Conveyor systems are the unsung heroes of modern manufacturing, enabling seamless material handling in industries ranging from automotive to e-commerce. At the core of these systems lies the conveyor belt frame—a structural backbone that ensures durability, precision, and stability. With the increasing demand for conveyor systems across industries, manufacturers are turning to Conveyor Belt Frame Roll Forming Machines to produce high-quality frames at scale.

In this detailed guide, we’ll explore what Conveyor Belt Frame Roll Forming Machines are, their applications, pricing, advanced technological features, and why Wuxi Sunway Machinery is the go-to provider for these machines in 2025. Whether you’re a conveyor system manufacturer, a factory owner, or a logistics company, this article is packed with insights you need.

What is a Conveyor Belt Frame Roll Forming Machine?

ए Conveyor Belt Frame Roll Forming Machine is a specialized piece of industrial equipment designed to manufacture the structural frames or profiles used in conveyor belt systems. These machines transform raw metal coils into precisely shaped components, such as side rails, support beams, and brackets, through the roll-forming process.

With the ability to produce components in large volumes with consistent quality, these machines are a game-changer for conveyor system manufacturers. The roll-forming process ensures that frames are lightweight yet sturdy, corrosion-resistant, and easy to assemble—meeting the exacting standards of modern manufacturing and logistics.

Applications of Conveyor Belt Frame Roll Forming Machines

Conveyor belt frames find applications across a wide range of industries where efficient material handling is a priority. Here’s a closer look at their key applications:

1. Manufacturing Plants

- Use Case: Conveyor systems for assembly lines in automotive, electronics, and machinery manufacturing.

- Why It Matters: Roll-formed frames provide the structural stability required for heavy-duty operations.

2. Warehousing and Distribution

- Use Case: Conveyor systems in warehouses and distribution centers for sorting and transporting packages.

- Why It Matters: Lightweight yet durable roll-formed frames ensure efficient material handling and reduced maintenance.

3. Food and Beverage Industry

- Use Case: Conveyor systems for processing and packaging food and beverages.

- Why It Matters: Corrosion-resistant roll-formed components meet the hygiene and durability standards of the industry.

4. Mining and Quarrying

- Use Case: Heavy-duty conveyor systems for transporting coal, ore, and aggregates.

- Why It Matters: High-strength roll-formed frames withstand the harsh conditions and heavy loads of mining operations.

5. Airports and Logistics

- Use Case: Luggage handling systems in airports and conveyor systems for logistics hubs.

- Why It Matters: Precision-engineered roll-formed components ensure reliable operation in fast-paced environments.

6. E-Commerce Fulfillment Centers

- Use Case: Conveyor systems for automated sorting, packing, and shipping in e-commerce warehouses.

- Why It Matters: Roll-formed frames enable the scalability and speed required for high-volume operations.

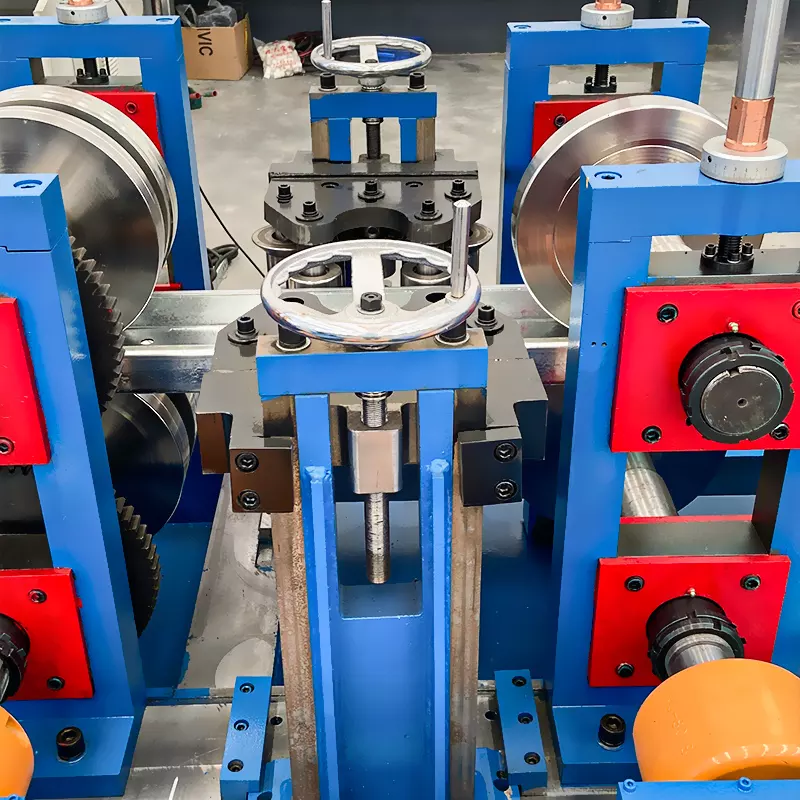

Key Features of Wuxi Sunway Conveyor Belt Frame Roll Forming Machines

When it comes to manufacturing conveyor belt frames, Wuxi Sunway Machinery offers state-of-the-art roll-forming machines that deliver unmatched performance, precision, and customization. Here’s why their machines are trusted by manufacturers globally:

1. Multi-Profile Capability

- What It Offers: Machines can produce a variety of profiles, including side rails, support beams, and brackets.

- Why It’s Revolutionary: Supports the production of conveyor systems with diverse designs for different industries.

2. Material Versatility

- Supported Materials:

- Galvanized steel

- Stainless steel

- Aluminum alloys

- High-tensile steel

- Why It Matters: Enables the production of frames that are lightweight, durable, and resistant to corrosion.

3. Precision Engineering

- What It Does: Produces components with tight tolerances and smooth finishes.

- Why It’s Important: Guarantees perfect alignment and fit during conveyor system assembly, reducing installation time and costs.

4. Integrated Cutting and Punching Systems

- Features: Servo-controlled cutting units and punching systems create holes, slots, and custom features with high precision.

- Why It Matters: Eliminates secondary operations, saving time and labor.

5. High-Speed Production

- Performance: Capable of producing up to 18 meters of profiles per minute, depending on the design.

- Why It Matters: Meets the high-volume demands of conveyor system manufacturers.

6. Fully Automated Operations

- Features:

- PLC-controlled systems with real-time monitoring.

- User-friendly touchscreen interface for easy operation.

- Automatic error detection and diagnostics.

- Why It’s Revolutionary: Reduces reliance on skilled labor while ensuring consistent quality.

7. Modular and Compact Design

- What It Includes: Machines are designed to integrate seamlessly into existing production lines.

- Why It Matters: Optimizes factory floor space while providing flexibility for future upgrades.

8. Eco-Friendly Operation

- What It Offers: Energy-efficient motors and waste-reducing technologies.

- Why It Matters: Supports manufacturers in achieving sustainability goals and reducing operational costs.

Production Workflow of a Conveyor Belt Frame Roll Forming Machine

The production process for conveyor belt frames is designed for maximum efficiency and precision. Here’s a step-by-step overview:

1. Decoiling

- Raw metal coils are loaded onto the decoiler, which feeds the material into the machine.

2. Leveling

- A leveling system ensures the material is flat and free from warping or defects before entering the roll-forming section.

3. Roll Forming

- The material passes through a series of rollers that gradually shape it into the desired profile, such as a side rail or support beam.

4. Punching and Cutting

- Integrated punching units create holes or slots, while cutting systems trim components to the required lengths with high precision.

5. Stacking

- Finished components are automatically stacked for easy packaging and transportation.

Pricing of Conveyor Belt Frame Roll Forming Machines

The cost of a Conveyor Belt Frame Roll Forming Machine depends on its features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic frame production | $200,000–$350,000 |

| High-Precision Machines | Advanced tolerances and multi-profile output | $350,000–$550,000 |

| Fully Customizable Machines | Multi-material compatibility and advanced features | $550,000–$800,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Advantages of Using Conveyor Belt Frame Roll Forming Machines

Investing in a Conveyor Belt Frame Roll Forming Machine offers significant advantages for manufacturers:

1. Enhanced Efficiency

- High-speed production reduces lead times and increases output.

2. Precision and Consistency

- Ensures uniform quality across all components, minimizing assembly errors.

3. Material Flexibility

- Supports a wide range of materials, including corrosion-resistant alloys.

4. Cost Savings

- Reduces material waste and labor costs, improving overall profitability.

5. Scalability

- Suitable for both small-scale manufacturers and large-scale production lines.

FAQs About Conveyor Belt Frame Roll Forming Machines

| Question | Answer |

|---|---|

| What is the production speed? | Machines can produce up to 18 meters of profiles per minute, depending on the design. |

| Can the machine process stainless steel? | Yes, it is designed to handle durable, corrosion-resistant materials like stainless steel. |

| What is the typical lead time for delivery? | Delivery typically takes 3–6 months, depending on customization requirements. |

| Does Sunway provide after-sales support? | Absolutely! Wuxi Sunway offers training, maintenance, and troubleshooting services. |

| What is the expected lifespan of the machine? | With proper maintenance, the machine can last 10–15 years or more. |

| Can the machine produce custom profiles? | Yes, it supports multi-profile capabilities for customized conveyor systems. |

Global Trends Driving Demand for Conveyor Belt Frames

The conveyor belt industry is experiencing unprecedented growth, driven by the rise of automation, e-commerce, and smart manufacturing. Below are the global trends fueling the demand for Conveyor Belt Frame Roll Forming Machines:

1. Automation in Manufacturing

- The Trend: Manufacturers are increasingly automating their production lines to boost efficiency and reduce labor costs.

- Impact on Conveyor Systems: Automated systems rely heavily on conveyor belts to transport materials between processes.

- Why It Matters: Roll-forming machines enable the high-volume production of conveyor frames that meet the precision and durability requirements of automated systems.

2. Growth of E-Commerce

- The Numbers: Global e-commerce sales are projected to reach $7.4 trillion by 2025, driven by increased online shopping.

- Impact on Conveyor Systems: Fulfillment centers are investing in advanced conveyor systems to handle high order volumes.

- Why It’s Relevant: Roll-formed frames provide the structural integrity needed for high-speed, high-volume operations in e-commerce warehouses.

3. Sustainability in Logistics

- The Push: Companies are adopting green logistics practices to reduce their environmental footprint.

- Impact on Conveyor Frames: Lightweight and recyclable materials are becoming a priority for conveyor frame production.

- Why It’s Crucial: Roll-forming machines are designed to process eco-friendly materials like aluminum and galvanized steel, supporting sustainable manufacturing goals.

4. Expansion of Mining and Heavy Industries

- The Trend: The global mining industry is projected to grow at a CAGR of 6% through 2025, with increased demand for raw materials.

- Impact on Conveyor Systems: Heavy-duty conveyor systems are essential for transporting materials in mining and quarrying operations.

- Why It Matters: Roll-forming machines produce high-strength frames that can withstand the extreme conditions of mining environments.

5. Technological Advancements in Smart Factories

- The Shift: Smart factories are leveraging IoT, AI, and robotics to optimize operations.

- Impact on Conveyor Systems: Conveyor systems must integrate seamlessly with smart factory technologies.

- Why It’s Exciting: Advanced roll-forming machines, like those from Wuxi Sunway, produce components with the precision and customization required for smart manufacturing.

Technological Advancements in Conveyor Belt Frame Roll Forming Machines

The evolution of Conveyor Belt Frame Roll Forming Machines is being driven by cutting-edge technologies that enhance efficiency, precision, and sustainability. Let’s explore the most impactful innovations shaping this field:

1. Real-Time Monitoring with IoT

- What It Does: IoT-enabled sensors collect real-time data on machine performance, output quality, and material usage.

- Benefits:

- Enables predictive maintenance, reducing unexpected downtime.

- Provides actionable insights to optimize production.

- Facilitates remote monitoring for enhanced operational control.

2. Servo-Driven Roll Forming

- The Technology: Servo motors ensure precise control over rollers, punching units, and cutting systems.

- Why It’s Revolutionary:

- Guarantees consistent accuracy across all components.

- Increases production speed while maintaining quality.

- Reduces energy consumption, improving overall efficiency.

3. AI-Powered Quality Control

- What It Does: Artificial intelligence analyzes production data to detect defects and optimize machine settings.

- Why It Matters:

- Ensures flawless components by identifying issues early in the production process.

- Reduces material waste and rework costs.

- Enhances overall system efficiency through adaptive learning.

4. Customizable Tooling Systems

- What It Offers: Machines come with interchangeable tooling systems for quick transitions between different profiles.

- Why It’s Important:

- Supports the production of a wide range of conveyor frame designs.

- Reduces downtime during profile changes.

- Simplifies customization for specific industry applications.

5. Energy-Efficient Design

- The Innovation: Machines are equipped with energy-saving motors, optimized power distribution, and regenerative braking systems.

- Why It’s Crucial:

- Lowers electricity consumption, reducing operational costs.

- Aligns with global sustainability initiatives.

- Enhances the environmental credentials of manufacturers.

6. Multi-Material Processing

- What It Supports: Machines can process an array of materials, including lightweight aluminum, stainless steel, and high-tensile steel.

- Why It’s Revolutionary:

- Expands manufacturing capabilities to meet diverse industry needs.

- Enables the production of corrosion-resistant frames for outdoor applications.

- Supports the creation of lightweight designs for high-speed conveyor systems.

Environmental Impact of Conveyor Belt Frame Roll Forming Machines

In a world increasingly focused on sustainability, Conveyor Belt Frame Roll Forming Machines are setting new standards for eco-friendly manufacturing. Here’s how they contribute to environmental goals:

1. Material Efficiency

- How It Works: The roll-forming process precisely shapes metal into the desired profiles, minimizing scrap and waste.

- Impact:

- Conserves raw materials, reducing environmental impact.

- Lowers material costs for manufacturers.

2. Recyclable Outputs

- The Advantage: Components made from materials like aluminum and galvanized steel are fully recyclable.

- Why It Matters:

- Promotes a circular economy by enabling material reuse.

- Reduces landfill waste and supports green manufacturing.

3. Energy Efficiency

- The Technology: Modern machines consume less energy while maintaining high production speeds.

- Why It’s Crucial:

- Helps manufacturers reduce their carbon footprint.

- Lowers electricity costs, improving profitability.

4. Localized Production

- What It Enables: Machines allow manufacturers to produce conveyor frames locally, reducing the need for long-distance transportation.

- Outcome:

- Cuts down on emissions associated with shipping.

- Enhances regional sustainability while supporting local economies.

Comparison: Conveyor Belt Frame Roll Forming Machines vs. Traditional Methods

Let’s compare Conveyor Belt Frame Roll Forming Machines with traditional manufacturing methods, such as manual fabrication or extrusion:

| विशेषता | रोल बनाने की मशीन | Traditional Methods |

|---|---|---|

| Precision | High; ensures consistent dimensions | Moderate; prone to human error |

| उत्पादन गति | High; up to 18 meters per minute | Slow; labor-intensive processes |

| Automation | Fully automated with IoT and PLC integration | Mostly manual or semi-automated |

| Material Waste | Minimal; optimized processes reduce scrap | Higher; less efficient material usage |

| 成本效益 | Higher initial cost, lower operational costs | Lower initial cost, higher long-term costs |

| Scalability | Ideal for high-volume production | Limited scalability for large-scale demand |

Additional FAQs About Conveyor Belt Frame Roll Forming Machines

| Question | Answer |

|---|---|

| Can the machine produce custom conveyor frame profiles? | Yes, it supports multi-profile capabilities for customized designs. |

| What is the lead time for delivery? | Delivery typically takes 3–6 months, depending on customization requirements. |

| Can the machine handle lightweight materials? | Absolutely! It is designed to process aluminum and other lightweight alloys. |

| Does Sunway provide operator training? | Yes, comprehensive training is included with every machine purchase. |

| What is the warranty period? | Sunway machines come with a standard warranty and optional extended service agreements. |

| Are financing options available? | Yes, flexible financing options are offered to qualified buyers. |

Why Choose Wuxi Sunway Machinery for Conveyor Belt Frame Roll Forming Machines?

Here’s why Wuxi Sunway Machinery continues to lead the industry in roll-forming solutions:

- Proven Expertise: Decades of experience in delivering innovative and reliable roll-forming machines.

- Global Reputation: Trusted by clients in Asia, Europe, the Americas, and beyond.

- Customization Excellence: Machines tailored to meet specific conveyor frame designs and material requirements.

- Sustainability Leadership: Eco-friendly designs that minimize waste and reduce energy consumption.

- Advanced Technology: Features like IoT integration, servo-driven systems, and AI-powered quality control.

- Comprehensive Support: From installation to troubleshooting, Sunway ensures seamless operations and customer satisfaction.

Conclusion: Leading the Conveyor Revolution with Roll Forming Technology

The Conveyor Belt Frame Roll Forming Machine is revolutionizing material handling systems by enabling the efficient production of durable, lightweight, and customizable frames. Whether you’re building conveyor systems for manufacturing, logistics, or mining, these machines provide the scalability, precision, and sustainability needed to lead in 2025 and beyond.

Ready to elevate your production capabilities? Contact Wuxi Sunway Machinery today to explore their advanced roll-forming solutions. Together, let’s move industries forward—one conveyor frame at a time!