattern |

| Noise Reduction | Reduced noise during rain | Noisy during rain |

| Application Flexibility | Widely used for industrial, commercial, residential buildings | Primarily rural or agricultural use |

Types of Box Profile Sheets

Choosing the right type of box profile sheet depends on your project’s requirements for thickness, durability, and coating. Here’s a breakdown of some popular models:

| Model Name | Material Type | मोटाई | Coating Type | Key Features |

|---|---|---|---|---|

| Box Profile 32/1000 | गैल्वेनाइज्ड स्टील | 0.5-0.7 mm | Polyester or PVC | Lightweight, durable, rust-resistant |

| Box Profile 34/207 | एल्यूमीनियम | 0.6-0.8 mm | PVDF or Zinc-Aluminum | High corrosion resistance, excellent for coastal areas |

| Box Profile 40/960 | गैल्वेनाइज्ड स्टील | 0.8-1.0 mm | Polyester, Polyurethane | High load resistance, preferred for industrial use |

| Box Profile 45/150 | Aluminum Alloy | 1.0 mm | PVDF, Polyester | Long lifespan, used for heavy-duty applications |

| Box Profile 50/250 | Steel-Zinc Alloy | 1.2 mm | Zinc-Aluminum | Superior durability, suitable for warehouses |

| Box Profile 60/200 | Stainless Steel | 0.8-1.2 mm | Polyurethane | Ideal for extreme weather resistance |

| Box Profile 75/350 | गैल्वेनाइज्ड स्टील | 1.5 mm | Polyester, PVDF | Robust, ideal for high-load environments |

| Box Profile 100/500 | Aluminum Composite | 0.9 mm | Polyurethane, PVDF | Lightweight, heat-resistant |

| Box Profile 105/400 | Copper Alloy | 1.0 mm | Natural Finish | Aesthetic appeal, suitable for custom designs |

| Box Profile 120/700 | Zinc-Aluminum Alloy | 1.2-1.5 mm | Polyurethane, Zinc Coating | Maximum durability, large span applications |

Each type is designed for specific purposes, whether it’s heavy industrial load-bearing needs or residential applications focused on aesthetics.

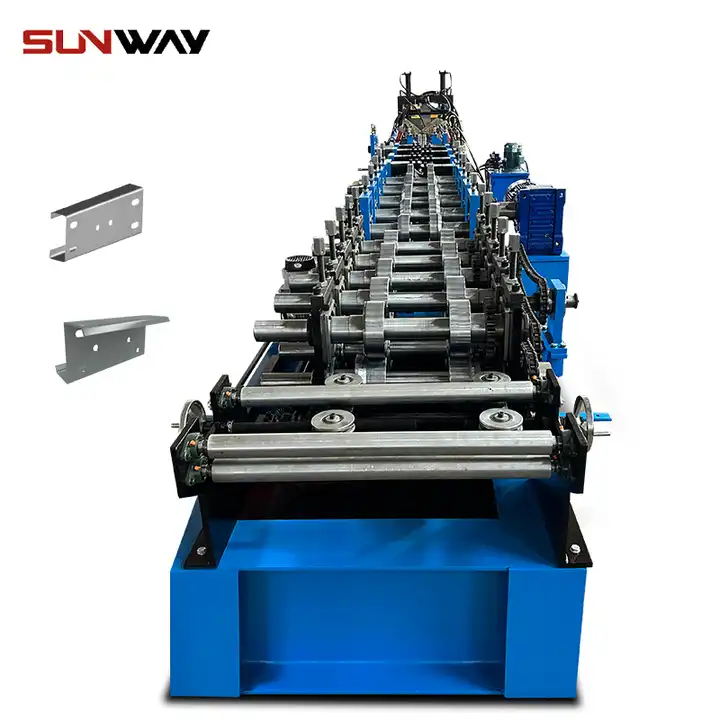

Working Process of Box Profile Sheets

The manufacturing process of box profile sheets involves precision and automation to ensure consistent quality. It starts with metal sheets that are coated and treated to prevent rust and increase durability. Here’s a breakdown of the main steps:

- सामग्री तैयारी

The sheet metal is cut to the desired thickness and treated with anti-corrosion coatings. This treatment extends the sheet’s life, especially in harsh weather environments. - Profiling and Forming

The sheets are passed through a profiling machine, where rollers shape the sheet into the distinct box profile. The process involves a careful combination of pressure and speed to avoid deformities. - Coating Application

Depending on the intended application, a variety of coatings like PVDF or polyurethane are applied. This coating step not only enhances appearance but adds to the sheet’s durability, ensuring it withstands elements like UV rays and moisture. - Quality Inspection

Each sheet is inspected for uniformity, coating quality, and dimensional accuracy. Quality checks ensure that only high-quality sheets make it to the market. - Packaging and Shipping

Finally, the sheets are bundled and packaged with protective wrapping to prevent damage during transport.

Key Components of Box Profile Sheets and Their Functions

The construction of box profile sheets involves several essential components, each contributing to their effectiveness and durability.

| Component | Function |

|---|---|

| Base Metal Sheet | Provides structural strength and rigidity |

| Anti-Corrosion Layer | Protects from rust and extends sheet life |

| Primer Layer | Enhances the bond between base metal and coating |

| Top Coating | Provides color, UV protection, and additional durability |

| Backing Coat | Protects the underside of the sheet from corrosion |

Machine Speed and Efficiency in Box Profile Production

| Machine Type | Production Speed (m/min) | Efficiency (%) |

|---|---|---|

| Standard Profile Machine | 30-50 m/min | 85% |

| High-Speed Profile Machine | 70-100 m/min | 95% |

| Custom Profile Machine | 20-30 m/min | 80% |

Customized Mechanical Parameters for Box Profile Sheets

| Parameter | 定制选项 |

|---|---|

| Sheet Thickness | 0.5 mm – 1.5 mm |

| Profile Width | 500 mm – 1200 mm |

| Profile Height | 32 mm – 120 mm |

| Coating Type | PVDF, Polyester, Polyurethane |

| रंग | Custom colors available |

Applications of Box Profile Sheets

| आवेदन | 描述 |

|---|---|

| Residential Roofing | Durable and aesthetic roofing solution |

| 商业建筑 | Ideal for warehouses, factories, and shopping malls |

| Agricultural Sheds | Long-lasting and cost-effective for rural setups |

| 工业设施 | Withstands heavy loads and adverse weather conditions |

Installation, Operation, and Maintenance

| Aspect | Key Steps |

|---|---|

| Installation | Secure panels with screws, overlapping as specified |

| Operation | Maintain load-bearing limits, avoid undue pressure |

| Maintenance | Regular inspections, clean to avoid debris buildup |

Choosing a Supplier: What to Consider

When choosing a supplier for box profile sheets, it’s essential to balance cost, quality, and delivery options. Consider aspects such as material durability, customer reviews, and warranty options to ensure long-term satisfaction.

Pros and Cons of Box Profile Sheets

| 优势 | Limitations |

|---|---|

| Durable and Long-Lasting | Initial cost may be higher than alternatives |

| Weather Resistant | Requires professional installation |

| Aesthetic Variety | May require regular maintenance in harsh climates |

सामान्य प्रश्न

| Question | Answer |

|---|---|

| What are box profile sheets made of? | Typically galvanized steel, aluminum, or zinc-aluminum alloys |

| Are box profile sheets good for coastal areas? | Yes, especially those with anti-corrosion coatings like PVDF. |

| How often should they be maintained? | Inspect annually and clean if necessary to prolong lifespan. |