About 24-32

Floor Deck Roll Forming Machine 02

ए Floor Deck Roll Forming Machine 03 Floor Deck Roll Forming Machine 04

Floor Deck Roll Forming Machine 05

Floor Deck Roll Forming Machine 2

Floor Deck Roll Forming Machine 3

Floor Deck Roll Forming Machine 4

Floor Deck Roll Forming Machine 5

कई अलग-अलग प्रकार के होते हैं रोल बनाना Floor Deck Roll Forming Machine 6

H4666e9799d9942f28f41539eb8ed85e9K

-

बैरल नालीदार रोल बनाने की मशीन

बैरल नालीदार रोल बनाने की मशीन -

2 वेव्स हाईवे गार्डरेल रोल फॉर्मिंग मशीन

2 वेव्स हाईवे गार्डरेल रोल फॉर्मिंग मशीन -

三波型高速公路护栏辊压成型机

三波型高速公路护栏辊压成型机 -

डाउनस्पॉट पाइप रोल बनाने की मशीन

डाउनस्पॉट पाइप रोल बनाने की मशीन -

गटर रोल बनाने की मशीन

गटर रोल बनाने की मशीन -

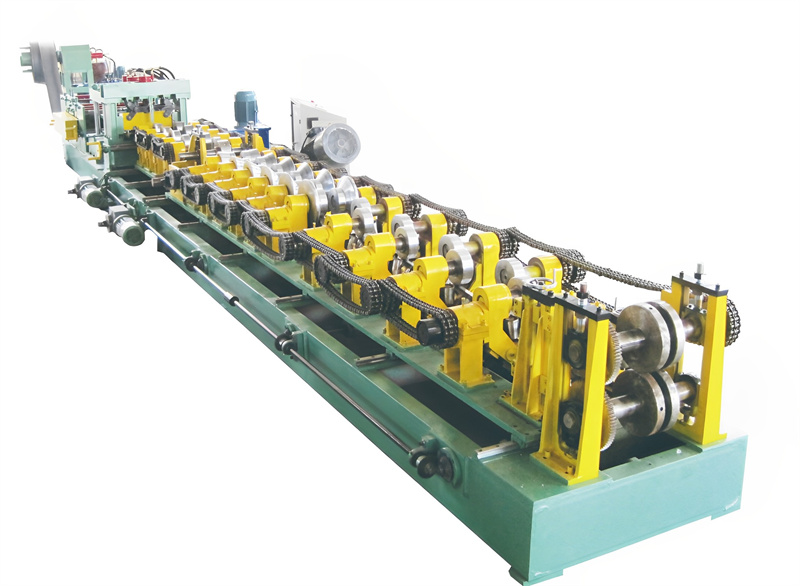

ऑटो आकार बदलने योग्य घन शहतीर रोल बनाने की मशीन

ऑटो आकार बदलने योग्य घन शहतीर रोल बनाने की मशीन -

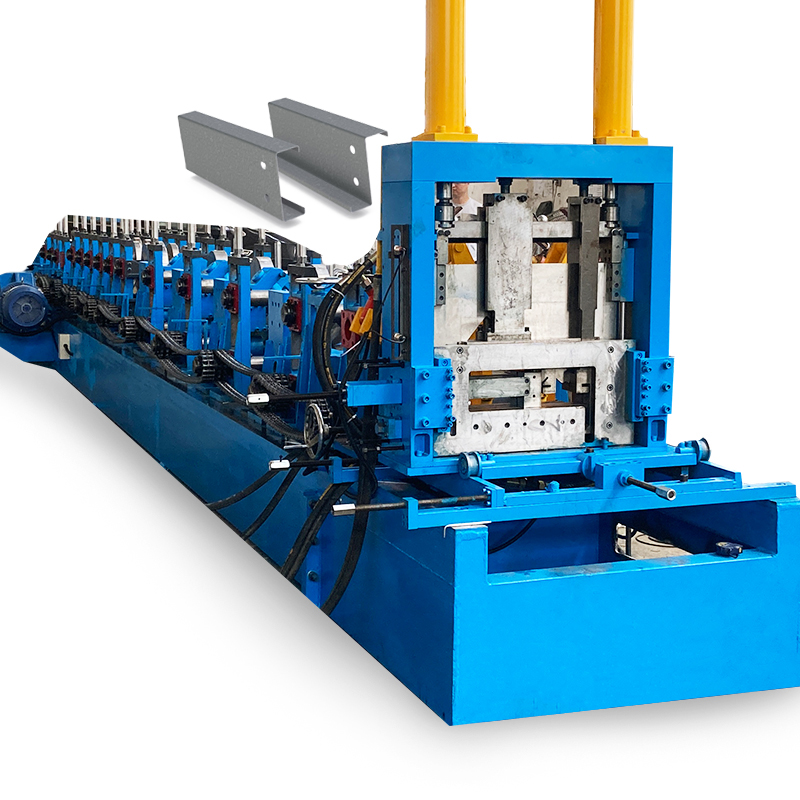

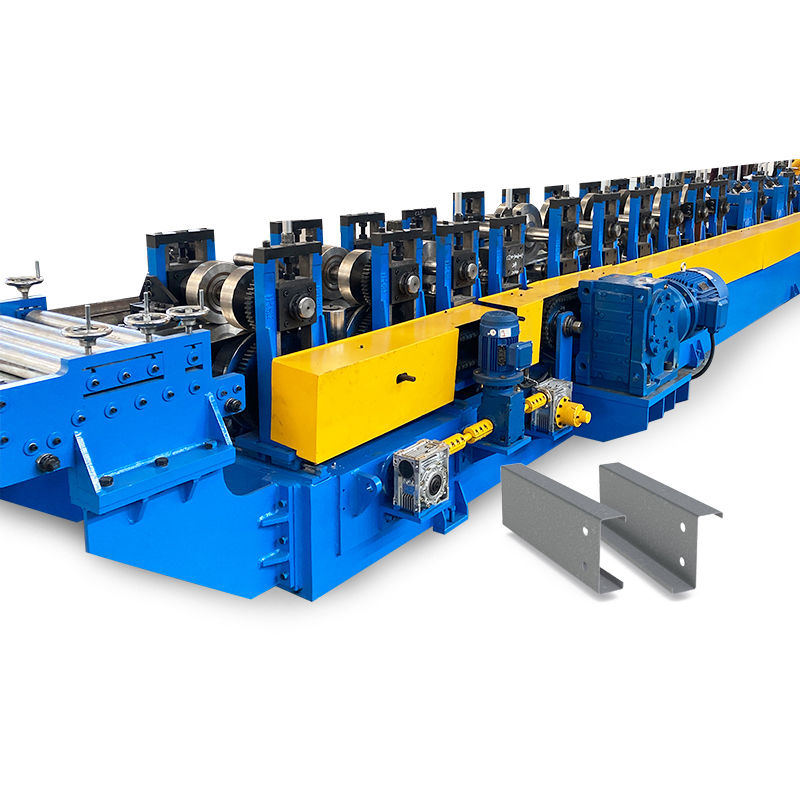

हाई स्पीड सी शहतीर मशीन

हाई स्पीड सी शहतीर मशीन -

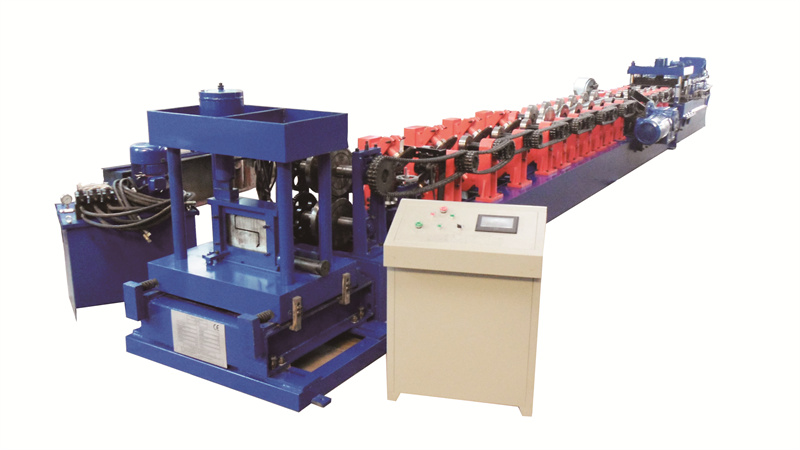

पूर्ण स्वचालित सी शहतीर रोल बनाने की मशीन त्वरित परिवर्तन

पूर्ण स्वचालित सी शहतीर रोल बनाने की मशीन त्वरित परिवर्तन -

सी शहतीर रोल बनाने की मशीन की कीमत

सी शहतीर रोल बनाने की मशीन की कीमत

Hc338a800105849c98c3fb0bea82d3fa13

H035faf76eeeb4e0f80ea434c0299dda9m

Floor Deck Roll Forming Machine

how-a-pipe-roll-forming-machine-works-and-why-its-used

How a Pipe Roll Forming Machine Works and Why It’s Used - SUNWAY Machine

A pipe roll forming machine shapes metal tubing for fluid transfer across industries.

Round Pipe Roll Forming Machine

Selecting the right pipe for your machine is challenging, especially for new businesses. This article explains pipe roll forming machine operation and applications.

निष्कर्ष

Ideal for custom pipe shapes like headers, flanges, elbows, tees, and more.

Additional Frequently Asked Questions (FAQ)

1) What materials and thicknesses can a Roll Forming Machine for C Purlin handle?

Typical lines process galvanized steel (ASTM A653), Galvalume (ASTM A792), and high-strength low-alloy coils from 1.2–3.0 mm thickness and 120–600 mm web widths. Some auto-size CU lines can handle up to 3.5 mm with 350–550 MPa yield strength.

2) What is the difference between C, Z, and Sigma purlin roll forming?

- C purlin: Symmetric section for interior supports and secondary framing.

- Z purlin: Overlapping capability for longer spans and improved continuity.

- Sigma: Higher torsional rigidity; used in high-load or seismic applications. Machines may be dedicated (C-only) or combo CZ with automatic punch and lip adjustments.

3) How fast do modern C Purlin machines run and how accurate are they?

In 2025, production speeds commonly reach 25–60 m/min with flying cutoff; cut-length tolerance ±0.5–1.0 mm and hole-position tolerance ±0.3–0.5 mm using servo feed and encoder/laser verification.

4) What options are essential for structural steel compliance?

Inline hydraulic or servo punching (web/lip holes, slots), material certification traceability (heat/coil IDs), automatic gauge/profile recipe control, and compliance with AISI S100/EN 1090 fabrication practices, plus CE/UL safety.

5) What maintenance plan maximizes uptime?

- Daily: Check roll cleanliness, coil edge burrs, hydraulic level, safety interlocks.

- Weekly: Inspect bearings and chain/sprocket alignment; verify encoder calibration.

- Quarterly: Check roll wear with profile gauges; re-level stands; update PLC backups; conduct oil analysis on hydraulics.

2025 Industry Trends for Roll Forming Machine For C Purlin

- Auto-size changeover becomes standard: Motorized roll gap, cassette tooling, and auto-punch templates reduce changeover to 6–12 minutes on CU/CZ combo lines.

- Higher-strength coils: Wider adoption of 500–600 MPa grades enables weight reduction of 8–15% while meeting span requirements.

- Connected QC: Inline cameras measure web width, lip height, and hole spacing; SPC dashboards track Cp/Cpk for key dimensions.

- Energy and safety upgrades: Regenerative VFDs, hydraulic-on-demand, and Cat 3/PL d safety circuits lower kWh/ton by 10–20% and improve compliance.

- Regionalization of supply: More buyers favor local or regional OEMs/integrators to reduce lead time, with typical delivery 8–16 weeks for standard C lines and 16–28 weeks for high-automation CZ lines.

2024–2025 Benchmarks and Buying Data

| KPI | 2024 Typical | 2025 Best-in-Class | 注意事项 | Sources |

|---|---|---|---|---|

| Line speed (1.5–2.5 mm) | 20–40 m/min | 45–65 m/min | With servo flying cutoff | The Fabricator; OEM datasheets |

| Auto changeover time (C↔Z or size) | 18–35 min | 6–12 min | Motorized stands/cassettes | OEM catalogs (Bradbury, Samco) |

| Length tolerance (±) | 1.0–1.5 mm | 0.5–0.8 mm | Laser encoder feedback | Inline metrology vendors |

| Hole-position tolerance (±) | 0.7–1.0 mm | 0.3–0.5 mm | Servo punch + vision check | AISI best practices |

| Energy intensity (kWh/ton) | 110–150 | 90–115 | Regenerative drives | U.S. DOE AMO guidance |

| Installed price (USD) | $120k–$280k | $180k–$420k | C-only vs. auto CZ combo | 2025 RFQ ranges |

Authoritative references:

- AISI S100, cold-formed steel design: https://www.buildusingsteel.org

- ASTM A653/A792 coated steel: https://www.astm.org

- EN 1090 (execution of steel structures): https://standards.cen.eu

- U.S. DOE Advanced Manufacturing Office: https://www.energy.gov/eere/amo

- OPC Foundation (OPC UA for machinery): https://opcfoundation.org

- The Fabricator (roll forming insights): https://www.thefabricator.com

Latest Research Cases

Case Study 1: Auto-Size CU/CZ Line Cuts Changeover to 9 Minutes (2025)

Background: A mid-size steel building fabricator struggled with 25–40 minute changeovers between 150–300 mm C and Z purlins, causing missed delivery windows.

Solution: Implemented an auto-size changeable Roll Forming Machine for C Purlin with motorized stand adjustments, recipe-driven roll gaps, servo punching templates, and OPC UA data logging.

Results: Average changeover reduced to 9 minutes; OEE improved from 68% to 82%; hole-position Cpk rose from 1.1 to 1.7; annual throughput +18% without additional shifts.

Case Study 2: High-Strength Coil Adoption Reduces Weight 12% (2024)

Background: Designer sought to lower steel usage in light-gauge frames while meeting AISI S100 serviceability.

Solution: Switched from 350 MPa to 550 MPa coils on a C purlin roll forming line; updated punch program and roll gaps; validated with coupon tests and third-party inspection.

Results: Section thickness reduced from 2.0 mm to 1.7 mm on select SKUs; weight down 12%; cost/ton up 6% but net cost per linear meter down 7%; deflection and strength within spec.

Expert Opinions

- Michael Klukas, Executive VP, The Bradbury Group

Viewpoint: “For C and Z purlin producers, servo-controlled punching ahead of the mill with vision feedback is delivering the biggest scrap reduction per dollar invested.”

Company: https://www.bradburygroup.com - Jennifer Kinder, Director of Product Management, Samco Machinery

Viewpoint: “Standardizing RFQs with coil grade, gauge, speed, hole tolerances, and changeover method lets buyers compare Roll Forming Machine For C Purlin proposals fairly.”

Company: https://www.samco-machinery.com - Dr. Benjamin Schafer, Professor of Civil and Systems Engineering, Johns Hopkins University

Viewpoint: “Accurate lip and web geometry in C purlins directly influences lateral-torsional buckling capacity—tight process control pays back in structural performance.”

Profile: https://engineering.jhu.edu

Practical Tools/Resources

- Design and standards

- AISI S100 cold-formed steel design manual: https://www.buildusingsteel.org

- EN 1090 execution and CE marking overview: https://standards.cen.eu

- Process and quality

- NIST SPC/how-to for process capability: https://www.nist.gov/manufacturing

- DOE AMO motor/drive system efficiency tools: https://www.energy.gov/eere/amo

- Sourcing and benchmarking

- The Fabricator buyer’s guides and technical features: https://www.thefabricator.com

- Precision Metalforming Association directory: https://www.pma.org

- Representative OEMs: The Bradbury Group, Samco Machinery, Dallan, Formtek (review specs for Roll Forming Machine For C Purlin and CZ lines)

- Connectivity and data

- OPC UA Industrial Interoperability: https://opcfoundation.org

Last updated: 2025-10-22

Changelog: Added 5 FAQs; inserted 2025 trends with KPI table and sources; provided two recent case studies; compiled expert opinions with citations; listed practical tools/resources tailored to Roll Forming Machine For C Purlin buyers and operators

Next review date & triggers: 2026-04-22 or earlier if AISI/EN standards are revised, OEM catalogs change speed/price ±10%, or new case data shifts best-in-class KPIs by >10%