As the global shift toward renewable energy accelerates, solar power has emerged as a cornerstone of the sustainable energy revolution. At the heart of every solar installation is the strut channel, a critical component that supports and secures 太阳能电池板s. To meet the growing demand for precision-engineered strut channels, manufacturers are turning to advanced equipment like the C41 Solar Mounting Strut Channel Roll Forming Machine.

This machine is a game-changer, combining speed, precision, and customization to produce high-quality strut channels for solar mounting systems. In this guide, we’ll explore everything you need to know about the C41 Solar Mounting Strut Channel Roll Forming Machine—its applications, features, pricing, and why Wuxi Sunway Machinery is the trusted leader in roll-forming technology. Whether you’re in the solar industry or a manufacturer looking to scale up, this guide will provide you with valuable insights.

What is a C41 Solar Mounting Strut Channel Roll Forming Machine?

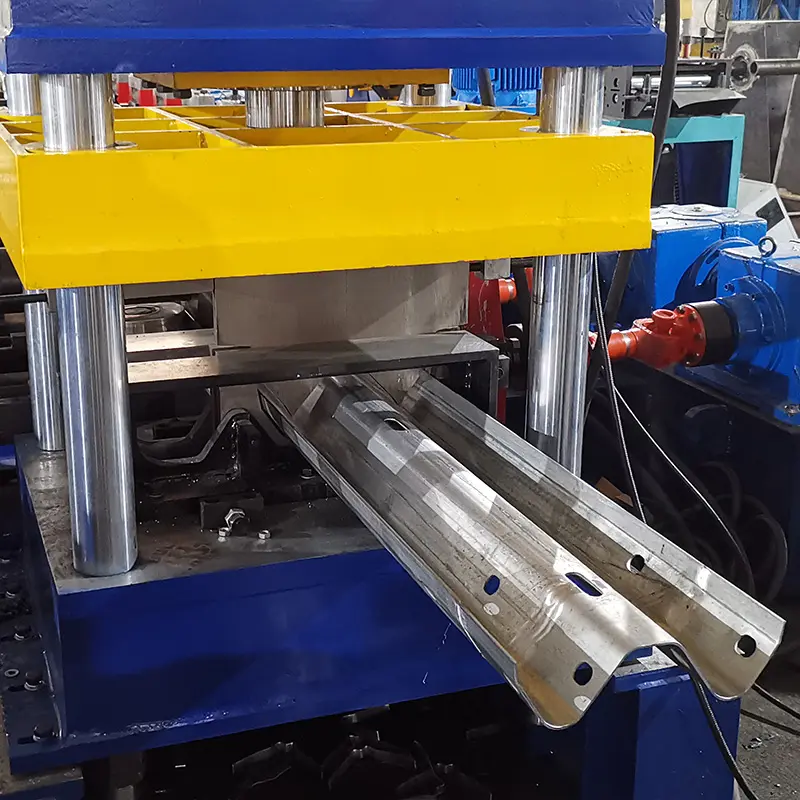

The C41 Solar Mounting Strut Channel Roll Forming Machine is a specialized piece of equipment engineered to produce strut channels used in solar mounting systems. Strut channels are essential for securing solar panels on rooftops, ground mounts, and other structures. These channels need to be robust, precise, and compatible with various mounting configurations.

The C41 machine automates the production of strut channels by feeding metal coils through a series of rollers that gradually shape the material into the desired profile. Equipped with features like punching, cutting, and embossing, the machine ensures that the strut channels meet exact specifications and are ready for immediate use.

Applications of C41 Solar Mounting Strut Channels

Strut channels produced by the C41 machine are versatile and widely used in various industries. Let’s take a closer look at their primary applications:

1. Solar Panel Mounting Systems

- Strut channels are the backbone of solar installations, providing a sturdy framework to secure panels on rooftops, ground mounts, or carports.

2. Electrical and Cable Management

- These channels are used to organize and secure electrical wiring and cables in solar power systems.

3. Rooftop Solar Installations

- Strut channels enable easy installation on sloped or flat rooftops, ensuring panels are securely mounted against wind and weather conditions.

4. Ground-Mount Solar Farms

- In large-scale solar farms, strut channels are essential for creating stable mounting structures that can withstand harsh environmental conditions.

5. Industrial Applications

- Beyond solar, strut channels are used in industrial settings for mounting electrical equipment, HVAC systems, and more.

Key Features of Sunway C41 Solar Mounting Strut Channel Roll Forming Machines

When it comes to roll-forming technology, Wuxi Sunway Machinery sets the gold standard. Their C41 Solar Mounting Strut Channel Roll Forming Machines are designed to deliver unmatched precision, efficiency, and durability. Here’s what makes them stand out:

1. High-Speed Production

- Capable of producing up to 15–20 meters of strut channels per minute, ensuring you can meet tight deadlines and large orders.

2. Customizable Profiles

- The machine can produce a wide range of strut channel profiles, including:

- Width: 41mm (C41)

- Thickness: 1.5mm–3.0mm

- Lengths and hole configurations tailored to customer requirements.

3. Pre-Punching and Cutting Systems

- Integrated hydraulic punching units allow for precise hole patterns, essential for bolting and assembling solar mounting systems.

- Servo-driven cutting systems ensure clean, burr-free cuts for accurate lengths.

4. Advanced PLC Control

- User-Friendly Interface: Operate the machine easily with a touchscreen control panel.

- Programmable Settings: Store multiple strut channel designs for quick transitions.

- Real-Time Monitoring: Track production metrics and system performance in real time.

5. Material Compatibility

- The machine can process a variety of materials, including:

- Galvanized steel

- Stainless steel

- Mild steel

- Pre-coated steel

6. Compact and Durable Design

- Built with high-strength steel frames, Sunway machines are designed for long-term reliability while occupying minimal factory floor space.

7. Safety Features

- Emergency Stop Buttons: Strategically placed for operator safety.

- Protective Covers: Shield operators from moving parts.

- Overload Protection: Prevents damage caused by power surges or material jams.

Production Workflow of the C41 Solar Mounting Strut Channel Roll Forming Machine

Understanding the production process helps manufacturers appreciate the efficiency and precision of this machine. Here’s how it works:

1. Material Loading

- Metal coils are loaded onto the automatic uncoiler, which feeds the material smoothly into the machine.

2. Roll Forming

- The material passes through a series of rollers that gradually shape it into the desired strut channel profile.

3. Pre-Punching

- Holes are punched in precise locations to accommodate bolts and connectors, ensuring compatibility with various mounting systems.

4. Cutting

- The servo-driven cutting system trims the strut channels to the exact required lengths, ensuring clean edges.

5. Stacking and Output

- Finished strut channels are automatically stacked and prepared for packaging or immediate use.

Pricing of C41 Solar Mounting Strut Channel Roll Forming Machines

The cost of a C41 Solar Mounting Strut Channel Roll Forming Machine depends on its features, production capacity, and level of customization. Here’s a general pricing guide for 2025:

| Machine Type | Primary Use | उत्पादन गति | Price Range (USD) |

|---|---|---|---|

| Standard Machines | Basic strut channel production | 10–15 meters/min | $50,000–$80,000 |

| High-Speed Machines | Large-scale production | 15–20 meters/min | $80,000–$120,000 |

| Fully Customizable Machines | Advanced profiles and features | 15–20 meters/min | $120,000–$180,000 |

For an accurate quote and financing options, contact Wuxi Sunway Machinery.

Benefits of Using the C41 Solar Mounting Strut Channel Roll Forming Machine

Investing in a C41 Solar Mounting Strut Channel Roll Forming Machine offers numerous advantages for manufacturers:

1. High Efficiency

- The automated production process minimizes manual labor, saving time and reducing costs.

2. Superior Quality

- Precise punching, cutting, and forming ensure consistent quality, meeting international standards.

3. Customization Flexibility

- Produce strut channels tailored to specific solar mounting system requirements.

4. Scalability

- High production capacity allows you to scale operations to meet growing market demands.

5. Cost Savings

- Reduced material waste and labor costs improve overall profitability.

Environmental Benefits of C41 Solar Mounting Strut Channel Roll Forming Machines

Sustainability is at the core of the solar industry, and the C41 machine aligns perfectly with green manufacturing practices:

1. Reduced Material Waste

- Precision cutting and punching minimize scrap, conserving resources and reducing costs.

2. Energy Efficiency

- Advanced servo motors and hydraulic systems consume less energy, lowering the carbon footprint.

3. Use of Recyclable Materials

- The machine processes recyclable metals like galvanized steel and aluminum, supporting a circular economy.

4. Minimal Emissions

- Automated processes reduce material handling and transportation, cutting down on emissions.

FAQs About the C41 Solar Mounting Strut Channel Roll Forming Machine

| Question | Answer |

|---|---|

| What materials can the machine handle? | Galvanized steel, aluminum, stainless steel, and pre-coated steel. |

| Can I customize the punching patterns? | Yes, punching patterns can be fully customized via the PLC system. |

| What is the average production speed? | The machine operates at speeds of 15–20 meters per minute, depending on the material. |

| What is the warranty period? | Sunway machines come with a 12-month warranty, with extended service options available. |

| Is operator training provided? | Yes, comprehensive training is included with every purchase. |

| Can the machine integrate with automated production lines? | Absolutely! Sunway machines are designed for seamless integration into automated systems. |

Global Market Trends for Solar Mounting Strut Channels in 2025

The solar energy boom has created an unprecedented demand for high-quality mounting systems, including strut channels. Here’s a closer look at the global trends shaping the market:

1. Explosive Growth in Solar Installations

- The Numbers Speak: According to the International Renewable Energy Agency (IRENA), global solar capacity is projected to surpass 2,000 GW by 2025.

- Impact on Strut Channels: Every new solar installation requires mounting systems, driving demand for precision-engineered strut channels.

2. Shift Toward Green Manufacturing

- Why It Matters: Governments worldwide are incentivizing green manufacturing practices, including the use of recyclable materials and energy-efficient processes.

- How Sunway Fits In: Machines like the C41 are designed to minimize waste and consume less energy, aligning with sustainability goals.

3. Rising Demand for Customization

- Customers increasingly prefer custom mounting solutions tailored to specific solar panel layouts and site conditions.

- Trend Impact: Manufacturers need roll-forming machines capable of producing strut channels with customizable lengths, hole patterns, and profiles—something the C41 excels at.

4. Growth in Utility-Scale Solar Projects

- What’s Happening: Large-scale solar farms are being developed in regions like Asia-Pacific, South America, and the Middle East.

- Market Need: These projects require durable, corrosion-resistant strut channels capable of withstanding harsh environmental conditions.

5. Technological Advancements in Solar Mounting Systems

- Innovation Alert: The rise of single-axis trackers and floating solar systems is driving demand for specialized mounting components, including strut channels with unique profiles.

- Industry Response: Machines like the C41 are equipped to handle these emerging requirements with ease.

6. Increase in Rooftop Solar Installations

- As urban areas embrace renewable energy, rooftop solar installations are becoming common.

- Relevance to Strut Channels: Lightweight, flexible strut channels are critical for rooftop mounting systems, making the C41 machine a necessity for manufacturers targeting this sector.

7. Government Incentives and Regulations

- Subsidies and tax benefits for renewable energy projects are fostering growth in the solar industry.

- Manufacturer Opportunity: By investing in high-capacity roll-forming machines, manufacturers can capitalize on the surge in solar installations.

Automation Trends in C41 Roll Forming Machines

Automation is at the forefront of modern manufacturing, and the C41 Solar Mounting Strut Channel Roll Forming Machine is no exception. Here are the top automation trends revolutionizing roll-forming technology:

1. IoT Integration

- What It Does: IoT-enabled machines connect to a network, allowing operators to monitor production remotely via smartphones or computers.

- Key Benefits:

- Real-time insights into production metrics.

- Immediate alerts for maintenance or operational issues.

- Seamless integration with other factory systems.

2. Predictive Maintenance

- How It Works: Sensors collect data on machine performance, which is analyzed by Artificial Intelligence (AI) to predict maintenance needs.

- Why It Matters:

- Reduces downtime caused by unexpected breakdowns.

- Extends the lifespan of critical components like rollers and punching systems.

3. Adaptive Production Systems

- What It Is: Machines adjust settings automatically based on material properties or desired output.

- Example: The C41 can adapt to different metal thicknesses and profiles without requiring manual intervention, improving efficiency.

4. Fully Automated Workflows

- From Start to Finish: The C41 handles everything from material loading to stacking finished strut channels, reducing the need for manual labor.

- Result: Consistent quality and faster production cycles.

5. Enhanced Safety Features

- Automation Meets Safety: Emergency stop systems, overload protection, and automated error detection ensure operator safety without compromising productivity.

- Why It’s Essential: Modern safety standards demand machines that protect both workers and the environment.

6. Digital Twin Technology

- What’s New: A digital replica of the machine allows manufacturers to test and optimize production processes virtually.

- Benefits:

- Reduces material waste during setup.

- Identifies bottlenecks before production begins.

7. AI-Driven Quality Control

- How It Works: Cameras and sensors analyze each strut channel in real time, ensuring they meet exact specifications.

- Outcome: Lower defect rates and higher customer satisfaction.

Advanced Troubleshooting for C41 Roll Forming Machines

Even with cutting-edge machines like the C41, occasional issues can occur. Here’s how to troubleshoot some common problems:

1. Misaligned Strut Channels

- Cause: Improper roller alignment or material feeding.

- Solution:

- Inspect and realign the rollers.

- Ensure the material is loaded correctly in the feeding system.

2. Punching Errors

- Cause: Worn punching dies or synchronization issues.

- Solution:

- Replace worn dies to maintain punching accuracy.

- Recalibrate the punching unit using the PLC system.

3. Material Jams

- Cause: Debris in the feeding system or improperly tensioned material.

- Solution:

- Clean the feeding area thoroughly.

- Adjust the material tension settings.

4. Cutting Inaccuracies

- Cause: Calibration issues in the cutting system.

- Solution:

- Recalibrate the cutting parameters via the PLC interface.

- Check the cutting blade for wear and replace it if necessary.

5. Electrical Failures

- Cause: Power surges or faulty wiring.

- Solution:

- Use a stable power source with surge protection.

- Inspect and repair wiring as needed.

For persistent issues, contact Wuxi Sunway Machinery’s technical team for expert troubleshooting and support.

FAQs About the C41 Solar Mounting Strut Channel Roll Forming Machine

| Question | Answer |

|---|---|

| What materials can the machine process? | Galvanized steel, aluminum, stainless steel, and pre-coated steel. |

| Can the machine handle custom hole patterns? | Yes, punching patterns can be fully customized via the PLC system. |

| What is the average production speed? | The machine operates at speeds of 15–20 meters per minute, depending on the material. |

| What is the warranty period? | Sunway machines come with a 12-month warranty, with extended service options available. |

| Can the machine integrate with factory automation? | Yes, the C41 is designed for seamless integration into automated production lines. |

| Is operator training included? | Absolutely! Comprehensive training is provided with every purchase. |

Why Choose Wuxi Sunway Machinery for C41 Roll Forming Machines?

Wuxi Sunway Machinery is the global leader in roll-forming technology, and here’s why:

- Decades of Expertise: Over 20 years of experience in designing and manufacturing roll-forming machines.

- Global Network: Trusted by clients in Asia, Europe, Africa, and the Americas.

- Innovative Technology: Equipped with IoT, AI, and PLC systems for unparalleled efficiency.

- Custom Solutions: Machines tailored to meet your specific production needs.

- Sustainability Commitment: Designed to minimize waste and energy consumption.

- Comprehensive Support: From installation to ongoing maintenance, Sunway provides end-to-end service.

Conclusion: The Future of Solar Mounting Strut Channel Production

The C41 Solar Mounting Strut Channel Roll Forming Machine is more than just equipment—it’s an investment in precision, efficiency, and sustainability. As the solar energy market continues to expand, manufacturers equipped with advanced roll-forming technology will lead the way.

Ready to take your production to the next level? Contact Wuxi Sunway Machinery today and explore their state-of-the-art roll-forming solutions. Together, let’s power the renewable energy revolution—one strut channel at a time!