When it comes to modern vineyard management, the vineyard post is a critical structural component. These posts provide the backbone for trellis systems, supporting grapevines as they grow and ensuring proper alignment, spacing, and durability. But how are these posts produced at scale with precision and efficiency? Enter the वाइनयार्ड पोस्ट रोल बनाने की मशीन, a specialized piece of equipment designed to manufacture high-quality vineyard posts to meet the demands of today’s agricultural industry.

In this guide, we’ll explore the वाइनयार्ड पोस्ट रोल बनाने की मशीन, its applications, features, pricing, and why Wuxi Sunway Machinery is the global leader in this field. Whether you’re a manufacturer in the agricultural sector or an investor exploring roll-forming solutions, you’ll find all the insights you need right here. Let’s get growing!

What is a Vineyard Post Roll Forming Machine?

ए वाइनयार्ड पोस्ट रोल बनाने की मशीन is a specialized piece of equipment used to manufacture steel posts for vineyard trellis systems. These posts are designed to provide structural support for grapevines, ensuring optimal growth, proper alignment, and long-term durability.

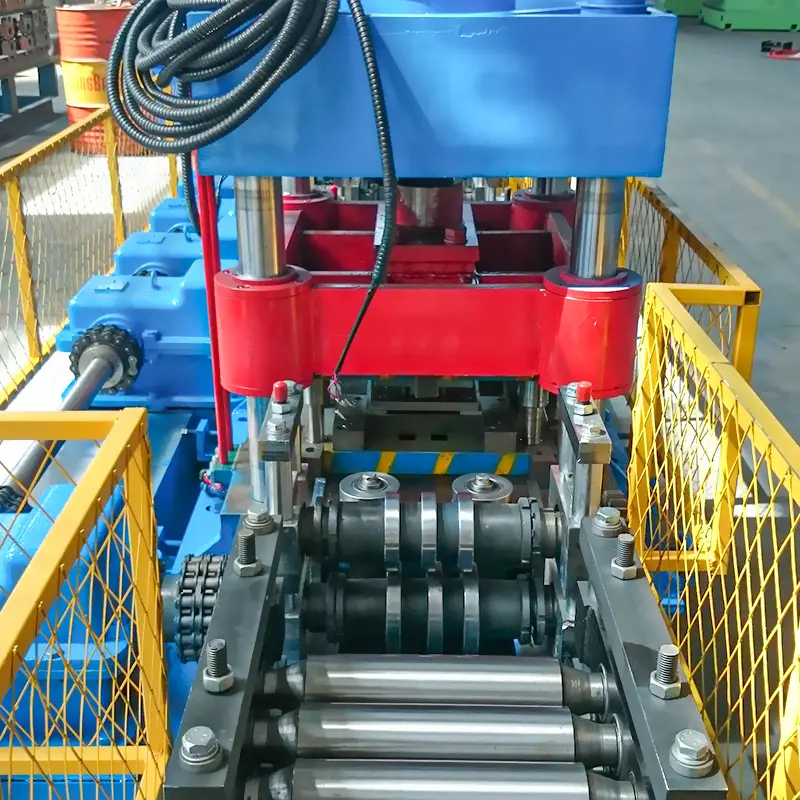

The machine works by feeding a metal coil (usually galvanized steel, high-tensile steel, or aluminum) through a series of rollers, which gradually bend and shape the material into the desired post profile. Some machines also integrate punching systems to create slots, holes, or hooks that facilitate wire placement and attachment during vineyard installation.

Applications of Vineyard Posts

Vineyard posts produced by these roll-forming machines are widely used in the agricultural sector, particularly in viticulture (grape cultivation). Here’s a closer look at their applications:

1. Trellis Systems for Vineyards

- Vineyard posts act as the primary support for trellis systems, ensuring proper alignment and spacing for grapevine rows.

- They provide anchoring points for training wires, which help manage vine growth and optimize fruit production.

2. Orchard Support Systems

- Beyond vineyards, these posts are also used in orchards for supporting fruit trees, such as apple, cherry, or pear trees.

3. Agricultural Fencing

- Vineyard posts double as fencing components, providing durable and weather-resistant solutions for enclosing agricultural fields.

4. Greenhouse Structures

- High-tensile vineyard posts are sometimes used in the construction of greenhouses and protective structures for crops.

5. Renewable Energy Projects

- Vineyard posts are increasingly being utilized in solar farms for mounting panels, given their durability and ease of installation.

Key Features of Sunway Vineyard Post Roll Forming Machines

Wuxi Sunway Machinery is a globally recognized leader in roll-forming technology, offering machines designed to deliver precision, efficiency, and reliability. Here’s why their Vineyard Post Roll Forming Machines stand out:

1. High-Speed Production

- With production speeds of up to 15–30 meters per minute, Sunway machines are ideal for meeting high-demand markets without compromising quality.

2. Customizable Post Profiles

- Sunway machines can produce a wide range of vineyard post profiles, including:

- Y-shaped posts

- T-shaped posts

- U-shaped posts

- Omega profiles

- Custom post dimensions, thickness, and slot designs can be easily configured.

3. Integrated Punching System

- The hydraulic punching system enables the creation of slots, hooks, and holes directly on the post during the roll-forming process.

- Punching patterns are fully programmable through the advanced PLC system, allowing for customization based on vineyard requirements.

4. Material Versatility

- Compatible with various materials, including:

- Galvanized steel

- High-tensile steel

- एल्यूमीनियम

- Stainless steel

5. Precision Cutting

- The servo-driven cutting system ensures burr-free edges and consistent post lengths, delivering professional-grade results.

6. Advanced PLC Control System

- User-Friendly Interface: Operate the machine with ease using the touchscreen control panel.

- Customizable Programs: Store multiple post profiles and punching configurations for quick production transitions.

- Real-Time Monitoring: Track machine performance and production metrics in real time.

7. Compact and Durable Design

- Designed to maximize factory floor space while delivering long-term reliability, even in high-demand environments.

8. Energy Efficiency

- Advanced servo motors and hydraulic systems optimize energy usage, reducing operational costs and supporting sustainable manufacturing.

9. Safety Features

- Emergency Stop Buttons: Strategically placed for quick and easy access.

- Protective Covers: Shield operators from moving parts, ensuring a safe work environment.

- Overload Protection: Safeguards the machine components from damage caused by power surges or material jams.

Production Workflow of a Vineyard Post Roll Forming Machine

The production process is a seamless blend of automation and precision. Here’s how Sunway Vineyard Post Roll Forming Machines operate:

1. Material Loading

- Steel or aluminum coils are loaded onto the automatic uncoiler, which ensures smooth and consistent feeding into the machine.

2. Roll Forming

- The material is passed through a series of rollers, which gradually shape it into the desired vineyard post profile.

- This step ensures uniformity and precision, even for complex shapes.

3. Punching

- The integrated punching system creates slots, holes, and hooks on the posts as per the programmed design.

- This eliminates the need for secondary operations, saving time and labor.

4. Cutting

- The formed posts are cut to the required length using the servo-driven cutting system, delivering clean, burr-free edges.

5. Stacking and Output

- Finished posts are automatically stacked and prepared for packaging or further processing.

Pricing of Vineyard Post Roll Forming Machines

The cost of a वाइनयार्ड पोस्ट रोल बनाने की मशीन depends on its features, production capacity, and level of customization. Here’s a general pricing guide for 2025:

| Machine Type | Primary Use | उत्पादन गति | Price Range (USD) |

|---|---|---|---|

| Standard Machines | Basic vineyard posts | 10–20 meters/min | $70,000–$100,000 |

| High-Speed Machines | Large-scale production | 15–30 meters/min | $100,000–$150,000 |

| Fully Customizable Machines | Unique or niche post profiles | 10–25 meters/min | $150,000–$200,000 |

For an exact quote and financing options, contact Wuxi Sunway Machinery.

Automation Trends in Vineyard Post Roll Forming Machines

Automation is transforming the agricultural manufacturing sector, and Sunway machines are at the forefront of this revolution. Here’s how automation enhances these machines:

1. IoT Connectivity

- Monitor machine performance, production data, and maintenance schedules remotely via IoT-enabled systems.

- Receive real-time alerts for troubleshooting or maintenance requirements.

2. Predictive Maintenance

- AI-powered sensors analyze machine data to predict potential failures, enabling proactive maintenance and reducing downtime.

3. Fully Automated Workflows

- From material feeding to cutting and stacking, Sunway machines handle every step automatically, minimizing labor costs and errors.

4. Digital Twin Technology

- Simulate machine performance and test new vineyard post designs virtually before actual production begins, saving time and materials.

FAQs About Vineyard Post Roll Forming Machines

| Question | Answer |

|---|---|

| What is the maximum thickness the machine can handle? | Sunway machines can process materials with thicknesses up to 4.0mm. |

| Can the machine produce custom post profiles? | Yes, the PLC system allows for easy customization of profiles, punching patterns, and dimensions. |

| What is the average production speed? | Most machines operate at speeds of 15–30 meters per minute, depending on the material. |

| Do these machines require skilled operators? | No, the user-friendly PLC system ensures simple operation with minimal training. |

| What is the warranty period? | Sunway machines come with a 12-month warranty, with extended service options available. |

| Can the machine handle aluminum materials? | Yes, the machine is compatible with aluminum, galvanized steel, and other materials. |

| Are financing options available? | Yes, flexible financing plans are available. Contact Wuxi Sunway Machinery for details. |

Troubleshooting Common Issues in Vineyard Post Roll Forming Machines

Even the most advanced roll-forming machines can encounter occasional hiccups. Knowing how to troubleshoot effectively can save you valuable time and prevent production delays. Here’s a guide to addressing common challenges with your वाइनयार्ड पोस्ट रोल बनाने की मशीन:

1. Misaligned Vineyard Posts

- Cause: Rollers are improperly adjusted or material is inconsistently fed into the machine.

- Solution:

- Regularly inspect the alignment of rollers and recalibrate them as needed.

- Ensure the steel coil feeder is set up correctly, with consistent tension and alignment.

2. Punching Errors (Slots or Holes Misaligned)

- Cause: Incorrect PLC programming or wear in the punching mechanism.

- Solution:

- Double-check the coordinates set in the PLC system and make adjustments if necessary.

- Inspect the punching unit for signs of wear and replace any faulty components.

3. Burrs on Edges

- Cause: Dull cutting blades or improper cutting angle.

- Solution:

- Sharpen or replace the cutting blades regularly to ensure clean edges.

- Adjust the cutting system to optimize the angle and alignment.

4. Material Jams

- Cause: Debris in the feeding system or improperly loaded steel coils.

- Solution:

- Clean the feeding system to remove any obstructions.

- Check coil alignment and ensure proper tensioning to prevent material slipping or jamming.

5. Overheating of Components

- Cause: Continuous high-speed operation or insufficient lubrication.

- Solution:

- Allow the machine to cool down periodically during heavy production runs.

- Regularly maintain and replenish the lubrication system to prevent wear and overheating.

6. Inconsistent Production Speed

- Cause: Servo motor malfunction or fluctuating power supply.

- Solution:

- Inspect the servo motor for faults and recalibrate if necessary.

- Verify that the machine is connected to a stable power source and consider adding surge protection.

For persistent issues, Wuxi Sunway Machinery’s technical team is always on standby to provide expert assistance. Get in touch via this link for troubleshooting and maintenance support.

Environmental Benefits of Vineyard Post Roll Forming Machines

As sustainability becomes increasingly important in the agricultural industry, manufacturers need to adopt eco-friendly practices in their production processes. The वाइनयार्ड पोस्ट रोल बनाने की मशीन from Wuxi Sunway Machinery is designed to support these goals. Here’s how:

1. Minimal Material Waste

- Traditional manufacturing often results in significant material waste due to inefficiencies.

- Sunway machines use precision roll forming and cutting systems to maximize material usage, reducing scrap and lowering costs.

2. Energy Efficiency

- Equipped with advanced servo-driven motors and hydraulic systems, these machines consume significantly less energy compared to older models.

- Lower energy consumption translates to reduced operational costs and a smaller carbon footprint.

3. Recyclable Materials

- Vineyard posts produced using galvanized steel or aluminum are highly recyclable, making them a sustainable choice for agricultural applications.

4. Reduced Labor Requirements

- Automated workflows minimize the need for manual intervention, reducing emissions associated with labor-intensive processes and transportation.

5. Long-Lasting Products

- The vineyard posts manufactured by Sunway machines are extremely durable, reducing the need for frequent replacements and conserving resources in the long term.

By investing in a वाइनयार्ड पोस्ट रोल बनाने की मशीन, you’re not just improving your production capabilities—you’re also contributing to a greener future in agriculture.

Global Market Trends for Vineyard Posts and Roll Forming Machines

The demand for vineyard posts and roll-forming machines is growing rapidly, driven by advancements in agriculture, infrastructure, and renewable energy projects. Here are the key trends shaping this market:

1. Rising Global Wine Production

- The global wine market is expected to grow at a CAGR of 6.4% between 2023 and 2030, creating a surge in demand for vineyard infrastructure, including trellis systems supported by vineyard posts.

2. Expansion of Commercial Farms

- Governments and private investors are increasing their investments in large-scale agriculture to meet the rising demand for food and beverages.

- Vineyard posts are a critical component of these commercial farming operations.

3. Adoption of Automation in Agriculture

- Agricultural businesses are increasingly adopting automated tools and systems to improve efficiency and reduce labor costs.

- Automated roll-forming machines align perfectly with this trend, enabling high-speed production with minimal human intervention.

4. Growth of Solar Energy Projects

- Vineyard posts are finding new applications in solar farms, where they are used to support solar panels.

- As renewable energy projects expand globally, the demand for durable, customizable posts will continue to rise.

5. Eco-Friendly Farming Practices

- Sustainable farming practices are becoming the norm, driving demand for recyclable materials and energy-efficient manufacturing solutions like Sunway’s roll-forming machines.

6. Increased Demand for Customization

- Farmers and agricultural businesses are seeking customized solutions for their trellis systems to optimize crop yields.

- Machines capable of producing unique post profiles with custom punching patterns are in high demand.

Future of Vineyard Post Roll Forming Machines

What does the future hold for vineyard post manufacturing? Here’s how technology is shaping the next generation of roll-forming machines:

1. IoT Integration

- Advanced machines will feature IoT-enabled systems, allowing operators to monitor performance, production data, and maintenance status remotely.

- Real-time alerts will enable predictive maintenance, reducing downtime and increasing efficiency.

2. Artificial Intelligence

- AI-powered systems will analyze production data to optimize machine settings automatically, improving precision and reducing waste.

3. Digital Twins

- Manufacturers will use digital twin technology to simulate machine performance and test new post designs virtually before production begins, saving time and materials.

4. Modular Design

- Future machines will feature modular components that can be easily swapped or upgraded, ensuring long-term adaptability to evolving production needs.

5. Enhanced Sustainability

- Machines will continue to improve energy efficiency and material utilization, aligning with global sustainability goals.

Additional FAQs About Vineyard Post Roll Forming Machines

| Question | Answer |

|---|---|

| What is the typical lead time for delivery? | Most machines are delivered within 8–12 weeks, depending on customization. |

| Can the machine handle weather-resistant coatings? | Yes, Sunway machines can process pre-coated materials like galvanized steel and aluminum. |

| What is the average lifespan of these machines? | Sunway machines are built to last 10–15 years or more with proper care and maintenance. |

| Can I produce multiple post profiles on the same machine? | Absolutely! The machine allows for quick profile changes via its programmable PLC system. |

| What is the warranty period? | Sunway offers a 12-month warranty, with extended service plans available upon request. |

| Is operator training included? | Yes, comprehensive training is provided as part of the installation process. |

| Are replacement parts readily available? | Yes, Sunway offers a full range of replacement parts and technical support worldwide. |

Why Wuxi Sunway Machinery is the Best Choice for Vineyard Post Roll Forming Machines

Wuxi Sunway Machinery has earned its reputation as the global leader in roll-forming technology. Here’s why:

- Global Expertise: Trusted by agricultural manufacturers across Asia, Europe, Africa, and the Americas.

- Custom Solutions: Tailored machines designed to meet your specific production needs.

- Advanced Technology: Equipped with IoT, PLC systems, and predictive maintenance capabilities.

- Unmatched Quality: Built to international standards for reliability, precision, and durability.

- Comprehensive Support: From installation and training to troubleshooting and spare parts, Sunway offers end-to-end service.

- Sustainability Focus: Machines designed to minimize waste and energy consumption, aligning with green manufacturing goals.

Conclusion: Why Invest in a Vineyard Post Roll Forming Machine?

The वाइनयार्ड पोस्ट रोल बनाने की मशीन is more than just a tool—it’s a strategic investment in the future of sustainable agriculture and high-efficiency manufacturing. With its speed, precision, and versatility, this machine is the ideal solution for meeting the growing demands of the agricultural, renewable energy, and infrastructure industries.

Ready to scale your production? Contact Wuxi Sunway Machinery today to learn more about their industry-leading roll-forming solutions. Together, let’s cultivate the future of agricultural manufacturing—one vineyard post at a time.